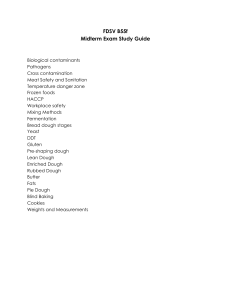

BREAD MAKING INTRODUCTION Bread is a popular staple food throughout the world There are many varieties of bread that differ according to the ingredients and preparation methods used The basic ingredients for bread making are flour, yeast, salt, and water Due to the increased awareness of the importance of healthy eating, along with environmental issues nowadays, breads containing whole grain, or other functional ingredients are becoming increasingly available in the market BREAD-MAKING PROCESSES The qualities of bakery products rely on both formula and processing conditions Bread is produced mainly according to two methods: the sponge and dough method and the straight dough method With technological innovations and design of improvers, several modifications of these methods have arisen Sponge and dough process One third or a half of the total amount of flour is mixed with part of water and total amount of yeast allowed to ferment for 3 to 20 h at 21°C to 27°C, depending on the amount of yeast, consistency of the dough, temperature, and bread type After the first fermentation is ended, the remaining ingredients are added and mixed to form the dough The disadvantage of this process is that more bowls for the sponge and more space are needed BREAD-MAKING PROCESSES Straight dough process All ingredients are mixed together at the same time The bulk fermentation lasts from 0.5 to 3 h, depending on the quality of the flour, yeast level, dough temperature, and variety of bread produced The resulting breads have fine and uniform crumb structures, but lower volume and harder crumb than breads produced by indirect methods BREAD-MAKING PROCESSES Straight dough process Modification of this methods the no-time method refers to having no resting time or a short resting time of up to 30 min before dividing the bulk of the dough requires high-intensity mixers and a larger quantity of yeast Eg. Chorleywood bread-making process dough is prepared by high-speed mixing of all ingredients for 3 to 5 min BREAD-MAKING PROCESSES Chorleywood bread-making process After a short resting time, the dough is conventionally shaped, proofed, and baked Process is suitable for weak flours and produces bread of high quality with respect to volume, color, and shelf life Large bakeries commonly use this method because it considerably reduces the cost and time of production (1 to 2 h for completion) BREAD-MAKING PROCESSES Sourdough bread-Making process Traditionally, a mixture of flour and water was fermented in several refreshing stages with microbes originating from the flour It is fermented for up to 24 or even 48 h at 22°C to 30°C until reaching pH ≤ 4 Nowadays, the interest in sourdough has been renewed because of its positive effects on nutritive value, texture, flavor, and the shelf life of bread BREAD-MAKING PROCESSES Continuous System The most common are the Do-Maker and Amflow systems A liquid preferment or liquid sponge is prepared and fermented in stainless steel tanks under controlled conditions for several hours Optionally, the fermented mixture is cooled by refrigerated coils between the walls of the tanks until needed Preferment is mixed with other ingredients and then pumped to a developer that kneads the dough at high speed under pressure for 1 to 5 min BREAD-MAKING PROCESSES Continuous System Air can be injected into the developer There is no bulk fermentation, or if there is, it is achieved in the machine The dough is pumped from the developer into an integrated divider, and then proofed and baked The bread produced by this method has a finer, more uniform structure and more consistent quality compared with other systems Raw materials Flour It is the contributor of the proteins necessary for gluten formation The higher the protein content of a flour, the better is its ability to trap and retain carbon dioxide gas and the larger can be the bread volume Protein quality also influences final product quality The higher the grade colour figure (GCF), ash or Branscan value, the lower will be bread volume, because of the dilution effect on the functional protein content Raw materials Yeast Saccharomyces cerevisiae form Wet Yeast –known as Cake Yeast, Fresh Yeast, or Compressed Yeast Dry Yeast – Sold as Active Dry and Instant Yeast Yeast + carbohydrates = alcohol + CO2 The yeast produces carbon dioxide gas to expand the dough Salt A basic function is to contribute flavour but it also has an inhibiting effect on the formation of gluten during mixing and on yeast activity Sugar (sucrose) Raw materials High levels of sugar inhibit yeast activity even though it is fermentable It also contribute to product sweetness and crust colour Fat are used to improve the gas retention of dough and thereby increase volume and softness level used will vary according to the type of flour Raw materials Water Too little and the dough will be firm and difficult to mould producing breads that have small volume and poor external appearance Too much and the dough will be soft and also difficult to mould; it will flow in the prover and give poor-quality bread Improvers any ingredient added to ‘improve’ the breadmaking potential of a given flour Improvers ingredients used in improvers Oxidising agents to improve the gas retention abilities of the dough Reducing agents such as L-cysteine may be added to ‘weaken’ the dough structure reducing dough resistance to deformation it helps in moulding and shape forming without structural damage Emulsifiers may be added to bread to improve its quality DATA (diacetyl tartaric acid esters of mono and diglycerides) esters, sodium stearoyl lactylate, distilled monoglycerides and lecithins Bread-making steps Dough Mixing Objectives To uniformly incorporate all ingredients, To hydrate the flour and the other dry ingredients, and Air inclusion To develop the gluten via mechanical energy input In mixing water is absorbed by flour’s components Bread-making steps Dough Mixing The mixing speed and work input must be above a certain value to develop the gluten network and produce bread of satisfactory quality If the mixing energy is larger than the optimum, the dough becomes wetter; it starts to stick to trough walls and its gas-holding ability drops An optimum work input or mixing time varies depending on the mixer type, flour composition, and ingredients Bread-making steps Mixing time is influenced by Mixer design Water absorption of the flour Dough size in relation to mixer Amount of shortening capacity Dough temperature Efficiency of cooling systems Quality of the flour Amount and type of reducing and oxidizing agents Amount of milk solids and other dry ingredients that compete for the water Bread-making steps Dough mixing affects dough rheology Gas is occluded and concentrated in the liquid phase of dough only during the mixing stage of bread making Oxygen and nitrogen gases present in the dough after mixing, but the oxygen is relatively quickly used up by the yeast cells within the dough But nitrogen is remains entrapped, and it providing bubble nuclei into which the CO2 produced later by yeast fermentation can diffuse and cause dough expansion Dough Mixing The production of a defined cellular structure in the bread depends entirely on the creation of gas bubbles in the dough during mixing and their retention during subsequent processing spiral mixer Ribbon mixer Bread-making steps Dough dividing To generate the shape and size, the bulk dough has to be first divided from the mixer into individual pieces and then shaped At optimum dividing accuracy with minimal compression damage The success of dividing depends on the homogeneity of the dough, which is largely determined by the distribution of gas bubbles Bread-making steps Dough is divided volumetrically with Piston dividing Extrusion dividing ** o Based on the ability to pump dough, usually by means of a helical screw density o The dough is worked considerably and best suited to strong doughs So use single-stage dividers directly from the hopper into the measuring chamber where the dough volume is set and cut Rounding and first moulding Modification of the shape of the divided dough piece to deliver a uniform dough piece to the final moulder Mimics an action that carried out by hand in the craft bakery Mechanical moulding subjects the dough to stresses and strains and may lead to damage to the existing gas bubble structure present During rounding the dough piece is rotated on its axis between the two inner surfaces of a V- or U-shaped trough Factor affecting rounders were rotational speed, angle of cone, angle and shape of track, inclination of track and surface finishes Rounder and moulder Bread-making steps Intermediate or first proving A period of rest between the work carried out by dividing and rounding and before final shaping The length of time chosen for this process is related to the dough rheology required for final moulding its elimination can lead to a reduction of loaf volume and an increase in damage to the bubble structure in the dough The pocket-type prover is held in fixed frames round the proving cabinet from charging to discharging stations Bread-making steps Final moulding To shape the dough to fit the product concept and to re-orientate the cell structure Passage of the round dough piece through sets of parallel rolls moving at high speed to reduce its thickness The dough pieces should have low resistance to deformation and minimal elasticity; otherwise the high pressures required to change the dough’s shape can cause loss of product quality Indicate WAC and optimizing added water levels during mixing Bread-making steps Proving and retarding Proving is the practice of holding yeast based products under controlled temperature and humidity conditions The temperature is designed to maximise yeast growth while the humidity is normally high to prevent the dough forming a dry skin sometime referred to as fermentation During proof the starch from the flour is progressively converted into dextrins and sugars by enzyme action Proving Proving Bread-making steps Proving and retarding Yeast feeds on the sugars to produce carbon dioxide and alcohol The carbon dioxide diffuses into the gas bubbles in the dough, causing them to grow and the dough to expand Progressively the size of the gas bubbles increases Retarding is holding a dough at a low temperature, around a refrigerator temperature, to hold up the fermentation process retarding Bread-making steps Proving and retarding Under retarding conditions the activity of the yeast is slowed but the activity of the flour amylase enzymes is reduced much further Retarding can prevent a dough ‘‘going rotten’’ as the action of the amylase breaks up so much starch that the dough becomes sticky and unhandleable The ability of a dough to stand these conditions is referred to as its tolerance retarder is regarded as a life saver BREAD-MAKING PROCESSES Scaling Is the process of weighing the dough out To ensure that under-weight loaves do not leave the bakery BAKING OVENS Transform dough into a light, readily digestible and flavorful product under the influence of heat Phenomena caused by oven heat includes expansion in volume, the formation of an enveloping crust, the inactivation of yeast and enzymatic activities, the coagulation of the flour protein, and partial gelatinization of flour starch, it absorb any free H2O BREAD-MAKING PROCESSES Types of oven include reel ovens, traveling tray ovens, tunnel ovens, conveyorized ovens, rack ovens, etc. The selection of a particular type of oven is often based on the following considerations: the bakery’s production volume, product varieties, plant space, and cost, Reel ovens are suited for low production volume at retail stores Larger production volumes, in industry or supermarkets, traveling tray ovens Evaluation of Bread Quality Quality parameters include density specific volume pH, water activity, color, and Texture------Crust and crumb----for brown & Glossy Interior Proximate analysis Flavor