Overview

Enhancement of high temperature

strength and room temperature ductility of

iron aluminides by alloying

Aruna Bahadur

The chemical ordering in intermetallics results in reduced atomic mobility and therefore increased resistance to

plastic deformation at elevated temperatures. This intrinsic source of high temperature strength leads to the inherent

brittleness of polycrystalline ordered intermetallics at room temperature. The requirements for optimum high

temperature strength and ductility at ambient temperature are often incompatible. Iron aluminides possess high

strength up to 873 K. There is an anomalous (positive) temperature dependence of yield and ow strengths. Iron

aluminides have yet to achieve satisfactory elevated load bearing capability. Alloy additions have the potential for

improving elevated temperature strength and room temperature ductility; whichever is more critical for the

application. Elements such as Cr, Ti, Mn, Co, and Mo produce higher ow stress due to solid solution strengthening.

Elements such as Zr, Ta, Nb, Re, and Hf go into solution partly, reprecipitate, effectively pin dislocations and

thereby cause strengthening. Mo, Zr, and Hf produce good tensile strength at elevated temperatures but ductility

decreases. Element B strengthens by grain boundary cohesion. The improvement in room temperature ductility can

be achieved through modi cation of the crystal structure by changes in stoichiometry, macroalloying, microalloying,

and control of the environment. B, TiB2, and Cr are notable for enhancing ductility. The paper is an overview of the

present status of iron aluminides in this respect.

MST/5682

The author is in the National Metallurgical Laboratory, Jamshedpur 831007, India (aruna@nmlindia.org).Manuscript received

29 October 2002; accepted 14 April 2003.

# 2003 IoM Communications Ltd. Published by Maney for the Institute of Materials, Minerals and Mining.

Introduction

Increasing demand for inexpensive materials with high

strength and low density for elevated temperature applications in highly corrosive environments has stimulated

interest in the development of iron aluminides (Fe – Al).

Ordered intermetallics possess a stronger bonding between

dissimilar atoms and a strong tendency for chemical

ordering, resulting in reduced atomic mobility and therefore, increased resistance to plastic deformation at elevated

temperatures. The principal effects of ordering on mechanical properties arise from the changes in dislocation

con guration due to the added constraints that ordering

places on the nucleation and the motion of dislocations.

This intrinsic source of high temperature strength leads to

the inherent brittleness of polycrystalline ordered intermetallics at room temperature. Both strength and ductility

are important for structural applications, however, the

requirements for optimum strength at elevated temperatures during operation and optimum ductility at ambient

temperature during fabrication and handling are often

incompatible and a compromise has to be arrived at.

Mechanical properties of Fe – Al

A large number of ordered intermetallics are shown to

exhibit anomalous increase in yield strength at temperatures

around half the homologous melting point,1 but Fe – Al was

not believed to be one of them. Recent studies have shown

that Fe – Al alloys do exhibit anomalous strengthening and

a yield strength peak at around 0.45 of melting temperature.2 High quenched in thermal vacancy concentration at

low temperatures as well as ne grain microstructure raises

the low temperature strength and obscured the yield

strength peak earlier. Good mechanical properties can thus

DOI 10.1179/026708303225008266

be maintained even up to about 0.7Tm in these materials,

which makes them attractive for high temperature applications. Iron aluminides are reportedly superior in strength to

316 stainless steels and modi ed 9Cr – 1Mo steels up to

873 K. The strengths of all three drop rapidly above this

temperature (Fig. 1).3 The peak in the yield and ow

strengths for Fe 3 Al alloys (Fig. 2)4 depends upon the

critical temperature Tc for the DO3 dB2 transition. The

temperature– strength anomalous behaviour of Fe3 Al in

the DO3 region is associated with the degree of ordering.

The strength peak is observed at some intermediate degree

of DO3 below DO3 „B2 transformation temperature. A

simplistic hypothesis to explain the anomaly is that the

increase in YS on heating DO3 alloy occurs because of age

hardening due to a precipitation as well as B2 formation.

The rapid decrease in YS above Tc is considered to be due to

overaging of this structure.5

The rst type of model to explain the yield strength

anomaly (YSA) involves dislocation locking. For Fe 3 Al,

only unit dislocations with associated anti phase boundary

(APB) trails are observed for Al less than 25% with DO3

order. The spacing r between dislocation pairs comprising

superlattice dislocations is inversely proportional to the

square of long range parameter L. Between 673 K and Tc ,

L decreases from 0.8 to 0.6 At low temperatures, L is high;

unit dislocations tend to associate in pairs. Their motion

does not create APBs and hence strength decreases. At

low values of L, r is large and energy of connecting

APBs is small, allowing constituent dislocations to glide

independently, leaving APB trails, creating wrong bonds,

and hardening the alloy. At T greater than Tc , L~0,

strengthening is due to short range order and is less marked

compared to the strength in the presence of long range

order. The strength is the maximum at intermediate values

of L where superlattice dislocations # 111$ can dissociate

into constituent # 001$ z# 110$ unit dislocations.7 ,8 The

dislocations multiplication is balanced by a strong exhaustion resulting from thermally activated locking.9 ,1 0 For a

Materials Science and Technology

December 2003 Vol. 19 1627

1628 Bahadur Enhancement of high temperature strength and room temperature ductility of iron aluminides

3 Comparison of temperature dependence of yield stress

of large grained low temperature annealed FeAl alloys

near stoichiometry, strained at 1610 4 s 1 (Ref. 12)

1 a Yield strength and b ductility of various Fe3 Al type

alloys (courtesy C. G. McKamey, Oak Ridge National

Laboratory3 )

Fe – 40Al (all compositions in this paper are in at.-%), the

change in deformation mode by # 111$ slip at low

temperature and # 100$ slip at higher temperatures appears

to be responsible for the peak in YS.8 ,1 1 The dislocations are

much less mobile at {100} planes. The reduction of YS at

very high temperatures occurs because of enriched dislocation mobility on {100} planes, which reduces and nally

eliminates the pinning centres formed at lower temperatures. By adding elements which increase Tc , i.e. cause

stability of DO3 structure relative to B2 structure, the yield

2 Variation of 0.2% yield stress with temperature for

Fe – 25Al alloy4

Materials Science and Technology

December 2003 Vol. 19

strength peak can be pushed to higher temperatures. A

small addition of B (100 at. ppm) reportedly shifts the yield

strength peak 200°C and 175 MPa higher compared to the

B free alloy.1 0 The prominence in the yield strength peak

decreases as aluminium concentration increases (Fig. 3).1 2

No peak was observed in stoichiometric FeAl. 1 2 However,

this transition of type of dislocations alone cannot explain

the peak in yield strength since the temperature of the peak

stress appears to be approximately independent of composition, whereas the temperature of the slip transition

depends strongly on composition. Also, a mechanism is

needed whereby # 111$ slip becomes increasingly dif cult

with increasing temperature in order to produce a yield

stress peak. The proposed decomposition of # 111$

dislocations locally into # 001$ and # 110$ segments,

which then act as primary centres against # 111$ slip was

not observed in a boron doped Fe – 45Al, which exhibited

anomalous yield behaviour.1 3

The second model to explain YSA does not depend upon

the change of slip vector. The concentration of thermal

vacancies in intermetallic compounds with bcc derived

ordered structures is generally high. It was suggested to be

on the basis of interaction between dislocations and thermal

vacancies.1 4 – 1 6 Since the vacancy concentration Cv varies as

exponential (21/T) and the hardening due to vacancies

varies as (Cv )1 /2 (Fig. 4),1 7 this model predicts an exponential increase in strength at intermediate temperatures

with increase in temperature. Accordingly, solid solution

4 Relationship between microhardness and square root

of vacancy concentration in FeAl17

Bahadur Enhancement of high temperature strength and room temperature ductility of iron aluminides 1629

5 Schematic diagram showing subdivision of yield stress15

hardening by thermal vacancies describes the anomalous

yielding behaviour for FeAl quite well. It was suggested that

at temperatures immediately below yield stress peak, region

III in Fig. 5,1 5 thermal vacancies are essentially immobile

and impede dislocation motion. However, at temperatures

above the peak, region IV in Fig. 5, and the vacancies are

suf ciently mobile to migrate and assist climb, instead of

impeding dislocations so that deformation occurs by dislocation creep. This vacancy hardening model is supported

by many experimental observations and it predicts new

effects. Nevertheless, it has not been possible so far to

explain the orientation dependence of the yield peak in

single crystals. Also, the tension/compression asymmetry of

the yield stress cannot be explained yet.

Iron aluminides have yet to achieve satisfactory elevated

temperature load bearing capability for use in structural

applications. Room temperature ductility of polycrystalline

iron aluminides decreases rapidly with the onset of ordering.

A sharply reduced ductility is reported at 477 K as the

Al content approaches 25%.1 8 Alloys made conventionally

by the ingot route containing 25 – 50%Al are usually

very brittle at room temperature (RT). The low ductility

is however restricted to lower temperatures only. The

challenge lies in developing materials with the strength of

ceramics and the plasticity of metals.

Why inadequate mechanical properties?

The ow behaviour consists of extensive cross slip of # 111$

dislocations and there are more than ve independent slip

systems present in Fe3 Al, yet it fails by brittle cleavage

fracture. B2 alloy fails predominantly by intergranular

fracture (IG) at ambient temperatures. Therefore, both

grain boundaries as well as crystalline planes are the

potential sites for brittle fracture in Fe – Al. The brittleness

in these alloys may be due to the following.

1. Having ve independent slip systems is a necessary,

but not suf cient condition for good ductility. All slip

systems should be operative simultaneously for dislocations

to pass through, otherwise dislocations move in a grain, pile

on the grain boundary building up pressure on both sides.

Grain boundaries decohesion takes place. Some grain boundaries are less stable than others due to wrong neighbour

considerations. Fe3 Al gives straight slip lines on plastic

deformation, therefore, either, cross slip is impeded or only

one type of slip system prevails during deformation.

2. Large grain size: the tendency for both transgranular

(TG) and cleavage fracture of highly alloyed ferritic alloys is

inversely proportional to the square root of the grain size.

3. Intrinsic weak grain boundaries leading to IG fracture

or because the disorder associated with the grain boundaries

leads to intrinsic poor cohesion.

4. Detrimental grain boundary segregation such as S is

responsible for extrinsic grain boundary brittleness.1 9

5. Environment effects: it has been established that Fe –

Al alloys are not inherently brittle, but extrinsic effects like

environment may be the reason for poor RT ductility.

Fe – Al exhibits a peak in susceptibility to hydrogen at

ambient temperatures, which diminishes to negligible levels

at temperatures more than 100 K above or below the

ambient.2 0 This may be due to the concentration of atomic

hydrogen at critical trap sites such as grain boundaries or

dislocations. Low temperatures limit diffusion rates and at

high temperatures, trap occupation decreases rapidly. Other

studies demonstrated that the embrittlement is due to the

chemical reaction of water vapours (not dry hydrogen) at

the metal surface (e.g. crack tip), resulting in atomic

hydrogen. It enhances dislocation mobility at crack tips,

reduces cohesive strength and causes crack propagation.2 1

The susceptibility to hydrogen embrittlement is enhanced

by atomic ordering, since transport of hydrogen by moving

dislocations can be effectively accompanied by planar slip in

ordered states.2 2 A threefold increase in percentage elongation is reported in Fe3 Al in vacuum or oxygen atmosphere.2 3 Even Fe3 Al alloys heat treated to the DO3 state are

found to be more susceptible to environmental embrittlement than those in the B2 state.2 4 This effect may be

correlated to the different superlattice dislocations exhibited

by these structures or the differences that may exist in

surface chemistry, which may alter the rate of water

dissociation.2 5 As the amount of Al increases, the susceptibility to hydrogen embrittlement increases. Alloys with Al

greater than or equal to 40% fail intergranularly and exhibit

low percentage elongation, irrespective of test environment.

RT embrittlement through the formation of hydrogen

leads to ductility being strain rate dependent because of

several time dependent steps in the embrittlement process.2 6

The ductility in air increases sharply with increase in strain

rates. At the highest strain rates of 6.66102 1 s2 1 , ductility

of Fe – 40Al tested in air, vacuum, and oxygen were found

to be the same,2 7 thus eliminating the effect of environmental embrittlement at this strain rate.

6. Excess thermal vacancies: the mechanical properties

of iron rich iron aluminides are strongly affected by the

presence of thermal vacancies which may be retained in the

lattice following heat treatment. Most studies earlier were

conducted on materials that were not given a heat treatment

to remove excess thermal vacancies before testing. The

comparison of data of different workers is therefore

dif cult. Signi cant increase in hardness can be attained

in specimens by quenching or air cooling from temperatures

greater than 1000 K to achieve a supersaturation of thermal

vacancies.2 8 – 3 0 Prolonged anneals at low temperatures

:673 K to remove excess thermal vacancies lead to

softening3 1 and an increase in room temperature ductility.3 2

The effect of hardening by thermal vacancies increases with

Al content. An increase in room temperature ductility is

obtained in FeAl by heat treatment to remove excess

thermal vacancies3 2 and/or cavities.3 3 Random vacancy

distribution process is proposed as an elementary defect

mechanism in B2 FeAl.3 4

Improvement in mechanical properties

An improvement in high temperature strength and RT

ductility can be obtained through alloy design. The alloy

additions may adversely affect the oxidation resistance.

However, the alloying approach is much cheaper and has

the potential for improving the strength and ductility

Materials Science and Technology

December 2003

Vol. 19

1630 Bahadur Enhancement of high temperature strength and room temperature ductility of iron aluminides

whichever is more critical for the application under

consideration as follows:

SUBSTITUTIONAL ADDITIONS

Modi cation of the crystalline structure through macroalloying (several per cent) and processing imparts better

mechanical properties. Fe 3 Al and FeAl have body centred

cubic (bcc) related structures, are inherently less desirable

than face centred cubic (fcc) related structures like L12 . The

latter structure is stabilised through control of e/a (average

number of electrons per atom outside the inert gas shell).

The ductility improves by changing to high symmetry

structures through macroalloying.

Elements that form single phase after homogenisation such as Ni, Co, Ti, Mn, Cr, and Si

Solid solution strengthening takes place, increasing the

number of easy slip systems and improving the ductility. No

signi cant increase in high temperature (1300 K) compressive ow strength with respect to the binary B2 takes place.

The strengthening effect of the ternary addition of transition metals increased with the atomic number difference

between iron and the metal. A linear relationship between

the yield strength and atomic size mis t was established.3 5

Ti addition stabilises DO3 structure and leads to a

signi cant expansion of the azDO3 phase eld. Ti

substitutes for iron and increases Tc for B2 and DO3

ordering and produces anisotropic APBs.3 6 This is bene cial as alloyed Fe – Al can be ordered at higher

temperatures saving on precious processing times, as long

ordering time for Fe 3 Al (823 K/100 h) restricts commercial

applications. The mechanical properties of bcc material are

sensitive to the presence of interstitial elements like C, N,

and O. Addition of 0.5%Ti to alloys with 0.03 – 0.05%C

forms a stable carbide. RT ductility of Fe – Al alloys

has recently been enhanced to 10% by composition modi cation (1 – 2%Ti) and microstructure control.3 7 TiB2 dispersions in Fe3 Al reduces the grain size of atomised powders

and increases ductility of recrystallised material.3 8

Cr addition higher than 2% modi es surface composition

by inducing a passive layer and reduces susceptibility to

environmental embrittlement and improves ductility. Cr

adversely affects sulphidation resistance of Fe3 Al alloys

above 2% and of Fe – 40Al alloys above 4%.3 9 Cr addition

to Fe 3 Al lowers YS slightly but increases UTS due to work

hardening.4 0 ,4 1 It changes fracture mode from cleavage to

mixed (IGzcleavage) failure, suggesting that Cr enhances

cleavage strength. Fine wavy slip lines indicate easier cross

slip. It is expected that plastic deformation by slip will be

enhanced if ordering energies (or critical temperatures)

become small and/or if the alloy is appreciably disordered.

Relative to Fe – 28Al alloy, ordering energies and B2 critical

temperatures reportedly4 2 decrease with temperature in

Fe – 28Al – 5Cr alloy. Lowered ordering energies is responsible for improving RT ductility as observed in Cr bearing

alloy. The increase in RT tensile ductility in Fe – 28Al – 4Cr

occurred irrespective of DO3 or B2 order tested in air or

vacuum as long as surface oxide coating persisted. The

bene cial effect of Cr is modi cation of protective surface

oxide due to possible enhancement of atomic bonding

between Fe and Al atoms resulting in an increase in cohesive

strength across cleavage planes. Cr addition decreases

susceptibility of alloy to moisture embrittlement. The

removal of oxide lm by electropolishing showed no

ductility improvement.

Addition of 1.5%Mn to Fe – 28Al decreased the degree of

DO3 ordering, which is associated with decrease in grain size

and antiphase domain size. Besides, Mn could promote slip

and cross slip of super dislocations in the alloy because

of occurrence of mainly twofold super dislocations. This

Materials Science and Technology

December 2003 Vol. 19

may be one of the reasons for improving ductility of DO3

Fe3 Al alloy.4 3

Mn addition (6, 12%) raises Tc and improves RT

ductility.4 4 Si (3, 5%) raises Tc improving high temperature

mechanical properties, however it reduces RT ductility

frequently.4 5

Elements which show incomplete solubility

in Fe ± Al after long homogenising anneals at

high temperature such as Zr, Hf, Nb, Ta, and Re

They go into solution partly and form precipitate which

effectively pin grain boundaries and dislocations, causing

strengthening. Flow stress is much greater than that of the

binary. Zr and Hf produces good increase in YS and UTS at

RT and elevated temperatures (300 – 1100 K) due to grain

re nement and precipitation hardening in Fe – 40Al.4 6

However, ductility decreases at all temperatures for ternary

alloys. Additional increase in strength can be obtained on B

addition due to re nement of the grain size. B addition

changes the fracture mode from IG to TG and the ductility

is restored to 5% up to 700 K. At higher temperatures,

strength and ductility decrease as diffusion assisted

mechanisms including grain boundary sliding and cavitation become operative. Nb raises Tc and improves high

temperature tensile as well as creep strengths.4 7

Elements which show no signi®cant solubility

in Fe ± Al such as Mo, W, and V

These lead to second phase strengthening, and ow stress at

1300 K increases by more than a factor of six in the case of

Mo. Additional strength can be obtained by addition of B

which re nes grain size and changes fracture mode from

inter to transgranular. The most effective elements for

increasing high temperature strength and room temperature

ductility of FeAl alloys are small additions of Mo, Zr, and B

in combination giving a synergistic effect.4 6 – 4 9 The Fe – Al

based alloys containing Cr, Nb, Mo, Zr, C, and B possess

not only an optimised combination of mechanical properties but good weldability has also been developed.5 0 Carbon

addition is effective in suppressing hot cracking and makes

Fe – Al weldable.5 0 The simple core structure of the # 100$

dislocations operative at high temperatures, suggests that

introducing strengthening phases such as carbides, nitrides

and borides for precipitation hardening is the only way to

signi cantly increase tensile and creep strengths at temperatures above 873 K.5 1

Molybdenum stabilises the DO3 structure for a greater

range of Al2 0 ,5 2 by dramatically increasing the DO3 to B2

ordering temperature Tc up to 10%.5 3 Site substitution by

solutes such as Mo, Ti, and Si leads to an increase in

ordering energies of the DO3 superlattice. In addition to

improvement in high temperature strength, Mo, W, and V

additions also improve creep resistance and thermal

stability. However, ductility decreases at RT and all

temperatures with Mo higher than 0.5%.5 4 Therefore, no

signi cant commercialisation has yet taken place.

MICROALLOYING (ppm RANGE)

Electron donors such as B strengthen atomic bonding

and increase the cohesive strength of the grain boundaries

relative to the grains.5 4 B has a strong tendency to

segregate to the grain boundaries but not to free surfaces,

thus enhancing the grain boundary cohesion and suppressing IG fracture.5 5 On addition of B to FeAl, intergranular fracture is suppressed and the composition at

which ductility drops off is shifted to higher Al levels.

However, B does not signi cantly improve ductility since

environmental embrittlement occurs trans- granularly in

FeAl5 6 unlike in Ni3 Al where it occurs intergranularly. The

bene cial effect of B in FeAl is limited to enhancement of

Bahadur Enhancement of high temperature strength and room temperature ductility of iron aluminides 1631

boundaries, in contrast to ordered fcc or LI2 compounds

like Ni3 Al, where B reduces k.6 4 Microadditions of reactive

elements bind harmful impurities such as S in innocuous

forms through precipitation.

Adjusting stoichiometry

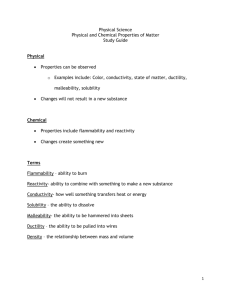

6 Strength increase per at.-% boron per unit strain, or

strength increase per fractional change in lattice parameter, as a function of at.-%Al; left and right hand

ordinates show absolute and value normalised with

respect to shear modulus, respectively57

grain boundary cohesion. Low levels of B enhance RT

ductility as well as high temperature strength.5 B addition to

FeAl shows strengthening at room temperature by increasing the lattice parameter, which induces lattice strain

(Fig. 6).5 7 The strengthening effect of B was found to

depend on both the Al concentration and the presence of

vacancies, suggesting that B interacted with the vacancies in

the material.5 8 The synergistic effect of the formation of the

boride precipitates on dislocation lines along with restriction of grain boundary sliding causes strengthening. B

improves high temperature strength, especially in combination with Nb and Zr. B in FeAl presumably partitions

between the grain boundaries and the lattice since B also

provided some solute strengthening.2 9 For FeAl, ductility

increases with decrease in grain size. Part of the difference in

ductility reported as a function of concentration is due to

the effect of grain size.5 9 The optimum B concentration

must vary with the grain size. If the B level is higher than

that needed for grain boundary cohesion, then a dislocation

structure containing stacking faults forms which results in

decrease of stacking fault energy making slip more dif cult

and increasing the matrix strength.6 0 A signi cant increase

in strength is obtained at 300 – 640 K. However, when both

the matrix as well as grain boundaries become strong, the

advantage obtained through the grain boundary strengthening alone is neutralised. For high levels of B, the rise in

YS causes fracture to occur by separation of cleavage planes

before extensive plastic deformation. B retards recrystallisation in FeAl and leads to slower grain growth, re ning the

grain size. In the presence of nitrogen, B reacts to form

boron nitride and renders B unavailable for any grain

re ning work. Ti addition takes care of nitrogen and leaves

B free for grain re ning work. When added even in

microadditions, B and Ti give rise to ne precipitates, which

restrict grain growth. B has so far not succeeded in

producing a spectacular improvement in ductility of Fe –

Al as it has done for nickel aluminides. B microaddition

leads to the best mechanical properties in stoichiometric

Ni3 Al. As the amount of Al increases, B segregation at grain

boundaries decreases. The critical amount of B is required

at grain boundaries. The optimum amount of B to Al

concentration has not yet been struck.6 1 The sensitivity of

the fracture transition by slight changes of composition is

well established. Also, B addition is known6 2 ,6 3 to increase

the Hall – Petch slope k for Fe – 40Al. This means that B

increases the dif culty of slip transmission across grain

It has been established earlier that up to 20%Al alloys

fracture in a ductile manner by void nucleation and

coalescence.1 8 Alloys containing 20 – 40%Al fail in a brittle

manner by TG mode, and higher Al alloys fracture in IG

mode. The exact composition of transition from TG to IG

fracture depends on grain size, point defect concentration,

grain boundary impurities, etc. Fe – 40Al with long duration

low temperature annealing to eliminate thermal vacancies

exhibits predominantly TG fracture.6 5 With increase in Al

concentration, intrinsic grain boundary weakness becomes

important in limiting the ductility of FeAl.

Modi cation of crystal structure can be achieved by

adjusting the stoichiometry of alloys. The deviations from

stoichiometry are accommodated either by the incorporation of vacancies in the lattice or by the location of antisite

atoms in one or either of the sublattices. Fe – Al alloys exist

over a range of compositions, but the degree of order

decreases as the deviation from stoichiometry increases.

Fe3 Al exists over the range 25 – 30%Al in the ordered DO3

structure up to 813 K, in B2 ordered structure between 813

and 1033 K, and in the disordered state above that. FeAl

exists in the B2 ordered structure up to the melting point

1520 K. As the amount of Al increases above 25%, the DO3

to B2 transition temperature decreases and the B2 ordering

temperature increases. Additional atoms may also be

incorporated in the structure without losing the ordered

structure. The changes in stiochiometry affect not only YS

but also dislocation substructure and fracture behaviour.

The strength is sensitive to the microstructure and Al

content. In Fe – Al alloys (0 – 44%Al), the maximum in yield

stress is observed near the DO3 critical temperature and the

maxima in isothermal yield stress is observed near the Fe 3 Al

composition.4 The RT yield strength drops gradually and

RT ductility increase steadily with increase of Al above 25%

Al.3 8 In tension tests in air, iron rich FeAl (å 45%Al)

exhibits ductility, whereas the stoichiometric compound is

brittle and fails before yielding. In vacuum, an approximately linear relationship was observed between elongation

and deviation from stiochiometic composition, as shown in

Fig. 7.1 2 In contrast, even stoichiometric compounds can

show considerable ductility in compression. The stoichiometric composition actually contains both ordered and

disordered phase, which may be responsible for the higher

strength. In another study,4 in the fully ordered condition at

RT, Fe – 25Al exhibited a higher YS and percentage

elongation than Fe – 31Al alloy. At 25%Al and lower, RT

plastic deformation consists of extensive movement and

cross slip of ordinary dislocations and associated nearest

neighbour (NN) and next nearest neighbour (NNN) trails.

The super stoichiometric alloy (31%Al) consists of limited

movement of imperfect variants of super dislocations with

only NNN APB trails. It was suggested that in 25%Al alloy,

the degree of order and the size of thermally produced APBs

have only a small in uence on RT tensile behaviour.4

In the author’s work,6 2 stoichiometric Fe 3 Al alloy shows

the maximum UTS. and percentage elongation at RT. The

hypo-stoichiometric Fe 3 Al alloys are found to be more

ductile than hyper-stoichiometric alloys. These alloys were

not heat treated to produce DO3 order. At RT, it is easy

to maintain B2 order. Whenever percentage elongation

increases, as in the case of stoichiometric alloys, environmental embrittlement does not take place. Therefore, UTS

also increases at RT.6 2 In B2 FeAl (34 – 50%Al), YS follows

Materials Science and Technology

December 2003

Vol. 19

1632 Bahadur Enhancement of high temperature strength and room temperature ductility of iron aluminides

7 Elongation versus aluminium concentration for low temperature annealed FeAl; material tested in air had ne

grains while that tested in vacuum had large grain size12

a Hall – Petch relationship and it is maximum at stoichiometric composition, but minimum around 45%Al.5 9 The

ductility of well annealed FeAl drops off signi cantly at Al

levels less than 37%, when tested in an ultrahigh vacuum

chamber.6 5 Therefore, FeAl becomes intrinsically brittle

when its composition approaches stoichiometric composition. Fracture mode changes from TG to IG as ductility

decreases, con rming earlier results based on tests in oxygen

that grain boundaries in FeAl become intrinsically brittle as

Al content increases. In stoichiometric FeAl, there are NN

Fe – Al bonds but no Al – Al bonds. At a grain boundary,

there will be some of these weak Al – Al bonds. Their

number will decrease as Al content decreases and hence

grain boundary cohesion may improve with decrease in Al

content, leading to an increase in RT ductility.

Early data for FeAl suggested that both hardness and

yield strength increase monotonically with Al content.

However, these data contained the effects of thermal

vacancies, which also depend on composition.6 3 In FeAl

(34 – 45%Al), it was found that the hardness and fracture

strain of FeAl do not change signi cantly over the

composition range if the material is given a long, low

temperature anneal to remove excess vacancies,6 4 but then

rise rapidly towards the stoichiometric composition.6 6 The

stoichiometric composition was found to be much stronger.6 7 The mechanical properties of B2 ordered Fe – Al

strongly depend upon the anneal temperature and/or

cooling rate. Varying either results in different concentrations of retained thermal vacancies, which are responsible

for hardening and strengthening effects. The ductility in

oxygen and air decreases with increasing annealing

temperatures. The excess vacancies affect the intrinsic

ductility of Fe – Al and not their susceptibility to environmental embrittlement.6 8 NiAl exhibits a critical grain size

below which polycrystalline aggregates are ductile in

tension. This size is expected to decrease with deviations

from stoichiometry.6 9 The grain size becomes an important

factor and needs to be re ned as we move away from

stoichiometry. All these parameters affect the measured

ductilities and lead to con icting data in the literature. The

subject of the nature and effects of lattice defects as a

function of stoichiometry needs further exploration.

CONTROL OF ENVIRONMENT

It is possible to eliminate or alleviate the effect of

environment as follows.

1. Solving the hydrogen embrittlement problem by

testing in dry oxygen alone does not ensure good ductility

in the case of Fe – 40Al, since another brittle fracture mode,

Materials Science and Technology

December 2003 Vol. 19

intergranular, intervenes before extensive plastic deformation can occur. To overcome the latter, B is added, which

segregates to grain boundaries and suppresses intergranular

fracture. When both embrittling mechanisms are overcome,

FeAl undergoes extensive plastic deformation prior to

fracture.

2. Heat treatment following forming. Retaining some

degree of B2 order by oil quenching above Tc at

973 – 1023 K results in stress relieved but unrecrystallised

microstructure. RT embrittlement is due to the entry of

hydrogen atoms along cleavage planes in loading. For

maximum strength and ductility at RT, a stress relieved but

unrecrystallised microstructure is desirable. This structure

minimises environmental effects. The mechanism could

involve texturing effects or enhancement of dislocation

mobilities due to quenched B2 order. Elongated grains

parallel to stress axis may disrupt the entry of hydrogen by

providing a minimum number of cleavage planes and a

minimum of grain boundaries.7 0 ,7 1

3. Addition of Cr. Cr presumably increases the resistance

to cleavage fracture by easing the cross slip (as shown by

wavy slip lines) and increases the cleavage strength. It

changes the fracture mode to 50% TGz50% IG, improving

the ductility. For a Fe – Al, approximately 15%Al is

required to suppress internal oxidation and overgrowth of

Al2 O3 scale by iron oxides.7 2 Cr addition to Fe – Al

decreases the critical amount of Al required to form pure

Al2 O3 layer and decrease oxidation rate of alloys with less

than 19.5%Al. Cr addition may accelerate the initial growth

of Al2 O3 , which helps in quickly establishing an external

protective oxide lm before exposure to aggressive or

deleterious environments.2 0 The bene cial effect of Cr

addition on RT ductility of Fe – Al may relate to an

oxidation effect during high temperature treatment and the

scale that forms serves as a better barrier to hydrogen

uptake at ambient conditions.

Tensile tests on Fe – 28Al – 4Cr samples show signi cant

increase in percentage elongation when tested in air or

vacuum, irrespective of the DO3 or B2 order as long as there

was a surface oxide lm. The removal of oxide showed no

improvement in percentage elongation. Moisture induced

hydrogen embrittlement can be completely eliminated by

alloying Fe – 28Al – 5Cr with 0.5%Zr and 0.05%C to

produce elongated microstructure7 3 ,7 4 or with 0.5%Zr and

0.05%B.7 5 Elongated grain structures with a high aspect

ratio substantially reduce embrittlement caused by moist

air. Hydrogen diffusivity experiments proved that hydrogen

diffusion coef cients are similar at the same temperature.

Grain shapes and sizes do not affect hydrogen diffusion in

Fe3 Al based alloy.7 1 Higher ductility of Fe 3 Al based alloy

with elongated grains in air may result from the increase of

resistance of grain boundaries to crack propagation making

such structures intrinsically more ductile.7 5

GRAIN SIZE REFINEMENT

The tendency for brittle fracture depends on the critical

grain size below which ductility is high. The stress

concentration is enhanced in coarse grains. The stress

required for crack to propagate increases with decrease in

grain size and fracture will be delayed in compounds with

ne grains below a critical size. Therefore, control of grain

size throughout casting, hot working, and heat treatment

is essential. Control of the hot rolling process to get a

re ned microstructure, giving a partially recrystallised work

hardened microstructure produces Fe – 25Al with improved

properties such as ultimate tensile strength, proof stress,

and percentage elongation.7 6 The manufacturing of cold

workable sheets of Fe – 40Al alloys through an innovative

combination of roll compaction and thermomechanical

processing is an example of progress in development

research.7 7 Such fully dense sheets have a ne grain

Bahadur Enhancement of high temperature strength and room temperature ductility of iron aluminides 1633

microstructure and tensile elongation of 5% at room

temperature and are used for manufacturing heating

elements. Ductilisation is possible through grain re nement

by rapid solidi cation. The improvement in ductility is

obtained only at compositions where a signi cant suppression of ordering and/or formation of thermal APBs occurs.

Fine grain size minimises macrosegregation, grain boundary segregation and causes reduction in homogenising

times. Rapid solidi cation is known to cause a reduction in

the degree of order as an interim step during processing. The

effect of ne grain size becomes evident when tests are

performed at high strain rates.2 6 At lower strain rates in air,

environmental effects tend to cloud grain size effects.

SINGLE CRYSTAL APPROACH

Directional solidi cation leads to formation of single or

aligned crystals. The elongated grain morphology developed is likely to impose resistance to environmental

embrittlement. The relatively small number of grain

boundaries intersecting the surfaces decreases access of

the atmosphere to the interior of the materials.7 8

PRECISE CONTROL OF DEFECT AND

IMPURITY CONTENT

Low RT ductility leads to sensitivity to defect population.

Therefore, defect ingress should be reduced and melt

cleanliness should be improved.

Conclusions

Iron aluminides were not favoured for structural applications because of their brittleness at ambient temperatures

and low strength at elevated temperatures. Recent studies

have shown that adequate engineering ductility (5 – 10%)

is obtainable through microstructure control and alloy

additions. It is now feasible to consider FeAl for commercially cast components that are currently being explored

for Fe3 Al as replacements for corrosion/heat resistant steels

or Fe – Cr – Ni alloys. The aluminides developed now are

stronger than austenitic steels and 9Cr – 1Mo steels at

ambient and elevated temperatures. Coupled with good hot

workability, very low costs, and excellent oxidation and

corrosion resistance, Fe – Al alloys are potential materials

for structural use up to 1073 K. They are especially useful in

fossil fuel red energy conversion systems. For a thermal

power plant, 813 – 873 K is a very critical temperature

region and a rise in Tc of aluminides by alloy addition

renders components useful up to higher temperatures. They

can also be used in molten salt containment and automobile

components such as exhaust or catalytic convertor components subjected to high temperature. The replacement of

strategic metals such as Co and Cr and the need to develop

energy ef cient propulsion systems will stimulate further

work. Hopefully, iron aluminides will not always remain a

material of the future.

Acknowledgement

The author wishes to thank Professor P. Ramachandra

Rao, former Director of the National Metallurgical

Laboratory for permission to publish this paper.

References

1. p. m. hazzeldine and y. q. sun: ‘High temperature ordered

intermetallic alloys VI’, (ed. J. Horton et al.), 171; 1995,

Pittsburgh, PA, Materials Research Society.

2. x. li and i. baker: Scr. Metall. Mater., 1997, 361, 387.

3. r. w. cahn: ‘Metals, materials and processes’, Vol. 1, (1), 1;

1989, Bombay, India, Meshap Science Publishers.

4. m. g. mendiratta, s. k. ehlers, d. k. chatterjee and h. a.

lipsitt: Metall. Trans. A, 1987, 18A, 283.

5. h. inouye: Mater. Res. Soc. Symp. Proc., 1985, 39, 255.

6. n. s. stoloff and r. g. davies: Acta Metall., 1964, 12, 473.

7. d. g. morris and m. a. morris: Intermettalics, 1997, 5, 245.

8. k. yoshimi, s. hanada and m. h. yoo: Acta Metall. & Mater.,

1995, 43, 4141.

9. f. louchet: Philos. Mag. A, 1995, 72A, 909.

10. o. calonne, a. fraczkiewicz and f. louchet: Scr. Mater.,

2000, 43, 69.

11. i. baker: ‘Processing, properties and applications of iron

aluminides’, (ed. J. H. Schneibel and M. A. Crimp), 287; 1994,

Warrendale, PA, TMS.

12. i. baker, h. xiao, o. klein, c. nelson and j. d. whitenberger:

Acta Metall. Mater., 1995, 43, 1723.

13. p. r. munroe and i. baker: Philos. Mag., 1995, 72, 1301.

14. r. l. carleton, e. p. george and r. h. zee: Intermettalics, 1995,

3, 433.

15. e. p. george and i. baker: Philos. Mag. A, 1998, 77A, (3), 737.

16. d. morris, c. t. liu and e. p. george: Intermetallics, 1999, 7,

1059.

17. y. a. chang, l. m. pike, c. t. liu, a. r. bilbrey and d. s. stone:

Intermetallics, 1993, 1, 107.

18. m. j. marcinkowski, m. e. taylor and f. x. kayser: J. Mater.

Sci., 1975, 10, 406.

19. r. ray, v. panchanathan and s. isserow: J. Met., 1983,

30.June

20. c. a. hippsley and m. strangwood: Mater. Sci. Technol., 1992,

8, 350.

21. j. p. tu, l. mong and m. s. liu: Scr. Metall. Mater., 1998, 38,

833.

22. c. t. liu: Proc. Int. Symp. on ‘Intermetallic compounds structure & mechanical properties’, (ed. O. Izumi), 703; 1991,

Sendai, Japan, Institute of Metals.

23. g. m. bond, i. m. robertson and h. k. birnbaum: Acta Metall.,

1989, 37, 1407.

24. a. castagna and n. s. stoloff: Scr. Metall. Mater, 1992, 26,

673.

25. x. pierron and i. baker: ‘Design fundamentals of high

temperature composites, intermetallics & metal ceramic

systems’, (ed. R.Y. Lin et al.), 271; 1995, Warrendale, PA,

TMS.

26. i. baker, o. klein, c. nelson and e. p. george: Scr. Metall.

Mater., 1994, 30, 863.

27. l. m. pike and c. t. liu: Scr. Metall. Mater., 1998, 38, 1475.

28. r. j. lynch and l. a. heldt: Scr. Metall. Mater., 1994, 30, 895.

29. o. klein and i. baker: Scr. Metall. Mater., 1994, 30, 627.

30. m. a. morris and d. g. morris: Scr. Metall. Mater., 1998, 38,

509.

31. p. nagpal and i. baker: Metall. Trans. A, 1990, 21A, 2281.

32. d. j. gaydosh and m. v. nathal: Scr. Metall. Mater., 1990,

24, 1281.

33. h. y. yasuda, a. behgozin and y. umakoshi: Scr. Metall.

Mater., 1999, 40, 203.

34. m. kogachi and t. haraguchi: Scr. Mater., 1998, 39, 159.

35. j. h. schneibel, e. p. george, e. o. specht and j. a. horton:

‘High temperature ordered intermetallic alloys VI’, (ed.

J. Horton et al.), 73; 1995, Pittsburgh, PA, MRS.

36. m. g. mendiratta and h. a. lipsitt: ‘High temperature ordered

intermetallic alloys’, (ed. C. C. Koch et al.), MRS Symp. Proc.,

Vol. 39, 155; 1985, Pittsburgh, Materials Research Society.

37. d. li and d. lin: Scr. Metall. Mater., 1997, 36, 1289.

38. j. o. stiegler and c. t. liu: ‘Encyclopedia of materials science

and engineering’, II suppl. vol., (ed. R. W. Cahn), 3; 1988,

Oxford, Pergamon Press.

39. j. h. devan: ‘Oxidation of high temperature intermatallics’,

(ed. T. Grobstein and J. Deychak), 107; 1989, Warrendale.

PA, TMS.

40. c. g. mckamey, j. a. horton and c. t. liu: Scr. Metall., 1988,

22, 1679.

41. c. g. mckamey, j. a. horton and c. t. liu: J. Mater. Res., 1989,

4, 1156.

42. s. m. kim and d. g. morris: Acta Mater., 1998, 46, 2587.

43. l. baiyang, l. maosen, c. xiaobing and m. zhiyuan: J. Mater.

Sci., 1999, 34, 4039.

44. p. f. tortorelli and j. h. devan: Mater. Sci. Eng. A, 1992,

153A, 573.

Materials Science and Technology

December 2003

Vol. 19

1634 Bahadur Enhancement of high temperature strength and room temperature ductility of iron aluminides

45. r. t. fortnum and d. e. mikkola: Mater. Sci. Eng., 1987, 91,

223.

46. d. j. gaydosh, s. l. draper and m. v. nathal: Metall. Trans. A,

1989, 20A, 1701.

47. c. g. mckamey, p. j. maziasz and j. w. jones: J. Mater. Res.,

1992, 7, 2089.

48. p. j. maziasz, g. m. goodwin, c. t. liu and s. a. david: Scr.

Metall. Mater., 1992, 27, 830.

49. d. pocci, o. tassa and c. testani: ‘Properties and applications

of iron aluminides’, (ed. J. H. Schneibel and M. A. Crimp), 19;

1994, Warrendale, PA, TMS.

50. p. j. maziasz, c. t. liu and g. m. goodwin: ‘Heat resistant

materials II’, 555, 1995, Materials Park, OH, ASM International.

51. d. g. morris: Intermetallics, 1998, 6, 753.

52. u. prakash, r. a. buckley and h. jones: Mater. Sci. Technol.,

1993, 9, 16.

53. c. g. mckamey and j. a. horton: Metal. Trans. A, 1989, 20A,

751.

54. c. t. liu, c. l.white and j. a.horton: Acta Metall., 1985, 33,

213.

55. c. t. liu and e. p. george: Scr. Metall. Mater., 1990, 24, 1285.

56. c. t. liu and e. p. george: ‘High temperature ordered

intermetallic alloys IV’, MRS Symp. Proc., Vol. 213, 527;

1991, Pittsburgh, PA, Materials Research Society.

57. i. baker, x. li, h. xiao, r. l. carelton and e. p. george:

Intermetallics, 1998, 6, 177.

58. s. c. deevi, v. k. sikka, b. j. inkson and r. w. cahn: Scr. Metall.

Mater., 1997, 36, 899.

59. i. baker, p. nagpal, f. liu and p. r. munroe: Acta Metall.

Mater., 1991, 39, 1637.

Materials Science and Technology

December 2003 Vol. 19

60. m. a. crimp and k. vedula: Mater. Sci. Eng., 1986, 78, 193.

61. a. bahadur and o. n. mohanty: J. Mater. Sci., 1991, 30, 2685.

62. a. bahadur, b. r. kumar and o. n. mohanty: J. Mater. Sci.,

1995, 30, 3690.

63. z. li and i. baker: Scr. Metall. Mater., 1996, 34, 1219.

64. i. baker: Scr. Metall. Mater., 1993, 29, 835.

65. j. w. cohron, y. lin, r. h. zee and e. p. george: Acta Mater.,

1998, 46, 6245.

66. p. nagpal and i. baker: Metall. Trans. A, 1990, 21A, 2281.

67. m. a. crimp and k. vedula: Philos. Mag. A, 1991, 63A, 559.

68. r. j. lynch and l. a. heldt: Acta Metall., 1964, 12, 287.

69. e. m. shulson and d. r. barker: Scr. Metall. Mater., 1983, 17,

519.

70. c. g. mckamey, j. h. devan, p. f. tortorelli and v. k. sikka:

J. Mater. Res., 1991, 6, 1779.

71. c. g. mckamey and d. h. pierce: Scr. Metall. Mater., 1993, 28,

1173.

72. p. tomaszewicz and g. r. wallwork: Oxid. Met., 1983, 19,

165.

73. d. a. alven and n. s. stoloff: Scr. Metall. Mater., 1996, 34,

1937.

74. c. t. liu, j. l. wright and n. s. stoloff: Scr. Metall. Mater.,

1998, 38, 1601.

75. x. y. chang and x. j. wan: Scr. Metall. Mater., 1998, 38, 1505.

76. j. r. blackford, r. a. buckley, h. jones and c. m. sellars:

Mater. Sci. Technol., 1998, 14, 1139.

77. m. r. hajaligol, s. c. deevi, v. k. sikka and c. r. scorey:

Mater. Sci. Eng. A, 1998, 258A, 249.

78. m. h. yoo, s. c. sass, c. i. fu, m. j. mills, d. m. dimiduk and e. p.

george: Acta Metall. Mater., 1993, 41, 987.

Copyright of Materials Science & Technology is the property of Maney Publishing and its content may not be

copied or emailed to multiple sites or posted to a listserv without the copyright holder's express written

permission. However, users may print, download, or email articles for individual use.