Foundation Design

Principles and Practices

Third Edition

Donald P. Coduto

William A. Kitch

Man-chu Ronald Yeung

Professors of Civil Engineering

California State Polytechnic University, Pomona

Boston Columbus Indianapolis New York San Francisco Hoboken

Amsterdam Cape Town Dubai London Madrid Milan Munich Paris Montreal Toronto

Delhi Mexico City São Paulo Sydney Hong Kong Seoul Singapore Taipei Tokyo

Vice President and Editorial Director, ECS: Marcia J. Horton

Executive Editor: Holly Stark

VP of Marketing: Christy Lesko

Director of Field Marketing: Tim Galligan

Product Marketing Manager: Bram van Kempen

Field Marketing Manager: Demetrius Hall

Marketing Assistant: Jon Bryant

Senior Managing Editor: Scott Disanno

Production Project Manager: Greg Dulles

Program Manager: Erin Ault

Global HE Director of Vendor Sourcing and Procurement:

Diane Hynes

Operations Specialist: Maura Zaldivar-Garcia

Cover Designer: Black Horse Designs

Manager, Rights and Permissions: Rachel Youdelman

Full-Service Project Management: Shylaja Gattupalli,

Jouve India

Composition: Jouve India

Printer/Binder: Edwards Brothers

Cover Printer: Phoenix Color/Hagerstown

Typeface: 10/12 Times LT Std-Roman

Copyright © 2016, 2001, 1994 by Pearson Education, Inc. or its affiliates. All Rights Reserved. Printed in the United States

of America. This publication is protected by copyright, and permission should be obtained from the publisher prior to any

prohibited reproduction, storage in a retrieval system, or transmission in any form or by any means, electronic, mechanical,

photocopying, recording, or otherwise. For information regarding permissions, request forms and the appropriate contacts

within the Pearson Education Global Rights & Permissions department, please visit www.pearsoned.com/permissions/.

Many of the designations by manufacturers and seller to distinguish their products are claimed as trademarks. Where those

designations appear in this book, and the publisher was aware of a trademark claim, the designations have been printed in

initial caps or all caps.

The author and publisher of this book have used their best efforts in preparing this book. These efforts include the

development, research, and testing of theories and programs to determine their effectiveness. The author and publisher

make no warranty of any kind, expressed or implied, with regard to these programs or the documentation contained in this

book. The author and publisher shall not be liable in any event for incidental or consequential damages with, or arising

out of, the furnishing, performance, or use of these programs.

Pearson Education Ltd., London

Pearson Education Singapore, Pte. Ltd

Pearson Education Canada, Inc.

Pearson Education—Japan

Pearson Education Australia PTY, Limited

Pearson Education North Asia, Ltd., Hong Kong

Pearson Educación de Mexico, S.A. de C.V.

Pearson Education Malaysia, Pte.Ltd.

Pearson Education, Inc., Upper Saddle River, New Jersey

Library of Congress Cataloging-in-Publication Data

Coduto, Donald P.

Foundation design : principles and practices / Donald P. Coduto, William A. Kitch, Man-chu Ronald Yeung,

Professors of Civil Engineering, California State Polytechnic University, Pomona. — Third edition.

pages cm

Includes bibliographical references and index.

ISBN 978-0-13-341189-8 (alk. paper)

ISBN 0-13-341189-3 (alk. paper)

1. Foundations. I. Kitch, William A. II. Yeung, Man-chu Ronald III. Title.

TA775.C63 2014

624.1’5—dc23

2014035178

10 9 8 7 6 5 4 3 2 1

www.pearsonhighered.com

ISBN 0-13-341189-3

ISBN 978-0-13-341189-8

Contents

Preface

Notation and Units of Measurement

xi

xiii

PART A – General Principles

1

1. Foundations

1.1 Foundation Classification

1.2 The Emergence of Modern Foundation Engineering

1.3 The Foundation Engineer

1.4 Codes, Standards, and Technical Literature

Summary

3

4

5

9

10

12

2. Uncertainty and Risk in Foundation Design

2.1 Sources and Types of Uncertainty

2.2 Probability Theory

2.3 Failure, Reliability, and Risk

2.4 Applying Reliability Theory in Practice

Summary

Questions and Practice Problems

13

14

16

25

28

32

33

3. Soil Mechanics

3.1 Review and Nomenclature

3.2 Soil Classification

3.3 Stress

3.4 Compressibility and Settlement

3.5 Shear Strength

3.6 Lateral Earth Pressures

Summary

Questions and Practice Problems

35

37

38

41

53

65

74

78

80

iii

iv

Contents

4. Subsurface Investigation and Characterization

4.1 Site Investigation

4.2 Laboratory Testing

4.3 In Situ Testing

4.4 Determination of Soil Properties for Foundation Design

4.4 Synthesis of Field and Laboratory Data

4.5 Economics

Summary

Questions and Practice Problems

84

86

96

106

127

141

143

145

146

5. Performance Requirements

5.1 Types of Failure and Limit States

5.2 Ultimate Limit States

5.3 Serviceability Limit States

5.4 Constructability Requirements

5.5 Economic Requirements

Summary

Questions and Practice Problems

148

149

150

162

179

180

181

183

PART B – Shallow Foundation Analysis and Design

187

6. Shallow Foundations

6.1 Spread Footings

6.2 Mats

6.3 Bearing Pressure

6.4 Presumptive Allowable Bearing Pressures

Summary

Questions and Practice Problems

189

189

196

197

210

211

212

7. Spread Footings—Geotechnical Ultimate Limit States

7.1 Bearing Capacity

7.2 Bearing Capacity Analyses in Soil—General Shear Case

7.3 Groundwater Effects

7.4 Selection of Soil Strength Parameters

7.5 Design of Spread Footings Against Bearing Capacity Failure

7.6 Bearing Capacity Analysis in Soil—Local and Punching Shear Cases

7.7 Bearing Capacity on Layered Soils

7.8 Bearing Capacity of Footings on or Near Slopes

7.9 Accuracy of Bearing Capacity Analyses

7.10 Design of Spread Footings Against Sliding Failure

Summary

Questions and Practice Problems

215

216

219

233

236

237

246

247

250

251

253

258

260

Contents

v

8. Spread Footings—Geotechnical Serviceability Limit States

8.1 Design Requirements

8.2 Modulus Based Methods of Computing Settlement

8.3 e-log-p Based Method of Computing Settlement

8.4 Differential Settlement

8.5 Rate of Settlement

8.6 Accuracy of Settlement Predictions

Summary

Questions and Practice Problems

264

265

266

283

290

296

297

302

303

9. Spread Footings—Geotechnical Design

9.1 Individual Footing Design Approach

9.2 Design Charts Approach

9.3 Allowable Bearing Pressure Approach

9.4 Rectangular and Combined Footings

9.5 Special Seismic Considerations

9.6 Lightly-Loaded Footings

9.7 Footings on or Near Slopes

9.8 Footings on Frozen Soils

9.9 Footings on Soils Prone to Scour

Summary

Questions and Practice Problems

307

308

313

317

328

329

330

333

334

340

341

342

10. Spread Footings—Structural Design

10.1 Selection of Materials

10.2 Footing Behavior and Design Methods

10.3 Design Methodology

10.4 Minimum Cover Requirements and Standard Dimensions

10.5 Square Footings

10.6 Continuous Footings

10.7 Rectangular Footings

10.8 Combined Footings

10.9 Lightly Loaded Footings

10.10 Connections with the Superstructure

Summary

Questions and Practice Problems

348

350

350

352

354

356

374

379

381

381

383

397

398

11. Mats

11.1

11.2

11.3

11.4

401

402

403

403

404

Configuration

Geotechnical Ultimate Limit States

Geotechnical Serviceability Limit States

Compensated Mats

vi

Contents

11.5 Rigid Methods

11.6 Nonrigid Methods

11.7 Structural Design

Summary

Questions and Practice Problems

PART C – Deep Foundation Analysis and Design

407

409

416

418

419

421

12. Deep Foundation Systems and Construction Methods

12.1 Deep Foundation Types and Terminology

12.2 Driven Piles

12.3 Drilled Shafts

12.4 Auger Piles

12.5 Other Pile Types

12.6 Caissons

12.7 Pile-Supported and Pile-Enhanced Mats

Summary

Questions and Practice Problems

423

424

427

451

469

476

484

488

489

491

13. Piles—Load Transfer and Limit States

13.1 Axial Load Transfer

13.2 Lateral Load Transfer

13.3 Installation Effects

Summary

Questions and Practice Problems

493

494

508

509

514

515

14. Piles—Axial Load Capacity Based on Static Load Tests

14.1 Objectives

14.2 Conventional Static Pile Load Tests

14.3 Interpretation of Test Results

14.4 Instrumented Static Pile Load Tests

14.5 Osterberg Load Tests (O-Cell)

14.6 Dynamic Axial Load Tests

Summary

Questions and Practice Problems

517

517

518

522

530

535

536

537

537

15. Driven Piles—Axial Load Capacity Based on Static

Analysis Methods

15.1 Toe Bearing

15.2 Side Friction

15.3 Analyses Based on the Cone Penetration Test

15.4 Upward Capacity

15.5 Group Effects

539

541

547

557

566

568

Contents

vii

15.6 Unusual Soils

15.7 Setup and Relaxation

Summary

Questions and Practice Problems

572

573

574

575

16. Drilled Shafts—Axial Load Capacity Based on Static

Analysis Methods

16.1 Toe Bearing

16.2 Side Friction

16.3 Upward Load Capacity

16.4 Analyses Based on CPT Results

16.5 Group Effects

Summary

Questions and Practice Problems

580

581

583

592

594

594

594

595

17. Auger Piles—Axial Load Capacity Based on Static

Analysis Methods

17.1 Augered Cast-in-Place Piles (ACIP)

17.2 Drilled Displacement (DD) Piles

Summary

Questions and Practice Problems

598

598

604

610

611

18. Other Pile Types—Axial Load Capacity

18.1 Jacked Piles

18.2 Pressure-Injected Footings (Franki Piles)

18.3 Micropiles

18.4 Helical Piles

Summary

Questions and Practice Problems

613

613

615

617

619

621

622

19. Deep Foundations—Axial Load Capacity Based on

Dynamic Methods

19.1 Pile Driving Formulas

19.2 Wave Equation Analyses

19.3 High-Strain Dynamic Testing

19.4 Conclusions

Summary

Questions and Practice Problems

623

623

627

647

662

662

663

20. Piles—Serviceability Limit States

20.1 Design Load

20.2 Settlement Analysis Based on Load Tests

20.3 Mobilization of Pile Capacity

665

666

666

666

viii

Contents

20.4 The t-z Method

20.5 Simplified Static Analysis Methods

20.6 Settlement of Pile Groups

20.7 Equivalent Spring Model

20.8 Other Sources of Settlement

20.9 Other Serviceabilty Considerations

Summary

Questions and Practice Problems

672

674

677

682

682

682

683

683

21. Piles—Structural Design

21.1 Design Philosophy

21.2 Design Criteria

21.3 Driven Piles

21.4 Drilled Shafts and Auger Piles

21.5 Pile Caps

21.6 Seismic Design

Summary

Questions and Practice Problems

685

686

687

692

706

707

709

709

710

22. Laterally Loaded Piles

22.1 Battered Piles

22.2 Response to Lateral Loads

22.3 Methods of Evaluating Lateral Load Capacity

22.4 Rigid Pile Analyses

22.5 Nonrigid Pile Analyses

22.6 p-y Curves for Isolated Piles

22.7 Lateral Load Tests

22.8 Group Effects

22.9 Depth to Fixity Method

22.10 Improving Lateral Capacity

22.11 Synthesis

Summary

Questions and Practice Problems

712

713

716

721

722

727

729

735

736

740

741

741

743

744

23. Piles—The Design Process

23.1 Unstable Conditions

23.2 Pile Type and Configuration

23.3 Required Axial Pile Capacity

23.4 Geotechnical Design

23.5 Structural Design

23.6 Verification and Redesign During Construction

23.7 Integrity Testing

Summary

Questions and Practice Problems

746

747

754

758

759

761

762

764

768

769

Contents

24. Pile Supported and Pile Enhanced Mats

24.1 Pile Supported Mats

24.2 Pile Enhanced Mats

24.3 Compensated Mat Foundations

Summary

Questions and Practice Problems

PART D – Special Topics

ix

770

771

772

774

775

776

777

25. Foundations in Rocks and Intermediate Geomaterials

25.1 Rock as a Structural Foundation Material

25.2 Design of Foundations in Rocks

25.3 Foundations in Intermediate Geomaterials

Summary

Questions and Practice Problems

779

779

797

815

818

819

26. Ground Improvement

26.1 Ground Improvement for Foundations

26.2 Removal and Replacement

26.3 Precompression

26.4 In Situ Densification

26.5 In Situ Replacement

26.6 Grouting

26.7 Stabilization Using Admixtures

26.8 Reinforcement

Summary

Questions and Practice Problems

822

823

823

824

828

831

832

835

836

837

838

27. Foundations on Expansive Soils

27.1 The Nature, Origin, and Occurrence of Expansive Soils

27.2 Identifying, Testing, and Evaluating Expansive Soils

27.3 Estimating Potential Heave

27.4 Typical Structural Distress Patterns

27.5 Preventive Design and Construction Measures

27.6 Other Sources of Heave

Summary

Questions and Practice Problems

840

841

853

865

870

871

882

884

885

28. Foundations on Collapsible Soils

28.1 Origin and Occurrence of Collapsible Soils

28.2 Identification, Sampling, and Testing

28.3 Evaluation and Remediaiton for Routine Projects

28.4 Advanced Testing and Analysis

887

887

891

893

893

x

Contents

28.5 Collapse in Deep Compacted Fills

28.6 Preventive and Remedial Measures

Summary

Questions and Practice Problems

Appendix A—Units and Conversion Factors

Appendix B—Probability Tables

References

Index

897

897

901

902

903

907

911

941

Preface

Publication of this third edition of Foundation Design: Principles and Practices comes

twenty years after the 1994 release of the first edition. The original book, along with the

second edition published in 2001, enjoyed widespread use among students, researchers,

and practicing engineers both in the United States and abroad.

Two new co-authors, William A. Kitch and Man-chu Ronald Yeung, have collaborated with the original author, Donald P. Coduto, to produce this third edition. All three

are professors at California State Polytechnic University, Pomona, and previously collaborated on a new edition of Geotechnical Engineering: Principles and Practices, which is

the companion volume to this book.

WHAT IS NEW IN THIS EDITION

This new edition reflects advancements in theory and practice over the past thirteen years,

constructive suggestions we have received from readers, as well as our experiences using

the book as a text in our undergraduate and graduate level foundation engineering courses.

As part of this update, some chapters have been deleted, others have been added, and

much of the book has been reorganized. Nearly every page has some revisions.

The most substantive and pervasive changes are the increased emphasis on limit

state design and the inclusion of load and resistance factor design (LRFD) in both the

structural and geotechnical aspects of the analysis and design process. These changes

reflect the broader use of limit state design in engineering practices, such as the AASHTO

code in North America and other codes around the world. Allowable stress design (ASD)

methods have been retained, as this method is still widely used. Other noteworthy changes

include:

• A new chapter on uncertainty and risk in foundation engineering.

• Design procedures that place greater emphasis on the distinction between serviceability limit states and ultimate limit states.

• Improved coverage of auger piles, including a new chapter on axial load design,

which reflects advancements in this technology.

xi

xii

Preface

• A completely revised chapter on pile dynamics with more in depth material on

Wave Equation Analysis and a new section on pulse load testing.

• Better integration with widely available software. For example, the chapter on laterally loaded piles is now based on the assumption that the reader has access to lateral

load analysis software.

• A new chapter on serviceability limit states in piles.

• New chapters on foundations in rocks and intermediate geomaterials and ground

improvement.

• Many new and updated example problems and homework problems.

A complete solutions manual as well as PowerPoint slides of the various illustrations

and tables may be downloaded from the Instructor’s Resource Center located at www.

pearsonhighered.com/Coduto. This material is provided solely for the use of instructors in

teaching their courses and assessing student learning. All requests for instructor access are

verified against our customer database and/or through contacting the requestor’s institution. Contact your local sales representative for additional assistance or support.

ACKNOWLEDGMENTS

In addition to insights gained from our review of the technical literature and from our own

professional experience, we received substantial help from numerous professional friends

and colleagues. Through many stimulating discussions, peer reviews of draft chapters,

and in many other ways, they helped us improve the manuscript. Dr. Frank Raushe, PE;

Daniel Zepeda, SE; Mike Kapuskar, GE; and Rick Drake, SE were especially generous in

their assistance.

Our current and former students Gerald Aspiras, Brian Barnhart, Alejandro

Irigoyen, Jiang Ly, Zachary Murray, Christopher Sandoval, and John Schober assisted

with proofreading, problem solutions, and various insights from a student’s perspective.

Kevin Coduto assisted with file management and photo editing. Multiple drafts also were

tested in the classroom at Cal Poly Pomona, and we appreciate our students’ patience as

we experimented with various methods of explaining different concepts, as well as their

assistance in proofreading the text.

We appreciate the support from Holly Stark and Scott Disanno at Pearson, who

made this project possible, as well as Pavithra Jayapaul and Shylaja Gattupalli at JouveIndia who provided excellent production support. Finally we thank our families for their

patience as we devoted long hours to finishing this project.

Donald P. Coduto

William A. Kitch

Man-chu Ronald Yeung

Claremont, California

Notation and

Units of Measurement

There is no universally accepted notation in foundation engineering. However, the notation used in this book, as described in the following table, is generally consistent with

popular usage.

Typical Units

Symbol

A

A0

A1

A2

Ac

Af

Ag

Ap

Ar

As

Atg

Atr

a

a

aunl

au

B

Bb

Be

Bg

Bq

Description

Base area of foundation

Initial cross-sectional area

Cross-sectional area of column

Base area of frustum

Cross-sectional area of concrete

Cross-sectional area at failure

Gross cross-sectional area

Area of an individual plate

Rod surface area

Steel area

Area of pile group tip

Area of transverse reinforcing steel

CPT net area ratio

Hoek-Brown constant given by Equation 25.5

Pile acceleration at the unloading point

Factor in Nq equation

Width of foundation

Diameter at base of foundation

Equivalent footing width

Width of pile group

CPT pore pressure ratio

English

SI

Defined in

Chapter

ft2

in2

in2

in2

in2

in2

in2

ft2

ft2

in2

ft2

in2

Unitless

Unitless

g

Unitless

ft & in

ft

ft

ft

Unitless

m2

mm2

mm2

mm2

mm2

mm2

mm2

m2

m2

mm2

m2

mm2

Unitless

Unitless

g

Unitless

mm

m

m

m

Unitless

Ch 3

Ch 4

Ch 10

Ch 10

Ch 10

Ch 4

Ch 10

Ch 18

Ch 18

Ch 10

Ch 15

Ch 10

Ch 4

Ch 25

Ch 19

Ch 7

Ch 3

Ch 16

Ch 8

Ch 15

Ch 4

xiii

xiv

Notation and Units of Measurement

Bs

B′

b

b0

bc, bq, bg

bw

C

C1

C2

C3

CA

CB

Cc

COCR

CP

CR

Cr

CS

Cs

Ct

COV

c

c

c

c

c′

c′adj

cn

cT

D

D

D

D

D

D2

D50

Dmin

Dr

Dw

d

Diameter of shaft

Effective foundation width

Unit length

Length of critical shear surface

Bearing capacity base inclination factors

Length of critical shear surface

Capacity of a structural element

Depth factor

Secondary creep factor

Shape factor

Aging factor

SPT borehole diameter correction

Compression index

Overconsolidation correction factor

Grain size correction factor

SPT rod length correction

Recompression index

SPT sampler correction

Side friction coefficient

Toe coefficient

Coefficient of variation of a random variable

Concrete cover or spacing between bars

Factor in Engineering News Formula

Wave velocity in pile

Column or wall width

Effective cohesion

Adjusted effective cohesion

Depth to the neutral axis in beam bending

Total cohesion

Depth of foundation

Demand placed on a structural element

Dead load

Depth of socket embedment

Disturbance factor

Distance from transducers to pile tip

Grain size at which 50 percent is finer

Minimum required embedment depth

Relative density

Depth from ground surface to groundwater

table

Effective depth

ft

ft-in

ft

in

Unitless

in

Varies

Unitless

Unitless

Unitless

Unitless

Unitless

Unitless

Unitless

Unitless

Unitless

Unitless

Unitless

Unitless

Unitless

Unitless

in

in

ft/s

in

lb/ft2

lb/ft2

in

lb/ft2

ft & in

Varies

Varies

ft

Unitless

ft

–

ft

percent

ft

m

m

m

mm

Unitless

mm

Varies

Unitless

Unitless

Unitless

Unitless

Unitless

Unitless

Unitless

Unitless

Unitless

Unitless

Unitless

Unitless

Unitless

Unitless

mm

mm

m/s

mm

kPa

kPa

mm

kPa

mm or m

Varies

Varies

m

Unitless

m

mm

m

percent

m

Ch 16

Ch 6

Ch 10

Ch 10

Ch 7

Ch 10

Ch 2

Ch 8

Ch 8

Ch 8

Ch 4

Ch 4

Ch 3

Ch 4

Ch 4

Ch 4

Ch 3

Ch 4

Ch 15

Ch 15

Ch 2

Ch 10

Ch 19

Ch 19

Ch 10

Ch 3

Ch 7

Ch 10

Ch 3

Ch 3

Ch 2

Ch 5

Ch 25

Ch 25

Ch 19

Ch 4

Ch 22

Ch 3

Ch 7

in

mm

Ch 10

Notation and Units of Measurement

d

d

db

dc, dq, dg

E

E

E

E

E0

E25

Ea

Ec

ED

Eh

Ei

El

Em

Em

Ep

Er

Es

Es

Es

Eu

EI

e

e

e

e0

ea

eB

eh

eL

emax

emin

F

F

Vane diameter

Depth factor in Equation 25.15

Reinforcing bar diameter

Bearing capacity depth factors

A probabilistic event

Portion of steel in center section

Modulus of elasticity

Earthquake load

Modulus at ground surface

Secant modulus

Energy lost in appurtenances during pile

driving

Modulus of elasticity for concrete

DMT modulus

Kinetic energy of hammer during pile driving

Deformation modulus of intact rock

Viscous energy lost in soil during pile

driving

SPT hammer efficiency

Rock mass deformation modulus

Energy lost in pile during driving

Rated energy of pile hammer

Equivalent modulus of elasticity

Work done on soil during pile driving

Modulus of elasticity for steel

Undrained modulus of elasticity

Expansion index

Eccentricity

Void ratio

Base of natural logarithms

Initial void ratio

Efficiency factor for appurtenance losses in

pile driving

Eccentricity in the B direction

Efficiency of pile driving hammer

Eccentricity in the L direction

Maximum void ratio

Minimum void ratio

Factor of safety

Force applied in pile driving or dynamic

testing

xv

in

Unitless

in

Unitless

NA

Unitless

lb/ft2

lb/ft2

ft-lb

mm

Unitless

mm

Unitless

NA

Unitless

MPa

Varies

kPa

kPa

Joules

Ch 4

Ch 25

Ch 10

Ch 7

Ch 2

Ch 10

Ch 2

Ch 5

Ch 8

Ch 20

Ch 19

lb/in2

lb/ft2

ft-lb

k/in2

ft-lb

MPa

kPa

Joules

MPa

Joules

Ch 14

Ch 4

Ch 19

Ch 25

Ch 19

Unitless

k/in2

ft-lb

ft-lb

lb/ft2

ft-lb

lb/in2

lb/ft2

Unitless

ft

Unitless

2.7183

Unitless

Unitless

Unitless

MPa

Joules

Joules

kPa

Joules

MPa

kPa

Unitless

m

Unitless

2.7183

Unitless

Unitless

Ch 4

Ch 25

Ch 19

Ch 19

Ch 8

Ch 19

Ch 14

Ch 4

Ch 27

Ch 6

Ch 3

–

Ch 3

Ch 19

ft

Unitless

ft

Unitless

Unitless

Unitless

k

m

Unitless

m

Unitless

Unitless

Unitless

kN

Ch 6

Ch 19

Ch 6

Ch 3

Ch 3

Ch 2

Ch 19

lb/in2

Varies

xvi

Notation and Units of Measurement

Fa

Fd

Fr

Funl

Fv

f

fa

fb

fc′

fn

fpc

fs

fv

fy

G

Gs

GSI

gc, gq, gg

H

H

H

h

h

h0

I

Ic

ID

IE, IF, IG

IP

Ir

Ie

Iec

Iep

Ies

Is

I0, I1

ic, iq, ig

Body force due to acceleration in dynamic

testing

Dynamic force applied in dynamic testing

CPT normalized friction ratio

Force in pile at the unloading point

Damping force applied in dynamic testing

Mobilized unit side friction resistance

Allowable axial stress

Allowable flexural stress

28-day compressive strength of concrete

Nominal unit side friction capacity

Effective prestress on gross section

CPT cone side friction

Allowable shear stress

Yield strength of steel

Shear modulus

Specific gravity of solids

Geological Strength Index

Bearing capacity ground inclination factors

Thickness of soil stratum

Earth pressure load

Initial height of specimen immediately before

soaking

Hammer stroke

Expansion of soil

Initial height of sample

Moment of inertia

CPT normalized soil behavior type index

DMT material index

Stress influence factors

Plasticity index

Rigidity index

Strain influence factor

Strain influence factor for continuous

foundation

Peak strain influence factor

Strain influence factor for square foundation

Stress influence factor

Stress influence factors

Bearing capacity load inclination factors

k

kN

Ch 19

k

Unitless

k

k

Ch 19

Ch 4

Ch 19

Ch 19

Ch 14

Ch 21

Ch 21

Ch 10

Ch 13

Ch 21

Ch 4

1b/in2

1b/in2

Unitless

Unitless

Unitless

Unitless

ft

Varies

in

kN

Unitless

kN

kN

kPa

MPa

MPa

MPa

kPa

MPa

MPa or

kg/cm2

MPa

MPa

Unitless

Unitless

Unitless

Unitless

m

Varies

mm

in

in

in

in4

Unitless

Unitless

Unitless

Unitless

Unitless

Unitless

Unitless

m

mm

mm

mm4

Unitless

Unitless

Unitless

Unitless

Unitless

Unitless

Unitless

Ch 19

Ch 27

Ch 27

Ch 21

Ch 4

Ch 4

Ch 8

Ch 3

Ch 15

Ch 8

Ch 8

Unitless

Unitless

Unitless

Unitless

Unitless

Unitless

Unitless

Unitless

Unitless

Unitless

Ch 8

Ch 8

Ch 3

Ch 8

Ch 7

1b/ft2

1b/in2

1b/in2

1b/in2

1b/ft2

1b/in2

T/ft2

Ch 21

Ch 10

Ch 4

Ch 3

Ch 25

Ch 7

Ch 3

Ch 5

Ch 27

Notation and Units of Measurement

JS

Jp

js

K

K

K0

Ka

KD

KE

Kp

Ks

Ksp

Kt

Kt

Ktr

k

ks

ks

kt

L

L

LF

Lg

LL

Lr

L′

l

ld

ldh

M

M

Mn

Ms

Mu

Muc

m

m

mb

Smith damping factor

Pile damping factor

Soil damping factor

Coefficient of lateral earth pressure

Bulk modulus

Coefficient of lateral earth pressure at rest

Coefficient of active earth pressure

DMT horizontal stress index

Factor in Fleming method

Coefficient of passive earth pressure

Side resistance flexibility factor

Empirical coefficient in Equation 25.15

Toe resistance flexibility factor

Coefficient of lateral earth pressure at ground

surface

Splitting term for development length

Factor in computing depth factors

Coefficient of subgrade reaction

LCPC side friction factor

LCPC toe bearing factor

Length of foundation

Live load

Factor in Fleming method

Length of pile group

Liquid limit (see wL)

Live roof load

Effective foundation length

Cantilever distance

Development length

Development length for hook

Constrained modulus

Moment load

Nominal moment load capacity

Flexibility factor

Factored moment load

Factored moment on the section being

analyzed

Safety margin

Factor in computing load inclination factors

Hoek-Brown constant given by Equation 25.3

xvii

Unitless

Unitless

Unitless

Unitless

Unitless

Unitless

Unitless

Unitless

Unitless

Unitless

Unitless

Unitless

Unitless

Unitless

Unitless

Unitless

Unitless

Unitless

Unitless

Unitless

Unitless

Unitless

Unitless

Unitless

Unitless

Unitless

Unitless

Unitless

Ch 19

Ch 19

Ch 19

Ch 3

Ch 4

Ch 3

Ch 3

Ch 4

Ch 20

Ch 3

Ch 20

Ch 25

Ch 20

Ch 15

in

Unitless

1b/in3

Unitless

Unitless

ft-in

Varies

ft

ft

Unitless

Varies

ft-in

in

in

in

1b/ft2

ft-k

ft-k

Unitless

ft-k

in-lb

mm

Unitless

kN/m3

Unitless

Unitless

mm

Varies

m

m

Unitless

Varies

m

mm

mm

mm

kPa

kN-m

kN-m

Unitless

kN-m

kN-m

Ch 10

Ch 7

Ch 11

Ch 15

Ch 15

Ch 3

Ch 5

Ch 20

Ch 15

Ch 3

Ch 5

Ch 6

Ch 10

Ch 10

Ch 10

Ch 4

Ch 5

Ch 10

Ch 20

Ch 5

Ch 10

Unitless

Unitless

Unitless

Unitless

Unitless

Unitless

Ch 2

Ch 7

Ch 25

xviii

Notation and Units of Measurement

mi

mv

mb for intact rock

Coefficient of compressibility

N

SPT blow count recorded in field

ft /1b

Blows/ft

N

N

NB

Nominal load capacity

Number of piles in a group

Becker blow count

Varies

Unitless

Blows/ft

Stress wave number

Bearing capacity factors

Bearing capacity factors

Unitless

1/kpa

Ch 25

Ch 4

Ch 4

Unitless

Unitless

Unitless

Blows/

300 mm

Varies

Unitless

Blows/

300 mm

Unitless

Unitless

Unitless

Breakout factor

Bearing capacity factor for rock

Unitless

Unitless

Unitless

Unitless

Ch 16

Ch 25

SPT blow count corrected for field procedures

and overburden stress

SPT blow count corrected for field procedures

Blows/ft

Ch 4

n

n

OCR

P

P(E)

Pa

Pa

Pa

Porosity

CPT stress exponent

Overconsolidation ratio

Normal load

Probability of event, E

Allowable downward load capacity

Active earth pressure resultant force

Atmospheric pressure

percent

Unitless

Unitless

k

NA

k

lb

Blows/

300 mm

Blows/

300 mm

percent

Unitless

Unitless

kN

NA

kN

kN

100 kPa

Ch 3

Ch 4

Ch 3

Ch 5

Ch 2

Ch 9

Ch 3

Ch 4

Pa,up

Pag

Pup

Pup,n

Pf

Pf

PI

Pj

PL

Pm

Pn

Pnb

Pp

Ps

Allowable upward load capacity

Allowable load capacity of pile group

Upward load

Nominal upward load capacity

Probability of failure

Axial load at failure

Plasticity index (see IP)

Final jacking force

Plastic limit (see wP)

p multiplier

Nominal downward load capacity

Nominal column bearing capacity

Passive earth pressure resultant force

Side friction resistance

kN

kN

kN

kN

Unitless

N

Unitless

kN

Unitless

Unitless

kN

kN

kN

kN

Ch 13

Ch 15

Ch 13

Ch 13

Ch 2

Ch 4

Ch 3

Ch 18

Ch 3

Ch 22

Ch 5

Ch 10

Ch 3

Ch 13

Nw

Nc, Nq, Ng

N *c , N *q,

N *g, Ns

Nu

N *cr

N1,60

N60

Unitless

2

Blows/ft

1 ton/ft2

k

k

k

k

Unitless

lb

Unitless

k

Unitless

Unitless

k

k

lb

k

Ch 5

Ch 15

Ch 4

Ch 19

Ch 7

Ch 15

Ch 4

Notation and Units of Measurement

Pt

P′t

Pu

p

p

p0, p1

Toe bearing resistance

Net toe bearing resistance

Factored normal load

Lateral soil resistance per unit length of pile

Air pressure inside pneumatic caisson

DMT pressure readings

pa

Atmospheric pressure

pu

Ultimate lateral soil resistance per unit length

of pile

Compressibility factor

CPT normalized cone tip resistance

Bearing pressure

Qc

Qtn

q

q

xix

k

k

k

lb

lb/in2

kN

kN

kN

kN

MPa

Ch 13

Ch 13

Ch 5

Ch 22

Ch 12

lb/in2

kPa

Ch 4

2

lb/in

lb

kPa

Ch 16

kN

Ch 22

Unitless

Unitless

Unitless

Unitless

kPa

Ch 4

Ch 4

Ch 6

lb/ft2

mm

kPa

Ch 19

Ch 6

lb/ft2

lb/ft2

in

q′

Quake

Net bearing pressure

q′

Mobilized net unit toe bearing resistance

kPa

Ch 14

qa

Allowable bearing capacity

2

lb/ft

kPa

Ch 7

qA

Allowable bearing pressure

lb/ft2

kPa

Ch 6

2

qA,SLS

lb/ft

kPa

Ch 9

lb/ft2

kPa

Ch 9

qc

Allowable bearing pressure based on

serviceability limit state

Allowable bearing pressure based on ultimate

limit state

CPT cone resistance

T/ft2

MPa or

kg/cm2

Ch 4

qE

Effective cone resistance

T/ft2

kg/cm2 or

MPa

Ch 15

qEg

Factor in Eslami and Fellenius method

T/ft2

Ch 15

qeq

Equivalent bearing pressure

lb/ft2

kg/cm2 or

MPa

kPa

Ch 6

qmax

Maximum bearing pressure

2

kPa

Ch 6

qmin

Minimum bearing pressure

2

lb/ft

kPa

Ch 6

qn

Nominal unit bearing capacity

lb/ft2

kPa

Ch 7

q′n

Nominal unit toe bearing capacity

2

kPa

Ch 13

qt

Corrected SPT cone tip resistance

2

T/ft

Ch 4

q′tr

Reduced net unit toe bearing resistance

lb/ft2

MPa or

kg/cm2

kPa

Ch 15

qu

Unconfined compressive strength

kPa

Ch 4

R

R

R

Reliability

Rain load

Total resistance of pile during driving

Unitless

Varies

kN

Ch 2

Ch 5

Ch 19

qA,ULS

lb/ft

lb/ft

2

lb/ft

Unitless

Varies

k

xx

Notation and Units of Measurement

Rd

Rf

RMR

RQD

Rs

Ru

Rur

r

S

S

S

S

S

Smi

SR

St

s

s

s

s

sc, sq, sg

su

sv

T

Tf

TMI

t

t

td

tp

tunl

U

u

u

u0

u2

uD

Dynamic resistance of pile during driving

Friction ratio in CPT

Rock Mass Rating

Rock quality designation

Static resistance of pile during driving

Ultimate static resistance of pile during

driving

Required ultimate static resistance of pile

during driving

Rigidity factor

Snow load

Slope of pile from the vertical

Elastic section modulus

Degree of saturation

Column spacing

Joint spacing of the ith discontinuity set

Spacing ratio

Sensitivity

Shear strength

Center-to-center spacing of piles or reinforcing bars

Pile set

Hoek-Brown constant given by Equation 25.4

Bearing capacity shape factors

Undrained shear strength

Vertical spacing of discontinuity

Thickness of foundation

Torque at failure

Thornthwaite moisture index

Time

Factor in rock bearing formula

Aperture of discontinuity

Wave propagation time in pile driving

Time at which pile velocity is zero

Generic factored load

Displacement of pile or pile segment

Pore water pressure

Equilibrium pore water pressure

Pore water pressure behind CPT cone

Pore water pressure at bottom of foundation

Unitless

Unitless

Unitless

Unitless

Unitless

k

Unitless

Unitless

Unitless

Unitless

Unitless

kN

Ch 19

Ch 4

Ch 25

Ch 25

Ch 19

Ch 19

k

kN

Ch 19

Unitless

Varies

radians

in3

percent

ft

ft

Unitless

Unitless

Unitless

Varies

radians

mm3

percent

m

m

Unitless

Unitless

kPa

Ch 8

Ch 5

Ch 22

Ch 21

Ch 3

Ch 5

Ch 25

Ch 25

Ch 3

Ch 3

mm

Ch 15

in

Unitless

Unitless

lb/ft2

ft

ft-in

in-lb

Unitless

yr

Unitless

in

s

s

Varies

in

lb/ft2

lb/ft2

mm

Unitless

Unitless

kPa

m

mm

N-m

Unitless

yr

Unitless

mm

s

s

Varies

mm

kPa

kPa

Ch 19

Ch 25

Ch 7

Ch 3

Ch 25

Ch 10

Ch 4

Ch 27

Ch 7

Ch 25

Ch 25

Ch 19

Ch 19

Ch 5

Ch 19

Ch 3

Ch 4

lb/ft2

lb/ft2

kPa

kPa

Ch 4

Ch 6

lb/ft2

in

Notation and Units of Measurement

ue

V

Va

Vc

Vn

Vnc

Vs

Vu

Vuc

Vv

v

v

W

Wf

Wr

w

wL

wP

ws

Y50

y

yt

ZM

z

z

zf

zi

zw

a

a

a

aM

aP

aE

b

b

b

b0, b1

bz

Excess pore water pressure

Shear load

Allowable shear load capacity

Nominal shear capacity of concrete

Nominal shear load capacity

Nominal shear capacity on critical surface

Nominal shear capacity of reinforcing steel

Factored shear load

Factored shear load on critical surface

Volume of voids

Pile hammer impact velocity

Velocity of pile or pile segment

Wind load

Weight of foundation

Hammer ram weight

Moisture content

Liquid limit

Plastic limit

Shrinkage limit

Lateral deflection required to achieve one-half

of the ultimate soil resistance

Lateral deflection

Lateral deflection at top of foundation

DMT gage zero offset pressure

Depth below ground surface

Settlement

Depth below bottom of foundation

Depth of the midpoint of the socket

Depth below the groundwater table

Wetting coefficient

Adhesion factor

Slope of footing bottom

Constrained modulus coefficient for CPT

Load sharing ratio

Joint modification factor

Modulus to shear strength ratio

Normalized modulus

Side friction factor in b method

Correlation factors for modulus based on SPT

Footing shape and rigidity factor

xxi

lb/ft2

k

k

lb

k

lb

lb

k

lb

m2

in/s

ft/s

Varies

lb

lb

percent

Unitless

Unitless

Unitless

in

kPa

kN

kN

kN

kN

kN

kN

kN

kN

ft2

m/s

m/s

Varies

kN

kN

percent

Unitless

Unitless

Unitless

mm

Ch 3

Ch 5

Ch 7

Ch 10

Ch 7

Ch 10

Ch 10

Ch 5

Ch 10

Ch 3

Ch 19

Ch 19

Ch 5

Ch 6

Ch 19

Ch 3

Ch 3

Ch 3

Ch 3

Ch 22

in

in

lb/in2

ft

in

ft

ft

ft

Unitless

Unitless

deg

Unitless

Unitless

Unitless

Unitless

Unitless

Unitless

Unitless

Unitless

mm

mm

kPa

m

mm

m

m

m

Unitless

Unitless

deg

Unitless

Unitless

Unitless

Unitless

Unitless

Unitless

Unitless

Unitless

Ch 22

Ch 22

Ch 4

Ch 3

Ch 20

Ch 3

Ch 25

Ch 3

Ch 27

Ch 15

Ch 7

Ch 4

Ch 24

Ch 25

Ch 4

Ch 8

Ch 15

Ch 4

Ch 25

xxii

Notation and Units of Measurement

g

g

g′

g′

gb

gc

gd

gw

∆sz

d

da

dc

dD

dDa

dd

de

ds

ds

dt

dt

dtoe

dw

dz

e

e50

ea

ec

ef

er

et

ew

ez

h

h

ua

l

l

Unit weight

Load factor

Buoyant unit weight

Effective unit weight

Buoyant unit weight

Unit weight of concrete

Dry unit weight

Unit weight of water

Change in vertical stress

Total settlement

Allowable total settlement

Consolidation settlement

Differential settlement

Allowable differential settlement

Distortion settlement

Settlement due to elastic compression

Secondary compression settlement

Settlement due to mobilization of side friction

Settlement due to mobilization of toe bearing

Vertical displacement required to mobilize

the full side friction resistance, assumed to be

25 mm (1 in)

Displacement at pile toe

Heave or settlement due to wetting

Displacement at a point on the pile

Normal strain

Axial strain at which 50 percent of the soil

strength is mobilized

Axial strain

Hydrocollapse strain

Strain at failure

Radial strain

Tensile strain in reinforcement

Potential swell strain

Vertical strain

Factor in Shields chart

Group efficiency factor

Allowable angular distortion

Factor in Shields chart

Lightweight concrete factor

Ch 3

Ch 5

Ch 2

Ch 7

Ch 3

Ch 6

Ch 3

Ch 3

lb/ft3

Unitless

lb/ft3

lb/ft3

lb/ft3

lb/ft3

lb/ft3

lb/ft3

lb/ft2

in

in

in

in

in

in

in

in

in

in

in

kN/m3

Unitless

kN/m3

kN/m3

kN/m3

kN/m3

kN/m3

kN/m3

kPa

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

Ch 3

Ch 3

Ch 5

Ch 3

Ch 5

Ch 5

Ch 3

Ch 20

Ch 3

Ch 20

Ch 20

Ch 25

in

in

in

Unitless

Unitless

mm

mm

mm

Unitless

Unitless

Ch 20

Ch 27

Ch 20

Ch 3

Ch 22

Unitless

Unitless

Unitless

Unitless

Unitless

Unitless

Unitless

Unitless

Unitless

radians

Unitless

Unitless

Unitless

Unitless

Unitless

Unitless

Unitless

Unitless

Unitless

Unitless

Unitless

radians

Unitless

Unitless

Ch 4

Ch 28

Ch 4

Ch 4

Ch 10

Ch 27

Ch 3

Ch 7

Ch 15

Ch 5

Ch 7

Ch 10

Notation and Units of Measurement

l

li

m

m

n

nm

r

r

rmin

s

s

s

s′

s′1

s′3

s′c

sci

s′h

s′m

sn

sp

ss

st

sx

s′x

sz

s′z

s′z 0

szD

s′zD

s′zf

s′zp

Φ(x)

f

f′

f′adj

Vane shear correction factor

Frequency of the ith discontinuity set

Average or mean of a random variable

Coefficient of friction

Poisson’s ratio

Poisson’s ratio of rock mass

Mass density

Steel ratio

Minimum steel ratio

Total stress

Normal pressure imparted on a surface

Standard deviation

Effective stress

Major effective principal stress at failure

Minor effective principal stress at failure

Preconsolidation stress

Uniaxial compressive strength of the intact rock

Horizontal stress

Preconsolidation margin

Fluid pressure exerted by the concrete in

socket during placement

Representative passive pressure

Swell pressure

Threshold collapse stress

Horizontal total stress

Horizontal effective stress

Vertical total stress

Vertical effective stress

Initial vertical effective stress

Vertical total stress at depth D below the

ground surface

Vertical effective stress at depth D below the

ground surface

Final effective stress

Initial vertical effective stress at depth of peak

strain influence factor

Cumulative distribution function for the standard normal distribution

Resistance factor

Effective friction angle

Adjusted effective friction angle

xxiii

Unitless

ft-1

Unitless

Unitless

Unitless

Unitless

lb m/ft3

Unitless

Unitless

lb/ft2

lb/ft2

Unitless

lb/ft2

lb/ft2

lb/ft2

lb/ft2

k/in2

lb/ft2

lb/ft2

lb/ft2

Unitless

m-1

Unitless

Unitless

Unitless

Unitless

kg/m3

Unitless

Unitless

kPa

kPa

Unitless

kPa

kPa

kPa

kPa

MPa

kPa

kPa

kPa

Ch 4

Ch 25

Ch 2

Ch 7

Ch 4

Ch 25

Ch 19

Ch 10

Ch 10

Ch 3

Ch 3

Ch 2

Ch 3

Ch 25

Ch 25

Ch 3

Ch 25

Ch 25

Ch 3

Ch 25

lb/ft2

lb/ft2

lb/ft2

lb/ft2

lb/ft2

lb/ft2

lb/ft2

lb/ft2

lb/ft2

kPa

kPa

kPa

kPa

kPa

kPa

kPa

kPa

kPa

Ch 3

Ch 27

Ch 28

Ch 3

Ch 3

Ch 3

Ch 3

Ch 3

Ch 7

lb/ft2

kPa

Ch 7

lb/ft2

lb/ft2

kPa

kPa

Ch 3

Ch 8

Unitless

Unitless

Ch 2

Unitless

deg

deg

Unitless

deg

deg

Ch 5

Ch 3

Ch 7

xxiv

Notation and Units of Measurement

ff

f rc

fT

c

ce

cs

ct

Ω

v

Soil-foundation interface friction angle

Socket wall interface friction angle, assumed

to be 30 degrees

Total friction angle

Factor in Shields chart

Coating factor for computing development

length

Reinforcement size factor for computing

development length

Location factor for computing development

length

Probability or sample space

Tilt of a structure

deg

deg

deg

deg

Ch 15

Ch 25

deg

Unitless

Unitless

deg

Unitless

Unitless

Ch 3

Ch 7

Ch 10

Unitless

Unitless

Ch 10

Unitless

Unitless

Ch 10

NA

NA

Ch 2

Unitless

Unitless

Ch 5

Part A

General Principles

1

Foundations

The foundations are properly called the basis of the fabrick, viz. that part

of it under ground which sustains the whole edifice above; and therefore of all the errors that can be committed in building, those made in

the foundation are most pernicious, because they at once occasion the

ruin of the whole fabrick, nor can they be rectified without the utmost

difficulty.

Venetian architect Andrea Palladio (1508–1580)

as translated by Isaac Ware, 1738

Builders have long recognized the importance of a solid foundation, and that the integrity of a structure can be no greater than that of its foundation. If a foundation fails,

the overlying structure fails with it. These truths were especially evident in Palladio’s

renaissance Venice, where heavy masonry structures were being built on small islands

in a lagoon underlain by very soft soils. In addition, as Palladio observed, defects in

the foundation are very difficult to repair after the structure has been built. Thus, welldesigned and well-constructed foundations continue to be an essential part of successful

construction.

However, foundations can also be very expensive, so over-designed foundations are

needlessly wasteful and inefficient. Our goal is to provide sturdy foundations that properly support the superstructure, while avoiding costly over-design. The methods of doing

so form the subject of this book.

3

4

1.1

Chapter 1

Foundations

FOUNDATION CLASSIFICATION

Foundations are structural elements that transfer loads from the superstructure to the underlying soil or rock. A structure may be supported on a system of individual foundations, or

on a single large foundation. Engineers classify foundations into two broad categories:

shallow foundations and deep foundations, as shown in Figure 1.1.

Shallow foundations transmit the structural loads to the soils immediately beneath the

foundation, and are discussed in Chapters 6 to 11. The most common type is a spread footing,

which spreads the applied load over a sufficiently large area to maintain soil stresses within

tolerable limits. Spread footings are easy and inexpensive to build, and are most often used

to support small to medium size structures on sites with good soil conditions. Typically, each

column has its own spread footing, although sometimes multiple closely-spaced columns are

supported on a single footing. Thus, a building might have dozens of individual footings.

The second type of shallow foundation is a mat foundation (also called a raft foundation), which normally encompasses the entire footprint of the structure. Mats have the

advantage of providing structural continuity and rigidity, as well as spreading the load

over a larger area.

Conversely, deep foundations transmit much, or all, of the applied load to deeper

soils, and are discussed in Chapters 12 to 24. Piles are long slender structural members

that can be either prefabricated and driven into the ground, or cast in place. Caissons

are large prefabricated boxes that are sunk into place and filled with concrete to form a

foundation. The load-carrying capacity of soils generally increases with depth, and deep

foundations engage a larger volume of soil, so they are most often used on larger and

heavier structures, especially when the shallow soils are poor.

The terminology used to describe and classify foundations is sometimes inconsistent.

Different terms are sometimes used to describe the same thing, and the same term is sometimes used to describe different things. Even the term “foundation” is sometimes used to

describe the underlying soil or rock rather than a structural element. This book uses terminology that reflects common practice, and alternative terms are included in context.

Foundations

Shallow

Foundations

Spread Footings

Chaps 6–10

Driven Piles

Chap 15

Deep

Foundations

Chap 12

Mats

Chap 11

Drilled Shafts

Chap 16

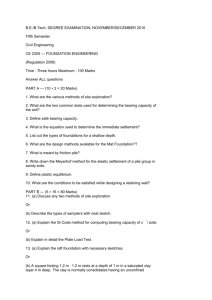

Figure 1.1

Piles

Chaps 13 –14, 19 –23

Auger Piles

Chap 17

Caissons

Other Types

Chap 18

Classification of foundations.

Pile Supported

and Pile Enhanced

Mats Chap 24

1.2

The Emergence of Modern Foundation Engineering

1.2

THE EMERGENCE OF MODERN FOUNDATION ENGINEERING

5

The history of foundations extends for thousands of years, and impressive projects were

built hundreds or even thousands of years ago. For example, 4,000 to 5,000 years ago the

alpine lake dwellers in Europe used timber piles to support their houses. Also, in the year

55 BCE, Julius Caesar built a pile-supported bridge across the Rhine River to facilitate his

conquest of Gaul. In Shanghai, the 40 m tall Longhua Pagoda was constructed on soft clay

in 977 CE using a foundation of bricks laid on a wooden raft supported by closely-spaced

wooden piles, a design very similar to today’s pile-supported mat, and has stood firm for

over 1,000 years while some newer buildings nearby have been badly damaged by excessive settlement (Kerisel, 1987).

Early foundation designs were based on precedent, intuition, and common sense.

Through trial-and-error, builders developed rules for selecting, sizing, and constructing

foundations. For example, even as late as the nineteenth century, the width of spread footings supporting masonry walls in New York City was set at 1.5 times the width of the

wall when founded on compact gravel, and 3.0 times the width of the wall when founded

on sand or stiff clay (Powell, 1884).

These empirical rules, combined with good judgment, usually produced acceptable results as long as they were applied to structures and soil conditions similar to those

encountered in the past. However, the results were sometimes disastrous when builders

extrapolated the rules to new conditions. This problem became especially troublesome

when new building materials and methods of construction began to appear during the last

quarter of the nineteenth century. The introduction of steel and reinforced concrete led

to a gradual transition away from rigid masonry structures supported primarily on bearing walls to more flexible frame structures that used columns. These new materials also

permitted structures to be taller and heavier than before. In addition, as good sites became

increasingly scarce, builders were forced to consider sites with poorer soil conditions,

which made foundation design and construction much more difficult. Thus, the old rules

for foundation design no longer applied.

The introduction of these new building materials led to more rational design methods,

the beginning of what we now call structural engineering, and this rational approach naturally extended to the foundations. Geotechnical engineering, which began in earnest during

the 1920s, further added to our understanding of foundations and the mechanical processes

of transferring loads into the ground. Thus, instead of simply developing new empirical

rules, engineers began to investigate the behavior of foundations and develop more rational methods of design, establishing the discipline of foundation engineering. This transition

began in the late nineteenth century, rapidly progressed through the twentieth century, and

continues in the twenty-first century.

These advances in analysis and design were accompanied by tremendous improvements in construction methods and equipment. For example, modern pile driving hammers enable construction of huge high-capacity piles that far exceed the capabilities of

timber piles driven by falling weights. These advances have enabled building at sites

where foundation construction had previously been impossible or impractical.

6

Chapter 1

Foundations

It is now possible to build reliable, cost-effective, high-capacity foundations for a

wide range of modern structures, even on very difficult sites. Advances in design and

construction continue to be developed in the twenty-first century, so future engineers will

probably have even greater capabilities. Nevertheless, precedent, empiricism, common

sense, and engineering judgment are still important, and continue to have a role in modern

foundation engineering.

The Eiffel Tower

The Eiffel Tower, Figure 1.2, is an excellent example of a new type of structure in which

the old rules for foundations no longer applied. It was built for the Paris Universal Exposition of 1889 and was the tallest structure in the world. Alexandre Gustave Eiffel, the

designer and builder, was very conscious of the need for adequate foundations, and clearly

did not want to create another Leaning Tower of Pisa (Kerisel, 1987).

The Eiffel Tower is adjacent to the Seine River, and is underlain by difficult soil

conditions, including uncompacted fill and soft alluvial soils. Piers for the nearby Pont

de l'Alma (Alma bridge), which were founded in this alluvium, had already settled nearly

1 m. The tower could not tolerate such settlements.

Figure 1.2 Two legs of the Eiffel Tower are

underlain by softer soils, and thus could have

settled more than the other two. Fortunately,

Eiffel carefully explored the soil’s conditions,

recognized this potential problem, and designed

the foundations to accommodate these soil conditions. His foresight and diligence resulted in

a well-designed foundation system that has not

settled excessively (Courtesy by Shutterstock).

1.2

The Emergence of Modern Foundation Engineering

7

Eiffel began exploring the subsurface conditions using the crude drilling equipment

of the time, but was not satisfied with the results. He wrote: “What conclusions could one

reasonably base on the examination of a few cubic decimeters of excavated soil, more

often than not diluted by water, and brought to the surface by the scoop?” (Kerisel, 1987).

Therefore, he devised a new means of exploring the soils, which consisted of driving a

200 mm diameter pipe filled with compressed air. The air kept groundwater from entering

the tube, and thus permitted recovery of higher quality samples.

Eiffel’s studies revealed that the two legs of the tower closest to the Seine were

underlain by deeper and softer alluvium, and were immediately adjacent to an old river

channel that had filled with soft silt. The foundation design had to accommodate these

soil conditions, or else the two legs on the softer soils would settle more than the other

two, causing the tower to tilt toward the river.

Based on his study of the soil conditions, Eiffel placed the foundations for the

two legs furthest from the river on the shallow but firm alluvial soils. The bottoms of

these foundations were above the groundwater table, so their construction proceeded

easily. However, he made the foundations for the other two legs much deeper so they

too were founded on firm soils. This required excavating about 12 m below the ground

surface (6 m below the groundwater table). As a result of Eiffel’s diligence, the foundations have safely supported the tower for more than a century, and have not experienced excessive differential settlements.

Chicago

The advancement of foundation engineering in Chicago also illustrates many of the worldwide changes in practice that occurred during the late nineteenth and early twentieth centuries (Peck, 1999). Rapid population growth and other factors drove a sustained construction

boom that, in many ways, made the city a laboratory for new design and construction methods. Chicago is particularly interesting from a geotechnical perspective, because the city is

underlain by saturated clay to a depth of about 100 ft. This is a stark contrast to New York

City, where competent bedrock is often easily within reach and provides adequate bearing

for the large buildings in most of Manhattan.

During the early part of this period, virtually all buildings in Chicago were comparatively small and supported on spread footings. This foundation type continued to be used

as the size and weight of buildings increased. A significant advance came in 1873 when

Frederick Baumann, a Chicago architect, published the pamphlet The Art of Preparing

Foundations, with Particular Illustration of the “Method of Isolated Piers” as Followed

in Chicago (Baumann, 1873). He appears to be the first to explicitly recommend that the

base area of a footing should be proportional to the applied load, and that the loads should

act concentrically upon the footing. He also gave allowable bearing pressures for Chicago

soils and specified tolerable limits for total and differential settlements.

As buildings became increasingly larger and heavier, foundation settlement became

increasingly problematic. The auditorium building, constructed between 1887 and 1889

on spread footings, is one of the most noteworthy examples. Most of the building had a

height of 10 stories, but part of it consisted of a 19-story tower, as shown in Figure 1.3.

8

Chapter 1

Foundations

Figure 1.3 The auditorium building in Chicago experienced 28 in of settlement, but is still in service more

than a century after its completion. This structure helped usher in new foundation designs that are less susceptible to settlement.

Although designed according to the state of the art at the time, the tower portion ultimately settled 28 in, with significant differential settlements between the tower and the

less heavily loaded areas.

It became clear that spread footings were not adequate for larger buildings, even

when designed according to Baumann’s guidelines. Driven piles were then used on some

buildings, but a new method, the Chicago caisson,1 was introduced in 1892 by William

1

In this case, the term “caisson” is being used to describe a foundation that we would classify as a cast-in-place

pile. This is quite different from our usage of the term, which describes a method that uses large prefabricated

boxes that are sunk into place and filled with concrete.

1.3

The Foundation Engineer

9

Sooy-Smith, a former civil war general turned foundation engineer. This method consisted

of hand-excavating a cylindrical hole about 1 m in diameter down to harder bearing stratum, then filling the hole with cast-in-place concrete. Local engineers developed methods

of designing and building these caissons, which solved the excessive settlement problem

and soon became the foundation of choice. Modern high-rise buildings in Chicago, such as

the Willis Tower (formerly known as the Sears Tower), still use drilled shafts, which are

modern machine-dug versions of the Chicago caisson.

San Francisco–Oakland Bay Bridge

The original San Francisco–Oakland Bay Bridge, constructed between 1933 and 1936,

required innovative foundations because of the poor soils conditions and deep water (Husband, 1936). For example, the foundation for one of the piers on the west span extends

through an unprecedented 21 m (70 ft) of water, then 43 m (140 ft) of soil (much of it

soft clay) to bedrock. This was far too deep for pneumatic caissons, which were the standard method of the day, so legendary foundation engineer Daniel Moran (1864–1937) was

retained to help develop new technologies for building these foundations.

Based on Moran’s work, several of the piers on both spans were constructed using

a new type of massive caisson constructed of concrete and steel in a nearby shipyard.

Initially airtight, the caisson was floated to the site, then accurately positioned in place

on the bay floor by slowly filling its chambers with water. The underlying soil was then

progressively excavated through the chambers using clamshell buckets until reaching

the required depth. The caisson was then filled with concrete. In contrast, portions of the

bridge near the Oakland shore were in much shallower water and had much shorter spans,

so the piers were supported on groups of driven timber piles.

The eastern span was subsequently replaced with a new bridge, which was completed

in 2013. Advances in heavy marine driven pile technology over the intervening 80 years,

much of which was developed for offshore drilling platforms, resulted in a completely different foundation system. The new bridge is supported on 1.8 to 2.5 m (6–8 ft) diameter

steel pipe piles driven with an exceptionally large hydraulic pile hammer to depths of 60 to

100 m (200–330 ft) (Saba et al., 2004). A total of 160 piles were used on the entire project.

1.3

THE FOUNDATION ENGINEER

Foundation engineering does not fit completely within any of the traditional civil engineering subdisciplines. Instead, the foundation engineer must be multidisciplinary and possess

a working knowledge in each of the following areas:

• Structural engineering—A foundation is a structural member that must be capable

of transmitting the applied loads, so we must also understand the principles and

practices of structural engineering. In addition, the foundation supports a structure,

so we must understand the sources and nature of structural loads and the structure’s

tolerance of foundation movements.

10

Chapter 1

Foundations

• Geotechnical engineering—All foundations interact with the ground, so the design

must reflect the engineering properties and behavior of the adjacent soil and rock.

Thus, the foundation engineer must understand geotechnical engineering. Most

foundation engineers also consider themselves to be geotechnical engineers.

• Construction engineering—Finally, foundations must be built. Although the

actual construction is performed by contractors and construction engineers, it is

very important for the design engineer to have a thorough understanding of construction methods and equipment to develop a design that can be economically

built. This knowledge also provides essential background when solving problems

that develop during construction.

This book focuses primarily on the design of foundations, and thus emphasizes the

geotechnical and structural engineering aspects. Discussions of construction methods and

equipment are generally limited to those aspects that are most important to design engineers. Other important aspects of foundation construction which are primarily of interest

to contractors are beyond the scope of this book.

1.4

CODES, STANDARDS, AND TECHNICAL LITERATURE

Foundation design and construction is subject to the provisions of various codes, which

define the methods for computing applied loads, the load-carrying capacity of various

structural materials, performance requirements, detailing requirements, and other aspects.

Some of these provisions are similar to those that apply to other structural members, while

others are unique to foundations. Most codes have a separate chapter specifically addressing foundations.

Codes are legally binding, and thus must be followed. The two most commonly

used codes in the United States are:

• The International Building Code (IBC), which governs the design of most buildings

(ICC, 2012). This code replaced the American model building codes (the Uniform

Building Code, the National Building Code, and the Standard Building Code) as well

as many local codes. The IBC has legal authority only when adopted by a state, city,

or other regulatory authority, and these authorities sometimes include modifications.

For example, building construction in California is governed by the California Building Code, which is a modified version of the IBC. Although the IBC and its variants

is by far the most commonly used building code in the United States, some parts of

the country use different codes. For example, the City of Chicago has its own unique

building code.

• AASHTO LRFD Bridge Design Specifications (AASHTO, 2012) governs the

design of highway structures. The American Association of State Highway and

Transportation Officials is a consortium of the various state departments of transportation (DOTs), and thus has substantial influence on state DOT construction

projects, as well as those for local governments. These state and local agencies

1.4

Codes, Standards, and Technical Literature

11

sometimes modify the AASHTO specifications and add additional requirements.

For example, the Washington State Department of Transportation specifies a particular type of concrete be used in all drilled shaft foundations.

Other widely-used codes include:

• Eurocode, which is used in the European Union, typically with country-specific

modifications. Eurocode 7 addresses geotechnical design, including foundations.

• The National Building Code of Canada (NBC)

• The National Building Code of India

A number of standards also impact the design and construction of foundations.

Unlike codes, standards do not have the force of law (except when explicitly referenced

or adopted in a code). However, they have a very significant impact on practice. Applicable standards widely used in North America include:

• The AREMA Manual for Railway Engineering, published by the American Railway

Engineering and Maintenance of Way Association. It governs the design of railroad

structures in the United States and Canada.

• Various standards published by the American Petroleum Institute (API) which

govern facilities used to produce petrochemical products. The most notable of

these from a foundation engineering perspective are offshore drilling platforms

(API, 2000).

• Minimum Design Loads for Buildings and Other Structures, ASCE/SEI Standard

7-10, published by the American Society of Civil Engineers.

• Building Code Requirements for Structural Concrete (ACI 318-11), published by

the American Concrete Institute (ACI, 2011).

• Steel Construction Manual, published by the American Institute of Steel Construction (AISC, 2011).

• Various standards published by the American Society for Materials and Testing

(ASTM). These standards typically address test procedures and construction material specifications.

Detailed discussions of the requirements for all of these codes and standards are

beyond the scope of this book, and they are constantly changing. Selected provisions from

the 2012 IBC and the 2012 AASHTO codes and the ASCE 7-10 and ACI 318-11 standards are included when appropriate and other codes are occasionally referenced. These

references are included in brackets. For example, [IBC 1801.1] refers to Section 1801.1

of the IBC. However, this book is not a substitute for codes or standards, so engineers

should always refer to the current edition of the applicable publications when designing

foundations.

Building codes represent minimum design requirements. Simply meeting code