Relationship between Carbon-Type Composition, Viscosity-Gravity

Constant, and Refractivity Intercept of Viscous Fractions of Petroleum

STEWART S. KURTZ, Jr., RICHARD W. KING, WILLIAM J. STOUT', DOROTHY G. PARTIKIAN, and E. A. SKRABEK2

Sun

Oil Co., Marcus Hook and Norwood, Pa.

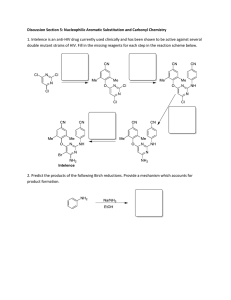

A triangular graph has been developed which relates

carbon-type composition in terms of per cent aromatic

carbons, per cent naphthenic carbons, and per cent

paraffinic carbons to viscosity-gravity constant and

refractivity intercept for viscous petroleum fractions.

If both viscosity-gravity constant and refractivity intercept are known, carbon-type composition can be determined from this graph with reasonable accuracy.

Viscosity, gravity, and refractive index are the only

experimental data required for the use of this graph.

It is useful in following the effect of solvent extraction,

acid treating, hydrogenation of the viscous fractions

of petroleum, and for comparing the composition of

the viscous fractions from various crude oils.

T

WO other laboratories have been working independently

on the correlation of density, refractive index, and viscosity to

provide a simple method for the analysis of petroleum fractions

(5, 41). The method presented here is believed to be as accurate

as the other methods, and more simple to use.

The information v hich has been accumulated in recent years

concerning the lubricating oil fraction of petroleum indicates

that the structures of the molecules in the lubricating oil fraction

are fairly uniform ( I , 2, 5-11, 14, 16, 17, 20-22, 24-27, 29-33,

36-37, 39, 40, 43-46). It seems probable that only a very small

portion of the theoretically possible structures actually exist in

lubricating oil.

Both viscosity-gravity constant (12) and refractivity intercept (16, 18, 19) were developed with the intent of obtaining

constants which were indicative of the type of hydrocarbon composition and independent of molecular weight. Therefore, it

seemed possible that lines of equal viscosity-gravity constant and

equal refractivity intercept could be established on a three-component graph for carbon-type composition. Carbon type composition is used in the conventional sense (30, 31, 43). Specifically, per cent aromatic ring carbon means the per cent of the

total carbon atoms in aromatic ring structures; per cent naphthenic ring carbon means the per cent of the total carbon atoms

in naphthenic ring structures; and per cent paraffinic chain

carbon means the per cent of the total carbon atoms in chain

structures, free as \\ell as combined with naphthenic and aromatic

rings.

Van Xes and van Westen, in their book "Aspects of the

Constitution of Mineral Oils" (31), have discussed both refractivity intercept (33) and viscosity-gravity constant (32) in

relation to the carbon-type composition, and presented the following approximate equations:

= 0.01065

ri

V.G.C.

=

( % Ca)

+ l l ( 5 6 C A ~ O - +~ )0.0103('%

~

CN) +

0.0105 ("/c C P ) (1)

O.OllO(G C a )

+ 0.00925(% CN)0.00743(%

+

CP)

2

address, University of Delaware, Newark, Del.

Present address, University of Wisconsin, Madison 6, Wis.

V.G.C.

T7.G.C.=

\-.G.C.

=

=

10G - 1.Oi52 log ( V , - 38)

10 - log ( J r i - 38)

G - 0.21 - 0.022 log (1'2 - 3 5 . 5 )

0.755

d - 0.1384 log ( V , - 20)

0.1526[7.14 - log (V3 - 20)]

~~

+

0,579

(3)

(-1)

(5)

where

G

=

=

VI =

V 2=

V 3=

d

specific gravity 60/60° F.

density a t 20" C./4" C.

Saybolt viscosity a t 100' F.

Saybolt viscosity a t 210' F.

kinematic viscosity in centistokes a t 20" C.

These equations all give viscosity-gravity constants equivalent to the Hill and Coats equation for 100' F., which is

Equation 3. Some of the carbon-type composition data

were obtained by the Martin method (16, 26) of calculation and

some by the n-d-M method (30, S1, 43). For aromatic extracts

and other compounds rich in aromatic rings, which are outside

the range recommended for the n-d-Lf method, the Martin analytical technique was used.

VISCOSITY-GRAVITY CONSTANT CORRELATION

(2)

These equations were presented as somewhat tentative, and

were not recommended for general use because of the uncertainty

in regard to the effect of aromatic carbons on the physical properties. These authors quote Leendertse (20) in regard to the

reliability of the refractivity intercept for determining the

1 Present

naphthene carbon content and the paraffin carbon content of

aromatic-free lubricating oil fractions. They were impressed

with its reliability for saturated mineral oil fractions. The

intercept for paraffin carbons chosen by Leendertse (1.0502)

and the value used here (1,0500) both correspond closely with the

value for the limiting point of the paraffin homologous series

(1.0498) (4). A lower value (1.0480) has also been investigated,

because there is no reason to believe that the limiting CH, inO

crement is necessarily the best increment to use in the C ~ to

Cto molecular weight range. However, the higher value is better

for data on lubricating oil fractions. This will be discussed in

more detail below.

The basic problem was to collect enough data for viscous oils

and fractions of viscous oils so that the relation between carbontype composition, viscosity-gravity constant, and refractivity

intercept could be established on an empirical basis. Carbontype composition can be obtained by the n-d-M procedure if

data are available for density, refractive index, and molecular

weight (31, 43). If molecular tveight is not available it can be

estimated from published correlations of molecular weight with

physical properties (28). D a t a were collected from the authors'

own files (42) and from the literature (10, 25, S1) for approximately 258 lubricating oils and fractions of lubricating oils for

which carbon-type composition, viscosity-gravity constant, and

refractivity intercept were available.

Viscosity-gravity constants were calculated with the following

equations or the corresponding nomographs:

I n development of Equation 2 van Nes and van Westen observed ( 3 2 ) that for saturated oils a linear relationship existed

between the viscosity-gravity constant (V.G.C.) and percentage

carbon in paraffinic structures ('% Cp). There also seemed to be

some relation between viscosity-gravity c o n s t p t and % CP for

a number of oil fractions from widely differing crude sources.

Their observations suggested that it might be possible to establish

lines of constant viscosity-gravity constant on a triangular coordinate system by first establishing a relationship between

viscosity-gravity constant and the percentage carbon in aro-

1928

V O L U M E 2 8 , NO. 1 2 , D E C E M B E R 1 9 5 6

1929

Table I.

Data Necessary for C o n s t r u c t i o n of ViscosityGravity Constant Lines" in F i g u r e s 5 and 7

Coordinate Point 1

Coordinate Point 2

V.G.C.

% CA % CN % CP

% CA % CN % CP

0.78

4.0

17.0

79.0

0

23.0

77.0

0.79

5.7

18.0

76.3

0

27.0

73.0

0.80

7.5

19.5

73.0

0

31.6

68.4

20

70.2

0

35.8

64.2

0.81

9.8

0.82

12.5

20

67.5

0

40.0

60.0

0.83

15.5

20

64.5

0

45.0

55.0

0.84

18.2

20

61.8

0

60.0

50.0

0.85

21.0

20

59.0

0

54.8

45.2

0.86

23.6

20

56.4

0

60.0

40.0

0.87

26.4

20

53.6

0

66.1

33.9

20

51.0

0

73.0

27.0

0.88

29.0

0.89

31.6

20

48.4

0.7

79.3

20

0.90

34.0

20

46.0

7.5

72.5

20

0.91

36.3

20

43.7

13.7

66.3

20

0.92

38.2

20

41.8

19.9

60.1

20

0.93

40.0

20

40.0

25.0

55.0

20

0.94

41.5

20

38.5

30.0

50.0

20

0.95

43.0

20

37.0

34.5

45.5

20

0.96

44.4

20

35.6

38.4

41.6

20

41.9

38.1

20

0.97

45.7

20

34.3

0.98

46.9

20

33.1

44.5

36.0

19.5

0.99

48.0

20

32.0

47.3

34.7

18.0

1.00

49.2

20

30.8

50.0

33.0

17.0

1.01

50.5

20

29.5

52.0

31.7

16.3

Table 11. Accuracy of Viscosity-Gravity C o n s t a n t Carbon-Type Correlation

Source of D a t a

Lit.

Ref.

No. of

FracAv.

tions V.G.C.

Std.

Dev.

Dev.

of

Averagea

0 830

0 926

0.845

0,813

0.858

0.004

0 004

0.004

0,004

0.006

0.000

+O.OOQ

-0.002

- 0 002

-0,004

+ O 006

-0,006

-0.007

-0,006

+0.010

+0.010

-0.007

Max.

Dev.

Whole oils and cuts

thereof

Water White Oils

Borneo Crude

OklahomaCrude

Pennsylvania Crude

Webster Crude

Distillation fractions

from Naphthenic

Crudes

P a . 180 S e u t r a l

Midcontinent

Neutral I

California Neutral

Gulf Coast Keutral

Rodessa Pieutral

Midcontinent

Seutral 2

($6)

11

(91)

(91)

5

5

(91)

(SI)

4

4

(Sf)

(10)

21

20

0.883

0.819

0.004

0.002

0 000

0.000

17

17

15

0.860

0 892

0.879

0.830

0.003

0.002

0.003

0.002

+O 001

0.000

0.000

- 0 002

005

-0 005

$0.006

-0 004

+ O 006

(10)

(10)

(IO)

(IO)

18

+O

19

0.849

0.004

+ O 001

156

0 858

0.003

0.000

(86)

(48)

12

3

0.800

0.874

0.002

0.007

0,000

+O 006

+ O 004

+ O 011

(42)

21

0.836

0.004

+0.003

+0.009

36

0.837

0.004

t 0 001

+0.011

(42)

3

0.802

0.008

-0

-0

(48)

(48)

3

0.956

4

0.966

0.008

0.014

-0 007

- 0 014

-0,010

- 0 015

(48)

2

0.945

0.014

-0

014

- 0 015

(48)

6

0.9G9

0.005

-0

001

-0

010

1

32

0.948

0 009

- 0 006

-0

015

224

0.005

-0 001

-0

015

Coordinate points given are terminal points of the V.G.C. lines

and define area of composition over which correlation has been tested.

a

t

t

1

40

44

40

52

56

60

64

68

72

76

PER CENT Cp

F i g u r e 1.

Viscosity-gravity constant cs.

saturated oils

7'

C p for

All whole oils

Saturated oils

Water White Oils

Vebster Crude

Distillation fractions

froni Naphthenic

Crudes

All saturated oils

Aromatic extracts

Aromatic conc. froni

solvent refined

lube b

Aromatic cone. from

light lubes b

Aromatic extracts

Aromatic conc. from

Webster Crudeb

Aromatic conc. from

Duosol and furfuralextractionsb

Aromatic conc. of

(10)

-411 aromatic extracts

Complete total

.92

z

z

4

L

0

~

.90

.88

c

>

.86

a

i-

010

010

a Deviation from average of each d a t u m averaged, taking sign into account.

b Concentrated on silica gel; a t least one aromatic ring per molecule.

.94

r

00;

+O

.84

v)

0

:-: . 8 2

>

.80

Viscosity-gravity constant plots for w h o l e o i l s

1930

ANALYTICAL CHEMISTRY

matic, naphthenic, or paraffinic structures on rectangular coordinates.

For saturated oils, the linear relationship betvieen viscositygravity constant and % C p observed by van Xes and van Kesten

(32) was confirmed, as shown in Figure 1. Because theae oils

contained no carbon in aromatic structures, it was possible to

transfer this line to the saturated base line of a triangular coThis gives a series of

ordinate graph for % C P , % C.V, and lo

CP-% CS side of the

viscosity-gravity constant points on

triangle.

I n order to establish a second point for the viscosity-gravity

constant lines, it was necessary to plot tn-o of the composition

variables as a function of viscosity-gravity constant for the series

of whole oils. Per cent C P and % C A gave the best approxiniations to a linear relationship when so plotted (Figures 2 and 3,.

I'ISk

B

.90

t

A plot of 70 C.V showed considerably greater scattering, and is

presented in Figure 4 merely to show that a line constructed from

% C A )fits the

Figures 2 and 3 so that 70C.V = 100 -(70C p

data reasonably well.

It was possible t o fit the data for

C P and % C A n-ith a

straight line up to viscosity-gravity constant values of about

0.885. Above 0.885 the effect of the carbons in aromatic structures became large, and it was necessary to change the slope

abruptly in order to fit the data in this region. These data

mere transferred to triangular coordinates and points of equal

viscosity-gravity constant connected to give a series of lines

covering the viscosity-gravity constant range from 0.790 to 0.910

I n the range from 0.910 to 1.00 the lines were placed by inspection

to give the best fit to the data.

Adjustments to the correlation mere made until the average

deviation was a minimum and the deviation of the average was

close to zero. The viscosity-gravity constant lines on Figure 5

are the final adjusted lines.

Table I gives the data necessary to lay out the lines for viscosity-gravity constant on a three-component graph. For the

present, a t least, the lines are being restricted to that area of the

graph for which supporting experimental data exist. Table I1

shows the degree of agreement obtained for 224 fractions between

the viscosity-gravity constant determined experimentally and

that derived from composition by using a chart corres onding

to Figure 5 . The agreement between experimental and cafculated

values, while not perfect, is satisfactory. It indicates that the

reverse computation-that

is, relating viscosity-gravity constant to composition-should be satisfactory, provided anothei

function, also independent of molecular weight, could be plotted

on the graph in order to obtain intersecting lines.

+

REFRACTIVITY INTERCEPT CORREL4TION

I.80

I I I I I I I I I I I I I

0

IO

20

30

40

50

60

70

80

PER CENT C N

Figure 4.

Viscosity-gravity constant

whole oils

TS.

YC C.v

for

It seemed reasonable to use refractivity intercept as the other

plotted function, provided the effect of aromatic carbons could

be evaluated on a reasonable basis. As the aromatic content of

lubricating oil fractions increases, there is evidence that the proportion of condensed aromatic ring structures increases. Because

the composition data for the 224 fractions that Rere available

to the authors formed a fairly narrow band on the triangular

diagram of carbon-type composition, it seemed reasonable to

anticipate that a fairly smooth curve should be obtained if the

equivalent refractivity intercept of the aromatic carbons were

plotted against the observed refractivity intercept of the sample.

Therefore, the equivalent refractivity interiept of the aromatic

carbons was calculated using the follon-ing equation:

r,A =

% AROMATIC RING

CARBONS

% NAPHTHENE

RING CARBONS

Figure 5 ,

r,sample(100) - 1.0300(7,C\) - l . O 5 O O ( % C p )

-

% PARAFFIN

CHAIN CARBONS

Viscosity-gravity constant in relation to carbon-type

composition

n

Figure 6 shows the calculated refractivity intercepts for aromatic ring carbons plotted against

the refractivity intercept of the sample for those

samples which had 5% or more of aromatic ring

carbons. Although some scattering is observed,

the anticipated trend is clear. Because the available data did not include points rich in naphthene

ring carbons and having low intercept values,

some assumption was needed to establish tentative intercept lines in the more naphthenic portion

of the composition chart. -4s there cannot be less

than one aromatic ring per molecule and as it was

not believed necessary to extend the chart below

1.035 refractivity intercept, the intercept value of

benzene (1.0616) was plotted opposite the value

1.035 for refractivity intercept to provide a tentative terminal point for this curve. This was a

rather arbitrary step which xould only be justified if the chart ultimately developed was reliable.

T h e refractivity intercept lines on Figure 7 were

established by interpolating betxeen 1.0300 and

1,0500 on the naphthene and paraffin side of the

triangle and between 1.0300 and r,A on the naphthene and aromatic side of the triangle, and 1.0500

and riA on the paraffin and aromatic side of the

triangle. r,A is determined in each case using

Figure 6 or Table 111. The data necessary for

establishing the intercept lines in Figure i are

given in Table IV.

Study of the oints in Figure 6 suggests the

possibility that &ere should be a sharp downward

curvature of the line for the calculated aromatic carbon intercept betneen the values 1.045

1931

V O L U M E 28, NO. 12, D E C E M B E R 1 9 5 6

;tnd for API 42 compounds (2, 39, 40) would indicate that a

paraffin intercept value of 1.0480 would be better in the range

from 20 to 40 carbon atoms than a value of 1.0500. The corresponding naphthene value is 1.0320. A complete graph was

constructed and evaluated. A statistical study showed little

difference between this graph and Figure 7 . However, when

compared by plotting data for a series of hydrogenated oils, the

graph based on the paraffin intercept value of 1.0480 and a

naphthene intercept value of. 1.0320 showed the completely

hydrogenated naphthene fractions, falling about 2y0 below the

base line representing 0% aromatic carbons. The graph based

on 100% CP = 1.0500 and 1007, CN = 1.0300 showed the completely hydrogenated fractions falling on the base line (Figure 8 )

For this reason it was decided to adhere to values of 1.0500 and

1.0300 for the paraffin and naphthene apexes, respectively,

In constructing this type of graph some thought needs to be

given to what is meant by per cent composition. The data for

per cent carbon type arp in terms of percentage of aromatic,

naphthenic, and paraffinic carbons in the molecule (16, SI j. Refractivity intercept is, ingeneral, additive on a volume per cent

basis for mixtures of liqui s. As shown by Leendertse (2Oj, there

is good agreement between carbon-ty e composition and refractivity intercept for complex saturate8molecules. The graph in

Figure 7 , as derived, represents carbon-type composition and

not volume per cent composition or weight per cent compositiorl.

This should be kept in mind if it is applied to blends.

'Table 111. Data Needed for Drawing Curve of Equivalent

Intercept of Aromatic Carbons os. Intercept of Lube Oil a s

Shown in Figure 6

Intercept

Intercept

of

of Aromatic

Oil

Carbons

1 0616

1.0350

1 ,0695

1.0400

1 0775

1.0450

1 0855

1.0500

1 0926

1,0550

1.0986

1.0600

1.1042

1 ,0650

1.1094

1 ,0700

1.1140

1.0750

1.1186

1.0800

Data for Establishing Refractivity Intercept

Lines"

NaphtheneNaplitheneParaffinItefracParaffin

Aromatic*

Aromatic

Base Line

Side of Triangle Side of Triangle

tivity

% CP % CS 5% CA 7%C.V yo CA 7% C P

Intercept

25

75

15 8

84 2

1 035

74.7

50

25.3

i 040

50

68.4

25

31.6

75

1.045

63.9

36.1

0

1.050

100

60 1

88.3

39 9

11.7

1.055

56 3

79.5

20 5

43

7

1 060

72.3

52 8

27 7

47 2

1 065

po 4 49 6 33 7 66 3

1 070

39 1

46 4

93 6

BO 9

1 n7.5

i &I

56.4

43 4

43.7

56 3

In constructing Figure i values for intermediate lines can he 011tained by plotting columns 2 to 7 us. column 1 and interpolating.

h working graph should have lines for each 2% of carbon-type (TJYIposition, for each unit in the third decimal place of the refractirit?.

intercept, and for each unit in the second decimal of viscoeit!.-gravit!.

constant.

Table IV.

~~

APPLICATIO\

The carbon-type composition of the lubricating oils and frwtions of lubricating oils used in developing Figure 7 , as well as :L

number of other oils on n hich data were available, was determined

by plotting the viscosity-gravity constant and refractivity intercept for all these points on a large graph and reading off the corresponding composition. This study showed that the aromatic.

carbon contents are usually in agreement with the authors'

best analyses to within 1 or 2%, although occasionally deviation3

as large as 4 or 5% may be observed. On the paraffin and naphthene compositions, the agreement is good for fractions containing 30% or less of aromatic carbons. Between 30% and 50%

aromatic carbons, there is an increase of uncertainty in the values

for the paraffin and naphthene carbons, because the angle at

11-hich the correlation lines intersect decreases rapidly. Thp

chart should not be used for samples having viscosity-gravity

constant values between 0.95 and 1.01 which fall below 20%

C,vor 20% CP. This is practical because very few samples having

less than 20% CNor 2O%Cp have been found in this range. Table

V presents data on a number of samples for which rather complete analytical data were obtained in connection with studies

and 1.050 for the intercept of the oliginal oil. This was tried, but

led to an irregular spacing of the intercept lines on the triangular

diagram. The lines so placed did not agree well with the limited

available data for this region. Therefore, as explained above, the

coordinatee 1.0616 and 1.0350 were tried as the terminal point

of the curve. This led to more reasonable spacing of the intercept

lines and better agreement with the data.

Considerable thought has been given to the significance of

pure compound data in relation to locating the intercept lines on

Figure 7 . Consideration of data from the A4PI44 tables ( 3 , 35)

I

I

In

I

I

I

I

I

I

1.12

m

a

4:

g

gI

1.11

1.10

a

LL

..-

0

1.09

n

w

tj

1.08

i8

1.07

1.030

1.040

1.050

1.060

1.070

1.080

r i OF SAMPLE

Figure 6.

Refractivity intercept of aromatic carbons us. refractivity

intercept of sample

ANALYTICAL CHEMISTRY

1932

of rubber processing oils (16, 48). I n general, the agreement

between composition obtained with Figure i and the composition obtained by more complete analysis is satisfactory-that is,

within 1 or 2%. -4few deviations larger than 4% are shonn.

Table V also contains data obtained by the n-d-bI procedure

of Tadema, van Xes, and associates (31, 43). I n the range for

which the n-d-11 method is recommended-that is, for samples in

which the ratio of % C A to yo Cy is 1.5 or less-the agreement is

quite good. I n the higher aromatic range the data obtained by

Figure 7 are in better agreement with detailed analyses b j the

Martin (16, 26) method than are the data by the n-d-11

method .

Table VI compares carbon-type analyses obtained x ith Figuie

i and with the n-d-?\I procedure on the cuts of five tlpical oils

studied by Hill and Ferris (13). The data on these oils xere

used by Hill and Coats (12) in deriving the viscosity-gravity constant, The t a o methods agree xell for these typical oils. The

range of carbon-type composition is about 20% for % C.4 and

% C Vand about 40% for % C p . To prepare Table VI data weie

read from photostatic enlargements of the curves published by

Hill and Ferris. Data were corrected to 20' C. when necessary.

A statistical study of all the data (Table YII) shows that, for

oils having a viscosity-gravity constant of 0.900 or less, Figure

i nil1 give the value of yo C A n ith a standard deviation of ahout

1.0%. For % C.V and % C p the standard deviation is roughly

1.5% for samples m-ith a viscosity-gravity constant below 0.900.

Most naturally occurring crude oils have viscosity-gravity constant values below 0.900.

For samples with viscosity-gravity constants between 0.900

and 1.000, the standard deviation for % C A is approximately 2.0%

and for % C,y and % C p , approximately 4.5%. The samples

having viscosity-gravity constant above 0.900 are, for the most

part, aromatic concentrates obtained either by solvent extraction

or gel separation. These samples are outside the range of materials for x hich the viscosity-gravity constant was originally

developed.

Table 1-111presents corresponding data arranged b j groups

based on per cent carbon in aromatic rings. For samples having

less than 30% carbon in aromatic rings the standard deviation is

as follons: per cent aromatic carbons, 1.2%; per cent naphthenic

carbons, 2 . 0 % ; per cent paraffinic carbons, 1.7%.

The data used in developing this chart represent a Fide variety

of samples. Consideration of the data indicates that Figure 7

is sufficiently reliable for obtaining many of the carbon-type composition data ahich are needed in practical petroleum refining.

The relation betn-een refractivity intercept and composition,

and beta een viscosity-gravity constant and composition is more

accurately presented by Figure 7 than hy Equations 1 and 2

% AROMATIC RING

CARBONS

.os00

LRBONS

V O L U M E 2 8 , NO. 1 2 , D E C E M B E R 1 9 5 6

1933

Table V. Comparison of Carbon-Type Analysis by

Viscosity-Gravity Constant-Refractivity Intercept and

Other Methods

011

No.

1

Mol. wt.

V.G.C

.

T%

n

d

2

Mol. nt.

V.G.C.

1L

n

d

3

A I O l , n.t.

T.G.C.

ri

n

d

4

1101. a t .

T.G.C.

ri

ri

d

5

698

0.798

1.0448

1.4865

0,8835

T.G.C.

rt

d

7

>roi.art.

V.G.C.

T l

n

d

8

3101. wi.

1.. G.C.

rt

12

d

9

JIol. rvt.

T.G.C.

ri

n

d

10

IIOl. wt.

V.G.C.

rt

n

d

11

Mol. ai.

V.G.C.

1%

d

12

\r01.nt.

V.G.C.

rt

71

d

13

Mol. wt.

1'. G .C.

rl

n

d

14

Ll01.nt.

T.G.C.

IL

n

d

1.5

16

x-z

352

0.818

1.0440

1.4748

0.8613

Fig. 7

x

n-d-XI u

Martin z

464

0,842

1.0419

1.4971

0.9105

Fig. 7

z

n-d-XI

y

Martin z

x-2

2-y

2-2

FIE. 7

2-2/

z-z

442

0 892

1 ,0332

1.5352

0.9600

Fig. 7

x

n-d-XI y

Martin z

2-Y

365

0,915

1.0501

1.5291

0,9580

Fig. 7

s

n-d-11 y

Martin z

427

0 927

1.0631

1 5550

0 9837

Fig. 7

x

n-d-ll y

Martin z

369

0.93fj1 ,066.2

Fig, 7

n-d-115

hIartin

x-z

x-2

x-y

2-2

z-y

2-2

x

y

z

x-y

0.9783

2'-2

373

0.936

1 0039

1.5537

0.9797

Fig. 7

x

n-d-Ma y

Martin z

373

0,943

1.0654

1.5649

0,9990

Fig. 7

x

n-d-MQ y

LIortin z

361

0.970

1.0735

Fig. 7

x

n-d-Ma y

Martin z

x-y

x-z

s-y

x-z

1,5804

z-y

1.0138

5-2

Fig. 7

x

n-d-Ma u

Nartin z

2-y

2-2

Fig. 7

z

n-d-lIe y

Martin z

x-y

l f o l . wt.

V.G.C.

Fig. 7

x

n-d-3Ia y

n

d

310

0 997

1.0734

1.5872

1.0236

x-z

Martin

z

x-y

s-2

0

70

69

70

+ I

0

3

3

3

33

33

35

64

64

0

0

0

0

3

3

3

34

34

34

0

0

0

0

4

45

43

45

0

0

50

0

+ I

4

64

0

0

63

63

63

0

0

51

-

2

3

3

1

1

49

47

47

+ 7

49

50

50

- 1

+ 2

- 1

20

19

16

1

4

38

39

42

- 1

42

42

42

0

0

25

24

25

1

0

34

35

30

i - 4

41

41

45

0

- 4

45

43

45

+ ?

0

3<5

33

- 5 5

- 5 5

++

+

25.5

22

20

3.5

5.5

++

36

36

33

0

3

- 4

- 1

28.5

22

26

6.5

2 5

+

++

39

42

35

- 3

4

26

16

26

+10

0

+

37

39

33

- 2

4

35.5

42

41

- 6.5

5.5

-

29

22

33

+ 7

- 4

32

- 3

0

46

- 9

1

23.5

12

19

+ll 5

4.5

+

31.5

34

35

- 2.5

- 3.5

40

55

46

- 9

0

30.5

15

30

+l.5 5

0.5

+

23.5

30

24

- 6.5

0.5

37

21

31

+16

+ 6

25

-10

- 8

-

46

52

+-

44

6

2

49

59

46

-10

+

3

31

11

31

+20

0

NO.

of

Data

64

118

(3.4

Group

0- 9 9

10-19 9

Standard Deviation

% CA

5% C Y

70 cp

1 1

1 1

2 2

1 4

1 4

1 6

- 6

- 3

3"

3.5

-

17

27

20

30

23

-10

- 3

Mol. wt. 314

Fig. 7

x

50

15

35

1 010

V.G.C.

6

31

n-d-lIa 1~

1 0825

hlariin z

23

25

rl

n

1.5997

z-y

-13

+ 9

A 4

1.0343

d

2-2

- 2

- 8

+lo

a Beyond range f o r which n-d-11 method is recommended: also beyond

range for which T.G.C. w a s derived.

:;

5%

6

39

43

35

- 4

54

Table YIII. Standard Deviation of Carbon-Type ,inalj sis

by Figure 7 for Per Cent 4romatic Groups

;3;

+ 8

43

Q

36

42

39

- 7

- 4

+

+4

Table VIIS Standard Deviation of Carbon-Type Analysis

by Figure 7 for V.G.C. Groups

NO.

V.G.C.

of

Standard Deviation

Group

Data

% Ca

%Cv

%CP

Less than 0 819

36

0 7

1 2

1 0

0 820-0 849

75

0 8

1 9

1 4

0 850-0 899

103

1 3

2 3

2 0

0 900-0 949Q

25

2 8

4 2

3 5

0 950-0 999a

16

1 8

3 5

3 4

Above 1 OOa

3

1 2

6 1

7 3

258

Maximum V.G.C. shown in Hill and Coats (12) is 0.935; above

0.935 V.G.C. is extrapolated function.

29 5

;

;

31

- 1

Comparison of Figure 7 and n-d-3%Analysis

[Data of Hill and Ferris (13) ]

Characteriaation

%

%

%

V.G.C.

Factor Method CA C N C P

Pennsylvania

0.808

12.4

Fig. 7

6 . 5 24.5 69

n-d-11 6 . 5 24.5 69

1Iidcontinent

0.839

12.0

Fig. 7 1 2 . 5 29

58.5

n-d-;\I 12.5 2 8 . 5 59.0

Gulf Coast No, 1 0.863

11.7

Fig. 7 1 6 . 5 34

49.5

n-d-M 15

3 4 . 5 50.5

Gulf Coast No. 2 0,883

11.5

Fig. 7 17.5 42.5 40.0

n-d-M 16

42.5 41.5

Gulf Coast No. 3 0.910

11.2

Fig. 7 2 4 . 5 44.5 31

n-d-M 22

44

34

Range (maximum - minimum)

1 8 . 0 20.0 38

51

0

1

z

n-d-RI y

Martin z

% CP

28

28

28

0

0

1

x-y

Fig.7

z

n-d-11 y

Martin z

s-Y

272

0 982

1.0724

1.5737

1.0026

-

5-2

39s

0 883

1.0491

1.5210

0.9439

1, 5 5 3 6

2

3

2

2-y

Mol. nt. 278

0.983

V.G.C.

1.0700

rt

n

1.5725

d

1 ,0050

Ti

17

2-y

Fig. 7

x

n-d-;\.I y

Martin z

3101. nt. 347

1 .G.C.

0.846

1.0407

I1

1,4847

d

0.8879

1101.xi.

Fig. 7

x

n-d-11 y

lIartin z

419

0.815

1.0441

1,4793

0.8704

rt

G

Composition of Oil

% CA % CY

Propel.iy of Oil

Table VI.

Table I S s h o w data for aromatic concentrates obtained by

silica gel from five rubber processing oils. These data indicate

that Figure 7 gives good values on the per cent aromatic carbons

in such aromatic concentrates, but poor values for the yo (23, and

% C P . By subtracting 0.015 from the viscosity-gravity constant

value in each case, much better agreement is obtained, as shown

in the table. I n general, any method of this sort must be used

with caution for fractions which are too homogenous as to type

and, therefore, may not fit correlations based on averages.

The effect of sulfur on a correlation of this sort is important if

i t is to be used with high-sulfur oils. When d a h were used for

approximately 60 oils on which sulfur data were available, the

following correction factors were derived for % Cy and % Cp:

Sulfur correction for 5 2 C.,-

=

41 C p

=

Sulfur correction for

~

~

-Kt.?<

0.288

s

+Wt.C7,

0.216

s

(7)

( 8)

The corrected values for % C.4 can be obtained from the equation

70 C a

=

100 -

i%

C,.

+ % CP)

(9)

Table S s h o w the effectiveness of the sulfur correction in

ANALYTICAL CHEMISTRY

1934

reducing the deviations between values read from Figure 7 and

those obtained using more detailed methods of analysis. The

tabulation only includes those samples containing more than

0.5% sulfur. I n the region above 0.8% sulfur, the agreement

between the viscosity-gravity constant-refractivity intercept

method and other methods may be substantially improved by

applying the sulfur correction.

I n addition to viscosity-gravity constant another relation

between viscosity and gravity, the characterization factor, hap

been widely used (46, 4 7 ) . A graph similar to Figure 7, based

on characterization factor, could undoubtedly be developed. The

authors have preferred to provide tables so that data recorded in

terms of characterization factor can be converted to viscositygravity constant and studied with the aid of Figure i .

% AROMATIC RING

CARBONS

A

1.0300

/e

'

-1.0600

1.0400

NAPHTHENE RING

CARBONS

% PARAFFIN CHAIN

CARBONS

Figure 8. Hydrogenation and solvent extraction data in relation to carbontype composition

Lines 1, 2, and 3 explained i n text

Table IX. Aromatic Fractions Concentrated by Silica Gel

[From rubber processing oil (48) I

Aromatic

Fraction

of

Si, relatively

naphthenic

Property of Oil

Mol. \vt. 366

V.G.C.

0.900

ti

1,0530

1,5269

n

d

0,9465

Ss, relatively

Mol. u t . 435

naphthenic V.G.C.

0.886

112

1 0536

n

1 5330

d

0 9588

Sr. relatively

Mol. a t . 350

paraffinic

Y.G.C.

0.898

T,

1 0547

n

1 5223

d

0 9355

91. relatively

Mol. wt. 418

paraffinic

V.G.C.

0 879

ti

1,0530

n

1.5180

d

0.9300

As, relatively Mol. wt. 409

aromatic

V.G.C.

0.957

Ti

1.0706

n

1.5767

d

1.0124

a 0.015 subtracted from V.G.C.

.

~

Composition of Oil

c'r C.V

% CP

30

38

32

44

28

45

4-8

- 7

- 1

7-4

B Tr

42

% CA

Figure 7

Correcteda

Martin

Figure 7

Correcteda

Martin

X

d

z

2-2

- 1

u-2

- 3

22

22

24

- 2

2:

u

z

+-z

21-2

Figure 7

Correcteda

Martin

5

Y

z

X-Z

ll-2

Figure 7

Corrected"

Martin

Figure 7

Corrected"

Martin

26

24

27

X

u

z

- 1

27

25

27

0

- 2

23

21

24

2-2

- 1

21-2

- 3

x-2

42

42

42

0

u-2

0

2

21

2

50

44

28

82

+.I

- 4

- 2

C 6

33.5

29

27

6 .5

A 2.0

+

30.3

27

12

+ 8 5

+ 5

25

22

21

+ 4

+ I

-

39 5

46

46

6 5

0

16 5

'0

54

- 7 5

- 2

33

36

37

- 4

- 1

Table XI gives enough data so that viscositygravity constant can be obtained from characterization factor and viscosity by interpolation.

An example of the application of Figure 7 is

given in Figure 8. Line 1 on this graph represents data from the paper by M. R. Lipkin,

C. C. Martin, and R. C. Worthing (33)shon-ing

steps in the hydrogenation of a viscous oil

fraction. The gradual decrease in aromatic carbon content and increase in naphthenic carbon

content is clearly shown. There is also an indication that the final hydrogenation ti eatments,

which were continued in an effort to eliminate the last trace of ultraviolet absorption,

may have resulted in some ring opening, because

there is a decrease of between 2 and 4% in the

naphthene ring carbons and a corresponding increase in the paraffin chain carbons during these

last hydrogenations Other data for hydrogenated samples confirm the constancy of % C p as

aromatic rings are converted to naphthenic

rings. Line 2 on this graph shows the change

in an oil on repeated solvent extraction (34).

I n this case there is a progressive decrease in

V O L U M E 28, NO. 12, D E C E M B E R 1 9 5 6

1935

Table X.

Correction of Carbon-Type Composition Data for Effect of Sulfur

Deviation from Best Analvses

V.G.C. V S . rt

V.G.C. us. r ,

(corr. for % SI“

Lit.

Sample

%

S

%

C

a

%

C

\

%

CP

%

C

a %C.v % C P

Ref.

NO.

V.G.C.

rl

16

0.997

1.0754

0.57 + 3 . 0

0

- 3 . 0 $2.4 - 2 . 0

-0.4

(42)

18

0,943

1,0607

0.73 + 3 . 6 - 1 . 3 - 2 . 3 + 2 . 7 - 3 . 8 + l , l

(42)

20

1,0699

0.72 - 2 . 1 + 3 . 8 - 1 . 7 - 2 . 9 + 1 . 4 + 1 . 5

(42)

0,970

21

0.965

1.0693

0.67 - 2 . 3 + 0 . 9 t 1 . 4 - 3 . 1 - 1 . 4 1-4.5

(42)

1.0739

0.75

0

- 0 9 + 0 . 9 - 0 . 9 - 3 . 5 +4 4

23

0.982

(42)

24

0.973

1.0746

0.73 $ 2 . 5 - 3 . 6 $ 1 . 1 $ 1 . 6 - 6 . 1 + 4 . 5

(42)

25

0.980

1.0700

0 . 5 6 + 1 . 2 S i 6 - 8 . 8 +0.5 $ 5 . 7 - 6 . 2

(48)

26

1.011

1.0788

0 . 5 7 + 1 . 8 $ 5 . 3 - 7 . 1 $1.2 + 3 . 3 - 4 . 5

(42)

27

0.956

1.0642

0 . 7 7 - 3 . 2 $ 3 . 7 - 0 . 5 - 4 . 1 $1.0 + 3 . 1

(42)

11

0.936

1.0639

0.56 1 4 . 3 - 1 . 0 - 3 . 3 + 3 . 6 - 2 . 9 - 0 . 7

(42)

9

1.0631

0.62 + 3 . 0 + 2 . 5 - 5 . 5 $ 2 . 4 $ 0 . 3 - 2 . 7

0.927

(42)

14

1.0724

0.55

0

-0 5 - 0 . 5 - 0 . 7 - 1 . 3 + 2 0

0.982

(42)

1.0665

0.73 $ 3 . 8

0

-3.8 $2.9 -2.5 -0.:

10

0,936

(48)

0 70

33

0.831

1.0434

-1.5 +3 0 -1 5 -2.3 $0.6 + l . t

(34)

34

1.0670

0.79 i 3 . 0 - 3 0

0

+ I 5 -5.2

0.909

+3.7

(42)

35

0

- 1 . 0 +O.l -2.7

1,0560

0.77 7 1 . 0

0.929

S2.6

(49)

Std. dev. ( 0 . 5 to 0 . 8 % E)

2 0

3 1

3 R

2 4

3.2

3 2

Dev. of av.

+1.2 +1.1 - 2 3 f 0 . 3 -1.2 + 0 . 9

i o 9 1 4 G - 5 5 - 0 . 1 +1 8 - 1 7

19

1 0629

0.82

0 946

22

1 0709

1.08 -0 6 $ 1 5 - 2 . 1 - 0 . 6 -2 3 + 2 9

0 971

1 0816

0 . 9 2 - 1 . 0 - 3 0 t 4 0 -2 1 - 6 1 + 8 2

1011

36

1.01

0 892

1 0532

0

+ 4 3 - 4 3 - 1 . 2 +O 8 + o 4

1 . 0 3 -1 0 +4 5 - 3 . 5 -2 2 +o 9 + I 3

1

0735

13

0 970

1 0543

28

0 892

2.05

+ 1 . 0 +8 0 - 9 . 0 - 1 . 4 +O 9 $ 0 5

1 0498

29

0 870

1 . 6 7 $0 5 + 4 5 - 5 . 0 - 1 . 2 -1 5 +2 7

1 0468

30

0 854

1.35 + 0 . 5 +:3 0 - 3 5 - 1 . 1 -1 7 +2

31

1.12 - 1 0 + 3 5 - 2 5 - 2 3 - 0 4 +2 i

1

0452

0 844

32

1 0441

0.89 -1 0 + 3 0 - 2 0 - 2 0 -0 1 +2 1

0 837

37

1 0501

+1 5 +4 0 - 5 5 + 0 5 $1 0 -1 5

0 838

0.86

1 0505

38

0 866

1.50 + l . 5 + 5 n - 6 5

- 0 2 - 0 2 +o 4

39

0 871

1.62 + 4 0 +2 5

1 0544

+2.1 -3 1 + I 0

- n .i $0 1 $0 4

1.70 + l . 5 +8 0 - !

40

0 892

1 0515

1.50 + 0 . 5 +9 5 - 1 0 0 - i i + 4 3 - 3 1

41

0 8.59

1 0522

42

1.51 + 1 . 0 + 8 0 - 9 0 - 0 7 +2 8 - 2 1

1 0.534

0 863

1.73 + l . 5 +9 0 - 1 0 5 - 0 5 + 3 0 - 2 5

43

1 0550

0 871

Std. dev. ( 0 . 8 to 2.0% S )

1.4

5 -5

6.3

1.4

2 4

2 8

D e i . of av.

+O.B

+ 4 . G -5 2 - 0 . 9

0 0 +0.9

a Correction applied to % C.Yand % CP; % CA adjusted accordingly

-!.e

Table XI. Viscosity-Gravity Constant Corresponding to

Indicated Viscosity and Characterization Factor

VlSCO’.ltJ,

1000 E

Characterization Factor

12 5

12

11 5

11

10 5

10

KineSa.\niatir

bolt

Visrosity-Gravit> Constant

6

45 6 0 795 0 828 0 865 0 908 0 954 1 006

52 1 0 796 0 830 0 869 0 910 0 958 1 013

8

58 9 0 797 0 832 0 872 0 914 0 962 1 019

10

97 8 0 799 0 836 0 879 0 924 0 973 1 0 3 5

20

232

0 801 0 842 0 886 0 937 0 991 1 0 5 3

50

100

463

0 802 0 845 0 890 0 942 1 001 1 067

200

927

0 803 0 846 0 894 0 948 1 011

500

3317

0 804 0 848 0 898 0 953 1 023

1000

4635

0 805 0 849 0 901 0 957 1 0 3 0

2100 r

_____

5

10

20

50

100

12 7

59 3

98 5

234

467

0 796

0 803

0 806

n 809

0 811

0 837 0 884 0 938 0 995

0 844 0 892 0 947 1 005

0 849 0 898 0 954 1 015

o 854 o 904 o 960 1 021

0 856 0 906 0 963 1 0 2 3

1

082

1 073

1 080

1 086

1 087

aromatic carbon conteiit and increase in paraffinic and naphthenic carbon content up to the last stage of extraction. In the

last stage of extraction, aromatic carbon content changes

little and naphthenic carbon decreases as paraffinic carbon

increases.

The oil for which data are presented in Line 2 contained 2.05%

sulfur before eutraction. The composition of this oil as read

from the graph is 26% ‘2.4, 32% CY,and 42% Cp. After applying

the sulfur corrections, the composition is 24% C A , 25% C.V,

and 51% C P . Van S e s and van Westen give 25% C A ,24% C r ,

and 51% C p . Line 3 shows the composition data corrected

for the effect of sulfur These data confirm both the usefulness

of the plot of the raw data to show trends, and the validity of

the sulfur correction.

ACKNOWLEDGMENT

The authors JS ish to acknoa ledge the assistance and helpful

discussion of C. C. Martin, J. C. S. Wood, and J. W. Loveland.

LTTER.4TURE CITED

(1) American Petroleum Institute, Research Project 6, Carnegie

Institute of Technology, Pittsburgh, Pa.

(2) Ibid., Research Project 42, Pennsylvania State University,

University Park, Pa.

(3) Ihid.,Research Project 44, Carnegie Institute of Technology,

Pittsburgh, Pa.

(4) Beverly, J. B., Marschner, R. T., Preprints, Petroleum Division

ACS, iipril 1955.

( 5 ) Boelhouwer, C., Watermarl, H. I., J . In& Petroleum 40, 116

(1954).

(6) Bondi. A . , “Physical Chemistry of Lubricating Oils,” Reinhold,

Sew York, 1951.

(7) Charlet, E. bI.,Laniieau, K. P.. Johnson, F. B., ANAL CHEM.

26, 861 (1954).

( 8 ) Clark, R. J.. Hood, .\.. O’Keal, LI. J., Jr., Ibid., 27, 868 (1955).

(9) Dudenbostel, B. F., Jr.. Priestley, William, Jr., “Chemistry of

Petroleum Hydrocarbons,” Vol. 1, Chap. 12, Brooks, B. T.,

others, eds.. Reinhold. Nem- York, 1954.

(10) Fenske, 11. R.,Carnahan, F. L., Breston, J. N., Caser. A . H.,

Rescorla. A . R., Ind. E ~ L Q

Chem.

.

34, 63846 (1942).

(11) Hazelwood. I?. S’.,ANAL.CHEM.26, 1072 (1954).

(12) Hill, J. B., Coats. H. B., I n d . Eng. Chem. 20, 6 4 1 4 (1928).

(13) Hill, J. B., Ferris, S.W., Ibid., 17, 1250 (1925).

(14) Kurtr. S. S., Jr., “Chemistry of Petroleum Hydrocarbons,” 5-01.

1, Chap. 11, Brooks, B. T., others, eds., Reinhold, New York,

1954.

(15) Kurtr, S. S., Jr., Headington, C. E., IND.ENG. CHEM.,-4x.4~.

ED. 9, 21 (1937).

(16) Kurtr, S. S.,Jr., Martin, C. C., India Rubber World 126, 495

(1952).

ANALYTICAL CHEMJSTRY

1936

Kurta, S. S., Jr., Sankin, d.,“Physical Chemistry of Hydrocarbons,” 1-01. 11, Chap. 1 , Farkas, d.,ed., Academic Press,

Sew York, 1953.

Kurtz, S. S., Jr., Xard, d.L., J . Franklin I71St. 222, 563 (1936).

(33) Ibid., p. 370.

(34) Ibid., p. 429.

(35) O’Seill, J., “Applied

Ibid., 224, 583, 697 (1937).

Leendertse, J. J., in “Aspects of the Constitution of 11ineral

Oils.” a. 368. Elsevier. Kew York. 1951.

Lillard, i.G., Jones, W,C.,

Jr., Anderson, J. A , , Jr., I n d . Eng.

Chern. 44, 2623 (1952).

Lipkin, RI. R., Hoffecker, 11‘. A., Martin, C. C.,Ledley, R. E.,

. h A L . CHEM. 20, 130 (1948).

Lipkin, AI. R., Martin, C. C., Worthing, R. C., Third World

Petroleum Congress, Section VI, 1951; E. J. Brill, Leiden,

Rossini, F. D., Mair, B. J., Streiff, A . J., “Hydrocarbons from

Petroleum.“ Reinhold, New York, 1954.

(37) Ibid., Chap. 22.

(38) Rossini, others, “Tables of Physical and Thermodynamic Properties,” API 4 4 , Carnegie Press, Pittsburgh, Pa.

(39) Schiessler, R. W., Rytina, C.H., Weisel, Fischl, F., JIcLaughlin.

R. L., Keuhner, H. H., Proc. Am. Petroleum Inst., 26, 111,

Holland, 1951.

Lipkin, l f . R., Sankin, A, Martin, C.C., ANAL. CHEM.20, 598

(40) Schiessler, R . W.,

Whitmore, F. C., I n d . Eng. Chem. 47, 1660

(1948).

AIair, B. J., Schicktane, 8. T., I n d . Eng. Chem. 28, 1446-51

(1936).

Martin, C. C., Sankin, A , , A~NAL.

CHEV.25, 206 (1953).

llikeska. L. -4.,

I n d . Eng. Chem. 128, 978-84 (1936).

Mills, I. IT.,Hirschler, A. E., Kurte, S.S., Ibid , 3 8 , 442 (1946).

hliron, S., ANAL.CHEW27, 1947 (1955).

Xes, K. van, “Chemistry of Petroleum Hydrocarbons,” Vol. 1 ,

Chap. 16, Brooks, B. T., others, eds., Reinhold, New York,

1954.

Kea, K. van, Westen, H. A . van, “..lspects of the Constitution of

Mineral Oils,“ Elsevier. K e n . York. 1951.

(32) Ibid., p. 200.

Mass Spectrometry,” pp. 27-46, Report

Conference. published by Institute of Petroleum, London,

1954.

(36)

254 (1946).

(1955).

Smith, Edwin E., Engineering Experiment Station, Bull. 152.

Ohio State University, Columbus, Ohio, May, 1953.

(42) Sun Oil Co., unpublished data.

J., in “Aspects of the Constitution of Mineral Oils.”

pp. 250, 317, 318, Elsevier, Ken. York, 1951.

(44) Waterman, H. J., Brennstof Chemie 36, 169 (1955).

(41)

(45) Ibid., p . 199.

(46) Katson, K. AI.,

“Science of Petroleum,” Vol. 2, p. 1377, Dunstan, et al., Oxford University Press, London, 1938.

(47) Watson, K. lI.,Selson, E. F., I n d . Eng. Chem. 29, 880-7 (1933).

(48) Weinstock, K. V., Storey, E. B., Sweely, J. S., Ibid., 45, 1036

(1953).

R E C E I T - Efor

D review N a y 8 , 1956. Accepted September 14, 1S5B.

Composition of Lubricating Oil

Use of Newer Separation and Spectroscopic Methods

F. W. MELPOLDER, R. A. BROWN, T. A. WASHALL, WILLIAM DOHERTY, and C . E. HEADINGTON

The Atlantic Refining Co., Philadelphia, Pa.

A study was made of the composition and physical

properties of fractions separated from a solvent-refined

oil heart cut. The oil charge was fractionated by means

of 20-stage molecular distillation, silica gel chromatography, and liquid thermal diffusion to yield saturated

fractions ranging from predominantly isoparaffins to

multiring cycloparaffins. Hydrocarbon-type analyses

were determined by mass and ultraviolet spectrometr?

and several molecular structures were postulated from

mass and infrared data. One fraction which exhibited

extreme ph) sical properties w-as found to contain from

four to ten rings per molecule.

THE

present-day trend in the refining of petroleum products

and the development of new and more ponerful analytical

techniques have promoted a growing interest in the composition

of heavy petroleum product-. Detailed information concerning

the molecular structure of hydracarbon types is needed because

of the many factors related to performance and stabilitj- characteristics of lubricants.

A long-range approach to the problem has been extensivelj

investigated during the past t v o decades by API Project 6

(14). This work has been directed toward a separation of oil

according to hydrocarbon types, and measurements of numerous

physical properties of the fractions. Additional data for a group

of “homogeneous” fractions were recently reported for a cooperative spectroscopic study ( 9 ) . Further progress in this field has

been dependent on the development of more efficient separation

techniques, extension of spectroscopic methods of analysis, and

the synthesis of representative hydrocarbons as standards to

guide the interpretation of spectra. Despite the lack of such

standards, O’Keal (IS)and Lumpkin and Johnson (8) were able

t o postulate the structure of many aromatic h j drocarbons and

sulfur compounds in gas oil. 3Ielpolder and coworkers were also

able to make a mass spectrometric analysis of thermal diffusion

fractions separated from a light lubricating oil ( I O ) .

I n viex of the significant new developments which have been

made in the past fen- years in both separations and spectroscopic

methods, the authors have undertaken a thorough study of the

composition of a heart cut lubricating oil fraction. Working on

the saturated portion only, many fractions were separated from

the oil, in which specific hydrocarbon types of a narrow molecular

Jveight range were concentrated. Physical properties and spectrometric anal>-sesof the fractions were determined, and an effort

was made to determine molecular structures from the interpretation of niass ppectrometric data.

LUBRICATIYG OIL STOCK

The oil charge used in this work \vas a solvent-refined lubricating oil in the SAE-20-30 grade viscosity range. The oil was obtained from a mixed crude source as a pipe still distillate, solventextracted n-ith nitrobenzene, dewaxed n-ith methyl ethyl ketone,

and filtered through clay. Inspections of the oil are shown in

Table I

SEPARATION PROCEDURES

T h e lubricating oil charge stock n-as separated by means of

distillation, adsorption, and liquid thermal diffusion to yield 43

fractions containing concentrates of paraffin and cycloparaffin

hydrocarbons. The procedures are summarized in the block

diagram shown in Figure 1.

Starting with 5.5 liters of oil, having a molecular weight range

of from CIB to Cso, a series of distillations was made in a 20-stage

molecular still (11) a t 1-micron pressure. A total of 14 separate

equilibrium-type distillation runs and one batch distillation run

was required t o process the oil. The boiling range of the resulting