I

DEDICATION

========================================

To my loving and esteemed father Idrees Ahmed Butt and mother

Rakshanda Butt who have really enlightened my future by the dint of

their keen interest, devotion and heart felt prayers.

AUTHOR

II

ACKNOWLEDGEMENT

We would like to express our profound gratitude, most sincere appreciation and

special thanks to our project advisor Prof. Tahir Nadeem Malik, Engr.Abdul Samad (DGM

Hec Hattar) and Engr.Fazal (Asst.DGM Hec Hattar) . They helped us in every regard.

Without there continuous moral support and enthusiasm it would have been impossible to

complete our project.

III

Preface

Power industry in on the rise. With power shortage jinx haunting the country new

power projects are bound to be started. With every power plant there comes the use of

power transformers. Doesn’t matter whether its hydro power plant or diesel power plant,

to transfer electric power over greater distances and distribute it among the consumers we

need power transformers. So this was the incentive that gave us the passion to dig deep

into the design of power transformers. That was our main aim. How an actual power

transformer is designed. What are the constraints and limitations? What is the cost? How

do we make an actual power transformer? What is the core? What is the winding? How

do we select the winding? How do we select the core diameter? How we select the type of

winding? How do we calculate the losses? All these questions were in our mind when we

started this project. And now while writing these preface we can proudly say that we have

found the answers. This thesis will help any learning engineer to take an insight to the

design world.

We have divided this book into three broad sections. The first section deals with

the elementary theory of the power transformer. It covers the core and winding in detail.

And then we have explained briefly the operation of tap changers and bucholz relay.

After knowing about the basics of transformer we come to our main topic which is

design of course. We present the design consideration section. Here we have mentioned

every single design aspect with formulas. What is the type of transformer? What are the

cooling methods? What are the line and phase currents? What are the line and phase

voltages? How we select the volt/turn? How do we balance the ampere turns? All these

topics have been covered.

After giving the design considerations we design an actual 20/26 MVA 132/11.5 KV

power transformer. All the design calculations are included with formulae and adequate

explanation. In the end there is a small section in which we have compared prices of

power transformers being made both in our country and out of country.

In the end we would thank Allah who gave us the courage to pursue our objective. And

then Prof. Tahir Nadeem Malik who has been guiding us for the whole year. He always

helped us and told us better ways of doing things. Then we would like to thank

Engr.Abdul Samad(DGM Hec Hattar) and Engr.Fazal (Asst.DGM Hec Hattar) who

provided us with the practical knowledge and concept of design

IV

TABLE OF CONTENTS

1.

Introduction.........................................................................1

1.1 Introduction of power transformer...................................................1

1.2 Significance of power transformer...................................................2

1.3 Utilization of our work.....................................................................2

1.4 Methodology....................................................................................2

2. Power Transformer ---- An Overview...............................3

2.1 Application of transformers.............................................................3

2.2 Working principles transformer........................................................4

2.3 Elementary theory of an ideal transformer.......................................5

2.4 EMF equation of a transformer.........................................................6

2.5 Ideal transformer...............................................................................8

2.5.1

Transformer on No-load..................................................8

2.5.2

Transformer on load........................................................9

2.6 Transformer having winding resistance but no magnetic leakage....12

2.7 Magnetic leakage...............................................................................13

2.8 Transformer with resistance and reactance.......................................14

2.9 Transformer core...............................................................................15

2.10

The winding................................................................................21

2.10.1 Continuous disk winding................................................23

2.10.2 Helical winding...............................................................28

2.11

Transformer winding arrangement for on-load tap changing.....30

2.12

External insulation.......................................................................34

2.13

Transformer Tank, Cooler, Oil conservator................................34

2.13.1 The tank...........................................................................35

2.13.2 Cooler..............................................................................38

2.13.3 Oil Conservator................................................................40

2.14

Breather.......................................................................................41

2.15

Oil sampler...................................................................................43

2.16

Protective Devices and Instrument..............................................44

V

2.16.1 Explosion Vent................................................................44

2.16.2 Buchholz Relay................................................................45

3. Design Considerations.........................................................47

3.1 Basic Procedure for design calculation..............................................47

3.2 Evaluation of core diameter and calculation of winding turns..........48

3.3 Calculations of winding.....................................................................51

3.4 Calculation of impedance voltage......................................................57

3.5 Calculation of Winding Parameters...................................................59

3.6 Calculation of core data.....................................................................62

3.7 Calculation of tank dimensions..........................................................64

3.8 Calculation of stray losses..................................................................65

3.9 Calculation of temperature-rise..........................................................68

3.10 Calculation of axial mechanic stress of windings............................71

3.11 Calculation of stress conductor under short-circuits........................74

3.12 Calculation of weight.......................................................................76.

4. Design Calculations of 20/26 MVA, 132/11.5 KV Power

Transformer....................................................................................84

4.1 Current calculation ...............................................................................84

4.2 Core Calculation...................................................................................85

4.3 L.V Winding calculations.....................................................................86

4.4 H.V winding calculations......................................................................88

4.5 R.V winding calculations......................................................................89

4.6 Calculation of Load Losses...................................................................91

4.7 Stray Losses..........................................................................................94

4.8 No Load Losses.....................................................................................97

4.9 No Load Current...................................................................................99

4.10 Regulation of Transformer ................................................................100

4.11 Efficiency...........................................................................................102

VI

4.12 Calculation of Winding Temperature Rise.........................................103

4.13 Short Circuit Current for H.V Winding..............................................112

4.14 Highest Average temperature rise of Winding Under Short Circuit...114

4.15 Balance of ampere turns......................................................................115

4.16 Axial Mechanical Stress under Short Circuit Condition ....................117

4.17 Calculations of weight ......................................................................120

5. Problems And Failures In Power Transformers.......................124

5.1 Procurement problems of power transformers.................................................124

5.2 Problems in magnetic circuits..........................................................................126

5.3 Problems in winding.........................................................................................128

5.4 Problems due to various structural defects and to other causes .......................130

5.5 Prices of Power Transformers………………………………………………..132

6. Conclusion And Recommendations............................................138

7. References.....................................................................................142

1

Chapter 1

Introduction

1.1 Introduction

Power industry is at its peak in Pakistan due to scarcity of Electrical power

generation. The industry for construction of Power Transformer locally will grow keeping

in view the demand of power transformer. We want to have:

1) Experience of design of power transformer for which we

Perform survey/review of different design aspects.

Effects of changing design aspects on power transformer.

We cover all the following aspects of Construction.

(i) Body

(ii) Winding

(iii) Core

(iv) Other parts

2) Experiences tap changer installation and working.

2

1.2 SIGNIFICANCE OF PROPOSED PROJECT

Why were we doing this project? That’s the most important question.

Presently the power transformers are being made by a handful of companies like

HEC Hattar, Siemens and now PEL have joined in. So they need design and

maintenance engineers. If we have a detailed study of power transformers then we

will be ideally suited for these kinds of jobs. Since we already have mentioned our

project will cover all the aspects related to design.

1.3 UTILIZATION OF THIS WORK

Power transformers are very costly. Their prices are in millions of rupees. Our

work will give any engineer a full-fledged research work on these transformers. Although

we may find books on power transformers. But our research is based on practical work.

Going to construction sites watching everything being built and then writing it down. This

will provide a lot of help to anyone interested in design and construction of power

transformers.

1.4 METHODOLOGY

By methodology we mean our approach to this project. We start from the design

aspects of power transformers. For this we visit factory sites and meet the design

engineers asking them about the various designing tools and at the same time study

different books so that we can get an insight into the various design aspects. For the

construction of these transformers again we visit the factory and watch every part being

made and then being assembled in the assembly section.

So basically our work includes a lot of visits to factory where these transformers

are being designed. To pursue our project we went to HEC Hattar. We had detailed

discussions with the design engineer there. That has helped us to complete our project.

3

Chapter 2

Power Transformer --- An Overview

2.1 Application of transformers

Electrical energy generated by fuel-fired (thermal) power stations usually located

near large fuel deposits and by hydroelectric stations built in regions where waterpower

resources are, available has to be transmitted to industrial canters which may lie hundreds

and thousands of kilometers away from the stations, hence the need for vast transmission

lines between the greeting plant and the consumers.

It is a well-known fact that when current is transmitted over a line, some of the

power it carries is dissipated as heat in the line conductors. This loss grows higher as the

current and the resistances of the conductors are increased. It is not economical to try to

reduce the loss by solely decreasing the conductor resistance, because this would require

a substantial increase in the cross-sectional area of the conductor entailing a large

consumption of costly nonferrous metals.

It is precisely to reduce the power loss and consumption of nonferrous metals that

the transformer is used. The transformer while leaving the transmitted power unchanged

decrease current by increasing voltage and the loss which is proportional to the square of

the current (I2R loss) is thus sharply reduced. For example, ten-fold increases in the

supply voltage reduce the power loss by a factor of 100.

At the beginning of a power transmission line the voltage is raised by step-up

transformers and at the end of the line step-down transformers to a value convenient for

the consumer (from 127 V to a few kilovolts) lower it. Electric power is distributed

among the consumer (works. Factories. Residential areas. etc) through transformer

substations the prime role in the present-day power engineering is played by power

transformers. I.e. transformers used to raise or lower voltages in the supply networks of

power

systems, which serve to transmit electric power over great distances and

4

distribute it among the consumers. Power transformers are notable for their high power

capacity and operating voltage.

Since electricity has to be conveyed over thousands of kilometers to the integrated

power grid the load centers and directly to numerous minor consumers it has to be

transformed four or even five times, hence the need to install a large number of set-up and

step-down transformers. Also, it should be noted that at each transformation Stage

operating at progressively lower voltage the total capacity of power transformers is

usually greater than that at the preceding stage. Therefore, in a y power system the

installed transforming capacity is six or seven times the installed generation capacity. As

an example figure shows the layout of a transmission and distribution network.

Supply networks operating at a voltage of 220 KV and higher make wide use of

autotransformer. Such transformers have two or more windings conductively connected

so that there is some winding portion to both the primary and the secondary circular. Now

we shall consider the structural components of a transformer in greater detail.

2.2 WORKING PRINCIPLE OF A TRANSFORMER

A transformer is a static piece of apparatus used for transferring power from one

circuit to another without change in frequency . it can raise or lower the voltage with the

corresponding decrease or increase in current . in its simplest form the transformer

consists of a conducting coil have mutual inductance . the primary is the winding which

5

receives electric power and secondary is the one which delivers it. The coils are wound on

laminated core of magnetic material.

The physical basis of transformer is mutual inductance between two circuits linked by

common magnetic flux through a path of low reluctance as shown in the following figure.

The two coils possess high mutual inductance if one coil is connected to a source of

alternating voltage. An alternating flux is setup in the laminated core. Most of which is

linked up with other coil. In which it produces mutually induced e.m.f(electromotive

force). According to the Faraday’s law of electromagnetic induction.

e = M di/dt

Where

e=induced emf

M= mutual inductance

If second circuit is closed a current flows in it and so electric energy is transferred from

the first coil (primary coil) to the second coil (secondary winding).

2.3 Elementary theory of an ideal transformer

An ideal transformer is one which has no losses i.e. its

windings have no ohmic resistance and there is no magnetic leakage. In other words an

ideal transformer consists of two coils which are purely inductive and wound on a loss

free core. It may, however, be noted that it is impossible to realize such a transformer in

practice yet for convenience we will first analyze such a transformer and then an actual

transformer .

6

Since the primary coil is purely inductive and there is no cutput the primary

draws the magnetizing current only. The function of this current is to merely to magnetize

the core.

It is small in magnitude and lags v1 by 90 degree. This alternating current produces an

alternating flux which is proportional to the current and hence is in phase with it. This

changing flux is linked with both the windings therefore it produces self-induce emf in

the coil. This self induce emf e1 is, at any instant, equal to and in opposition to v1. This is

also known as counter emf of the primary.

Similarly in the secondary winding as induced emf e2 is produced this is known as

mutually induced emf. This emf is in phase opposition with V1 and its magnitude is

proportional to the rate of change of flux and the number of secondary turns. Figure

shows the vectorial representations of the above quantities.

2.4 EMF EQUATION OF A TRANSFORMER

Let

N1 = Number of turns in primary

N2 = Number of turns in secondary

Φm = maximum flux in the core in Weber’s

Bm = flux density in Weber/sq M (Tesla)

A = Net cross-sectional area of core in sq m

f = frequency of ac input in Hz

V1 = Instantaneous value of applied voltage in primary winding in

volts

V1m = Maximum value of applied voltage involtes

The instantaneous value of counter electromotive force e1 is

e1 = N1 dΦ /dt – volt

the counter emf e1is equal and opposite to applied voltage V1, I.e.

7

V1 = N1 dΦ /dt

If the applied voltage is sinusoidal, that is

V1 = V1m sin 2лft

Then

Φ = Φm sin 2лft

Hence

e1 = ¯ N 1 Φm cos 2л ft X 2лf

These equation are expressed as vectors as shown in Figure where’s V1 and e1 are the

rms values of V1 and e1. To obtain the rms value of counter emf e1, divided its maximum

value given above by V2.

Then

E1 = 2л / V2 f N1Φm

The cosine term has no significance except to derive the instantaneous

Values.

i.o.

E1 = 4.44 f N l ф m

or

E1 = 4.44 f N l B m A

Similarly rms value of emf induced in secondary is

E2 = 4.44 f N2 Bm A

In an ideal transformer

V1 = E1

and

V1 = E2

Where V2 is the secondary terminal voltage

8

VOLTAGE TRANSFORMATION RATIO (K)

From transformer equations we get

E2 = N1

=K

E1 N2

This constant is known as voltage transformation ratio.

(a) If, N2 > N1, i.e, K > 1, then the transformer is called as step-up transformer.

(b) If N2 < NI, i.e, K < l, then the transformer is called as step-down transformer.

Again for an ideal transformer

Input = Output

V1 I1 = V2 I2 (neglecting Iµ)

Or

I2 = V1 = 1

I2

V2

K

Where I1 and. I2 are primary and secondary currents

Hence the currents are in the inverse ratio of the transformation ratio.

2.5 IDEAL TRANSFORMER

We will consider two cases

1. When such a transformer is on no-load and

2. When it is loaded

2.5.1 Transformer on No-Load

The primary input current under no-load condition has to supply (i)iron-loss in the

core i.e, hysteresis loss and eddy current loss and (ii)a very small amount of copperloss in primary. Hence the no-load primary input current Io is not at 90 degree behind

V1 but lags by an angle θ 0 which is less than 90 degree. No-load primary input power

Wo= V1 Io cos θ 0 . No-load condition of an actual transformer is shown vectorially in

9

the following figure.

As seen from the figure primary current Io has two components.

(i)

One in phase with V1 . This is known as active or working or iron-loss

component Iw, because it supplies the iron-loss plus a small quantity of

primary Cu-loss.

Iw=Io cos θ 0

(ii)

The other component is in quadrature with V1 and is known as magnetizing

component because its function is to sustain the alternating flux in the core. It

is wattless.

Iu=Io sin θ 0

Obviously Io is the vector sum of Iw and Iu hence

Io= ( Iu 2 + Iw 2 )

The no load primary current Io is very small as compared to full-load primary current.

As Io is very small hence no-load primary copper-loss is negligibly small which

means that no-load primary input is practically equal to the iron-loss in the

transformer.

2.5.2 TRANSFORMER ON LOAD

When the secondary is loaded, secondary current I 2 is

set up. The magnitude of I 2 is determined bye the characteristic of the load. The

secondary current sets up its own mmf(= N 2 I 2 ) and hence its own flux φ2 which is in

opposition to the main primary flux φ , which is due to I o . The opposing secondary

flux φ2 weakens the primary flux momentarily and primary back emf E1 tends to

10

reduce. For a moment V1 gains the upper hand over E1 and hence causes more

current ( I 2 ' ) to flow in the primary.

The current I 2 ' is known as load component of primary current. This current is in

phase opposition to current I 2 . The additional primary mmf N1I 2 ' sets up a flux φ2 '

which opposes φ2 (but is in the same direction as φ ) and is equal to it in magnitude.

Thus the magnetic effects of secondary current I 2 get neutralized immediately by

additional primary current I 2 ' . The whole process is illustrated in the following

figure.

Hence whatever may be the load conditions the net flux passing through the core is

approximately the same at no-load. Due to this reason the core-loss in also practically

the same under all load conditions. Due to this reason the core-loss is also practically

the same under all load conditions.

As

11

φ2 = φ2 '

N 2 I 2 = N1I 2 '

I 2 ' = N 2 / N1 × I 2 =K I 2

Hence when transformer is on load, the primary winding has two currents I o and

I 2 ' (which is antiphase with I 2 and K times its magnitude). The total primary current

is the vector sum of I o and I 2 ' . In the following we show the vector diagrams of a

loaded transformer.

In fig(a) current I 2 ' is in phase with E 2 (for non-inductive loads). In Fig(b) it is

lagging behind E 2 (for inductive loads).

If we neglect I o as compared to I 2 ' as shown in fig(c), then φ1 = φ2 and thus

N1I 2 ' = N1 I1 = N 2 I 2

I1 / I 2 = N 2 / N1 = K

It shows that under all load conditions the ratio of primary and secondary current is

constant.

12

2.6 TRANSFORMER HAVING WINDING RESISTANCE

BUT NO MAGNETIC LEAKAGE

An ideal transformer was supposed to possess no resistance but an actual

transformer has primary and secondary windings with some resistances. Due to these

resistances there is some voltage drop in the two windings.

The result is that:

(a) The secondary terminal voltage V2 is equal to the vector difference of the

secondary induced emf E2 and I 2 R2 where R2 is the resistance of the secondary

winding.

V2 = E2 - I 2 R2

(b) Similarly primary induced emf E1 is equal to the vector difference of V1 and I1R1

R1 is the resistance of the primary winding.

E1 = V1 - I1R1

The vector diagrams for non-inductive, inductive and capacitive loads are shown

In Fig (a),(b) and (c) respectively.

13

2.7 MAGNETIC LEAKAGE

In an ideal case it is assumed that all the flux linked with the

primary winding also links the secondary winding. But in practice it is impossible to

realize this condition as magnetic flux cannot be confined. The greater the portion of the

flux(i.e, the mutual flux) flows in the core while a small proportion(Fig) called the

leakage flux links one or the other winding but not both.

On account of the leakage flux, both the primary and secondary windings have leakage

reactance, that is, each will become the seat of an emf of self induction, of a magnitude

equal to a small fraction of the emf due to main flux. The terminal voltage V1 applied to

the primary must, therefore, have a component I1 X 1 (where X 1 is leakage reactance of

primary) to balance the primary leakage emf. In the secondary, similarly, an emf of self

induction I 2 X 2 (where X 2 is leakage reactance of secondary) is developed. The primary

and secondary coils in figure are shown on separate limbs an arrangement that would

result in an exceptionally large leakage. Leakage between primary and secondary could

be eliminated if the windings could be made to occupy the same space. This of course is

physically impossible but an approximation to it is achieved if the coils of primary and

secondary are placed concentrically. Such an arrangement leads to a marked reduction of

leakage reactance. If on the other hand the primary and secondary are kept separate and

widely spaced there will be much room for leakage flux and the leakage reactance will be

greater.

14

2.8 TRANSFORMER WITH RESISTANCE AND

REACTANCE

The following figure

shows the primary and secondary windings of a transformer with resistance and leakage

reactances taken out of the windings.

The primary impedance is given by

Z1 = ( R12 + X 12 )

And the secondary impedance is given by

Z 2 = ( R22 + X 2' )

V1 = E1 + I1 ( R1 + jX 1 ) = E1 + I1Z1

E2 = V2 + I 2 ( R2 + jX 2 ) = V2 + I 2 Z 2

.

The vector diagram of such a transformer for different kinds of loads is shown in the

following figure

15

In these diagrams vectors for resistive drops are drawn parallel to current vectors,

whereas reactive drops are perpendicular to the current vectors. The angle θ1 between V1

and I1 gives the power-factor angle of the transformer.

2.9 Transformer Core

The transformer core is a closed magnetic circuit built up of thin laminations of

electrical sheet steel. It is intended to concentrate the main magnetic flux linking with the

windings and consists of limbs, which carry the winding, and yokes, which close the

magnetic circuit. The core laminations are insulated from one another by a film on heatresistant coating or varnish or by a combination of both. There are may be two forms of

magnetic circuit the shell types and the core type.

A magnetic circuit of the shell type is branched there are two yokes per limb

which encircle the limbs on both sides. As the magnetic flux leaves a limb it branches off

into two parts therefore in shell-type transformers, the cross-sectional area of the limb is

twice that of the yokes. The limbs and yokes are rectangular in section, which necessitates

the use of rectangular disk windings. Because of the insufficient strength of such

windings in the event of short circuit complications in assembly and also somewhat

greater mass of the shell-type magnetic circuit as compared with the core-type circuits

using cylindrical windings the shell type in the soviet union is employed only for singlephase transformers in household appliances and for some special-purpose transformers.

The core-type magnetic circuit of butt-joint or interleaved (of imprecated)

construction are used in power transformers. In such circuit two or three (depending on

the number of phase) vertical limbs are bridged over by two horizontal yokes -- the top

and the bottom one – so that a closed magnetic circuit is formed.

The core limbs and yokes are built up of separate laminations of electrical sheet steel 0.35

or 0.5 mm thick.

Limbs 1(see Figure below) and yokes 3 and 5 are stacked up separately and then buttjoined and clamped with vertical tie-rods 4 to obtain a butt-joint core. Butt-joint cores are

easy to assemble but they suffer from a number of substantial drawbacks. At present, this

type of core construction can be found only in old transformers and in some models

manufactured in other countries.

16

Most power transformers are made of the imbricated-core type. In such cores, the

limbs and yokes laminations are interleaved (see Figure below) in one layer. The short

limb laminations are butt-joined with the long yoke laminations and in next layer the long

limb laminations are butt-joined with the short yoke laminations so as to overlap the

joints between the laminations in the preceding layer by stacking layer upon layers of

such alternately arranged laminations a core of the required thickness is obtained. Such an

assembly of core laminations is called interleaving with right-angled joints between the

laminations.

17

To speed up the assembly each layer is made two or three laminations thick. Accordingly,

the

assembly

is

called

double

lamination

interleaving

or

triple-lamination

interleaving.The arrangement of lamination in the alternating layers of an imbricated

three-limb core with right-angled joints between the laminations is shown in Figure.

The interleaving with right-angled joints between laminations was widely used for cores

made from hot-rolled steel. When using cold-rolled steel to make the most of its

properties the cores are designed and assembled in such a way as to ensure that the lines

of magnetic flux many coincide with the steel rolling direction not only in the core limbs

and yokes and vice versa (in Figure these areas are hatched).

This is achieved by making use of beveled (miter) joints between the limb and yoke

laminations (see Figure below). The miter joints reduce the magnetic circuit areas where

the lines of magnetic forces do not coincide with the steel rolling direction. Moreover

they increase the length and hence the area of the joint by factor of √2, thus reducing the

magnetic induction in the gap and consequently the exciting current.

18

The use of interleaved cores with miter joints between aminations may reduce the no-load

losses of transformers by 10 to 12% and the exciting current. By 25 to 30% how ever

such joints complicate the fabrication of laminations and core assembly therefore resort is

frequently made to some simplifications imbricated cores are made with four miter joints

(at the corners) and three right joints or a combined pattern is used where in the miter

joints at two corners of the core in one layer of laminations alternate with the right –

angled joints in the next layer (see Figure)

Transformers are also made with spatial rather than plane cores of butt-joint construction,

which are noted for the symmetrical arrangement of their limbs.

Such cores consist of two triangular yokes wound from electrical steel strip or ribbon

between which there are three stepped section limbs built up of laminations of the same

length. The chief advantage of this core is its simple construction which make possible

extensive mechanization and complete automation of production processes.

Size I transformers also use distributed three-frame wound magnetic circuits consisting of

three O-shaped cores wound from electrical steel strip and arranged in space so as to from

19

a trihedral prism. In such transformers the winding are wound directly on the core limbs

by passing wire through the opening in the adjacent O-shaped cores.

The limbs and yoke section are built up of a number of steps in order to make their shape

approximately a circle (see Figure). The steps are obtained by using laminations differing

in width. In order transformer models the yokes were made rectangular T-shaped or

cross-shaped in section.

To obtain the required electromagnetic characterstics of the core and to make it

mechanically strong the core field clamping tightness is attained. In transformers with a

capacity of up to 630 KVA, the core limbs are not clamped because they are sufficiently

rigid to ensure stable vertical position of the core. When fitting windings on the core

limbs of transformers with a capacity of 250 to 630 KV A the limbs are temporarily

compressed with screw clamps.

20

After fitting the binding, the required clamping tightness of the core limbs is ensured by

wedging them which beech wood blockers and cleats.

21

2.10 The Windings

Transformer windings differ from one another in type, number of turns, wire

grade and gauge, hand, creep age distances, and interterm insulation thickness. The higher the

voltage of the transformer the greater the number of turns in its windings, and the higher its

capacity, the heavier the wire gauge and the greater size of the windings the density, in the

windings, calculated on the basis of temperature rise. Ranges from 2.5 to 4.5 A/mm2 depending

on the capacity and design of the transformer.

One must strictly distinguish between right and left hand windings. The hand of single

layer windings is determined by the direction in which their turns have been wound during

manufacture, no matter which of their ends (upper or lower) is considered the start. In multiplelayer windings wound during with the same conductor passing from one layer in another without

interruption, the hand alternates from layer to layer. The hand of such windings is considered to

be that of the layer whose entrance end is taken as the start of the winding.

Disk windings made in the form of flat spiral coils are considered left- or right-hand,

according as their back or front end is taken to be the start. From the figure it is clear that if the

front ends of such windings are considered the start, the first winding (the one on the left) will

then be right-hand, and the second (on the right) will be left-hand. Now if we consider the back

ends of the coils to be the start of the windings, their hand will then change to the left and right,

respectively. If a disk coil is turned upside down, its hand will be reversed: a left-hand coil will

become right –hand and a right-hand one will become left-hand.

Disk coils are usually arranged in pairs (as shown in figure). In this case, the front ends of

the coils are the entrance ones,

22

Left-hand and right-hand windings

(a) single-layer; (b) multiple-layer; (c) single disk (flat spiral) coils;

(d) Paired disk coils

and the interdisk connections made at the back. Here, the winding hand remains strictly defined,

and a winding consisting of any number of paired coils of the same hand in series will have the

same hand as the separate paired coils.

To give them mechanical strength and improve their moisture resistance, the windings

are dried and the impregnated with varnish and baked in an oven at 100 to 110 C. Recent

advances in the design, manufacture, and assembly of transformer windings have made it

possible to dispense with the winding impregnation and baking. The materially cuts down the

cost of the windings and clears production space.

The LV and HV windings are arranged on the core limbs concentrically: the L.V

windings are placed on the inside and the HV ones, on the outside (in some special transformers,

the LV and HV windings are arranged the other way round). The windings are separated by

insulating cylinders.

23

The following types of transformer windings are most widely used in the USSR and other

countries; single-, double and multiple-layer cylindrical windings, multiple-layer bobbing

windings, continuous disk windings, helical and pancake windings.

2.10.1 Continuous-Disk Winding

This consists of several series-connected flat coils or disks 1 of the same radial size (as

shown in Figure). The disks are placed one above another, with horizontal cooling ducts 2

formed between

them by pressboard spacing blocks 3. Each disk is wound with a strip conductor on the flat and

may have several turns touching in the radial direction.

Each turn of the disk may be wound with a single or several parallel conductors. The

disks in the winding shown in above Figure are wound with a single conductor per turn, and

there are six voltage-control taps 8 arranged in the middle of the winding.

24

This type has been termed “continuous-disk” because a special winding technique is used

to make the conductor pass from disk to disk without a single break in its continuity.

The winding is wound around wooden bars 6 placed axially all the way round the

periphery of a paper base laminate cylinder 7 at regular intervals, so that vertical cooling ducts 5

are formed between the winding and the cylinder. Support insulation rings 4 provide reliable

bearing surfaces for the winding.

In transformers, continuous-disk windings, as a rule, have no paper base laminate

cylinders. They are wound around wooden bars placed on a special metal cylinder (template)

which is removed after the winding is competed. The cylinders (formers) for such windings are

made from pressboard blanks immediately before fitting the winding on the core limbs.

Insulation components are made of pressboard sheets. The horizontal ducts between the disks are

formed by spacing blocks stacked up from separate pressboard strips 2 on bars 1, as shown in

Figure. If the windings are not impregnated, their mechanical strength is improved by means of

pressboard bars passed through dovetail recesses in the strips at the front of the coils.

25

Continuous-disk windings for voltages up to 35 kV are made from conductors with a two

side insulation thickness from 0.45 to 0.55 mm, and those for 110 kV use conductors with 1.2 to

1.35 mm thick insulation. In 110-kV windings, the entrance or line end coils, i.e., the two first

and two last disks, are wound with conductors of increased insulation thickness in order to

improve their electric strength. This impairs the cooling of these disks, so one has to take a

heavier conductor for them. The disks are wound separately in pairs and then soldered in series

with the disks in the main part of the winding. The number of disks in the winding is always

even, therefore its start and finish are always at the back or the front of the extreme disks. In the

former

Figure Transposition of conductors

1 – conductor passing from the front of the coil to the back; 2 – conductor passing from the back

of the coil to the front; 3 – strip

case, the entrance disks are not reversed when making the winding, while in the letter case, they

have to be reversed.

The interdisk connections in continuous-disk windings are made in free spaces between

the pacing blocks. Here, the conductor is bent on the edge and reinforced with a press-board box

taped to it, or a special pressboard strip is placed under the bent conductor.

In cases where the windings are wound with several parallel conductors per turn , the

conductors arranged farther from the coil a axis will have a greater length than those closer to the

axis .To equalize the lengths and consequently, the resistances of the parallel conductors, they

26

are transposed so that each conductor may take each possible position when passing from disk to

disk, as shown in above figure. This makes for uniform distribution of current among the parallel

conductors and, also, reduces the losses due to circulating currents caused by stray fluxes.

Parallel conductors reduce eddy-current., losses in the winding copper and facilitate the

winding of the disks, because several light-gauge conductors are used in place of a single heavy

one.

Continuous-disk windings are solid and inechanically strong. They find application in

LV, MV, and HV coils. The MV and HV coils are usually rapped in accordance with the direct

and reverse tapped-winding arrangements.

As distinct from the winding for up to 35 KV, those of the 110 –KV class and upwards

include some special structural components serving the purpose of capacitive protection. Such a

protection is necessary, because there is always a possibility that the transformer may be

subjected to dangerous overvoltages likely to cause damage to its insulation

High –frequency pulses of large amplitude and short duration, which arise in power

transmission lines as a result of lightning discharges, propagate as waves along the lines at a

speed close to that of light. For the oncoming high-frequency wave with a steep front, the

transformer may be regarded as a capacitor, for at high frequencies the inductive reactance of the

transformer grows materially and its individual winding elements (disks) become as if disconnected from one another; the disked then begin to act like the plates of distributed capacitors .

When the oncoming wave reaches the transformer, its input capacitance charges in a few

fractions of a micro-second, and the surge voltage impressed on the entrance coils firs drops to

zero and then sharply rises, this setting up electromagnetic oscillations in the transformer

windings, which depend on the winding inductance, capacitance, and resistance. In the

27

transformer there sets in a process of transition fro the initial, no steady distribution of voltage

over the windings to the final, steady-state voltage distribution. In the course of these process,

potential differences tens of times in excess of normal may develop between the winding disks,

and still greater ones between the turns. The reason for this is the extremely non uniform

distribution of electric charge over the windings, stemming form the presence of distributed

capacitances (between the winding disks, and between the disks and earthed parts. Such as the

core, tank, etc.) That disturbs the uniformity of electric field. Here the line end turns and coils are

most liable to insulation break-down.

To make the initial distribution of potential over the entrance parts of the winding more uniform

and to bring it closer to the final, steady –state distribution, use is made of capacitance-grading

rings. These rings increase the input capacitance of the windings and equalize the electric field of

the line –end coils and turns, thus reducing voltage gradients across them. The capacitancegrading rings are electrically connected to the line ends of the coils and are reliably insulated

from the earthed parts of the transformer.

28

Arrangement of a capacitance-grading ring and shielding turns (electrostatic shields) on a

winding

The initial and final distribution of voltage over the entrance parts of the windings are

equalized by means of electrostatic shields made in the from of open shielding turns encircling

the five entrance coils and electrically connected to the capacitance grading rings and line ends

of the windings

Above figure shows the arrangement of the capacitance grading ring and shielding turns on a

winding. The grading ring l is pressed from several pressboard washers, and is of the ring 60 to

70 mm long is left unwrapped in order to avoid the formation of closed turn.

2.10.2 Helical Winding

In this winding, the turns follow a helical line, each turn consisting of several parallel

strip conductors touching in the radial direction (such a winding is sometime referred to as the

spiral winding).

Figure shows a singly re-entrant helical winding wound with eight parallel conductors per turn.

The insulation components of this winding are chiefly the same as in the continuous-disk

winding. Spacers 7 between the turns form horizontal oil ducts, shield bars 4 form vertical ducts

between the winding and cylinder 5.

Helical windings of transformers are wound around wooden bars placed on paper base laminate

cylinders, while those for bigger units, around bars arranged on

29

Temporary steel cylinders (templates). The end faces of the winding are made level by

gradually increasing the thickness of the spacers between the coil-end turns and insulation rings.

Since the parallel conductors in the helical winding are arranged concentrically and are at

different distances from the winding axis, the conductors closer to the axis will be shorter than

those farther away (as in the continuous –disk winding), unless some special measures are taken.

To equalize the resistances and inductive reactance’s of the parallel conductors and

reduce the losses due to circulating currents caused by stray fluxes, the conductors are transposed

three times each (see Figure). At one-fourth and three-fourths of the winding’s height, the

conductors are divided into two equal groups and the groups are transposed

30

These are group transpositions. In the middle of the winding, all the conductors are transposed.

This is general transpositions are made in the free spaces between the spacing blocks separating

the turns. As a result of the transpositions, the conductors of the helical winding (which usually

have an even count) change places in consecutive order, so that each conductor takes each

possible position, and the lengths of all the conductors are thus equalized.

To make the transitions smooth and to equalize the radial sizes of the winding turns,

special insulating wedges are placed under the conductors at placed where the transpositions are

made.

Besides the singly re-entrant helical winding considered above, doubly and quadruply reentrant helical windings also find application. Multiply re-entrant winding are used where the

number of parallel conductors per turn is rather great (from 18-50). The conductor transpositions

in such are more perfect, because the conductors during winding are made to continually pass

from one winding re-entry into another. Such a transposition is called distributed, or Hobart’s

31

transposition. There are also other types of transposition, for example, uniformly distributed and

DeBuda’s transposition.

Helical winding have a comparatively small number of turns; they are wound for heavy current.

2.11 Transformer Winding Arrangement for One-Load Tap

changing

Among the great variety of transformers using on-load tap changing, worthy of notice are

power transformers and autotransformers equipped with built-in switching devices which make it

possible to change taps and thus to maintain voltage within the required limits directly at the

transformer terminal business without interrupting the load. The Winding of Transformers using

on-load tap-charges differ from those of transformers equipped with no-load tap-charges in that

they have a greater number of voltage-control taps, provide for a wider voltage-control range and

are made up of two individual windings which are referred to as the excitation (or main) winding

and the regulating winding (separate winding for cross and fine voltage control may sometimes

be also include). As a rule, voltage control is carried out on the HV side; therefore Figure shows

the HV winding arrangements only. The arrangements for one phase only are shown, because all

the three phase windings of the transformer are indential. The design and operation of the onload tap-charges are considered elsewhere in the text and here we restrict ourselves to the

examination of transformer winding arrangements for use in conjunction with the on-load tapcharger.

Figure shows the reverse tapped-winding arrangement. It is similar to the one examined

earlier. Like all of the winding arrangements used for on-load tap changing this arrangements

includes two windings an excitation winding 1 and a regulation winding 2. the latter is made as a

separate tapped coil and is designed BW by means of a drive mechanism the movable contact

32

(finger) of a selector switch 3 (shown schematically) of the tap-changer is moved from tap to tap

without interrupting the load current and thus the required voltage corresponding to the selected

step is obtained between the points A and X.

To extend the voltage-control range, use is frequently made of an arrangement where in

the connection of the regulating winding can be reversed i.e changed from aiding to opposing

and vice versa with respect to the excitation winding With the aiding connection of the

regulating winding (a reversing 4 is in position III-I ) the number of turns being put in operation

as the

Selector switch is shifted from position 9 to position 1 is increased (if the winding 1 and 2 are

wound in opposite directions) and in position 1 the resultant voltage of the HV winding is raised

33

by the total voltage of the regulating winding. To lower the voltage the moveable contact of the

selector switch is shifted back from position 1 to position 9.

When the reversing switch is shifted to position III-II the regulating winding and the

excitation winding are connected in series opposition and at the same time the selector switch

contact is shifted to position 1. in switching from the 1st to the 9th step the number of the

opposing turns of the regulating winding grows larger and the total voltage of the Hv winding is

reduced. With the selector switch in position 9 the voltage is decreased by the total voltage range

of the regulating winding switching in the reverse direction increase the voltage.

Thus reversing the connection of the regulating winding doubles the voltage-control

range. Such an arrangement simplifies the regulating winding but complicates the tap changer

design.

A tapped-winding arrangement which two parallel branches (see Fig) has found wide

application. It ensures a better utilization of the core windows and winding wires. The upper and

lower portions of the winding are strictly symmetrical; they are wound in opposite directions and

consist of excitation winding 1 and 1’ and regulating windings 2 and 2’, respectively. Because of

the different directions of their turns, both winding halves can be connected in parallel and

provided with common voltage-control taps.

A more perfect tapped-winding arrangement for on-load tap changing is the multiply reentrant helical-winding arrangement having so many reentries as there are voltage control steps

the winding turns being uniformly spaced all along the winding (see Figure). with the winding

arrangements shown in Figure and c in switching from tap to tap(especially when the amount of

control is large) a “dead” zone is formed in the regulating winding where the turns are put out of

operation and thus do not take part in producing the magnetizing force (as measured in ampere

34

turns). To equal the magnetizing forces of the primary and secondary windings the latter have to

b spread i.e. their turns have to be pushed wider apart along the winding in the region of the

regulating winding in order to avoid heavy leakage fluxes. The multiply re-entered winding

meant is free from the above shortcoming because disconnection of one or several voltage

control steps (ding re-entries) does not disturb the uniform distribution magnetizing forces along

the windings and the magnetize forces of the secondary windings thus remain equalizer. Multiply

re-entrant layer-by-layer windings are not very difficult to manufacture they are wound with

several parallel wires each of which forms an individual winding entry serving as a voltagecontrol step and is provide a voltage control tap.

2.12 External Insulation

The external insulation comprising the air spaces between the live parts of the terminal

bushings and between the bushing and earthed parts of the transformer. Insulation clearances are

selected in accordance with the standard creep age distances for air. Here are some of them.

The insulation clearance between the bushing and earthed parts (explosion vent, oil

conservator, etc.) are taken at nearly the same values. In practice, these clearances are increased

by 10 to 15 mm to allow for possible size deviation in transformer assembly.

2.13 Transformer Tank, Coolers, Oil Conservator

In operation, the heat given off the core, windings, and other current carrying parts of the

transformer is transferred to the oil which surrounds them. The oil transfers the heat by

conduction and convection to the walls of the transformer tank whose external surface dissipates

it into the surroundings. Such a method of heat removal is called oil-natural cooling.

As the capacity of the transformer grows higher, the absolute power loss in it increases

and consequently, the amount of heat that the tank walls must dissipate. With natural oil

35

circulation, each square meter of the tank surface can dissipate from 400 to 450 watts of power.

If the incoming heat load on the tank surface should be greater, the temperature of the core-coil

assembly and the transformer as a whole would raise prohibitively high, this impairing its

reliability. In low-capacity transformers (25to 40 kV A), the absolute loss of power dissipate as

heat is comparatively low, so they use plain tanks. The cooling surface of larger units has to be

increased by welding steel tubes onto the tank walls or by fitting the radiators cannot provide for

adequate heat removal, a blast of air is forced onto them by means of special propeller- type fans.

This method of heat removal is called oil-natural air-blast cooling Transformers of very large

aixes use combination cooling systems, such as forced- oil-air-blast and forced-oil and water.

2.13.1 The Tank

The transformer tank is an oval or rectangular container intended for housing the core-coil

assembly of the transformer. It is arc-welded form steel sheets, all the welds being of the oil-tight

type. After manufacture, the tank is tested for tightness under a pressure of 0.5 x 10 Pa (gauge).

At the top of the tank, there is a frame with bolt holes for fastening the tank cover. The cover

closes the tank and serves as a support for mounting the oil conservator, terminal bushings, tapchanger drive, lifting lugs, etc. To facilitate moving the transformer, the tank is provided with a

truck or undercarriages on rollers.

In major repair work, the cover has to be removed and the core-coil assembly withdrawn

from the tank. The lifting of the core-coil assembly of high-capacity transformers requires heavy

hoisting equipment, transformers, so the tanks of such trans- -formers are made with a detachable

bottom in order to ease the uncovering of the core- coil assembly. In this case, instead of

unbolting the cover and lifting the core-coil assembly, they unbolt the bottom and lift the tank,

36

leaving the core-coil assembly on its support the tank bottom, the oil being preliminarily drained

from the tank.

Transformers of up to 40 kV A generally have terminal bushings mounted on the side

walls of the tank, which also carry an oil gauge, transformer nameplate, lifting hooks, spark-gap

protector bracket, oil-drain filler plug provided with an air-bleed hole, protective hood for the

operating knob of the tap-changer, and thermometer pocket

Transformer form 63 to 1600 kV A in capacity are equipped with tubular tanks. The

tubes on the tank walls may be arranged in one, two, or three rows, depending on the transformer

capacity. At present, the transformer manufacturers in this country are putting out transformer

equipped with elliptical tubes which, as compared with round tubes, provide for higher heat

removal efficiency and can be placed closer to one another along the tank periphery, so that more

tubes can be accommodated on a given tank. Figure shows the Type TM-630/10 transformer

whose cooling surface is increased by bank 2 of elliptical tubes. The tank is filled with oil

through a globe valve 1 which also serves for draining the oil from the tank. Oil samples can be

taken through a sampler mounted the tank wall. In the tank bottom there is a hole normally

closed by a sealed –off plug (not shown in the figure) which serves for drain-in oil residue from

the during repair.

The tank has four hooks 3 for lifting the transformer and a truck on four

rollers 5 for moving it horizontally the tank cover is provided with special opening and studs for

mounting and fastening the terminal bushing , tap-changer drive valve, thermometer pocket, and

pipe for connecting the tank to the oil conservator. Plates 4 welded on to the tube banks serve for

mounting the transformer nameplate and temperature indicator.

37

Figure shows the arrangement of the terminal bushings and other transformer fittings on a

transformer cover

38

2.13.2 Coolers

Transformers larger than 1600 kVA use detachable tubular radiators, so their tanks are

reinforce: by stiffening ribs and are provided with flanged ports for attaching the

Radiators and radiator valves. The radiators and valves are flange mounted and are fixed

in place by means of special steel bolts

A radiator consists of two rows of parallel tubes 1. top and bottom headers

headers 2. and flanged ports 6 which are welded into the ends of the headers and serve

for mounting the radiator on the tank. Each header carries a lifting lug 4, bracket 3 with a

hole for mechanical connection of separate radiator, while the top one is used for bleeding

air from the radiator when the transformer tank is being filled with oil. They give them

rigidity, the tubes in the parallel rows are joined by means of angle bars 7 and tubes 8

held together by bolts

39

Diagram of oil circulation in a radiator

The greater the surface of the radiator, the greater the amount of heat it can

remove from the transformer. Single sided tubular radiators are sufficient for units of 630

to 4000 kVA. In such radiators, the tubes are arranged only on one side of the headers,

and the flanged connecting ports are provided on the opposite side of the headers.

Lately, radiators with straight vertical tubes have been widely adopted. These use

round or elliptical tubes of smaller diameter and wall thickness that single or double row

tubular radiators of ordinary design. With several rows comparatively closely spaced

tubes, the straight tube radiators are lighter and more compact. Also their heat removal

efficiency is higher and they are more easy to assemble and repair, since the tubes are

straight and have the same length Straight type radiators are attached to the transformer

tank in the same way as the double row tubular radiators of ordinary design; in small

transformer, the attachment is without flanged connections, the connecting piper being

wiled directly into the tank walls.

In operation, hot oil raises to the top the tank and enters the top radiator header

(see Figure). The large cooling surface of the radiator causes the temperature of the oil to

drop. Since there is a difference in density between hot and cold oil the oil, while cooling,

descends down the radiator tubes giving away its heat to the tube walls that dissipate it

into the ambient air. Fresh portions of hot oil from the tank enter the top radiator header,

40

replacing the cooled oil which flows into the tank form the bottom header. In this way,

natural oil circulation sets in the transformer.

2.13.3 Oil Conservator

As the load on the transformer and the temperature of its surroundings vary, the

temperature of the oil filling the transformer also changes. Under the same load

conditions the temperature of the transformer oil is higher in summer than in winter.

Temperature variation cause changes in the oil volume in the transformer tank. To ensure

that the tank is always completely filled with oil, transformer having a capacity form 25

kVA upwards and working at 6 kV and over use a special expansion tank called oil

conservator.

The conservator is a metal vessel, usually cylindrical, which communicate with

the main transformer tank. Figure shows the oil conservator of a transformer. It is

installed slightly above the level of the tank cover 6. As the oil gains in temperature. It is

forced out of the tank and into the conservator via a a pipe connecting the tank to the

flanged connection 5 of the conservator; when its temperature falls, the oil flows back

into the tank. The conservator tank is mounted on the main tank cover on brackets 10 and

support plates 9.

The conservator reduces the oil surface exposed to air thus lowering the rate of

sludging and acid-production. Its capacity must be such as to ensure that it is never empty

of oil. Irrespective of any normal variations in the transformer operating conditions (from

of-circuit to full and ambient temperature (form –45C to +40C) the volume of oil in the

conservator amounting to 8 or 10% that in the main transformer tank.

One of the end walls or the conservator accommodates an oil level gauge 1 whose

glass hears three painted horizontal lines, marked – 45C,+15C, and +40C,which fix the

oil level in the inoperative transformer corresponding to the indicated ambient

41

temperatures. The opposite and wall of the conservator is made detachable to facilitate

cleaning and painting the conservator on the inside curing repair

The oil gauge server for checking the oil level in the transformer vessels, but to prevent

the ingress of atmospheric moisture and impurities, its upper part is made to communicate

with the air filled space above the oil in the conservator. Rather than directly with the

atmosphere.

2.14 Breather

This is a special air filter incorporating a dehydrating material (silica gel). It is

used to prevent the ingress of moist, contaminated air into the conservator. Depending on

the construction and size of the transformer, the breather is mounted either on the

conservator or on the main tank. At present, the breathers of transformer are built into the

conservators.

The breather consists of a metal cylinder 1 filled with silica gel 3, a wire mesh

screen 7, and a perforated cartridge 4 filled with a sight glass 6.

At the bottom to the breather there is an oil seal operating on the principle of

communicating vessels, which prevents the silica gel dehydrator from being constantly in

42

contact with the ambient air and thus continuously adsorbing moisture the oil seal also

serves to remove mechanical impurities from the air, which precipitate in the oil filling

the seal when the air passes through it.

When the oil level in the conservator drops. Fresh air is drawn into it through the

breather. The air passes the transformer oil 11 filling the seal wall 8, the wire mesh

screen, and the silica gel dehydrator which absorbs moisture from it. Then the cleaned.dry

air enters the conservator by a pipe connected to the flanged connected ion 2 of the

breather. When the oil volume in the conservator increases, the air flows in the opposite

direction and is exhausted into the atmosphere.

The oil seal is provided with several plugs. A 14 serves for filling the seal with

transformer oil, a plug 13, for draining the used oil from the seal, and a plug 10, for

draining any excess oil that might raise the oil level in the seal above the normal

(indicated by an arrow in the figure).

43

The silica-gel dehydrator in the breather is periodically changed. An indication

that the silica gel has become moist and requires replacement is the change of the colour

of the indicator silica gel from light blue to pink. The colour of the indicator silica gel is

observed through the sight glass in the cover of the indicator cartridge.

The breather uses Grade KCM silica gel in grain sizes from 2.7 to 7 mm,

impregnated with a calcium chloride solution. The indicator silica gel is additionally

impregnated with a cobaltic chloride solution. Silica gel is dried at a prior to charging the

breather with it.

2.15 Oil Sampler

Samples of transformer oil for tests are taken from the tank through a special

device (as shown in figure) mounted on the tank wall at the lower part of the transformer.

It consists of a steel body l, a stopper 2 which is free to turn in its seat in a plug 3, and a

nipple 4. as the threaded plug is screwed out of the body, the oil in the tank forces the

stopper to the right and flows out through the nipple.

44

2.16 Protective Devices and Instruments

2.16.1 Explosion Vent

Failures inside the transformer are frequently accompanied by arcing. The high

temperature of electric are causes intensive decomposition of transformer oil, the gas

evolved in the process greatly increasing the pressure inside the tank. In the event of a

short circuit the pressure inside the tank grows so high that the tank may explode and

cause an out break of fire.

To avoid damage to the transformer tank, an explosion vent (as shown in figure) is

provided. It consists of a knee-shaped tube 2 made of sheet steel 4.5 mm thick, whose top

end is closed by a diaphragm 4 with a flat, round glass. The lower end of the tube

communicates with the tank through an opening in the tank cover. Should the pressure

inside the tank grow too high, the glass will break and the gas, together with oil, will be

expelled from the tank through the tube.

The explosion vent tube at its lower end is provided with a flange I for bolting the

tube to the tank cover, and there are two flanges, 9 and 11, at the top end of the tube for

mounting the glass disk 12 sealed by rubber gaskets 7 and 8. a ring 10 welded to the

flange 9 serves for centering the gaskets. An oil tight weld is used on the joint between

the flange 9 and the tube wall 6.

Formerly, explosion vent tubes were equipped with a holed plug (at 3 in Figure) to

bleed air from the tube when filling the transformer tank with oil and to permit of the

ingress and egress of air in accordance with temperature variations in the tank, but

nowadays, to prevent any other contact of the oil with air except in the conservator, the

tube is connected to the air space of the conservator by means of a small gauge steel pipe

bolted to flange 5 on the tube. Where such plugs are still in use, they must be stopped

45

altogether and connecting pipes fitted between the explosion vent tubes and conservators.

Explosion vents are used on transformers of 1000 kV A and over.

2.16.2 Buchholz Relay

Any fault which occurs inside the transformer is generally accompanied by the

evolution of gas due to the decomposition of insulating materials (oil, paper, pressboard,

wood, etc.) under the influence of elevated temperature. With minor faults, the gas

evolution slow, the gas bubbles gradually rise to the tank cover and then enter the

conservator through the oil pipe connecting the tank to the conservator. In the case of

grave faults, oil rapidly flows through the pipe and is expelled into the conservator under

the pressure of a large amount of gas evolved.

The Buchholz relay is a gas-operated device connected between the transformer

tank and the conservator. It is fitted with alarm and tripping contacts, so that warning can

be given of incipient gas evolution and a major breakdown can be averted. On its way

from the tank to the conservator, the gas is collected in the relay housing, and after the

gas collected has reached a preset volume, the relay gives an audible or visible warning of

the fault. When there is an intensive flow of oil from the tank into the conservator, the

relay trips the circuit breaker of the transformer. Besides fault indication, this relay will

also indicate oil leakage should the conservator and pipe become empty of oil.

An analysis of a gas sample taken from the Buchhloz relay of a faulty transformer

helps to determine the nature of the fault. Usually under normal conditions, the gas

dissolved in the transformer oil has the following composition 70 to 79% nitrogen, 20 to

30% oxygen, and 0.1 to 0.2% methane; hydrogen and acetylene are absent. A sharp

change in the gas composition (for example, 50 to 70% hydrogen, 3 to 10% methane, 10

to 25% acetylene, 4 to 8% oxygen) testifies to a grave internal fault accompanied by

arcing (insulation puncture, shorted turns, flashover in the contact system of the tap-

46

changer, etc.) In the event of minor faults not accompanied by violent oil decomposition

and gas evolution, the gas composition may be as follows: 2 to 5% hydrogen, 0.5 to 1%

methane, 0.5 to 2% acetylene, 85 to 92% nitrogen and 5 to 8% oxygen. Such a gas

composition bears witness to a fault, such as shorted parallel conductors in the windings,

poor contacts in the tap connections or soldered joints, or closed paths in the magnetic

system of the core, which, if not remedied, may eventually lead to a serious trouble.

Soviet-made transformers use two types of Buchholz relay, namely,. The ITT-22

float-type relay and the PTH3-66 cup-type relay.

47

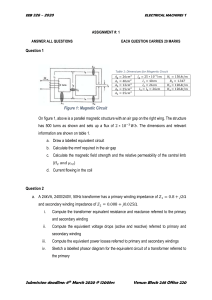

Chapter 3

Design Considerations

3.1 Basic Procedure for design calculation

a.

Voltage calculation.

Determine the line voltage and phase voltage for winding (HV. MV and LV)

b.

current calculation

Determine the line current and phase current for HV, MV and LV windings and

current flowing through winding.

c.

Evaluation of core diameter and calculation of number of winding turns:

d.

Calculation of main and long it urinal insulation distances for windings.

Chose and determine the type and the dimensions of

windings.

e.

Calculation of impedance voltage:

f.

Calculation of winding data:

g.

Calculation of core and lank dime nations:

h.

Calculation of stray losses:

i.

Calculation of temperature-rise:

j.

Calculation of axial mechanical stress for windings:

k.

Calculation of stresses in winding conductors:

l.

Calculation of weight:

HV, MV, and LV

48

Line and phase voltages for three-phase transformers

For three-phase transformers or single-phase transformer used as a three phase bank

with star-connection the phase voltage equals 1/ 3 of the line voltage i.e.

u g = (1 / 3 ) Ug

where U g = Rated phase voltage KV:

Un = Rated line voltage KV.

For delta-connection the phase voltage equals the line voltage Ug = Un

Three-phase transformers with YN (Y) connection

Ig = In =

se

3Un

=

3se

se

=

3Ug 3Ug

Where

In = Rated line current

Ig=Rated phase current

Three-phase transformer with delta connection

The calculation of current under this condition is as follows:

Line current In =

se

Un → rated line voltage

3Un

Phase current Ig = In

3=

se

3Un

The line current phase current and tapping currents may be calculated by the

formulated listed above with the given rated power rated voltages (including the

cores.

3.2 Evaluation of core diameter and calculation of winding

turns

Evaluation of core diameter

The determination of core diameter represents a very important job in the design

calculation which would affect directly the techno-economic indices of the

transformer such as raw material consumption manufacturing cost weight and

dimension for transportation etc.

49

Generally for a specific transformer the greater core diameter results in the heavier

mass of core and the more no-lead loss. But the weight of winding conductors and

their load losses would be comparatively with a dumpy configuration when the core

diameter is too small. The contrary results would be obtained.

The core diameter may be determined with an experimental formula by which the

calculation would be going on according to the design procedure. As the impedance

voltage calculated with core diameter aforesaid reveal too much deviation from their

standard values specified the core diameter should be adjusted to an appropriate

values small difference between the standard value and values calculated from the

predetermined core diameter the adjustment may be carried out by changing other

constructional dimensions.

The experimental formula for core diameter determination is.

D = k. 4 p1

Where

D- core diameter:

P1 – power for each core leg KVA:

K- Experimental coefficient.

The value k varies as the frequency of source flux density and construction of core;

here the values listed in table are recommendable foe design calculation.

Table

K

Categories

of

transformer

Al winding

Cold-

Hot-rolled

Cold- rolled

Hot-rolled

si-steel

Si-steel

Si-steel

50-54

56-60

53-57

60-64

48-52

54-58

51-55

58-62

rolled

steel

Two-

winding

transformers

Three-winding

transformers

Co winding

si-

Calculation of power for each core leg

The power for each core leg is defied as the power for core on which the windings are

mounted, referred to a double-winding transformer.

50

P1 = Se1/mt1

Where:

Se1 – power referred to a double-winding transformer (KVA), it does not need to

convert in the case of double-winding transformer, for three-winding transformers:

Se= (SG + SZ + SD)/2

SG , SZ , SD - power (KVA) for HV, MV, and LV winding respectively: Mt1 – number

of core legs on which the winding is mounted, e.g. for single-phase transformer with

two core legs, mt1 = 2: for three- phase transformer with three core legs and two side

yokes, mt1 = 3

Cross - Section of core

The cross- section of core leg and yoke are made up of a number of lamination stacks

to form a steeped periphery, for a specifies diameter, the more lamination stacks to be

encircled, the more effective cross-sectional area of core may be absorbed the

complexity of manufacturing labor force.

Calculation of winding turns

After the determination of core diameter, generally, the calculation of winding

translating with the winding without tapping (e.g. low-voltage winding) and

calculated the winding turns for HV or MV.

Calculation of volts per turns

For rated frequency = 50 HZ

et1 = B At x 103 /4.5

For rated frequency = 60 HZ

et1 = B At x 103/3.75

where

et1 – volts per turn calculated preliminarily , v :

At – core- sectional area of core m2:

B – flux density , T.

Generally, for 0.3 mm cold-rolled grain oriented silicon sheet steel (e.g. Z8H) The

flux density adopted may be 1.5-1.7T.

Preliminary calculation of low-voltage winding turns

W1D = UXI / e1t

Where

W1D – turns of low-voltage winding calculated; (take integer for WD)

UX I – Phase voltage for LV winding, V.

51

The value of W1D calculated with formula may be not an integer, when the decimal is

rounded to an integer, the flux density may be higher slightly than that calculated with