Mechanical & Electrical Systems in Architecture, Engineering, Construction

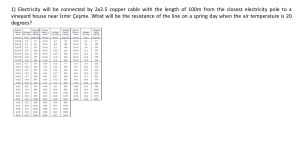

advertisement