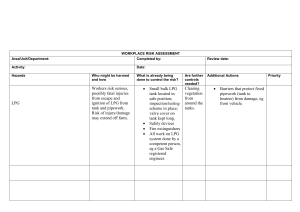

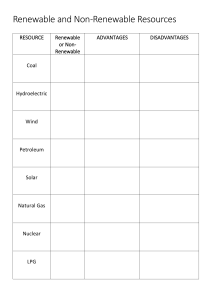

1 THE RED BOOK OF LPG ENGINEER Contents 2 Basics of LPG – Effects of Pressure and Temperature Flammability Other Hazards Vapor Pressures of Butane-Propane Mixtures Properties of Propane and Butane Properties of Hydrocarbon Gases Viscosity of Liquid LPG Flame Temperature and Flame Speed of Gases Mollier Chart of Propane Mollier Chart of Normal Butane Mollier Chart of Isobutane Calculating Motor Octane Number of a LPG Mixture Calculating Vapor Pressure of a LPG Mixture Unit Conversion Tables Filling Ratio of LPG Tanks LPG Tanks and Safety Tank Design Codes Certification Doesn’t Mean Same Quality Pressure Vessel Steels Periodic Inspection for LPG Tanks Codes and Standards for LPG Installations LPG Tank Accessories Safety Relief Valves for LPG LPG Level Gauges LPG Pumps LPG Compressors LPG Vaporizers LPG Regulators Vapour Condensing in LPG Piping Installation of LPG Storage Tanks Safety Separation Distances Cathodic Protection for Underground LPG Tanks 3 4 4 5 6 7 8 8 9 10 11 12 13 14 18 22 23 25 26 30 31 32 35 37 38 40 41 42 44 45 47 Basics of LPG – Effects of Pressure and Temperature 3 LP-Gas or LPG ... LPG or LPG stands for “Liquefied Petroleum Gas”. It is the term widely used to describe a family of light hydrocarbons called “gas liquids”. The most prominent members of this family are propane (C3H8) and butane (C4H10). Other members of the LP Gas family are ethane and pentane. These latter fuels have their own distinctive markets and are not further discussed here. C3H8 C4H10 kimya formülü biçimi Main source of LPG is natural gas; and crude oil-gas mixtures which come out oil or natural gas wells. The secondary supplies are the various refining processes at petroleum refineries. The term “liquefied gas” may seem a contradiction in terms since all things in nature are either a liquid, a solid or a gas. Yet, it is the unique character of LPG that makes it such a popular and widely used fuel. LPG at normal temperature and pressure is a gas. It changes to a liquid when subjected to moderate pressure or cooling. In liquid form the tank pressure is about twice the pressure in a normal truck tyre. The reason LPG is liquefied is to make it easy and efficient to transport and store. One unit of liquid has the same energy content as 270 units of gas. If left as a gas the container to hold the fuel would be 270 times larger than what is required as a liquid. In other words, LPG has density (compactness) for storage and transportation, yet all the benefits of a clean vaporous fuel when used. LPG usually consists of a mixture of propane and butane for standard heating and cooking purposes. Propane starts vaporizing above -45°C, so it is more versatile for general use. Butane starts vaporizing above -2°C and requires a propane/butane mixture in cold environments as it will not vaporize as readily as propane. LPG is also used in specialized applications that require a more rigorous specification. Such applications include food processing, aerosol propellants and automotive fuel (autogas). Inside a storage container, LPG exists both in liquid and vapor state. The LPG inside the container is boiling; somewhat similar to boiling water, but the boiling point of LPG is such low that it can boil at ambient temperatures. Heat is also required to boil LPG but generally, heat removed from ambient air is sufficient. When some vapor is consumed; a certain amount of liquid evaporates to fill the space and the pressure of the container doesn’t change. Although this is not an everyday practice, just imagine some vapor is added to the container by using a compressor. The vapor condenses, and the pressure of the container doesn’t change. When vapor is consumed at such a rate that exceeds the heat transfer rate from ambient; then heat is taken from the product itself. In this case, removal of vapor decreases the temperature inside the container, and the pressure decreases. The pressure inside the container is depending to the temperature. When temperature rises, more liquid evaporates and the pressure rises. When temperature falls, some vapor condenses and the pressure falls. Flammability Other Hazards LPG is highly flammable when mixed with air in the correct proportions. If the concentration of LPG vapor in the air is between 2% to 9.5%; then the mixture becomes flammable. 2% is the LEL (lower explosive limit) which means, below this limit the mixture is too lean to burn. 9.5% is the UEL (upper explosive limit) which means, above this limit the mixture is too rich to burn. LPG vapor is nearly twice dense than air. Therefore, when a leak occurs, the leaking gases tend to flow downwards and accumulate at ground level or somewhere below ground level, like sewage or drainage channels. However, when an LPG leak occurs it doesn’t homogenously mix with the surrounding air; some objects may limit or create air currents and flammable mixture may occur in some spots. LPG itself is odorless and colorless. An odorant which is added to LPG gives its characteristic, unpleasant odor and enables to detect and locate leaks. Since LPG vaporizes at low temperatures, skin contact with LPG liquid may contact frostbites. Effect of frostbite on body is similar to burns, and medical treatment is also the same as burns. LPG is not toxic; but is a simple asphyxiant. When a leak occurs in a confined space, LPG vapors will displace the air, prevent the livings inside from breathing oxygen and may cause deaths. LPG burning appliances shall be located in well ventilated places. If the appliance has a flue, this must be connected to a chimney. When these practices are neglected carbon monoxide poisoning may cause deaths. LPG water heaters inside bathrooms or flueless LPG stoves in living spaces poses a big risk of carbon monoxide poisoning. 4 Vapor Pressures of Butane-Propane Mixtures 5 Figure 1 Vapor Pressures of Butane-Propane Mixtures Properties of Propane and Butane FORMULA Boiling Point at 1.013 bars,°C 6 PROPANE N-BUTANE C3H8 C4H10 -42 -0,5 -43,7 +31,1 Relative density of gas (air=1.00) at 1.013 bars (14.696 psia), 15,6°C/15,6°C (60°F/60°F) 1,55 2,07 Relative density of liquid (water=1.00) at 15,6°C (60°F) 0,508 0,584 Weight, kg/m³ at 15,6°C lb/gal. at 60°F (**) 4,22 4,86 50,004 21,498 25,363 91,101 49,162 21,136 28,702 102,980 95,49 2,563 125,7 3,374 267 230 0,528 8,45 466 871 0,394 6,31 405 761 2,1 9,5 1,8 8,3 at 14.696 psi, °F Heat of combustion of liquid MJ/kg at 15,6°C Btu/lb at 60°F GJ/m³ at 15,6°C Btu/gal at 60°F (**) Heat of combustion of gas MJ/m³ at 1.013 bars, 15,6°C Btu/ft³ at 14.696 psia, 60°F Ratio of vapor volume at 1 bar (14.696 psi) and 15,6°C (60°F) to liquid volume at 15,6°C (60°F) Vapor volumes m³ vapor at 15,6°C/kg liquid at 15,6°C ft³ vapor at 60°F/lb liquid at 60°F Ignition temperature in air, °C (***) °F Limits of flammability, percentage of gas in air mixture at lower point at upper point * From API Technical Data Book-Petroleum Refining. The values are for pure propane and butane and do not necessarily apply to commercial products, which may have other hydrocarbons present in varying amounts. ** From GPSA Engineering Data Book *** From AGA Gas Engineers Handbook Table 1 Properties of Butane and Propane (*) Properties of Hydrocarbon Gases 7 Table 2 Properties of Several Hydrocarbon Gases Viscosity of Liquid LPG 8 Table 3 Viscosity of Hydrocarbon Gases in Saturated State Flame Temperature and Flame Speed of Gases Table 4 Flame Temperatures of Hydrocarbon Gases Mollier Chart of Propane 9 Figure 2 Mollier Chart of Propane Mollier Chart of Normal Butane 10 Figure 3 Mollier Chart of Normal Butane Mollier Chart of Isobutane 11 Figure 4 Mollier Chart of Isobutane Calculating Motor Octane Number of a LPG Mixture 12 When the composition of a LPG mixture is given; the motor octane number (MON) of this mixture can be calculated, following this procedure. The MON factors for hydrocarbon gases are given on “Table 5 : MON Factors for Hydrocarbon Gases”. The factors are given as separate columns; for molar, volumetric or mass percentage composition. Use the appropriate column with the composition data. For C2 and lighter hydrocarbons, use the MON factor for Propane, Table 5 MON Factors for Hydrocarbon Gases For C5 and heavier hydrocarbons, use the MON factor for N-Butane, Partial MON of a specific component in the mixture is calculated by multiplying [the percentage rate of component] x [MON factor] MON of the mixture is the sum of partial MON’s of all components. Sample Calculation: The MON of a LPG mixture, with the following mass percentage composition : Ethane : 2% Propane : 35% Iso-butane : 28% N-butane : 34% Pentane : 1% Total MON = (0,02 x 95,9) + (0,35 x 95,9) + (0,28 x 97,1) + (0,34 x 88,9) + (0,01 x 88,9) = 93,786 Since the composition of the mixture was given in % mass, the factors are taken from the appropriate column (% mass) of the table. Calculating Vapor Pressure of a LPG Mixture 13 When the composition of a LPG mixture is given; the vapor pressure of this mixture can be calculated, following this procedure. According to Dalton’s Law, the total pressure exerted by a mixture of gases is the sum of the partial pressures of the constituent gases. According to Raoult’s Law, the partial pressure exerted by the each component is the product of the vapor pressure of each component, at the existing temperature and the mol fraction of the component. A sample calculation, alongside with explanation is given on “Table 6 : Calculating Vapor Pressure of a Mixture”. Table 6 Calculating Vapor Pressure of a Mixture Unit Conversion Tables 14 15 16 17 Table 7 Unit Conversion Tables Filling Ratio of LPG Tanks 18 Heat input from the surrounding environment will both increase the liquid volume, and the vapor pressure inside the tank. Therefore, LPG cylinders and tanks shall be filled up to a limit. These limits can be determined by using the following tables: Table 8 : Maximum Filling Limit By Weight Table 9 : Maximum Filling Limit by Volume; which is prepared as 3 separate tables, for above ground tanks up to 4.5 m³ (1.200 gal.) for above ground tanks larger than 4.5 m³ (1.200 gal.) and for all underground storage tanks. Aboveground Containers Specific Gravity at 60o F (15.6o C) 0 to 1200 gal (0 to 4.5 m3) Total Water Capacity (%) > 1200 gal (> 4.5 m3) Total Water Capacity (%) Underground Containers All Water Capacities (%) 0.496 - 0.503 0.504 - 0.510 0.511 - 0.519 0.520 - 0.527 0.528 - 0.536 0.537 - 0.544 0.545 - 0.552 0.553 - 0.560 0.561 - 0.568 0.569 - 0.576 0.577 - 0.584 0.585 - 0.592 0.593 - 0.600 41 42 43 44 45 46 47 48 49 50 51 52 53 44 45 46 47 48 49 50 51 52 53 54 55 56 45 46 47 48 49 50 51 52 53 54 55 56 57 Table 8 Maximum Filling Limit by Weight 19 Maximum Permitted LP-Gas Volume (Percent of Total Container Volume): Aboveground Containers 0 to 1200 gal (0 to 4.5 m3) Specific Gravity C 0.496 to 0.503 0.504 to 0.510 0.511 to 0.519 0.520 to 0.527 0.528 to 0.536 0.537 to 0.544 0.545 to 0.552 0.553 to 0.560 0.561 to 0.568 0.569 to 0.576 0.577 to 0.584 0.585 to 0.592 0.593 to 0.600 –50 -45 -40 -35 -30 -45.6 -42.8 -40 -37.2 -34.4 70 71 71 71 72 71 72 72 72 73 72 73 73 73 74 73 73 74 74 75 74 74 75 75 76 75 75 75 76 76 75 76 76 77 77 77 77 78 78 78 78 78 79 79 79 79 79 79 80 80 79 80 80 80 81 79 80 80 80 81 80 80 81 81 81 -25 -20 -15 -10 -5 -31.5 -28.9 -26.1 -23.3 -20.6 72 73 73 74 74 73 74 74 75 75 74 75 75 76 76 75 76 76 76 77 76 76 77 77 78 77 77 77 78 78 77 78 78 79 79 79 79 80 80 80 80 80 80 81 81 80 81 81 81 82 81 81 82 82 82 81 81 82 82 82 82 82 83 83 83 0 5 10 15 20 -17.8 -15 -12.2 -9.4 -6.7 75 75 76 76 77 76 76 77 77 78 76 77 77 78 78 77 78 78 79 79 78 78 79 80 80 79 79 80 80 80 79 80 80 81 81 81 81 82 82 83 81 82 82 83 84 82 83 83 83 84 83 83 84 84 84 83 83 84 84 84 84 84 84 85 85 25 30 35 40* 45 -3.9 -1.1 1.7 4.4 7.8 77 78 78 79 80 78 79 79 80 80 79 79 80 81 81 80 80 81 81 82 80 81 81 82 82 81 81 82 82 83 82 82 83 83 84 83 83 84 84 85 84 84 85 85 85 84 85 85 86 86 85 85 86 86 87 85 85 86 86 87 85 86 86 87 87 50 55 60 65 70 10 12.8 15.6 18.3 21.1 80 81 82 82 83 81 82 82 83 84 82 82 83 84 84 82 83 84 84 85 83 84 84 85 85 83 84 85 85 86 84 85 85 86 86 85 86 86 87 87 86 86 87 87 88 86 87 87 88 88 87 87 88 88 89 87 87 88 88 89 88 88 88 89 89 75 80 85 90 95 23.9 26.7 29.4 32.2 35 84 85 85 86 87 85 85 86 87 88 85 86 87 87 88 85 86 87 88 88 86 87 88 88 89 86 87 88 88 89 87 87 88 89 89 88 88 89 90 90 88 89 89 90 91 89 89 90 90 91 89 90 90 91 91 89 90 90 91 91 90 90 91 91 92 100 105 110 115 120 37.8 40.4 43 46 49 88 89 90 91 92 89 89 90 91 92 89 90 91 92 93 89 90 91 92 93 89 90 91 92 93 90 90 91 92 93 90 91 92 92 93 91 91 92 93 93 91 92 92 93 94 92 92 93 93 94 92 92 93 94 94 92 92 93 94 94 92 93 93 94 94 125 130 51.5 54 93 94 94 95 94 95 94 95 94 95 94 95 94 95 94 95 94 95 94 95 95 95 95 95 95 95 Liquid Temperature O F O 20 Maximum Permitted LP-Gas Volume (Percent of Total Container Volume): Aboveground Containers 0 to 1200 gal (0 to 4.5 m3) Specific Gravity C 0.496 to 0.503 0.504 to 0.510 0.511 to 0.519 0.520 to 0.527 0.528 to 0.536 0.537 to 0.544 0.545 to 0.552 0.553 to 0.560 0.561 to 0.568 0.569 to 0.576 0.577 to 0.584 0.585 to 0.592 0.593 to 0.600 –50 -45 -40 -35 -30 -45.6 -42.8 -40 -37.2 -34.4 75 76 76 77 77 76 77 77 78 78 77 78 78 78 79 78 78 79 79 80 79 79 80 80 80 80 80 80 81 81 80 81 81 82 82 81 81 82 82 83 82 82 83 83 83 83 83 83 84 84 83 84 84 84 85 84 84 85 85 85 85 85 85 86 86 -25 -20 -15 -10 -5 -31.5 -28.9 -26.1 -23.3 -20.6 78 78 79 79 80 79 79 79 80 81 79 80 80 81 81 80 81 81 82 82 81 81 82 82 83 82 82 82 83 83 82 83 83 84 84 83 83 84 84 85 84 84 85 85 85 84 85 85 86 86 85 85 86 86 87 86 86 87 87 87 86 87 87 87 88 0 5 10 15 20 -17.8 -15 -12.2 -9.4 -6.7 80 81 81 82 82 81 82 82 83 83 82 82 83 83 84 82 83 83 84 85 83 84 84 85 85 84 84 85 85 86 84 85 85 86 86 85 86 86 87 87 86 86 87 87 88 86 87 87 88 88 87 87 88 88 89 88 88 88 89 89 88 89 89 90 90 25 30 35 40* 45 -3.9 -1.1 1.7 4.4 7.8 83 83 84 85 85 84 84 85 86 86 84 85 86 86 87 85 86 86 87 87 86 86 87 87 88 86 87 87 88 88 87 87 88 88 89 88 88 89 89 89 88 89 89 90 90 89 89 90 90 91 89 90 90 91 91 90 90 91 91 92 90 91 91 92 92 50 55 60 65 70 10 12.8 15.6 18.3 21.1 86 87 88 88 89 87 88 88 89 90 87 88 89 90 90 88 89 89 90 91 88 89 90 91 91 89 90 90 91 91 90 90 91 91 92 90 91 91 92 92 91 91 92 92 93 91 91 92 92 92 92 92 93 93 94 92 92 93 93 94 92 93 93 94 94 75 80 85 90 95 23.9 26.7 29.4 32.2 35 90 91 92 93 94 91 91 92 93 94 91 92 93 93 94 91 92 93 93 94 92 92 93 94 95 92 93 93 94 95 92 93 94 95 95 93 93 94 95 96 93 94 95 95 96 93 93 94 95 95 94 95 95 96 96 94 95 96 96 97 95 95 96 96 97 100 105 110 115 37.8 40.4 43 46 94 96 97 98 95 96 97 98 95 96 97 98 95 96 97 98 95 96 97 98 96 97 97 98 96 97 97 98 96 97 98 98 96 97 98 98 96 97 98 98 97 98 98 99 97 98 98 99 98 98 99 99 Liquid Temperature O F O 21 Maximum Permitted LP-Gas Volume (Percent of Total Container Volume): All Underground Containers Specific Gravity C 0.496 to 0.503 0.504 to 0.510 0.511 to 0.519 0.520 to 0.527 0.528 to 0.536 0.537 to 0.544 0.545 to 0.552 0.553 to 0.560 0.561 to 0.568 0.569 to 0.576 0.577 to 0.584 0.585 to 0.592 0.593 to 0.600 –50 -45 -40 -35 -30 -45.6 -42.8 -40 -37.2 -34.4 77 77 78 78 79 78 78 79 79 80 79 79 80 80 81 80 80 81 81 81 80 81 81 82 82 81 82 82 82 83 82 82 83 83 84 83 83 83 84 84 83 84 84 85 85 84 84 85 85 86 85 85 86 86 86 85 86 86 87 87 86 87 87 87 88 -25 -20 -15 -10 -5 -31.5 -28.9 -26.1 -23.3 -20.6 79 80 80 81 81 80 81 81 82 82 81 82 82 83 83 82 82 83 83 84 83 83 84 84 84 83 84 84 85 85 84 84 85 85 86 85 85 86 86 86 85 86 86 87 87 86 86 87 87 88 87 87 87 88 88 87 88 88 88 89 88 88 89 89 89 0 5 10 15 20 -17.8 -15 -12.2 -9.4 -6.7 82 82 83 84 84 83 83 84 84 85 84 84 85 85 86 84 85 85 86 86 85 85 86 86 87 85 86 86 87 88 86 87 87 88 88 87 87 88 88 89 87 88 88 89 89 88 88 89 89 90 89 89 90 90 90 89 90 90 91 91 90 90 91 91 91 25 30 35 40 45 -3.9 -1.1 1.7 4.4 7.8 85 85 86 87 87 86 86 87 87 88 86 87 87 88 89 87 87 88 88 89 87 88 88 89 90 88 89 89 90 90 89 89 90 90 91 89 90 90 91 91 90 90 91 91 92 90 91 91 92 92 91 91 92 92 93 91 92 92 93 93 92 92 93 93 94 50 55 60 65 70 10 12.8 15.6 18.3 21.1 88 89 90 90 91 89 89 90 91 91 89 90 91 91 92 90 91 91 92 93 90 91 92 92 93 91 91 92 93 93 91 92 92 93 94 92 92 93 94 94 92 93 93 94 94 93 93 94 94 95 93 94 94 95 95 94 94 95 95 96 94 95 95 96 96 75 80 85 90 95 23.9 26.7 29.4 32.2 35 92 93 94 95 96 93 93 94 95 96 93 94 95 95 96 93 94 95 95 96 94 94 95 96 97 94 95 95 96 97 94 95 96 96 97 95 95 96 97 97 95 96 96 97 98 95 96 97 97 98 96 96 97 98 98 96 97 97 98 98 97 97 98 98 99 100 105 37.8 40.4 97 98 97 98 97 98 97 98 97 98 98 98 98 98 98 99 98 99 99 99 99 99 99 99 99 99 Liquid Temperature O F O Table 9 Maximum Filling Limit by Volume LPG Tanks and Safety What’s the key factor for success of a business? Profitability, productivity, efficiency, sales, cash flow? If we’re talking about LPG business, the key factor, definitely is safety. A minor leak may conclude an explosion which will ruin a whole storage terminal, kill hundreds of people and demolish the neighboring buildings. The financial loss will be several times of the value of the whole terminal. Consider the legal compensation for deaths and injuries and the cost will be even higher. Any owner and operator of a LPG system is taking the risk several million Euros; and all this can happen within minutes. Some real data from several LPG accidents in the history, will show the importance of safety: The “Mexico City Bleve” is considered among the worst industrial disasters of 20th century. The LPG storage terminal of PEMEX has completely demolished within 5 hours. There were 600 dead and 7.000 injuries. Everything triggered by the failure of a 8” vapor line, and the first BLEVE has occurred just within 10 minutes. The “Feyzin Refinery Bleve” has occurred in 1966. A fire has began, involving 5 spherical LPG tanks, with 1.200 to 2.000 m³ capacities, and the result is 81 death, 130 injuries and losses exceeding 125 million US dollars. In “Viareggio Train Derailment” several LPG 22 tank wagons caught fire and the result is 32 death, 100 people left homeless and around 1.000 residents of the town were evacuated. Looking from the safety aspect, tanks are definitely the most important element among the various other components of a LPG system. Tanks are the elements which keep highly flammable and hazardous gases “under control”. A failure of a pump, carousel or compressor may stop the production for some time, and the operator will lose some money. However, a failure of a tank means “10 minutes to a disaster”. a tank failure means.. The tank may look “simple” but tank manufacturing is definitely a complex business. It requires the co-operation of several engineering disciplines. Design, material, welding, NDT’s, corrosion protective coating are important topics of tank manufacturing. Moreover, every single item and every step of the process shall be tested, verified and these shall be recorded to enable tracking. This is a multiple aspect work, which requires high technology, knowledge, experience and hard working. Tank Design Codes Think of a pressurized nitrogen buffer tank. Nitrogen is neither flammable, nor corrosive; but a pressurized nitrogen tank may expose serious health risks. Pressure, is a form of stored energy and the sudden release of this energy, as a result of vessel failure can be destructive or fatal. Consider this pressure is exerted by a liquefied gas, and the risk is higher. This gas is also flammable, which raises the risk even higher. ...era and the invention.. The risks involving pressure vessels were well known for more than 100 years. Since the beginning of industrialization era, the invention of steam machine, steam boilers have became common. At the same time, industrial accidents related with steam boilers has appeared, in some cases causing deaths of many people. The first examples of pressure vessel design codes were prepared in those days. Experience from several countries, many installations and millions of different application has distilled and forged into the design codes; which form the basis for design, manufacturing, operating, repairing and maintaining pressure vessels. Two worldwide adopted and widely accepted design code throughout LPG industry are, ASME Boiler and Pressure Vessels Code (BPVC) of USA; and the Pressure Equipments Directive (PED) of European Union. The reason 23 may be the leadership of USA in oil industry and the leadership of Germany in chemical industry. ASME BPVC has organized in Sections on different topics, e.g. Section III includes the rules for nuclear facility components and Section X is for fiber reinforced plastic vessels. The whole Code is more than 16.000 pages. Section VIII is the section which is most related to LPG tanks. Section VIII, Rules for Construction of Pressure Vessels consists of three divisions. Division 1 is general rules, Division 2 is alternative rules. Division 3, which gives alternative rules for pressures above 10.000 psi (690 bar) is out of our scope. PED of Europe is a legislative framework which is obligatory throughout the EU, covering the equipment subject to a pressure hazard. This directive doesn’t include as much details as BPVC, and the “harmonized standards” takes the role here. Some examples to harmonized standards are AD Merkblatt of Germany, BS5500 of UK, and CODAP of France. In fact, these standards are older than PED and have dominated the industry many years before the appearance of PED. AD Merkblatt is the most popular among those and others still popular in their home country and in the countries influenced by those. There are not major differences between the harmonized standards, since they are conforming and harmonized to the same framework directive. However there may be some minor differentiation in details, between AD Merkblatt, BS5500 and CODAP. However, ASME BPVC and PED have different approach. These can be considered as are two different ways, going to the same destination. The materials, methods, procedures and certification of those are different for ASME and PED. The difference in the approaches of PED, BPVC Division 1, and BPVC Division 2 are given on Table 10 : Brief Comparison of Design Codes. An important regulation for tank vehicles and vehicle mounted tanks, especially when the vehicle will be used for transportation inside the European Union is ADR. ADR is the European Agreement Concerning the International Carriage of Dangerous Goods by Road. The recent version covers more than 1.000 pages. It is a mandatory regulation, involving both the technical and operational aspects of transportation of dangerous goods. ADR’s scope includes any type of dangerous goods, 24 ranging from nuclear wastes to cosmetic products. ADR has some clauses relating to the design, manufacturing, installation, labeling, periodic maintenance and re-qualification of LPG cylinders, vehicle mounted tanks, ISO tank containers and similar. The requirements of ADR can be summarized as follows; even the smallest part or detail, like the installation method of a bumper, is required to depend on an engineering design, to be tested, approved and certified by an authority. Brief Comparison of Design Codes PED and European Harmonized Standards Wall thickness of tanks are smaller; light tanks, savings in materials More comprehensive engineering, more detail in tests, higher cost of engineering Long term reliability depend on strict quality management and maintenance ASME Division 1 Wall thickness of tanks are bigger, heavier tanks, higher cost of materials Basic engineering, simpler tests, lower cost of engineering Long term reliabilitiy depend on bigger safety factors ASME Division 2 ASME’s interpretation of European approach. Wall thickness of tanks are close to PED design; light tanks, savings in materials More comprehensive engineering, more detail in tests, higher cost of engineering Less certified manufacturer, less manufacturing experience Table 10 Brief Comparison of Design Codes Certification Doesn’t Mean Same Quality A LPG tank must be designed and manufactured according to an applicable design code. This is the “Step 1” of the quality ladder. However, there can be a significant difference in safety between two LPG tanks designed and manufactured according to the same design code. Let’s see how and why: - The buyer shall pay attention to the coverage and details of the certificate. The paperwork of “full certification” may be quite similar in look to “certification of surveillance to hydrostatic test”. ten thousands of - A design code, and the other codes, pages of information. standards and regulations it refers makes ten thousands of pages information. Google the technical forums on the web, and you’ll see thousands of topics on design codes, where engineers discussing “how to interpret the Clause X of the code”. Here “specific experience” matters. - The information given in the design code is open to anybody who buys and reads it. Recent technological developments and innovations, patented technologies and processes, and similar information which pave the road to the “excellence” don’t take place in design codes. - Design codes rather determine the “minimum requirements for safety” than the “requirements for highest quality”. The features which create better safety, higher quality are above than the code requirements. 25 Pressure Vessel Steels European Standard “EN 10028-3 : Flat products made of steels for pressure purposes. Weldable fine grain steels, normalized” covers a range of weldable, fine grain steels supplied in the normalized condition and intended for pressure purposes. This is a very common pressure vessel material when the vessel design and manufacturing is made according to Pressure Equipment Directive and harmonized European Standards. It has three steel grades; P275, P355, and P460 which indicate each grade’s minimum yield strength in MPa (for plates 16 mm thick and below). These are further subdivided on the basis of impact testing (transverse) temperature: N and NH indicate impact testing at -20° C or above, 26 NL1 at -40° C or above, and NL2 at -50° C or above. Plates to EN 10028-3 are widely specified in the manufacturing of pressure vessels throughout Europe and the standard is regularly seen in other parts of the world where equipment has been originally designed by a European company. The designation EN 10028-3 P355NL1 shows that P : This is a grade of steel for pressure purposes 355 : Minimum yield strength is 355 MPa NL1 : Impact tested in the transverse direction at -40° C The designation EN 10028-3 P460N shows that P : This is a grade of steel for pressure purposes 460 : Minimum yield strength is 460 MPa N : Impact tested in the transverse direction at -20° C 27 Chemical Composition of Steels According to EN 10028-3 hizalama Table 11 Chemical Composition of Steels According to EN 10028-3 28 US standard “ASTM A516 : Standard Specification for Pressure Vessel Plates, Carbon Steel, for Moderate- and LowerTemperature Service” covers carbon steel plates intended primarily for service in welded pressure vessels, where improved notch toughness is important. This also is a very common pressure vessel material when the design and manufacturing is made according to ASME Boiler and Pressure Vessel Code. Chemical Composition of Steels According to ASTM/ASME According to different strength levels, the plates are available in four grades; Grade 55, 60, 65, and 70. The steel shall be killed and shall conform to fine austenitic grain size requirements. The mechanical properties such as tensile strength, yield strength, and elongation shall be determined by a tension test for the plates. köşelerdeki yeşil noktalar Table 12 Chemical Composition of ASTM/ASME A516 Steels 29 Mechanical Properties of Steels According to ASTM/ASME A516 Table 13 Mechanical Properties of ASTM/ASME A516 Steels Periodic Inspection for LPG Tanks 30 Isısan recommends the following periodical inspection for LPG storage tanks. However local codes, regulations and standards may require further tests and controls, or more frequent checks. Isısan recommends to have LPG tanks re-qualified by a notified body, following the test procedure given by this notified body and hiring NDT services when necessary, every 10 years. Period Recommended Inspection, Test and Controls 1 year • • • • • • External visual inspection Leak test of flanged and screwed connections Check temperature, pressure and level gauges are operating Check excess flow valves, emergency shut off valves and similar are operating Check cathodic protection is functional, for underground storage tanks. Possible leaks, malfunctioning equipment, paint defects shall be fixed 5 years • • Testing safety relief valves Check start to discharge pressure and tight closure of valve when pressure is released. Check for visual corrosion and defects on valve body and internals. Safety relief valves shall be renewed when necessary 10 years • Re-qualification by a notified body, following their advices and hiring NDT services when necessary. The following inspection and tests are must, further shall be determined by the notified body according to the test results and operating conditions: Internal visual inspection Corrosion mapping by measuring plate thickness (ultrasonic measurement) Hydrostatic pressure test at 1.3 times of design pressure • • • Codes and Standards for LPG Installations NFPA 58, Liquefied Petroleum Gas Code, prepared and published by National Fire Protection Association of USA is a well respected and worldwide accepted guideline for LPG industry. This is a code, not a standard and the diffence is, a code is adopted by governmental bodies and enforced by law. This is a comprehensive and useful guide, which will answer most questions. NFPA 58 also formed a base on many local standards. However, the rules defined by local authorities, -local codes, regulations and standards- may differ from NFPA 58. In this case, the owner shall consider to conform the strictest rule, which will be the safe choice. aynı şeyi yukarıda da yazmışım. The difference between a code and a standard is; code is adopted by one or more governmental bodies and enforced by law. A list of codes, standards and regulations which may be helpful to LPG engineers are given as follows. ASME Boiler and Pressure Vessel Code AD 2000 Code ADR European Agreement concerning the International Carriage of Dangerous Goods by Road EEMUA 190 Guide for the Design, Construction and Use of Mounded Horizontal Cylindrical Steel Vessels for Pressurized Storage of LPG at Ambient Temperatures API 2510 Design and Construction of LPG Installations API 2510A Fire-Protection Considerations for the Design and Operation of Liquefied Petroleum Gas (LPG) Storage Facilities Model Code of Safe Practice Part 9: Liquefied Petroleum Gas. Vol.1. Large bulk pressure storage and refrigerated LPG; by Energy Institute of UK Codes of Practice(s) published by UK LPG EN 12493 LPG equipment and accessories - Welded steel tanks for liquefied petroleum gas (LPG) - Road tankers design and manufacture EN 12252 LPG equipment and accessories - Equipping of LPG road tankers; German version EN 12252 ... LPG road tankers. EN 1442 Transportable refillable welded steel cylinders for LPG - Design and construction EN 1440 Periodic inspection of transportable refillable LPG cylinders EN 14678-1, 2 and 3 LPG automotive filling stations 31 LPG Tank Accessories Table 14 : The mandatory tank accessories determined by the recent version of NFPA 58, published in 2011, are given on Table 11 : Tank Appurtenances According to NFPA 58. One can easily see that the simpler forms of safety equipment are for the smallest tank (lower risk), and vapor connections (less amount of leak, lower risk). The basic approach is to establish more than one, independent, reliable means of shutoff. There are several options in the market, which have certain strength and weaknesses when compared with the other. First of all, the design engineer must always keep in mind that, only a manual shut-off valve can offer a “positive shutoff”. Excess flow valves, back flow check valves and internal valves are very helpful safety equipment, but may not offer complete sealing. In any case, a manual shutoff valve must be installed in series to these equipment. It is inevitable to do some repairs or maintenance on a LPG system, while isolating this part from where there’s LPG. In this case, there must be at least two means of separation equipment in series; and preferably one of those must be a blind flange or similar. There are many instances that a valve seal, which seem perfect before beginning the there's yerine contains 32 for the small tanks and vapor connections; where the amount of possible leak, therefore the risk is small repair works, has failed during these works and resulted a fire. The reason which leads this failure may be an increase of temperature, or pressure, or mechanical shocks during the repair, welding, hydrostatic test works. When not possible, the safest option, complete decanting and gas-freeing shall be preferred. Restricted orifice is the simplest and cheapest form of safety precaution; among those referred in “Table 14 : Tank Appurtenances According to NFPA 58”. It is definitely fail-safe. However, its application is only limited to small LPG flows. An excess flow valve is a purely mechanical device. It shuts off automatically when the gas flow exceeds a certain rate. When a LPG line has ruptures or breaks off, there’ll be a sudden increase of flow. Excess flow valves enables flow in both direction, but controls the flow just in one direction. However they cannot offer a perfect sealing; there’s always a small leak from an already shut off” excess flow valve. Several sizes and models of excess flow valves are available; which are designed for installation inside the tank, onto the tank nozzles and onto the pipe lines. A backflow check valve, also a purely mechanical device, allows flow in only one direction. This can be used at inlet connections of LPG tanks, which will prevent any flow from the tank to outside. They offer better sealing than excess flow valves, especially the double check models. It is allowed to use double check valves as a filler valve for small LPG tanks. These incorporate both a metal-to-metal seat check and a soft seat check; combining the advantages of both. Restricted... yeni paragraf olarak başlasın. increase of flow, which will trigger the closure of excess flow valve. "already shut off" veya tırnak işaretini tümden kaldıralım. Designers must consider that excess flow valves cannot offer ... 33 Table 14 Tank Appurtenances According to NFPA 58 34 Excess flow valves and check valves for LPG tank service are designed so that, external damages will not hamper their function. The valve either completely remains inside the tank; or has weakened shear points. An external force will cause the valve to shear from this point, keeping the critical sealing parts in place. Emergency shut-off valves are remote actuated shut-off valves which can be installed onto a piping. These may be actuated via cables, hydraulic or pneumatic operation; and can be connected to a control system. Emergency shut-off valves may be connected to the fire alarm system, or gas leak detection system for automatic closure. Internal valves are equipment which “almost completely” remain inside the tank when Manual valves also have different models, fitted. By this way, the valve is protected any of which offers certain advantages on from any type of external force, blast, fire, or the others. Quarter turn ball valves offer good similar. Internal valves may offer automatic performance in most conditions. They have closure function in cases of excess flow, very small resistance to flow, therefore the best fire or remote operation. These may be choice for pump inlet lines. There are fire-safe operated mechanically via cables, hydraulic models of ball valves, which are designed to or pneumatic actuators. Internal valves may offer sealing under fire; which is an important also function as an integral part of a control safety feature. Fire safe valves have additional system. For example, the internal valves on a metal-to-metal seats which function when the LPG tanker truck can be set to automatically soft seals are destroyed by fire. close when the parking brake is released. For A fire safe valve has example, internal valves may be connected to additional.. a fire detection system, or gas leak detection An other example is... system for automatic closure. Internal valves are robust equipment, but eventually will need some repair. This can only be done after the tank is completely decanted. An other disadvantage is, they often require modified flanges/coupling for installation; which means an internal valve may not fit on an existing LPG tank. Safety Relief Valves for LPG Safety relief valves are essential safety equipment for LPG installations. Any closed system containing liquid LPG is prone to the risk of high pressures. Heat transfer from the surrounding will increase the pressure to such levels that the equipment will fail, releasing highly flammable vapors to the environment. Safety relief valve is an effective, controlled means of relieving dangerous pressure and preventing BLEVE. 35 Pressure relief valves are also mandatory for underground and mounded tanks, however the relief capacity shall be 30% of an above ground tank. Safety relief valves must be “spring loaded”, however pilot operated models with a springloaded pilot are allowed for tanks with > 151 m³ capacity. The safety relief valves suitable for LPG service are pop-action, or full-lift types, which means that the valve opens fully at once, not gradually or proportional to the rate of pressure increase. The “start to leak” setting of the pressure relief valve shall be 100% of the container pressure BLEVE is the abbreviation of “Boiling Vapor Expanding Liquid Explosion”. This is the most dangerous fire accident which may happen to a LPG tank. The fire in contact with the tank makes the liquid to boil, increasing the pressure and at the same time heating up the tank shell. Increasing temperature weakens the tank shell, and the failure of the tank results the whole contents to release to the environment, a massive explosive gas cloud and a heavy explosion. The safety relief valves of a LPG storage tank shall be sized and selected considering the fire conditions. An empirical formula, which is based on some experimental data in the past, which is used for sizing safety relief valves is as follows : F = 53,632 x A0,82 Where: F = Discharge flow rate (SCFM air) A = Total outside surface area of the container (ft²) Figure 5 BLEVE 36 rating. The manufacturer of the relief valve has a “plus” tolerance, not exceeding 10% of this set pressure, marked on the valve. Safety relief valves must be so installed that to relieve vapors. No block valves are allowed at installation, except the specially made SRV manifolds, which prevents blocking of all SRV’s. A common industrial practice, even further the code requirements, is to have some extra, backup relieving capacity. Depending on the size of tank, the tank is preferably equipped with: 2 safety relief valves, one of which is spare (100% backup) 3 or 4 safety relief valves, one of which is spare (50% or 33% backup, accordingly) The outlets of SRV’s shall piped vertically upward for tanks > 7,6 m³. Rain caps and/or drain holes must be considered to protect the SRV against accumulating water. For underground storage tanks, the height of this piping shall be min. 2,1 meters (7 feets). Anything which will limit the discharge, are not allowed on this pipe, e.g. bends, obstructions, tight caps, etc. Safety relief valves shall be checked and tested every 5 years; and shall be replaced at 10 years intervals. During inspection, the valve shall be checked visually against defects and corrosion, then the valve shall be connected to a suitable test bench, including a calibrated pressure gauge. At the test bench some pressure will gradually applied to the valve to determine the “start to leak” pressure. The “start to leak” pressure shall be within 100% to 110% of the pressure valve rating; and the SRV will close again, with no leak after the pressure is released. Every piece of piping or hose, in which liquid LPG may be trapped between two isolation valves shall be equipped with a hydrostatic relief valve. Even looks similar, hydrostatic relief valves are different types, which are suitable to discharge liquid LPG. LPG Level Gauges 37 Overfilling is an important risk for LPG tanks; therefore LPG tanks shall be equipped with more than one level gauge. The mechanical movement of the internal parts are conveyed to the outer part by using a magnetic piece. Fixed liquid level gauge, which is not more than a bleeder valve/internal piping combination is simplest and most reliable form of level checking. It can be installed on above ground or underground tanks, even applicable to smallest sizes. A combination of fixed liquid level gauges can be installed to check several levels. The float follows the changes in liquid level and this movement mechanically conveyed to the dial, which shows the level as % full. Advantages of float gauge are: - Requires no source of energy - Can be used on both underground and above ground tanks. Can be installed at the centre or on the top of the tank A rotary level gauge is also a simple and reliable mechanical device; consisting of a rotary hollow tube dipping inside the tank, a bleeder valve connected on the other end of this tube outside - Doesn’t require operator access the tank, and a dial to see the measured level. The dial is prepared to show % full of the tank. - Can be incorporated with a level transmitter, The operator loosens the bleeder valve then enabling remote reading or the level signal can be slowly rotates the handle, while the end of tube further processed as an input to a control system. inside the tank moves from top of tank, slowly There are several types of electronic level to the bottom. While rotating the handle, the There are'dan operator checks the level at which vapor flow itibaren yeni paragraf replaces to liquid. Rotary level gauges can be installed only on above ground tanks. They’ll need a platform, ladder or similar to enable operator access. Magnetic float gauges or simply float gauges consist of two pieces. The float-arm assembly which works inside the tank and the dial assembly which remains outside the tank. Magnetic.. yeni paragraf gauges for LPG installations; but LPG is a hard application. Low cost types don’t work properly with LPG, and the models suitable for LPG application are generally more expensive. This makes electronic level gauges feasible for big size tanks or specific applications. For tanks up to 10 m³ there are filler valves offering automatic over fill protection, with a float operated mechanism. This can be done for bigger sizes, using an electric signal, an actuated valve and the control system. A pneumatic actuated ball valve works fine for this application. The level signal can be taken from the float gauge, however it’s a better approach to use a separate level detector for overfill protection. Vibrating fork type level detectors offer a good performance/cost ratio for overfill protection applications. a control circuit Figure 6 Fixed Level (left) and Rotary Level (right) Gauges LPG Pumps 38 Pumps are essential elements of LPG systems, for liquid transfer in various applications. The main challenge is; LPG is a fluid on saturated state. This means, a slight difference of temperature, a slight pressure drop, or a slight resistance to flow will cause the liquid to evaporate rapidly. flow rate combinations. The performance curve of a centrifugal pump is such that, it can produce higher pressure at low flow, and can handle higher flow rates at low differential pressures. When the pump rpm is increased, both the flow rate and the outlet pressure increases. Principally, pumps can only handle liquids and not vapors. The most important feature of LPG pumps is to handle some vapor when mixed with liquid. It is essential for pump operation and can be achieved by some special features. There are several models of LPG pumps, but mainly divided into two groups. Cylinder filling or autogas dispensing operations require very high differential pressure. The tank being filled is so small, and the filling time should be limited. Moreover, the flow must be forced through narrow openings inside the cylinder valve. The inside cross section of the multivalve on an autogas tank is not much bigger. The best option to fulfill this requirements is the multi stage centrifugal pump. A variant of this model is the side channel pump with open, radial blade impellers which can handle some vapor with liquid and called as “self priming”. These pumps often have a centrifugal first stage, in order to reduce NPSH (net positive suction head) requirement. Positive displacement pumps, in which the liquid is encapsulated in a volume and forced to move with the movement of this volume. These may be reciprocating (piston), or rotary (vane or gear pumps). In positive displacement pumps, the outlet pressure and flow rate remains nearly constant, independent of the inlet and outlet conditions. When the pump rpm is increased, the outlet pressure doesn’t change but the flow rate increases. Dynamic pumps are machines in which the liquid gains a speed (kinetic energy), then this is converted to pressure (potential energy). In dynamic pumps, the outlet pressure and flow rate depends on the inlet and outlet conditions. Same pump can operate at different pressure/ Regenerative turbine pumps, which are also a member of centrifugal pumps range, can achieve such high differential pressures in a single stage design. They have a single impeller, with open radial blades. These models can be preferred for small scale cylinder filling applications, autogas dispensing and vaporizer feeding. Gear pumps are used in some truck mounted applications for bulk transfer; but are not common. The most common truck pumps are of rotary vane design. These offer the high flow rate, compact design, low to moderate pressure and low rpm (since driven by the truck engine, running at idle speed) advantages to bulk delivery application. The physical contact of rotating parts inside these pumps create some wear, however these parts have a quite long service life and can be replaced at reasonable cost. Although not common, LPG tanks are installed on the roofs of high rise buildings (higher than 100 m.) in some countries. In this case, a pump with higher differential pressure is required for bulk deliveries. Multistage, side channel pumps are the solution for these applications. these requirements 39 Net positive suction head-required (NPSHR) is the minimum inlet pressure required at the pump inlet to avoid cavitation. Net positive suction headavailable (NPSHA) by the system must be greater than the required, for efficient pump operation. In order to achieve this, the pressure drop at the inlet piping of the pump must be kept to minimum; by following these guidelines: - the inlet piping shall be kept as short as possible - bends and reducers shall be avoided inlet strainer - stainer shall be one or two size bigger - full bore ball valves shall be preferred - the inlet line shall be so designed that the flow velocity is under 1 m/s Figure 7 Operating Principle of Regenerative Turbine Pumps LPG Compressors 40 Compressors are machines which transfer gases and vapors, however liquefied gases may also be transferred by using a compressor. Cavitation is a big problem in pump operation; and in some liquid transfer applications, the pump inlet conditions may be too poor for an efficient operation. In such cases, using a compressor may be more efficient for liquid transfer. An other advantage of compressor over pump is, the ability to transfer vapors. This is a must while gas freeing a tank before any repair. The vapors in the tank may not simply vent into the atmosphere, but must be transferred into an vented other storage tank. In such trading applications where the buyer already pays for the that the Compressor is by far the best choice while evacuating a LPG transportation tank after a road accident; and transferring the liquid and vapors into a safe tank, during haz-mat operations. In evacuating transport tanks, using a compressor is more efficient than using a pump, and is generally the preferred method. During this process, the liquid level continuously drops and cavitation begins below a certain level. However, the compressor may easily transfer all liquid, after that even the product in vapor phase. Vapor recovery takes a long time, and isn’t feasible unless there is a financial loss. Figure 8 Liquid Transfer by Using a Compressor How liquid is transferred by using a compressor is shown on “Figure 10 : Liquid Transfer by Using a Compressor”. Please note, that the direction of flow for liquid is, reverse of the direction of flow for vapor. The compressor reduces the pressure of the tank being filled, and increases the one being evacuated; thus creating a pressure differential between two tanks. This pressure differential drives the liquid flow. How vapor recovery is made, is shown on “Figure 11 : Vapor Recovery.” The four way valve, back flow check valve and isolation valves on the piping enables quick swift from liquid transfer to vapor recovery. As shown on the figure, the vapors are introduced into the liquid phase of the tank. The compression process adds some heat to the compressed gas, which is useful during liquid transfer. However, cooling the vapor is necessary during vapor recovery, otherwise the tank pressure will increase too high. The hot vapor cools down while passing through the liquid. In case of using a pump for this process Figure 9 Vapor Recovery LPG Vaporizers LPG is stored in liquid state, and needs to be evaporated before use. Evaporation either occurs naturally, by absorbing heat from the surroundings, or heat should be applied to LPG. Natural vaporization, which depends on the heat taken from the surrounding environment may work for domestic applications and in moderate climates. Applications with high gas demand, and installations at cold environment will require vaporizers. Vaporizers are classified according to the medium which gives heat energy. Direct fired vaporizers burn LPG directly to obtain heat. They’ve high performance/cost ratio and compact, ready to use equipment. They don’t need electricity, therefore applicable for site, temporary or portable applications where electricity is not available. Electric operated models are generally used for 25 to 300 kgs/hour LPG capacity. They’re compact, safe and generally preferred for domestic, commercial and light industrial applications. For higher demands; there are hot water or steam operated models. These require an external generator of steam or hot water, therefore either a separate boiler shall be installed or the vaporizer shall be connected to an existing boiler. These 41 models are cost effective when there’s some extra boiler capacity. In general, small scale installations rely on a single vaporizer; however in most cases two vaporizers are installed in parallel. In this case, one of the vaporizers will have enough capacity to feed the whole system and the other will serve as a backup. Different combinations with 3 or 4 vaporizers in parallel, one of which is serving as backup, are also possible. LPG Regulators Regulators are the essential equipment for bulk installations, which reduces the gas pressure and maintains a constant level of pressure for proper operation of boilers, burners, stoves and similar gas consuming appliances. Typically a gas stove or burner requires a gas pressure of 11 in. water column; which is nearly equal to 300 mm. water column or 30 milibars. The regulator should maintain this pressure regardless of the changes in gas flow rate; whether a small pilot or several appliances are operative. It must also protect the appliances from excessive pressure, especially when a faulty condition exists. Regulator selection for a specific application needs to analyze 42 only perform well under right conditions. A drop of inlet pressure will seriously decrease a regulator’s capacity. Although single regulator may be used to reduce container pressure directly to the pressure which appliance needs; two stage regulation has many advantages. In two stage regulation; first stage regulator is mounted on the storage tank. For high capacity applications, first stage regulator will be installed at vaporizer outlet. The outlet pressure for first stage regulators may be up to 2 bar, but typically this value is 10 psi, which equals to 700 mbar. Then the pressure is reduced down to 30 mbar at the second stage regulator. Several advantages of two stage regulation are: -since the outlet pressure of first stage regulator is high, the pressure can compensate pressure losses in pipe; therefore small pipe sizes may be used. - second stage regulator is closer to the appliance, and pressure losses in second stage piping don’t disturb the performance of appliances. - more uniform appliance pressure is obtained - when high pressure gas expands to a lower pressure, a chilling effect occurs inside the - inlet pressure and variations due to climatic changes, etc. - outlet pressure demand, - expected gas flow - pressure losses in piping between the regulator and the appliance Figure 12 : Regulator Performance Diagram shows the effects of inlet pressure and gas flow to regulator performance. A regulator may Figure 10 Regulator Performance Diagram 43 regulators. In case moisture is present in the LPG; this chilling effect may cause the regulator to freeze-up and be clogged. Since pressure difference is not so high as in single stage regulation, two stage regulation greatly reduces the risk of freeze-ups. - in general, capacity range of first stage regulators are very wide. They allow to handle capacity increases simply adding second stage regulators. An important, additional feature of the regulator is, to prevent excess pressure in the low pressure side. A relief valve is integrated in the regulators, which, in such case, relieves the excess pressure from the vent hole. Regulators have adjusting screws and/or different spring alternatives which allow to adjust the outlet pressures within a range, to satisfy different requirements. - second stage regulator is closer to the appliance, and pressure losses in second stage piping don’t disturb the performance of appliances. - more uniform appliance pressure is obtained - when high pressure gas expands to a lower pressure, a chilling effect occurs inside the regulators. In case moisture is present in the LPG; this chilling effect may cause the regulator to freeze-up and be clogged. Since pressure difference is not so high like single stage regulation, two stage regulation greatly reduces the risk of freeze-ups. - in general, capacity range of first stage regulators are very wide. They allow to handle capacity increases simply adding second stage regulators. bu bölüm yukarının tekrarı olmuş. Figure 11 Two stage regulation Vapour Condensing in LPG Piping 44 In general, 5 to 15 psi ( 350 mbar to 1 bar) is the normal range of pressure setting for the first stage regulators. The second stage regulators will offer greater capacity when higher first stage pressures are selected. However; if the intermediate pressure is high enough, the gas may condense in the piping, especially when the temperature is low. Butane, or butane rich mixtures are more prone to condensation and such risk begins for propane at temperatures below -25 oC. Vapour condensation will create safety and operational issues, and therefore shall be avoided. Selecting a first stage outlet pressure below the values given on Table 15 : Dew Point Pressures for LPG Mixtures, will overcome the vapor condensation problem. Table 15 Dew Point Pressures for LPG Mixtures Installation of LPG Storage Tanks Safety Separation Distances LPG tanks shall be fixed on concrete foundations. The dimensions of concrete columns shall fit to the size of tank. The foundation design shall be made by a qualified civil engineer, considering both the normal operating conditions, and the extra weight during hydrostatic testing of the tank. The weight of tank accessories, ladders, platforms, valves, instrumentation and piping; snow and wind loads shall be taken into account. In underground tank applications, the customer shall prepare the tank basin and tank foundation. The size of the basin shall fit to the size of tank. The concrete foundation design shall be made by a qualified civil engineer, considering normal operating conditions; and the anchorage to prevent floating. Since LPG is less dense than water, heavy rains may cause floating of the tank. The tank foundation must be heavy and the anchorages must be strong enough to prevent floating. The tank basin may be surrounded by a concrete wall. In this case, necessary openings shall be made to ensure drainage of the tank basin. The location and installation of LPG storage tanks shall conform to local regulations and standards. LPG storage tanks must be separated from potential sources of fire, or important buildings and structures which will be protected against fire. The minimum safety 45 separation distances, according to NFPA 58 are given on “Table 16 : Safety Separation Distances for LPG Tanks”. 3. The line of adjoining property 4. Main roads 5. Adjacent LPG storage tanks The user must also conform to the local regulations and standards. LPG storage tanks shall be installed outdoors. Tanks shall not be stacked one above another. For above ground tanks, safety separation distances are measured from the tank shell. For underground tanks, the safety separation distances are measured from any potential point of LPG discharge; like safety relief valve, LPG filling connection, and/or liquid relieving type level indicators. The recent version implies to The safety separation distance between the LPG storage tank and the following shall be at least the figures given on “Table 16 : Safety Separation Distances for LPG Tanks”: The earlier versions of NFPA 58 were 1. An important building implying to measure 2. Group of buildings safety separation distances for underground tanks measure from the tank shell, also for underground and mounded tanks Table 16 Safety Separation Distances for LPG Tanks 46 The distance from any part of an underground tank to any building or the line of an adjoining property shall be at least 3 m. There should be minimum 3 m. distance between the LPG tank and a potential source of ignition, any opening to the buildings, and openings to direct-vent appliances, mechanical air intakes, sewer and drainage channels. Electric devices shall be considered as a potential source of ignition. Loose or piled combustible material, such as weed or long, dry grass shall be separated 3 m. from the tank. To ensure it, rounded pebbles may be laid along the surrounding of tank. The horizontal distance between LPG tanks above the ground and tanks that contain liquids with a flash point lower than 90°C, should be at least 6 m. No part of any tank above the ground should ever be located on a site that would be horizontally 2 m away from an energy transmission line with nominal voltage between 0,6 – 10,5 kW; and 7,5 m away from one with nominal voltage greater than 10,5 kW, from all directions. Multiple underground tanks with a capacity of 1 m³ or higher, should be located such that cranes and similar machines can easily access their ends and edges. For a single above ground tank, with less than 5 m³ water capacity; the safety separation distance could be reduced up to 3 m. In order to consider this as a single tank, its distance from any tank with a capacity greater than 1 m³, should be at least 7,5 m. In applying the distance between buildings and LPG tanks of 125-gal (0,5-m³ or more water capacity, a minimum of 50 percent of this horizontal distance shall also apply to all portions of the building that project more than 5 ft (1,5 m) from the building wall and that are higher than the relief valve discharge outlet. This horizontal distance shall be measured from a point determined by projecting the outside edge of such overhanging structure vertically downward to grade or other level upon which the container is installed. This is not applicable to installations in which overhanging structure is 15 m or more above the relief valve discharge outlet. Neighboring storage of other flammable or hazardous materials, will result an increased risk. Refer to regulations and standards, or make a risk analysis in such cases. The above ground tanks shall be grounded and the performance of grounding shall be checked annually. The resistance of the grounding circuit (system to ground) shall be less than 5 Ohm. Cathodic Protection for Underground LPG Tanks Cathodic protection is compulsory for underground tanks. Otherwise, any possible scratches or small defects of paint may cause severe corrosion. Several methods for cathodic protection are applicable, however most common is the method of galvanic anode. The application of cathode protection should be done as follows: 47 The performance of cathodic protection system shall be checked annually. The potential difference between the reference electrode, the tank itself, every single anode, and the complete system shall be measured and evaluated, according to Table 17 : Performance Checking of Cathodic Protection Systems. cathodic • The appropriate size and number of anodes are determined according to the tank size and soil conditions. • The anodes shall be placed vertically at the center-line of the tank, roughly 1,5 meter away from the tank shell, and evenly distributed around the tank. Measurement • The connecting cable should not be used for the purpose of dangling the anode bag into the hole. • Each anode bag shall be soaked with 20-25 lt. of water. Nominal Value Comments / Troubleshooting -600 mV < Vref < -350 mV Vref > -350 mV : Paint Defect Vref < -600 mV : Measurement Error Tank Connected to Anodes -1100 mV < Vref < -650 mV Vref > -650 mV : Replace Worn-out Anodes Vref < -1100 mV : Disconnect Excessive Anodes Every Single Anode -1600 mV < Vref < --1400 mV : perfect -1400 mV < Vref < --1200 mV : OK Vref > -1200 mV : Replace Worn-Out Anodes Tank Itself • The excess of anode cables should not be cut out, but kept as is and buried in the ground. • The cable connection lug(s) on the vessel shall be cleaned & grinded for good electric contact, and the cable terminals shall be connected to these lugs. After then, the connections shall be isolated. • The tank basin then filled by salt free, washed and sieved sand. Table 17 Performance Checking of Cathodic Protection Systems