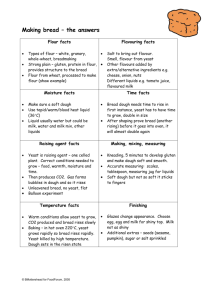

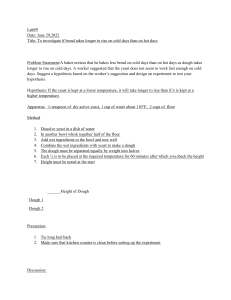

BREAD 1 Bread Staple food made from flour mixed with other dry and liquid ingredients, usually combined with a leavening agent, and kneaded, shaped into loaves, and baked One of the oldest processed food Most probably originated from the Middle East 2 Differ in sizes, shapes textures, and taste all over the world Vary in size from small sticks to loaves weighing several kilograms The product terminology is strongly linked with local consumer preferences and traditions All of the bread types require their own processing techniques, processing equipment and process control mechanisms 3 Types of Bread There are three main kinds of bread in the world: Those that rise highest and so have to be baked in pans, Those with a medium volume, like rye and French breads Those that hardly rise at all and consequently are called flatbreads 4 Wholemeal bread ❖ Mostly have 90% or more wholemeal flour in the recipe used, and wheatmeals any level of wholemeal flour mixed with white flour ❖ Processing of these differs in two ways from that of white bread: 1. During mixing the amount of water added to make an optimum dough consistency needs to be increased because the bran in the wholemeal absorbs more water 5 2. The dough is weaker because the bran particles break up the strong protein bonds in the bread dough, and this weakens the dough structure This means the dough could collapse when it rises Extra protein, called gluten, is added to make the dough stronger and stop it collapsing Wholemeal bread contains higher concentrations of minerals and vitamins than white bread as it retains the bran and germ of the wheat It is an excellent source of dietary fibre, containing twice that of white bread and more than multigrain breads 6 Multigrain and kibbled bread Mixed or multigrain breads are made from a mixture of wholemeal, white or rye flour May contain wheat germ, honey, gluten, non-fat milk solids, cracked and whole grains of wheat and other cereals such as rye, oats, corn, barley, rice millet and triticale A wide choice of multigrain breads can be achieved by blending various grains, vegetable pieces, nuts, seeds, fruit and 7 spices There are "light" and "heavy" multigrain breads "Light" multi-grains have an openness similar to white bread, with small kibbled grains, oats or other wheat mixed through the bread "Heavy" multigrain breads are characterized by small volume, dense texture and a high grain content "Light" breads are similar to white bread in terms of composition, whereas "heavy" breads are similar to or denser than wholemeal bread 8 Multigrain bread contains whole grains of different types Kibbled bread contains kibbled grain, the grain that has been broken into smaller pieces Many types of grain can be added to the bread including rye, barley, oats, corn, millet, soya, alfalfa and rice The grain should be soaked in water for several hours before mixing because un-soaked grain in bread is hard enough to break teeth This bread also needs extra protein (gluten) to make the dough 9 stronger and hold up the extra weight of the grains Fruit bread Fruit breads use a normal bread recipe to which fruit and often sugar are added Popular fruits used are raisins, currants, dates, orange peel and dried fruits such as apricots Hot cross buns and many fruit breads, also have spices added Ingredients used to enhance appearance and flavor of breads include cinnamon, nutmeg, egg wash and sugar/water wash 10 Hearth breads Some well known hearth breads include French sticks (bagettes) and Vienna bread which were traditionally baked directly on the hearth, that is, the brick floor of the oven Some bakeries overseas place brick or stone floors in their ovens so they can make this a selling point The oven for hearth breads requires steam to make the bread crusty 11 Special pans and baskets are now used to give loaf varieties a different shape and distinctive appearance Mostly hearth breads are permitted to contain only wheat flour, water, yeast and salt Bread with only these ingredients and without fats or emulsifiers will not keep for long 12 Flat breads The earliest breads made by humans The most basic are still a mixture of flour, water and salt kneaded into a pliable dough before being shaped by hand and baked Wheat is the most popular choice of grain although barley, millet, corn, oats, rice and rye are used to make various flatbreads 13 Flatbreads can be single or double layered: Single layered flatbreads can be made without yeast from a firm dough, e.g. tortillas from Mexico, or from runny mixtures poured onto a hotplate Alternatively they can be leavened (risen by a process of yeast fermentation), as with the baladi from Egypt Double layered flatbreads are leavened (with fresh yeast or a sourdough remnant of a former mix) and risen twice before baking 14 Baking at a very high oven temperature seals steam inside the bread, causing it to blow up like a football during the baking This forms a pocket that can later be filled with other food Egyptian pita bread is a good example of this pocket bread 15 Pita bread is a popular flatbread throughout the Middle East that has moved intoWestern cooking Flat breads are made throughout most of the world. Examples are pita (from the Middle East), chapati and naan (Pakistan), tortilla (Mexico) and focaccia (Italy) The bread may be leavened (have a raising agent of yeast or sourdough) or unleavened 16 There are two ways of shaping flat breads: The dough can be sheeted (rolled thinly) and cut to shape The bulk dough can be divided into pieces, rounded and then sheeted Pita bread is made with a mixture of flour, salt, yeast and water Fermentation time is short so the dough does not rise 17 When baked, heat quickly seals the top and bottom surfaces and the rapid expansion of gases between them tends to blow the crusts apart forming the pocket Naan is also a leavened bread that is baked by placing flattened pieces of dough onto the walls of an urn shaped oven 18 These breads are usually baked in an extremely hot oven with 19 temperatures of 450°C - 600°C Chapati is an unleavened round flat bread from Pakistan with most meals, wrapped around meat or vegetables Tortillas are an unleavened flatbread from Mexico made from corn flour or wheat flour They can be soft or crisp, depending on how long they are baked When they are soft they are used as burritos and when crisp are served as tostadas or corn chips Bagels These are round, chewy rolls about 10 cm in diameter with a hole in the middle They are in fact much like a doughnut in appearance, but the resemblance ends there (or it should!) The taste and texture of the bagel is very different to the doughnut although they have been referred to as 'cement doughnuts' or doughnuts with rigor mortis 20 White bread One of the most popular bread varieties It is made with a basic yeast dough of wheat flour (usually all-purpose or bread flour) There are many types of white bread based on slight variations of the basic recipe Most white breads feature a fine texture and close grain, which makes slicing easy Commercially prepared white bread is usually sliced before packaging and is most often known as sandwich bread 21 Rye breads Rye bread is a wholemeal bread made from rye or a mix of rye and wheat flour It was originally developed in Europe and is made in a wide variety of styles and shapes Rye flour is different from ordinary wheat flour It contains only small amounts of dough strengthening proteins, therefore producing weak dough 22 Rye flour also has more amylase enzyme which breaks down starch into sugars Rye doughs are made with less water than dough from ordinary flour, so they are stiff and keep their shape Moulding, proving and baking also need to be modified to handle the weak, sticky dough As with most grain and meal breads, some white flour or gluten can be used to improve the dough strength 23 The traditional way of making this bread includes several proving stages to raise the acidity and kill the amylase This stops the bread being doughy and sticky The sour dough method is the most popular means of making bread the traditional way 24 Bread formula Minimum formula for bread is flour, yeast salt and water Other ingredients often used in the formula are fat, sugar, milk or milk solids, oxidants, enzymes, surfactants and additives to protect against molds Each of the ingredient performs a special function in the production of bread loaf 25 Flour Major structural component to form viscoelastic dough to retain gas Usually, hard wheat with relatively high protein content is preferred for bread making The flour components play important role in the preparation of good quality bread 26 1. 2. 3. 4. 5. 6. 27 Wheat flour components can be classified into six groups Starch Storage (Gluten) proteins Non starch polysaccharides (NSP) Lipids Water soluble proteins Inorganic compounds Flour quality for breadmaking ▪ Breadmaking requires flour of specific characteristics ▪ A flour suitable for the production of cookies may not be suitable for breadmaking ▪ Being good for one use may not automatically mean it is not not good for another ▪ Normally hard wheat flour with protein contents about 10-14% is considered to be good for the production of good quality bread 28 Shortenings An optional ingredient that functions to enhance the product's general palatability rather than define its character When used as bread ingredient performs the following functions: 1. Tenderizing & imparting shortness to the crumb structure 2. Aiding in the aeration of the product 3. Stabilizing batters & creams by emulsification 29 Improving the over-all palatability of the product Extending the keeping quality or shelf life of the finished product Improve the flavor & color of product Improve the volume of the final product Increase the calorific value 30 Shortenings coat the flour proteins or water-proof them, contributing to tender baking recipe by reducing their contact with the moisture in the recipe and preventing gluten from forming They also shorten the length of the gluten strands when the flour is stirred with that moisture (that's why they're called "shorteners"), preventing a tough baked good or tenderize Fat coats the flour particles so the elastic formation slows down; it makes the gluten strands slippery so the gas bubbles can move 31 easily; and it gives the final recipe a finer grain Generally, when we refer to "moist" in a baked product, we refer to the fat content In traditional baking, where solid fats are creamed with crystalline sugar, tiny air cells are incorporated into the batter, so the baked good will have a fine, aerated texture When a shortener is removed or reduced, it increases the chances that the end product will lack flavor and be tough and full of tunnels 32 Different types of fat do different jobs in baking. A well-known baking fat, butter makes a very important flavor contribution, whereas margarine does not have as fine a texture and taste Fat can be found in other baking ingredients, such as the egg yolk which serves as both a tenderizer and emulsifier due to its fat and lecithin content Oils do not act as shortener because these are liquid and won't cream with crystalline sugar in the same way that solid fat does 33 Oils tend to coat each particle of flour, which causes a lack of contact of moisture and helps prevent gluten development It reduces dryness and enhances flavor Shortening acts as a lubricant in the dough, making the dough more pliable, prevents stickiness, and reduces the amount of dusting flour necessary during the make-up process 34 When shortening is used, the dough expands more easily and smoothly In the baked product it makes the crust more tender, improves the keeping quality and produces a crumb that is soft and chewy Because of the cutting effect on the bran in whole-wheat flour, it is almost impossible to produce a loaf of whole-wheat bread with acceptable volume without using shortening in the formula 35 Sources Bakery shortenings come from two sources: Animal sources Lard, tallow, butter Rarely used now a days due to limited supply Plant sources Hydrogenated plant oils e.g. sunflower etc. Have superior physical properties than the animal fats 36 Shortening types General purpose shortenings Designed to function optimally in a wide variety of applications Produced from a hydrogenated base oil with 4-12% hard fat addition to increase their plastic range Their solid contents fall within range of about 30% at 10 oC to 12% at 38 oC Their iodine value varies between 60-75 37 Free fatty acid content is just about 0.04% The melting point of these shortenings fall within the limits of 44-51 oC High emulsifier shortenings Designed for the production of cakes containing high moisture & sugar content & possessing superior tenderness, grain, & moisture retention The desirable functional properties are obtained by the addition of mono & diglycerides that exhibit pronounced surface active properties & effectively promote the uniform distribution of the 38 fat in doughs, batters & icings The fine dispersion of the fat confers superior strength on the batter and permits the use of higher ratios of sugar & liquid than is otherwise possible with ordinary fats These shortening are therefore referred as high ratio, high absorption or superglycerinated shortenings Exclusively used in the cakes, icings, sweet goods and similar products 39 High stability shortenings Used in the production of biscuits & crackers that must possess an extended shelf life, and frying operations in which the fat is exposed to high temperature for prolonged periods of time These are hydrogenated to lower iodine value in the interest of higher stability as their application does not require high plastic range The absence of hard fat and hydrogenation makes these shortenings hard and brittle at temperatures below 16 oC and 40 quite soft at temperatures above 90 oC Bread shortenings Formerly based on the animal fats but now based mainly on vegetable oils Distinguished by being formulated with mono and diglycerides and certain dough conditioners that act to improve the volume, grain and texture of the baked product and retard the rate of subsequent crumb firming The most common surfactants in current use in bread shortenings, aside from mono and diglycerides are ethoxylated monoglycerides and sodium stearoyl-2-lactylate 41 A number of additional emulsifiers and dough conditioners may be used in dough formulations, including lecithin, diaceytyl tartaric acid esters of mono and diglycerides, succinylated monoglyceride and sodium stearoyl fumarate The use of hard, high melting mono- and diglycerides in the bread shortenings is favored as these prolong maximum softness in the baked product Where more workable plastic shortenings are needed, medium- melting emulsifiers are selected for addition 42 Yeast All breads are not the same, some bread is yeasted and some are unyeasted Tortillas and pitas are flat and dense and are called unyeasted breads, while yeasted loaves of sandwich bread are puffy and light Yeasted bread types are caused by different species of yeast: Packaged or baker's yeast or yeast cultivated in a sourdough or sponge starter 43 It is responsible for leavening the dough, creating the texture of the crumb, maturing the gluten from the flour and providing the characteristic yeast leavened flavor and aroma In order to function properly, all yeast needs food (sugar), moisture and a warm environment During fermentation, consume food and release carbon dioxide, alcohol, and other organic compounds C 6H 12O 6 → 2C 2H 5OH + 2CO 2 44 Fermentation Maltose Glucose 2X Energy Pyruvate Biosynthesis Precursers Ketones Fusel Alcohols Acetyl CoA Ethanol 45 O2 Respiration Acetaldehyde Organic Acids 28X Energy Fatty Acids Esters The gas is the rising agent in bread, and the other "waste" products create the subtle flavors and texture that make a good loaf Yeast is very sensitive; too much heat will kill it, and cold will stunt its growth Moist dough between 78-80 oF (25-29 oC) is an ideal environment for yeast growth Since yeast is very sensitive to temperature, temperature is a major factor in how fast yeast multiples 46 Yeast is dormant and will not grow at 40 oF (5 oC) and grows only slowly at 55 oF (13 oC) degrees. Yeast dies instantly at 140 oF (60 oC) so do not use water warmer than 120 oF (~50 oC) to avoid accidentally killing the yeast Bread is baked when the internal temperature is between 190- 210 oF (88-99 oC) At higher temperatures than 78-80oF (25-29 oC), the dough may rise too quickly creating a crumbly texture to the bread At less, the bread will rise more slowly and will have a higher 47 alcohol content Packaged yeast Also known in some circles as baker's yeast Baker’s yeast is one species of yeast from the family Saccharomyces cerevisae, especially well-suited for the baking process: saccharo meaning sugar loving or feeding, myces meaning mold, and cerevisae being a word that was once used for beer It needs moisture, food, and the proper environment to function properly 48 TYPES Dry yeast: The most popular type, such as active dry yeast, is available in a dehydrated form in premeasured packages in the baking isle Others include: Instant Active Dry, Rapid Rise and Bread Machine Cake yeast: is also known as fresh or compressed yeast It is found in the form of a small, square shape wrapped in foil in the refrigerator case 49 Active DryYeast It is called active to distinguish it from Nutritional or Brewer's Yeast which is also dry and NOT the same thing It is the most commonly available and most widely used kind of yeast It is reliable and predictable and has been grown for flavor and speed of growth It also adds a nice yeasty flavor to the bread 50 It is available in the form of tiny brownish grains, larger than Instant Active Dry Yeast, making it necessary to proof before using Recommended water temperatures will vary by manufacturer between 100-115 oF These are clumps of dehydrated, pure yeast cells that has been air dried into dormant granules 51 In each yeast envelope, there are thousands of living plant- like microorganisms, which are finely ground and absorb moisture quickly to convert the flour's starches and sugar into carbon dioxide Active dry yeast will keep well beyond its expiration date printed on the package for 1 year if unopened at room temperature and even longer if frozen If frozen, you can use it directly without thawing 52 If opened, active dry yeast will keep 3 months in the refrigerator and 6 months in the freezer Keep yeast in its original container with the opened flap folded closed in a re-sealable plastic bag Stored at room temperature and opened without a protective outer container it loses its power at about 10% per month Always smell and proof yeast used beyond its expiration date 53 printed on the package Instant Active Dry Yeast Also known as RapidRise or Quick-Rise brand names and Bread MachineYeast A newly developed strain of yeast that can be mixed with the dry ingredients, as opposed to being proofed (dissolved) and requires only one rise Instant Yeast combines the qualities of both Active and Fresh Yeast -- the first one known for its convenience and the latter for its potency 54 These types of yeast also contain ascorbic acid resulting in increased loaf volumes The particle size of Instant Active Dry Yeasts are finely granulated to allow complete hydration of the yeast cells during the mixing process that become active the "instant" it contact moisture While Instant Active Dry Yeast is especially suited to the types of breads typically made in bread machines, it also works for general hand baking 55 It is added to the dry ingredients and then, the liquid portion of the recipe's ingredients, warmed to 120– 130 oF are added to make a dough Instant yeast will keep a year at room temperature if unopened If opened, it will keep 3 months in the refrigerator and 6 months in the freezer Keep yeast in its original container with the opened flap folded closed in a re-sealable plastic bag 56 Cake, Fresh or CompressedYeast Cake yeast is available in the form of small, soft and crumbly squares in a starch medium, found in the refrigerated case It is considered to be potent and it imparts a great flavor to the final loaf It can either be dissolved in water first or crumbled into the dry ingredients This yeast is especially well suited to long rises and sponges 57 Cake yeast must be kept refrigerated or frozen because cake yeast is highly perishable It must be used before the expiration date if stored in the refrigerator, but you have more leeway if stored in the freezer It has a refrigerated shelf life of about three to four weeks from the date of manufacture and can be frozen up to three months Do not leave fresh yeast out of the refrigerator for more than 30 minutes, close bag tightly after each use 58 Cake yeast should be white or light brown in color and crumble easily It should have a pleasant yeasty smell If it is dark brown, moldy, soft or gummy, it is either spoiled or has been stored improperly 59 4. Bread Machine Yeast, Instant Active Dry Yeast or Rapid Rise: "Bread machine yeast," also known as "instant" yeast, requires no proofing It becomes active the "instant" it contacts the liquid ingredients It is a special strain of yeast and is designed to disperse more thoroughly through the dough during mixing and kneading, well suited to bread machines 60 It can keep several months in the refrigerator and almost indefinitely in the freezer (no need to thaw before using) The temperature of the water or liquid in the recipe used has to be adjusted to 100-115 oF or as recommended by the manufacturer 61 Functions Yeast works by consuming sugar and excreting carbon dioxide and alcohol as byproducts In bread making, yeast has three major roles We are familiar with yeast's leavening ability, but it also helps to strengthen and develop gluten in dough and also contributes to incredible flavors in bread 62 Yeast Makes Dough Rise Yeast cells thrive on simple sugars As the sugars are metabolized, carbon dioxide and alcohol are released into the bread dough, making it rise The essentials of any bread dough are flour, water, and of course yeast As soon as these ingredients are stirred together, enzymes in the yeast and the flour cause large starch molecules to break down into simple sugars 63 The yeast metabolizes these simple sugars and releases carbon dioxide and ethyl alcohol into existing air bubbles in the dough. If the dough has a strong and elastic gluten network, the carbon dioxide is held within the bubble and will begin to inflate it, just like someone blowing up bubble gum As more and more tiny air cells fill with carbon dioxide, the dough rises and we're on the way to leavened bread 64 Yeast strengthens bread dough When flour and water are stirred together, two proteins in the flour -- gliadin and glutenin -- grab water and each other to form a bubble gum-like, elastic mass of molecules that we call gluten In bread making, we want to develop as much gluten as we can because it strengthens the dough and holds in gases that will make the bread rise Once flour and water are mixed together, any further working of the dough encourages more gluten to form 65 Manipulating the dough in any way allows more proteins and water to link together Yeast, like kneading, helps develop the gluten network With every burst of carbon dioxide that the yeast releases into an air bubble, protein and water molecules move about and have another chance to connect and form more gluten In this way, a dough's rising is an almost molecule-by-molecule kneading 66 When bread dough is punched down after its first rise, it become smooth and gluten strong At this stage, mostly the dough is stretched and tucked into a round to give it a smooth, tight top that will trap the gases produced by fermentation This very springy dough is let stand for 10-15 minutes This lets the gluten bonds relax a little and makes the final shaping of the dough easier 67 Fermentation Generates Flavor in Bread The big molecules in proteins, starches, and fats don't have much flavor, but when they break down into their building blocks -- proteins into amino acids, starches into sugars, or fats into free fatty acids -- they all have marvelous flavors Fermentation breaks down large molecules into smaller, flavorful ones At the beginning of fermentation, enzymes in the yeast start breaking down starch into more flavorful sugars 68 The yeast uses these sugars, as well as sugars already present in the dough, and produces not only carbon dioxide and alcohol but also a host of flavorful byproducts such as organic acids and amino acids A multitude of enzymes encourages all kinds of reactions that break big chains of molecules into smaller ones -- amylase and maltose into glucose, proteins into amino acids As fermentation proceeds, the dough becomes more acidic 69 This is due in part to rising levels of carbon dioxide, but there are also more flavorful organic acids like acetic acid (vinegar) and lactic acid being formed from the alcohol in the dough The acidity of the dough causes more molecules to break down & the dough becomes a veritable ferment of reactions Eventually, the amount of alcohol formed starts to inhibit the yeast's activity 70