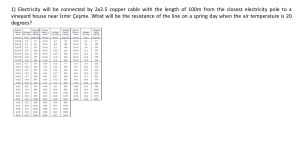

International Journal of Emerging Technology and Advanced Engineering Website: www.ijetae.com (ISSN 2250-2459, ISO 9001:2008 Certified Journal, Volume 3, Issue 3, March 2013) Fired Heater Design Mahesh N. Jethva1, C. G. Bhagchandani2 1 M.E., 2Associate Professor, Chemical Engineering Department, L.D. College of Engineering, Ahmedabad-380 015 Abstract- In fired heaters, heat is released by combustion of fuels into an open space and transferred to process fluids inside tubes. The tubes are ranged along the walls and roof of the combustion chamber. The heat is transferred by direct radiation and convection and also by reflection from refractory walls lining the chamber. The design and rating of a fired heater is a moderately complex operation. Here forced draft fired heater, which is fired by fuel gas, has been treated. For that all required equations and generalizations are listed from different fired heater design methods as per requirement. A fired heater design calculations are performed using Microsoft Excel Programming software. II. A. Radiant Heat Transfer in Radiant Section: Applying basic radiation concepts to process-type heater design, Lobo & Evans developed a generally applicable rating method that is followed with various modifications, by many heater designers. Direct radiation in the radiant section of a direct fired heater can be described by the equation shown below. Where, = Radiant heat transfer, Btu/hr = Stefan-Boltzmann constant, 0.173E-8 Btu/ft2-hr-R4 = Relative effectiveness factor of the tube bank = Cold plane area of the tube bank, ft2 = Exchange factor = Effective gas temperature in firebox, °R = Average tube wall temperature, °R Keywords- Convective heat transfer, Heat balance, Radiant heat transfer, Shield section. I. R ADIANT SECTION DESIGN INTRODUCTION A fired heater is a direct-fired heat exchanger that uses the hot gases of combustion to raise the temperature of a feed flowing through coils of tubes aligned throughout the heater. Depending on the use, these are also called furnaces or process heaters. Some heaters simply deliver the feed at a predetermined temperature to the next stage of the reaction process; others perform reactions on the feed while it travels through the tubes. Fired heaters are used throughout hydrocarbon and chemical processing industries such as refineries, gas plants, petrochemicals, chemicals and synthetics, olefins, ammonia and fertilizer plants. Most of the unit operations require one or more fired heaters as start-up heater, fired reboiler, cracking furnace, process heater, process heater vaporizer, crude oil heater or reformer furnace. Heater fuels include light ends (e.g. refinery gas) from the crude units and reformers as well as waste gases blended with natural gas. Residual fuels such as tar, pitch, and Bunker C (heavy oil) are also used. Combustion air flow is regulated by positioning the stack damper. Fuel to the burners is regulated from exit feed temperature and firing rate is determined by the level of production desired. A typical fired heater will have following four sections: (1) Radiant section, (2) Shield section, (3) Convection section, and (4) Breeching and stack. A fired heater may be a box (rectangular c/s) or vertical (cylindrical c/s) in shape. Same way, a fired heater may be classified depending on location of the burners and type of the draft. B. Heat Balance In The Radiant Section: There are four primary sources of heat input as well as four sources of heat output to the radiant section. We can now set up the heat balance equation as follows: Where, = = = = = = = = heat liberated by fuel, Btu/hr (LHV) sensible heat of combustion air, Btu/hr sensible heat of steam used for oil atomization, Btu/hr sensible heat of recirculated flue gases, Btu/hr heat absorbed by radiant tubes, Btu/hr Radiant heat to shield tubes, Btu/hr heat loss in firebox through furnace walls, bridgewall, casing, etc., Btu/hr heat of flue gases leaving the radiant section, Btu/hr C. Total Heat Transfer in Radiant Section (if Shield Section is present): The total heat transfer in firebox when shield section is present will be as follows: ( 61 ) ( ) International Journal of Emerging Technology and Advanced Engineering Website: www.ijetae.com (ISSN 2250-2459, ISO 9001:2008 Certified Journal, Volume 3, Issue 3, March 2013) Where, = Convective heat transfer to radiant tubes, Btu/hr = Convective heat transfer to shield tubes, Btu/hr III. Where the Reynolds number is, And the Prandtl number is, CONVECTION SECTION DESIGN A. Overall Heat Transfer Coefficient, : Where, = Heat transfer coefficient, liquid phase, Btu/hrft2-°F = Thermal conductivity, Btu/hr-ft-°F = Inside diameter of tube, ft = Absolute viscosity at bulk temperature, lb/ft-hr = Absolute viscosity at wall temperature, lb/ft-hr = Heat transfer coefficient, vapor phase, Btu/hrft2-°F = Bulk temperature of vapor, °R = Wall Temperature of vapor, °R = Mass flow of fluid, lb/hr-ft2 = Heat capacity of fluid at bulk temperature, Btu/lb-°F For two-phase flow, Where, = Overall heat transfer coefficient, Btu/hr-ft2-F = Total outside thermal resistance, hr-ft2-F/Btu And, Where, = = = Outside thermal resistance, hr-ft2-F/Btu Tube wall thermal resistance, hr-ft2-F/Btu Inside thermal resistance, hr-ft2-F/Btu And the resistances are computed as, Where, = Heat transfer coefficient, two-phase, Btu/hr-ft2°F = Weight fraction of liquid = Weight fraction of vapor ( ) Where, = Effective outside heat transfer coefficient, Btu/hr-ft2-F = Inside film heat transfer coefficient, Btu/hr-ft2F = Tube-wall thickness, ft = Tube wall thermal conductivity, Btu/hr-ft-F = Outside tube surface area, ft2/ft = Mean area of tube wall, ft2/ft = Inside tube surface area, ft2/ft = Inside fouling resistance, hr-ft2-F/Btu C. Effective outside heat transfer coefficient ( Fin tubes: Where, = Average outside heat transfer coefficient, Btu/hr-ft2-F = Fin efficiency = Total outside surface area, ft2/ft = Fin outside surface area, ft2/ft = Outside tube surface area, ft2/ft B. Inside film heat transfer coefficient, : The inside film coefficient needed for the thermal calculations may be estimated by several different methods. The API RP530, Appendix C provides the following methods, For liquid flow with ≥10,000, And for vapor flow with for i. Average outside heat transfer coefficient, : Where, = Outside heat transfer coefficient, Btu/hr-ft2-F = Outside radiation heat transfer coefficient, Btu/hr-ft2-F = Outside fouling resistance, hr-ft2-F/Btu ≥15,000, 62 International Journal of Emerging Technology and Advanced Engineering Website: www.ijetae.com (ISSN 2250-2459, ISO 9001:2008 Certified Journal, Volume 3, Issue 3, March 2013) ii. Outside film heat transfer coefficient, Inline pattern, : ( Where, = = = = = iii. ) Where, = = = Colburn heat transfer factor Mass velocity based on net free area, lb/hr-ft2 Heat capacity, Btu/lb-F Gas thermal conductivity, Btu/hr-ft-F Gas dynamic viscosity, lb/hr-ft iv. Number of tube rows Longitudinal tube pitch, in Transverse tube pitch, in Mass Velocity, : Colburn heat transfer factor, : Where, ( ) = = Where, = = = = = = = And, Net Free Area, Reynolds number correction Geometry correction Non-equilateral & row correction Outside diameter of fin, in Outside diameter of tube, in Average gas temperature, F Average fin temperature, F Reynolds number correction, Mass flow rate of gas, lb/hr Net free area, ft2 : Where, : = = = = Cross sectional area of box, ft2 Fin tube cross sectional area/ft, ft2/ft Effective tube length, ft Number tubes wide = = = = = Fin height, ft Outside diameter of tube, ft Transverse tube pitch, ft fin thickness, ft number of fins, fins/ft Where, = Reynolds number = Geometry correction, : For segmented fin tubes arranged in, a staggered pattern, v. an inline pattern, Surface Area Calculations: For the prime tube, And for solid fins, For solid fin tubes arranged in, a staggered pattern, ( ( ) ) And for segmented fins, an inline pattern, ( ) (( )( ) ( Where, = = Fin height, in Fin spacing, in Where, = = = = = Non-equilateral & row correction, : For fin tubes arranged in, Staggered pattern, ( ) 63 Outside diameter of tube, ft number of fins, fins/ft fin thickness, ft Fin height, ft Width of fin segment, ft )) International Journal of Emerging Technology and Advanced Engineering Website: www.ijetae.com (ISSN 2250-2459, ISO 9001:2008 Certified Journal, Volume 3, Issue 3, March 2013) Table I Radiant Section Design And then, vi. PROPERTY Tube Fin Efficiency, : For segmented fins, And for solid fins, ( ) Where, And, Where, Combustion Firebox Process fluid For segmented fins, ( ) Flue gas And for solid fins, vii. α (Radiant) α (Shield) Acp (Radiant) Acp (Shield) αAcp (Radiant) αAcp (Shield) (αAcp)r+(αAcp)s AR/ ((αAcp)r+(αAcp)s) Fin Tip Temperature, : The average fin tip temperature is calculated as follows, ( ) Where, = = IV. Gas Temperature, F Tube Wall Temperature, F Partial pressure Mean beam length P*l Emissivity Exchange factor Radiantion Heat Transfer EXCEL P ROGRAMMING Design of different sections of fired heater has been performed using Microsoft Excel Programming. For the calculation purpose, different calculation methods and equations are used in the programming. 64 DETAIL OD, in (do) thickness, in (tw) No of tubes (Nt) (Radiant) No of tubes (Nt) (Shield) Effective length, ft (Le) (Radiant) Effective length, ft (Le) (Shield) Tube spacing, in (CC) (Radiant) No of tubes per row (Nt/r) (Shield) Transverse pitch, in (Pt) (Shield) Fraction excess air Diameter, ft (D) Mean wall temperature, (Tt), ⁰R Flue gas temperature (Tg), ⁰R (-) Assumed (-) ft2 ft2 ft2 ft2 ft2 AT, ft2 Area of Shield Section, ft2 (As) AR, ft2 AR/ ((αAcp)r+(αAcp)s) atm (P) ft atm-ft E F Btu/hr MM Kcal/hr AMOUNT 8.626 0.05118 40 12 35.07 18.31 16 4 16 0.15 19.98 1097.95 2077.1 0.9086 1 1870.52 97.64 1699.51 97.64 1797.15 2103.81 97.64 306.66 0.17 0.256 13.32 3.406 0.5087 0.5129 3.37*10^7 8.488 International Journal of Emerging Technology and Advanced Engineering Website: www.ijetae.com (ISSN 2250-2459, ISO 9001:2008 Certified Journal, Volume 3, Issue 3, March 2013) Table II Convection Section Design PROPERTY Fin Tube Process Fluid Flue Gas Inside Film HT co- DETAIL Height, in (lf) Thickness, in (tf) No of fins, fins/ft (nf) Ther. Cond., Btu/hrft-⁰F (kf) OD, in (do) Thickness, in (tw) No of rows (Nr) No of tubes per row (Nw) Effective tube length, ft (Le) Pitch, in (Pt) Wall temp, ⁰F (Tw) Wall Ther. Cond., Btu/hr-ft-⁰F (kw) Inlet temp, ⁰F (t1) Outlet temp, ⁰F (t2) Ther. Cond., (Liq), Btu/hr-ft-⁰F (kl) Ther. Cond. (Vap), Btu/hr-ft-⁰F (kv) Sp. Heat (Liq), Btu/lb-⁰F (cp,l) Sp. Heat (Vap), Btu/lb-⁰F (cp,v) Viscosity (Liq), lb/hr-ft (µl) Viscosity (Vap), lb/hr-ft (µv) Mass flow rate, lb/hr Wt fraction (Liq) (Wl) Wt fraction (Vap) (Wv) Fouling factor,hrft2-⁰F/Btu (Rfi) Inlet temp, ⁰F (t1) Outlet temp, ⁰F (t2) Mass flow rate, lb/hr (Wg) Ther. Cond., Btu/hrft-⁰F (kg) Sp. Heat, Btu/lb-⁰F (cp,g) Viscosity, lb/hr-ft (µg) hi, Btu/hr-ft2-⁰F efficient Mass Velocity of Flue Gas Colburn HT Factor Outside Film HT co-efficient Average Outside HT co-efficient Fin Efficiency Effective Outside HT co-efficient Overall HT coefficient LMTD HT Area Convection Heat Transfer AMOUNT 1 0.05118 60 21.292 8.626 0.5 5 4 18.307 16 959 12.83 Gn, lb/hr-ft2 1017.79 j hc, Btu/hr-ft2-⁰F 0.00543 2.0291 ho, Btu/hr-ft2-⁰F 2.599 E he, Btu/hr-ft2-⁰F 0.9838 2.5595 Uo, Btu/hr-ft2-⁰F 1.9348 ⁰F ft2 Btu/hr MM Kcal/hr 430.28 10102.93 8.4*10^6 2.119 Table III Heat Balance PROPERTY Assumed amount of Radiant HT Assumed amount of Convection HT Thermal Efficiency Total Heat Input (Qfuel) Total Heat Transferred (Qht) Radiant HT (Qr) Convection HT (Qc) Heat Loss (Qloss) 609.8 621.1 0.04939 0.11995 0.694 0.8985 0.31448 0.0508 Heat out from HT area to stack (Qstack) % DETAIL AMOUNT 80 % 20 % (given) MM Kcal/hr MM Kcal/hr (given) MM Kcal/hr MM Kcal/hr MM Kcal/hr (2.5% of Qfuel) MM Kcal/hr (=Qfuel-Qht-Qloss) 90.7 11.70 10.61 8.488 2.122 0.2924 0.7955 1054905.3 V. 0.7 CONCLUSION Using Microsoft Excel Programming software, a design module has been prepared which can be used for different data values and gives satisfactory results. In present case, the design module gives required radiant heat transfer and convective heat transfer in the fired heater. 0.3 0.00391 1472 788 42620.545 REFERENCES [1] [2] [3] 0.0353 [4] 0.3087 [5] 0.0883 461.16 65 Process Heat Transfer by Donald Q. Kern, http://www.heatexchangerdesign.com, API 560, Fired Heaters for General Refinery Service, 4 th edition, August 2007, Chemical Process Equipment: Selection and Design by Stanley M. Walas, Paper by Asutosh Garg, Optimized Fired Heater saves Money.