Yuan Taur, Tak Ning - Fundamentals of Modern VLSI Devices (2013, Cambridge University Press) - libgen.lc

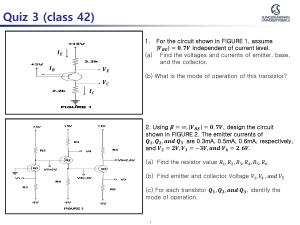

advertisement