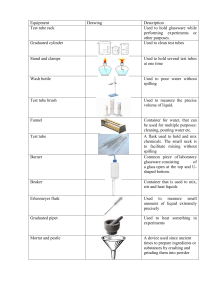

COVER PAGE STUDY OF DESIGN AND STANDARDIZATION OF FIRED HEATER FOR INDUSTRIAL APPLICATIONS Report submitted in partial fulfillment of the requirements for the B. Tech. degree in Mechanical Engineering By SHAH VRUND BHAVINKUMAR (17BME099) Under the supervision Of Dr. VIVEK KUMAR SCHOOL OF TECHNOLOGY PANDIT DEENDAYAL ENERGY UNIVERSITY GANDHINAGAR, GUJARAT, INDIA May 2021 INSIDE TITLE PAGE STUDY OF DESIGN AND STANDARDIZATION OF FIRED HEATER FOR INDUSTRIAL APPLICATIONS Report submitted in partial fulfillment of the requirements for the B. Tech. degree in Mechanical Engineering By SHAH VRUND BHAVINKUMAR (17BME099) Under the supervision Of Dr. VIVEK KUMAR SCHOOL OF TECHNOLOGY PANDIT DEENDAYAL ENERGY UNIVERSITY GANDHINAGAR, GUJARAT, INDIA May 2021 CERTIFICATE This is to certify that the report on “study of design and standardization of fired heater for industrial applications” submitted by the students, as a requirement for the degree in Bachelor of Technology (B. Tech) in Mechanical Engineering, under my guidance and supervision for the session 2020-2021. Name of the student SHAH VRUND BHAVINKUMAR Date: 22 May, 2021 Place: GANDHINAGAR Roll No. Signature 17BME099 Signature of the Supervisor Dr. VIVEK KUMAR CONTENT LIST OF TABLES Table 1 Mean beam length Table 2 Effect of pollutant on excess air LIST OF GRAPHS Graph 1 alpha factor vs (center to center)/(tube dia) Graph 2 F factor vs Gas emissivity Graph 3 Gas emissivity vs PL Graph 4 enthalpy vs temperature Graph 5 theta vs fin efficiency Graph 6 Thermal conductivity vs temperature Graph 7 Return bend equivalent length curve Graph 8 Return bend equivalent length Nre correction LIST OF FIGURES Fig 1 Typical fired heater Fig 2A Components of fired heater Fig 2B Components of fired heater Fig 2C Components of fired heater Fig 3A Vertical cylindrical fired heater Fig 3B Cabin fired heater Fig 3C Box fired heater Fig 4 Classification on basis of radiant tube coil configuration Fig 5 Classification on basis of burner arrangement Fig 6 Classification on basis of draft Fig 7 Cold plane area calculation Fig 8 Direct radiation in shield section Fig 9 Indirect, non-luminous radiation in shield section Fig 10 Draft in heater Fig 11 Air preheat system Fig 12A Regenerative air heater Fig 12B Rotor Fig 12C Basket Fig 13 Recuperative, Tubular Air heater Fig 14 Recuperative, Cast Tube Air heater Fig 15 Heating medium air heater Fig 16 Retractable soot blower Fig 17 Fixed rotary soot blower Fig 18 Stack Damper Fig 19 tab 1 input sheet Fig 20 Tab 2 fired heater 2D diagram Fig 21 Tab 3 load calculation Fig 22 total weight calculation ACKNOWLEDGEMENTS I would like to express my sincere gratitude to my mentors Dr.Vivek kumar , Assistant Professor, Department of Mechanical engineering , Pandit Deendayal Petroleum University, Mr.Manoj Kumar Prasad , Head of Mechanical static Department, Larsen and Toubro, Chiyoda and Mr.Amit Kumar , Manager in Mechanical static Department, Larsen and Toubro, Chiyoda for continually guiding me in the right direction in the face of any impediment in the course of this project. I would also like to extend my thanks to all who directly or indirectly succour me in bringing this project to this stage. Name of Student 1. SHAH VRUND BHAVINKUMAR (17BME099). Signature of Student List of table 4 List of graphs 4 List of figures 5 Acknowledgement 6 Chapter 1 Introduction 9 Chapter 2 Objective 10 Chapter 3 Fired heater 11 3.1 Radiant section 11 3.2 Convection section 12 3.3 Stack 13 Chapter 4 Components of fired heater 14 Chapter 5 classification of fired heater 15 5.1 Structural classification 15 5.2 Radiant tube coil configuration 16 5.3 Burner arrangement 16 5.4 Draft design 17 Chapter 6 Heat transfer mechanism in fired heater 18 6.1 Direct radiation in the radiant section 18 6.2 Convective heat transfer in the radiant section 22 6.3 Total radiant heat absorption in the radiant section 23 6.4 heat balance in the radiant section 24 6.5 Direct radiation in the shield section 24 6.6 In-direct, non-luminous radiation in the shield section 26 6.7 Convection transfer in the convection section , bare tubes 27 6.8 Convection transfer in the convection section , fin tubes 28 6.9 Convection transfer in the convection section , stud tubes 33 6.10 Thermal conductivity of metals 35 6.11 Tube wall temperature calculation 35 Chapter 7 Variation in properties 37 7.1 Single phase fluids 37 7.2 Mixed phase fluids 37 7.3 Heat transfer coefficient 38 7.4 In tube pressure drop 39 7.5 Gas side pressure drop across tube 40 Chapter 8 Heater stack Draft analysis 41 Chapter 9 ducting pressure loss 47 Chapter 10 Burner type and selection 51 10.1 Draft 51 10.2 Flame stability 51 10.3 Design excess air 52 10.4 Combustion air preheat 53 10.5 Turbine exhaust gas 53 10.6 Combustion air adjustment 54 Chapter 11 Auxiliary equipment 55 11.1 Air preheat system 55 11.2 Soot blower 56 11.3 Fans and blower 58 Chapter 12 heater design and engineering 61 12.1 Process/thermal engineering 61 12.2 Mechanical engineering 61 12.3 Structural /civil engineering 61 12.4 Environmental engineering 61 12.5 Interface engineering 61 Chapter 13 Load data sheet 62 Time line of the project 63 References 64 CHAPTER 1 INTRODUCTION Since the unabated rise in the increase for petrochemicals it becomes extremely important to study a technology that helps in obtaining them. There is no doubt in stating that petrochemical and refining industries are one of the Earth’s most important energy resources. Hydrocarbon mixtures are produced in the refineries by distillation as well as thermal cracking of higher boiling hydrocarbon fractions. Fired Heaters, often referred to as furnaces (direct fired heaters), are pieces of equipment often used in processing facilities to heat gases or liquids up to a desired temperature as mentioned above (for distillation or thermal cracking). Fired heaters in the petrochemical and refining industry are critical pieces of equipment that can have a major impact on process unit safety, reliability, and economics. They are complex pieces of equipment, where tubes and other pressure boundary components might fail due to relatively short periods of upset conditions. The project gave me opportunities to observe the designing of fired heaters first hand and importance of following standards while designing and also engineering used in designing the heater. It was completed as a fulfilment for the CP project. CHAPTER 2. OBJECTIVE The objective of this project was to teach me a plethora of skills and provide me firsthand experience which is supposed to help me in my future venture as an engineer working in a professional environment. I learnt the importance of teamwork, punctuality, professional etiquettes, time management, etc. It also involved the use of professional application software and hence giving me a hands on experience to that. CHAPTER 3. FIRED HEATER Fired heaters sometimes referred to as process heaters or process furnaces are heat transfer units designed to heat petroleum products, chemicals, and other liquids and gases flowing through tubes. The heating is done to raise the temperature of the fluid for further processing downstream or to promote chemical reactions in the tubes, often in the presence of a catalyst. Fired heaters may carry liquids at temperatures as high as 1500°F (810°C) and pressures up to 1600 psig (110 barg). The primary modes of heat transfer in process heaters are radiation and convection. The initial part of the fluid heating is done in the convection section of the furnace, while the latter heating is done in the radiant section. The fluids flow through an array of tubes located inside a furnace or heater. The tubes are heated by direct-fired burners that often use fuels that are by-products from processes in the plant and that vary widely in composition. Using tubes to contain the load is somewhat unique compared to the other types of industrial combustion applications. Heating the fluids in tubes has many advantages over heating them in the shell of a furnace. Advantages include better suitability for continuous operation, better controllability, higher heating rates, more flexibility, less chance of fire, and more compact equipment.A fired heater is defined as an exchanger that transfers heat from the combustion of fuel to fluids contained in tubular coils within an internally insulated enclosure(API 560).A typical fired heater consists of three main components namely radiant section, convection section and stack Fig 1. Typical fired heater 3.1 RADIANT SECTION Fuel flows into the burner and is burnt with air provided from an air blower. The flames heat up the tubes, which in turn heat the fluid inside in the first part of the furnace known as the radiant section or firebox, here the heat is transferred mainly by radiation to tubes around the fire in the chamber. The heating fluid passes through the tubes and is thus heated to the desired temperature. Tubes can be vertical or horizontal, placed along the refractory wall, in the middle, etc., or arranged in cells. Tube guides which are located at the top, middle and bottom hold the tubes in place. The radiant zone with its refractory lining is the costliest part of the heater and most of the heat is gained there. 3.2 CONVECTION SECTION The gases from the combustion of fuel are known as flue gas. After the flue gas leaves the firebox, most furnace designs include a convection section where more heat is recovered before venting to the atmosphere through the flue gas stack. Convection section is cooler than radiant section to recover additional heat. Heat transfer takes place by convection here, and the tubes are finned to increase heat transfer. The first two tube rows in the bottom of the convection section and at the top of the radiant section is an area of bare tubes (without fins) and are known as the shield section, so named because they are still exposed to plenty of radiation from the firebox and they also act to shield the convection section tubes, which are normally of less resistant material from the high temperatures in the firebox. . Crossover is the term used to describe the tube that connects from the convection section outlet to the radiant section inlet. 3.3 STACK The flue gas stack is a cylindrical structure at the top of all the heat transfer chambers. The transition from the convection section to the stack is called the breeching. The breeching directly below it collects the flue gas and brings it up high into the atmosphere where it will not endanger personnel. By the time the flue gas exits the stack, most of the heat is recovered and the temperature is less. CHAPTER 4. COMPONENTS OF FIRED HEATER Burners: they are critical devices installed in a heater that generate the energy absorbed by the fluid moving through the radiant and convection coils. Radiant coil: it carries the process fluid through the radiant section. As radiant heat is the primary energy transfer mechanism in this heater section, these coils have no extended surfaces. convection coil: it carries the fluid(s) being heated through the convection section. A key difference between convection and radiant coils is that most tubes that make up the convection coil have extended surface Fig 2A components of fired heater Refractory : insulating material that lines the interior of the heater. Its purpose is to reduce energy loss, while providing lower casing temperatures to protect operators. Stack: The stack collects the flue gas and discharges it to the atmosphere. Sample Ports: Nozzles near the stack exit where sampling probes or other sensors are inserted to measure flue gas composition, pressure, and/or temperature. Stack Damper: A “valve” located inside the stack used to control flow of flue gas and adjust draft. Breeching: The section of duct after the last row of convection tubes where flue gases are collected for transmission to the stack or exhaust ducts. Fig 2B components of fired heater Corbels: Protrusions from the refractory lining the convection section. These protrusions redirect flue gases travelling along the walls of the convection section back toward convection coil. Header Box: A refractory lined box covering the return bends and separated from the flue gas flow. Return Bends: U-shaped fittings connecting tubes in the convection coil. Tube Sheet: Support sheet for convection tubes passing through it. There are both end tube sheets and intermediate tube sheets. Fig 2C components of fired heater Bridgewall : sometimes called the arch is the area where flue gas leaves the radiant section. Coil Supports: Brackets installed in the radiant and convection section to keep the associated coil in the proper position while allowing for thermal growth. Observation Doors: Visual inspection ports that allow operators to view what is happening inside the furnace. Tube Skin Thermocouples (TSTCs): Sensors installed directly on the heater coils to monitor the coil’s skin temperature. These critical sensors are used to ensure that the allowable tube metal temperature is not exceeded Expansion Rows: Space left in the convection section for the future addition of rows. Tube sheets are also designed to accommodate these rows with the associated holes plugged to prevent flue gas from leaking into the header boxes. Crossover Piping: Interconnecting piping between the convection coil and radiant coil. CHAPTER 5 CLASSIFICATION OF FIRED HEATER Fired heater can be classified on basis of structural configurations, radiant tube coil configuration, burner arrangement and draft design 5.1 STRUCTURAL CLASSIFICATION VERTICAL CYLINDRICAL It is usually used for quite low power. These heaters can be “all radiant” type or they can have both radiant and convection section. In the first case the coil is composed of vertical tubes located around a circle, at the base of the heater there are the burners. While in the other case convection section, has horizontal axis and is located above the radiant section. The heater with radiant and convection section can reach higher power and allow higher efficiency. Fig 3A Vertical cylindrical fired heater CABIN HEATER It usually has a radiant section in the lower part and a convection section in the upper one. Fluid to be heated run through the convection section and then through the radiant one, to have a higher thermal head. Coil are composed of many tubes in parallel and connected with manifold at the end. Burners can be located on the floor with vertical axis in one or more rows or they can be located on the walls with horizontal axis. Tubes in convection section have triangular pitch. Fig 3B Cabin fired heater BOX HEATER It mainly composed of one or more chambers with rectangular section, the tubes are usually in horizontal position arranged on one on more rows along the wall of the section. Burners can be located on the floor or on the wall of the radiant section. Flue gases run through the convection section and exit from the stack in the atmosphere Fig 3C Box fired heater 5.2 RADIANT TUBE COIL CONFIGURATION Cylindrical heater with vertical coils Cylindrical heater with helical coils Box heater with vertical tube coil Box heater with arbor coils Cabin heater with horizontal coils Fig 4. classification on basis of radiant tube coil configuration 5.3 BURNER ARRANGEMENT The installation location and orientation of burners is known as the burner arrangement Burners can be installed in the floor, walls, or roof of the radiant section and can be positioned to be up fired, side fired, or down fired. Horizontally fired, wall mounted burners are further described as being end wall or side wall fired. End wall burners are fired horizontally across the length of the radiant section. Side wall fired burners direct flames across the radiant section’s width. Up fired End wall fired Side wall fired Fig 5 classification on basis of burner arrangement Side wall fired multi‐ level 5.4 DRAFT DESIGN According to API 560, draft can be defined as the negative pressure or vacuum of the air and/or flue gas at any point in the heater Natural draft Fig 6 classification on basis of draft These heaters use the suction generated by the “stack effect” to create negative pressure inside the heater, pulling ambient air through the burner(s) and into the combustion zone. Forced draft Forced Draft Heaters use a fan known as an “FD fan” to push combustion air through the burner(s) and into the combustion zone. Induced draft Induced Draft Heaters use a fan known as an “ID fan” to remove flue gas from the heater and pull air through the burner(s) and into the combustion zone. Balanced draft Balanced draft heaters use both FD and ID fans to push and pull combustion air through the burner and into the combustion zone CHAPTER 6 HEAT TRANSFER MECHANISM IN THE FIRED HEATER 6.1 DIRECT RADIATION IN RADIANT SECTION Direct radiation in the radiant section of a direct fired heater can be described by the equation shown below. qr = saAcpF(Tg4 - Tw4) Where, qr = Radiant heat transfer, Btu/hr s = Stefan-Boltzman constant, 0.173E-8 Btu/ft2-hr-R4 a = Relative effectiveness factor of the tube bank Acp = Cold plane area of the tube bank, ft2 F = Exchange factor Tg = Effective gas temperature in firebox, °R Tw = Average tube wall temperature, °R Cold Plane Area, Acp : The normal heat-absorbing surfaces in a fired heater consist of several parallel tubes. In the case of a fired heater design where the tubes are fired from one side only, the tubes are normally positioned in front of a refractory wall. Part of the radiation from the hot gas strikes the tubes directly, while the rest passes through and is radiated back into the chamber, where part is absorbed by the tubes.In the case of tubes fired from both sides, as when the tubes are positioned in the center of the chamber, the tubes absorb direct radiation from both sides. Expressing the tube area as an equivalent plane area simplifies this calculation. The calculated cold plane area is the area of a plane through the tube center lines, whether they are in a curved plane, such as in a cylindrical pattern or in a row side-by-side. For most tube panels, the width would be equal to the center/center spacing of the tubes times the number of tubes. The length is the length of tube exposed to the radiation. In the case of tubes penetrating a tube sheet it is the length between tube sheets. But for tubes with the return bends inside the firebox, the length may be taken as the distance from the centerline of the return on one end to the centerline of the return on the other end. For a firebox with the tubes down the center, or other pattern which results in the tubes being fired from both sides, the cold plane area would be twice the projected area. For single sided firing: Acp = Ntube*Stube*Ltube For double sided firing: Acp = Ntube*Stube*Ltube * 2 Where, Ntube = Number of tubes wide Stube = Tube spacing, ft Ltube = Effective tube length, ft Fig 7 cold plane area calculation Relative Effectiveness Factor, a : Because the tube bank does not absorb all the heat radiated to the cold plane, an absorption effectiveness factor, a, can be used to correct the cold plane area, depending on the arrangement of the tubes. The relative effectiveness factor can be described by the following curves: Graph 1 aplha factor vs (center to center)/(tube dia) Exchange Factor, F : Because the flue gas in the firebox is a poor radiator, the equation must be corrected using an exchange factor which is dependent on the emissivity of the gas and the ratio of refractory area to cold plane area. Since the radiant heat is reflected into the firebox, by the refractory, a heater having a larger ratio of refractory surface relative to the tube surface, will absorb more heat. Since the tubes themselves are not perfect absorbers, the curves are based on a tube-surface absorptivity of 0.9. Graph 2 F factor vs Gas emissivity Where, Aw/aAcp : The equivalent cold plane area, aAcp, is the product of the effectiveness factor and the cold plane area as described above. The Aw can be described as follows, Aw = Ar - aAcp and, Aw = Effective refractory area, ft2 Ar = Total refractory area, ft2 aAcp = Equivalent cold plane area, ft2 The total refractory area, Ar, is simply the total of the refractory area exposed to the radiant section of the heater. Flue Gas Emissivity : The tube wall temperature has only a minor effect. Therefore, the emissivity can be correlated as a function of PL product and the gas temperature, Tg. Variations in tube wall temperatures between 600 and 1200°F cause less than 1% deviation from these curves. Graph 3 Gas emissivity vs PL And, PL = Product of the Partial Pressure of the carbon dioxide and water times the Beam Length, in atm-ft. The only constituents normally in the flue gas that contribute significantly to the radiant emission are the carbon dioxide and the water, the sum of these are all that are considered. The Partial pressure of a gas component in atm's is the mole volume fraction percent of that component. Mean beam length For Box Type Heaters Dimension Ratio Mean Beam Length 1-1-1 to 1-1-3 2/3(Furnace Volume)1/3 1-2-1 to 1-2-4 1-1-4 to 1-1-inf 1 x Smallest Dimension 1-2-5 to 1-2-inf 1.3 x Smallest Dimension 1-3-3 to 1-inf-inf 1.8 x Smallest Dimension With the box dimensions, length, width, and height being in any order For Vertical Cylindrical Heaters Length/Diameter < 2 (((L/D)-1)*0.33 + 0.67)*D Length/Diameter >= 2 Diameter Table 1 Mean beam length Effective gas temperature in firebox, Tg For a radiant section that is considered "well mixed", this temperature is assumed to be equal to the temperature leaving the radiant section, i.e., the bridgewall temperature. But in a high temperature heater with a tall narrow firebox and wall firing, the Tg controling radiant transfer may be 200 to 300 °F higher than the exit temperature. Average tube wall temperature, Tw Tube wall temperature depends on the temperature of the process fluid and its transfer coefficient inside the tube, the thermal resistance of the tube wall, the heat flux, and the fouling. The average tube wall temperature may be one of either the average temperature of the front 180° face of the tube, or the overall average for the full circumference. 6.2 CONVECTIVE HEAT TRANSFER IN THE RADIANT SECTION Even though most of the heat exchanged in the radiant section is from radiant heat transfer, the convective heat transfer cannot be ignored. The heat exchanged by convection can be described with the following equation: qc = hcAt(Tg - Tw) Where, qc = Convection heat transfer, Btu/hr hc = Film heat transfer coefficient, Btu/hr-ft2- °R At = Area of the tubes in bank, ft2 Tg = Effective gas temperature in firebox, °R Tw = Average tube wall temperature, °R Film heat transfer coefficient, hc The arrangement of the tubes as well as the firebox design contributes to this factor. For horizontal tube, cabin type heater, which is normally small, this coefficient might = 1.5, where on large box heaters with multiple tube cells, it may be as high as 2.8. Vertical heaters with an L/D less than 2 would normally be designed with hc = 2, where for an L/D greater than 2.0, you could use 3.0. 6.3 TOTAL RADIANT HEAT ABSORPTION IN THE RADIANT SECTION The total heat absorbed by the radiant section tubes, now can be expressed by the following equation. qR = qr + qc Where, qR = Total heat transfered to radiant tubes, Btu/hr qr = Radiant heat transfer, Btu/hr qc = Convective heat transfer, Btu/hr 6.4 HEAT BALANCE IN THE RADIANT SECTION There are three primary sources of heat input to the radiant section, the burner release, qrls, the sensible heat of the combustion air, qair, and the sensible heat of the fuel and any atomizing medium, qother. Heat is taken out of the radiant section by the two heat transfer methods, qR and qS, and by losses through the casing, qloss, and sensible heat of the exiting flue gas, qout. qrls + qair + qother = qR + qS + qloss + qout Where, qrls = Heat released by burners, Btu/hr qair = Heat in the combustion air, Btu/hr qother = Heat in other items, Btu/hr qR = Heat absorbed by radiant tubes, Btu/hr qS = Radiant heat to shield tubes, Btu/hr qloss = Heat loss through setting, Btu/hr qout = Heat in gas leaving radiant section, Btu/hr qrls = Heat release by burners, Btu/hr The burner release can be easily calculated for a gas when we know the composition of the fuel and the heating values of the various components. For liquid fuels, the heating values are obtained by a calorimeter test. The heating values normally used in fired heater design are the LHV, lower heating values. qair = Heat in the combustion air, Btu/hr The heat available in the combustion air, such as from preheated air, or using Gas Turbine Exhaust, etc., is taken as the heat content above 60 °F, since that is the design datum temperature for fired heaters. qother = Heat in other items, Btu/hr The heat available in other items would include such things as the fuel when it is above 60 °F, atomizing air or steam, etc. qloss = Heat loss through setting, Btu/hr These losses, referred to as Setting Loss or Radiation Loss are usually not calculated during heater rating calculations. They are normally accounted for by allowances, such as a percent of burner release or a percent of heat absorbed. qout = Sensible heat in flue gas leaving radiant section, Btu/hr From the flue gas composition, we can calculate the overall enthalpy of the flue gas, at a specific temperature, by adding the proportion each of the components contribute to the total. These enthalpies can be obtained from the following curves: Graph 4 enthalpy vs temperature 6.5 DIRECT RADIATION IN THE SHIELD SECTION As already stated , Shield section normally refers to the first several rows in the convection section, which "shield" the remaining tubes from the direct radiation occurring in the radiant section. The shield section normally consists of two to three rows of bare tubes, but the arrangement varies widely for the many different heater designs. In a heater similar to this one, the lower rows are directly exposed to the hot gasses and flame in the radiant section. To calculate the heat transfered to these tubes by radiation, we use the same formula that we did in the radiant section. Fig 8 direct radiation in shield section qS = saAcpF(Tg4 - Tw4) Where, qS = Radiant heat transfer to shield, Btu/hr s = Stefan-Boltzman constant, 0.173E-8 Btu/ft2-hr-R4 a = Relative effectiveness factor of the tube bank Acp = Cold plane area of the tube bank, ft2 F = Exchange factor Tg = Effective gas temperature in firebox, °R Tw = Average tube wall temperature, °R Cold Plane Area, Acp : The cold plane area for the shield section is equal to the cold plane area of the first row of tubes. Acp = Ntube*Stube*Ltube Where, Ntube = Number of tubes wide Stube = Tube spacing, ft Ltube = Tube length, ft Relative Effectiveness Factor, a : Since all the heat directed toward this bank of tubes, leaves the radiant section and is absorbed by the tubes, the relative absorption effectiveness factor, a, for the shield tubes can be taken to be equal to one. Exchange Factor, F : Effective gas temperature in firebox, Tg Average tube wall temperature, Tw The values used for these factors are the same as the values to be used in the radiant section. The difference is, when there is a shield section, which is receiving direct radiation, the aAcp for the radiant and the shield are calculated independently, then added together to calculate the exchange factor, F. So the equation for Aw, becomes: Aw = Ar - ((aAcp)rad + (aAcp)shld) And for Aw/aAcp, Aw/aAcp = Aw/ ((aAcp)rad + (aAcp)shld) Where, Aw = Effective refractory area, ft2 Ar = Total refractory area, ft2 (aAcp)rad = Equivalent cold plane area of radiant tubes, ft2 (aAcp)shld = Equivalent cold plane area of shield tubes, ft2 Therefore, the corrected formula for the radiant heat transfer in the radiant section, when a shield section is present becomes, qtot-rad = s(aAcp)radF(Tg4 - Tw4) + s(aAcp)shldF(Tg4 - Tw4) And total transfer to radiant tubes, qR = s(aAcp)radF(Tg4 - Tw4) + qc And radiant only transfer to shield tubes, qS = s(aAcp)shldF(Tg4 - Tw4) It should be noted here, that the convective transfer, qc, for the radiant section remains as it was described and it does not apply to the shield tubes. The convection transfer to the shield tubes is calculated the same as for other convection tubes. It is also, important to remember that the Tg applies to the gas temperature after the shield radiant heat is removed, but before the shield convection heat is removed. 6.6 IN-DIRECT, NON-LUMINOUS RADIATION IN THE SHIELD SECTION In a heater similar to this one, the lower rows are not directly exposed to the hot gasses and flame in the radiant section. However they are exposed to the heat radiated off the refractory lined plenum beneath the tubes. To calculate the heat transfered to these tubes by radiation, we use the same formula that we did in the radiant section. Fig 9 indirect, non‐luminous radiation in shield section qn = saAcpF(Tg4 - Tw4) Where, qn = Non-luminous radiant heat transfer to the shield, Btu/hr s = Stefan-Boltzman constant, 0.173E-8 Btu/ft2-hr-R4 a = Relative effectiveness factor of the tube bank Acp = Cold plane area of the tube bank, ft2 F = Exchange factor Tg = Effective gas temperature in firebox, °R Tw = Average tube wall temperature, °R Relative Effectiveness Factor, a : Since all the radiant heat directed toward this bank of tubes is absorbed by the tubes in the convection, the relative absorption effectiveness factor, a, for the shield tubes can be taken to be equal to one. Cold Plane Area, Acp : The cold plane area for the shield section is equal to the cold plane area of the first row of tubes. Acp = Ntube*Stube*Ltube Where, Ntube = Number of tubes wide Stube = Tube spacing, ft Ltube = Tube length, ft Exchange Factor, F : Effective gas temperature in firebox, Tg Average tube wall temperature, Tw The values used for these factors are calculated the same way as was described in the radiant design section. The Ar factor being the only exception. This factor is the inside area of the plenum below the tubes. The openings where the flue gas enters are normally ignored, since the ducting connecting them perform the same reflective purpose. This type of shield calculation is totally independent of the radiant section where the heat balance is performed as if there where no shield. The radiant heat from this calculation will reduce the gas temperature used in the convection transfer calculation. 6.7 CONVECTION TRANSFER IN CONVECTION SECTION , BARE TUBES Overall Heat Transfer Coefficient, Uo: Uo = 1/Rto Where, Uo = Overall heat transfer coefficient, Btu/hr-ft2-F Rto = Total outside thermal resistance, hr-ft2-F/Btu And, Rto = Ro + Rwo + Rio Ro = Outside thermal resistance, hr-ft2-F/Btu Rwo = Tube wall thermal resistance, hr-ft2-F/Btu Rio = Inside thermal resistance, hr-ft2-F/Btu And the resistances are computed as, Ro = 1/he Rwo = (tw/12*kw)(Ao/Aw) Rio = ((1/hi)+Rfi)(Ao/Ai) Where, he = Effective outside heat transfer coefficient, Btu/hr-ft2-F hi = Inside film heat transfer coefficient, Btu/hr-ft2-F tw = Tubewall thickness, in kw = Tube wall thermal conductivity, Btu/hr-ft-F Ao = Outside tube surface area, ft2/ft Aw = Mean area of tube wall, ft2/ft Ai = Inside tube surface area, ft2/ft Rfi = Inside fouling resistance, hr-ft2-F/Btu Effective outside heat transfer coefficient, he he = 1/(1/(hc+hr)+Rfo) Where, hc = Outside heat transfer coefficient, Btu/hr-ft2-F hr = Outside radiation heat transfer coefficient, Btu/hr-ft2-F Rfo = Outside fouling resistance, hr-ft2-F/Btu Outside film heat transfer coefficient, hc: The bare tube heat transfer film coefficient, hc, can be described by the following equations. For a staggered tube arrangement, hc = 0.33*kb(12/do)((cp*mb)/kb)1/3((do/12)(Gn/mb)))0.6 And for an inline tube arrangement, hc = 0.26*kb(12/do)((cp*mb)/kb)1/3((do/12)(Gn/mb)))0.6 Where, hc = Convection heat transfer coefficient, Btu/hr-ft2-F do = Tube outside diameter, in kb = Gas thermal conductivity, Btu/hr-ft-F cp = Gas heat capacity, Btu/lb-F mb = Gas dynamic viscosity, lb/hr-ft Gn = Mass velocity of gas, lb/hr-ft2 6.8 CONVECTION TRANSFER IN CONVECTION SECTION , FIN TUBES Overall Heat Transfer Coefficient, Uo: Uo = 1/Rto Where, Uo = Overall heat transfer coefficient, Btu/hr-ft2-F Rto = Total outside thermal resistance, hr-ft2-F/Btu And, Rto = Ro + Rwo + Rio Ro = Outside thermal resistance, hr-ft2-F/Btu Rwo = Tube wall thermal resistance, hr-ft2-F/Btu Rio = Inside thermal resistance, hr-ft2-F/Btu And the resistances are computed as, Ro = 1/he Rwo = (tw/12*kw)(Ao/Aw) Rio = ((1/hi)+Rfi)(Ao/Ai) Where, he = Effective outside heat transfer coefficient, Btu/hr-ft2-F hi = Inside film heat transfer coefficient, Btu/hr-ft2-F tw = Tubewall thickness, in kw = Tube wall thermal conductivity, Btu/hr-ft-F Ao = Total outside surface area, ft2/ft Aw = Mean area of tube wall, ft2/ft Ai = Inside tube surface area, ft2/ft Rfi = Inside fouling resistance, hr-ft2-F/Btu Effective outside heat transfer coefficient, he: he = ho(E*Afo+Apo)/Ao Where, ho = Average outside heat transfer coefficient, Btu/hr-ft2-F E = Fin efficiency Ao = Total outside surface area, ft2/ft Afo = Fin outside surface area, ft2/ft Apo = Outside tube surface area, ft2/ft And, Average outside heat transfer coefficient, ho: ho = 1/(1/(hc+hr)+Rfo) Where, hc = Outside heat transfer coefficient, Btu/hr-ft2-F hr = Outside radiation heat transfer coefficient, Btu/hr-ft2-F Rfo = Outside fouling resistance, hr-ft2-F/Btu Outside film heat transfer coefficient, hc: hc = j*Gn*cp(kb/(cp*mb))0.67 Where, j = Colburn heat transfer factor Gn = Mass velocity based on net free area, lb/hr-ft2 cp = Heat capacity, Btu/lb-F kb = Gas thermal conductivity, Btu/hr-ft-F mb = Gas dynamic viscosity, lb/hr-ft Colburn heat transfer factor, j: j = C1*C3*C5(df/do)0.5((Tb+460)/(Ts+460))0.25 Where, C1 = Reynolds number correction C3 = Geometry correction C5 = Non-equilateral & row correction df = Outside diameter of fin, in do = Outside diameter of tube, in Tb = Average gas temperature, F Ts = Average fin temperature, F Reynolds number correction, C1: C1 = 0.25*Re-0.35 Where, Re = Reynolds number Geometry correction, C3: For segmented fin tubes arranged in, a staggered pattern, C3 = 0.55+0.45*e(-0.35*lf/Sf) an inline pattern, C3 = 0.35+0.50*e(-0.35*lf/Sf) For solid fin tubes arranged in, a staggered pattern, C3 = 0.35+0.65*e(-0.25*lf/Sf) an inline pattern, C3 = 0.20+0.65*e(-0.25*lf/Sf) Where, lf = Fin height, in sf = Fin spacing, in Non-equilateral & row correction, C5: For fin tubes arranged in, a staggered pattern, C5 = 0.7+(0.70-0.8*e(-0.15*Nr^2))*e(-1.0*Pl/Pt) an inline pattern, C5 = 1.1+(0.75-1.5*e(-0.70*Nr^2))*e(-2.0*Pl/Pt) Where, Nr = Number of tube rows Pl = Longitudinal tube pitch, in Pt = Transverse tube pitch, in Mass Velocity, Gn: Gn = Wg/An Where, Wg = Mass gas flow, lb/hr An = Net free area, ft2 Net Free Area, An: An = Ad - Ac * Le * Nt Where, Ad = Cross sectional area of box, ft2 Ac = Fin tube cross sectional area/ft, ft2/ft Le = Effective tube length, ft Nt = Number tubes wide And, Ad = Nt * Le * Pt / 12 Ac = (do + 2 * lf * tf * nf) / 12 tf = fin thickness, in nf = number of fins, fins/in Surface Area Calculations: For the prime tube, Apo = Pi * do (1- nf * tf) / 12 And for solid fins, Ao = Pi*do(1-nf* tf)/12+Pi*nf(2*lf(do+lf)+tf(do+2*lf))/12 And for segmented fins, Ao = Pi*do(1-nf* tf)/12+0.4*Pi*nf(do+0.2)/12+Pi*nf (do+0.2)((2*lf-0.4)(wn+tf)+ws*tf)/(12*ws) And then, Afo = Ao - Apo Where, ws = Width of fin segment, in Fin Efficiency, E: For segmented fins, E = x * (0.9 + 0.1 * x) And for solid fins, E = y * (0.45 * ln(df / do) * (y - 1) + 1) Where, y = x * (0.7 + 0.3 * x) And, x = tanh(m * B) / (m * B) Where, B = lf + (tf /2) For segmented fins, m = (ho (tf + ws) / (6 * kf * tf * ws))0.5 And for solid fins, m = (ho / (6 * kf * tf))0.5 Fin Tip Temperature, Ts: The average fin tip temperature is calculated as follows, Ts = Tg + (Tw - Tg) * 1/((e1.4142mB+e-1.4142mB)/2) Maximum Fin Tip Temperature, Tfm: The maximum fin tip temperature is calculated as follows, Tsm = Twm + q(Tgm - Twm) Where, Tsm = Maximum Fin Tip Temperature, F Tgm = Maximum Gas Temperature, F Twm = Maximum Tube Wall Temperature, F And, The value for theta, q, can be described by the following curve. Graph 5 theta vs fin efficiency 6.9 CONVECTION TRANSFER IN CONVECTION SECTION , STUD TUBES Overall Heat Transfer Coefficient, Uo: Uo = 1/Rto Where, Uo = Overall heat transfer coefficient, Btu/hr-ft2-F Rto = Total outside thermal resistance, hr-ft2-F/Btu And, Rto = Ro + Rwo + Rio Ro = Outside thermal resistance, hr-ft2-F/Btu Rwo = Tube wall thermal resistance, hr-ft2-F/Btu Rio = Inside thermal resistance, hr-ft2-F/Btu And the resistances are computed as, Ro = 1/he Rwo = (tw/(12*kw))(Ao/Aw) Rio = ((1/hi)+Rfi)(Ao/Ai) Where, he = Effective outside heat transfer coefficient, Btu/hr-ft2-F hi = Inside film heat transfer coefficient, Btu/hr-ft2-F tw = Tubewall thickness, in kw = Tube wall thermal conductivity, Btu/hr-ft-F Ao = Outside surface area, ft2/ft Aw = Mean area of tube wall, ft2/ft Ai = Inside tube surface area, ft2/ft Rfi = Inside fouling resistance, hr-ft2-F/Btu Effective outside heat transfer coefficient, he: For staggered and inline pitch, he = (hso*E*Afo+ht*Apo)/Ao Where, ht = Base tube outside heat transfer coefficient, Btu/hr-ft2-F hso = Stud outside heat transfer coefficient, Btu/hr-ft2-F Ao = Total outside surface area, ft2/ft Afo = Stud outside surface area, ft2/ft Apo = Tube outside surface area, ft2/ft Inline pitch correction, he = he*(do/Pl)0.333 Where, do = Outside tube diameter, in Pl = Longitudinal pitch of tubes, in Base tube outside heat transfer coefficient, ht: ht = (0.717/do0.333)(Gn/1000)0.67(Tb+460)0.3 And the stud coefficient, hs = 0.936*(Gn/1000)0.67(Tb+460)0.3 With fouling, hso = 1/(1/hs+Rfo) Where, hs = Stud outside heat transfer coefficient, Btu/hr-ft2-F Gn = Mass velocity of flue gas, lb/hr-ft2 Tb = Average gas temperature, F Stud efficiency, E: E = 1/((ex+e-x)/1.950) Where, X = Ls/12((2*hso)/(ks*Ds/12))0.5 And, Ls = Length of stud, in Ds = Diameter of stud, in ks = Conductivity of stud, Btu/hr-ft-F 6.10 THERMAL CONDUCTIVITY OF METALS The thermal conductivity of the tube material and the extended surface is needed for calculating the heat transfer coefficients. Graph 6 Thermal conductivity vs temperature 6.11 TUBE WALL TEMPERATURE CALCULATION The temperature of the tube wall may be calculated using the following equations. This method does not take coking into account. Tw = Flux*do/di*Rfi+Flux*do/di*1/hi+Flux*do/(do-tw)*tw/(kw*12)+Tf Where, Tw = Tube wall temperature, F Flux = Flux rate, Btu/hr-ft2 of bare tube do = Outside tube diameter, in di = Inside tube diameter, in tw = Tube wall thickness, in Rfi = Inside fouling factor, hr-ft2-F/Btu hi = Fluid film coefficient, Btu/hr-ft2-F kw = Thermal conductivity of tube wall, Btu/hr-ft-F Tf = Bulk process fluid temperature, F CHAPTER 7 VARIATION IN PROPERTIES 7.1 SINGLE PHASE FLUIDS The thermal properties of the process fluid flowing through the fired heater are extremely important to the fired heater designer. These properties not only have a direct affect on the amount of heat transferred, they also are important in predicting the pressure loss and furnace coking rates, etc. For single phase fluids, liquid or vapor, the properties can normally be assumed to change on a straight line basis from the inlet to the outlet of the heater. Therefore, providing the designer with the properties of the process fluid at the inlet and outlet conditions will normally suffice. The one exception to this, is the viscosity. The following formula may be used to correct the viscosity using the two given values. mnew = A * e(B/Tnew) And the constants, A = min * e(-B/Tin) B = ln(min/mout) / (1/Tin-1/Tout) Where, mnew = Corrected viscosity, Cp min = Inlet viscosity, Cp mout = Outlet viscosity, Cp Tnew = Temperature at new condition, °R Tin = Temperature at inlet, °R Tout = Temperature at outlet, °R 7.2 MIXED PHASE FLUIDS For mixed phase process, obtaining the thermal properties of the fluid at the different points in the fired heater is much more difficult than with the single phase flow. However, for a heater with mixed phase at the inlet, the thermal heat transfer calculations may be performed using a straight line approximation similar to that used with single phase, without much loss in reliability of the results. It should be noted that when a heater has mixed phase at inlet and multiple tube passes, the actual flow conditions in the various passes may not be equal. For the more normal situation, where the inlet process is a single phase liquid and vaporization begins at some unknown point in the heater, it becomes more difficult to estimate the properties. One way to do this is to set up a grid of the properties based on various pressures and temperatures. 7.3 HEAT TRANSFER COEFFICIENTS The inside film coefficient needed for the thermal calculations may be estimated by several different methods. The API RP530, Appendix C provides the following methods, For liquid flow with Re =>10,000, hl = 0.023(k/di)Re0.8*Pr0.33(mb/mw)0.14 And for vapor flow with Re =>15,000, hv = 0.021(k/di)Re0.8*Pr0.4(Tb/Tw)0.5 Where the Reynolds number is, Re = di*G/mb And the Prandtl number is, Pr = Cp*mb/k Where, hl = Heat transfer coefficient, liquid phase, Btu/hr-ft2-°F k = Thermal conductivity, Btu/hr-ft-°F di = Inside diameter of tube, ft mb = Absolute viscosity at bulk temperature, lb/ft-hr mw = Absolute viscosity at wall temperature, lb/ft-hr hv = Heat transfer coefficient, vapor phase, Btu/hr-ft2-°F Tb = Bulk temperature of vapor, °R Tw = Wall Temperature of vapor, °R G = Mass flow of fluid, lb/hr-ft2 Cp = Heat capacity of fluid at bulk temperature, Btu/lb-°F For two-phase flow, htp = hlWl + hvWv Where, htp = Heat transfer coefficient, two-phase, Btu/hr-ft2-°F Wl = Weight fraction of liquid Wv = Weight fraction of vapor 7.4 IN TUBE PRESSURE DROP The pressure loss in heater tubes and fittings is normally calculated by first converting the fittings to an equivalent length of pipe. Then the average properties for a segment of piping and fittings can be used to calculate a pressure drop per foot to apply to the overall equivalent length. Friction Loss: Dp = 0.00517/di*G2*Vlm*F*Lequiv Where, Dp = Pressure drop, psi di = Inside diameter of tube, in G = Mass velocity of fluid, lb/sec-ft2 Vlm = Log mean specific volume correction F = Fanning friction factor Lequiv = Equivalent length of pipe run, ft And, Vlm = (V2-V1)/ln(V2/V1) For single phase flow, V1 = Specific volume at start of run, ft3/lb V2 = Specific volume at end of run, ft3/lb For mixed phase flow, Vi = 10.73*(Tf/(Pv*MWv)*Vfrac+(1-Vfrac)/rl Where, Vi = Specific volume at point, ft3/lb Tf = Fluid temperature, °R Pv = Press. of fluid at point, psia MWv = Molecular weight of vapor Vfrac = Weight fraction of vapor %/100 rl = Density of liquid, lb/ft3 Equivalent Length Of Return Bends: The equivalent length of a return bend may be obtained from the following curves based on Maxwell table and can be corrected using the Reynolds number correction factor. Lequiv = FactNre*Lrb Where, FactNre = Reynolds number correction Lrb = Equivalent length of return bend, ft Return Bend Equivalent Length: Graph 7 Return bend equivalent length curve Reynolds Correction: Graph 8 Return bend equivalent length Nre correction Where, G = Mass velocity, lb/sec-ft2 Di = Inside tube diameter, in Visc = Viscosity, cp 7.5 GAS SIDE PRESSURE DROP ACROSS TUBE Bare Tube Pressure Loss: For bare tubes we can use the method presented here Dp = Pv /2 * Nr Where, Dp = Pressure drop, inH2O Pv = Velocity head of gas, inH2O Nr = Number of tube rows And the velocity head can be described as, Pv = 0.0002307 * (Gn /1000)2 / rg Where, Gn = Mass velocity of gas, lb/hr-ft2 rg = Density of gas, lb/ft3 The Mass velocity is described as, Gn = Wg / An Where, Wg = Mas gas flow, lb/hr An = Net free area, ft2 And, An = Ad - do/12 * Le * Nt For staggered tubes without corbels, Ad = ((Nt +0.5) * Pt/12) * Le For staggered tubes with corbels or inline tubes, Ad = (Nt * Pt/12) * Le Where, Ad = Convection box area, ft2 do = Outside tube diameter, in Le = Tube length, ft Pt = Transverse pitch of tubes, in Nt = Number of tubes per row Fin Tube Pressure Loss: For the fin tube pressure drop, we will use following method. Dp = ((f+a)*Gn2*Nr)/(rb*1.083E+109) And, For staggered layouts, f = C2 * C4 * C6 * (df/do)0.5 For inline layouts, f = C2 * C4 * C6 * (df/do)1.0 And, a = ((1+B2)/(4*Nr))*rb*((1/rout)-(1/rin)) Where, Dp = Pressure drop, inH2O rb = Density of bulk gas, lb/ft3 rout = Density of outlet gas, lb/ft3 rin = Density of inlet gas, lb/ft3 Gn = Mass gas flow, lb/hr-ft2 Nr = Number of tube rows do = Outside tube diameter, in df = Outside fin diameter, in And, B = An / Ad For staggered tubes without corbels, Ad = ((Nt +0.5) * Pt/12) * Le For staggered tubes with corbels or inlune tubes, Ad = (Nt * Pt/12) * Le Net Free Area, An: An = Ad - Ac * Le * Nt Where, Ad = Cross sectional area of box, ft2 Ac = Fin tube cross sectional area/ft, ft2/ft Le = Effective tube length, ft Nt = Number tubes wide And, Ac = (do + 2 * lf * tf * nf) / 12 tf = fin thickness, in nf = number of fins, fins/in Reynolds correction factor, C2: C2 = 0.07 + 8 * Re-0.45 And, Re = Gn * do/(12*mb) Where, mb = Gas dynamic viscosity, lb/ft-hr Geometry correction, C4: For segmented fin tubes arranged in, a staggered pattern, C4 = 0.11*(0.0 5*Pt/do)(-0.7*(lf/sf)^0.23) an inline pattern, C4 = 0.08*(0. 15*Pt/do)(-1.1*(lf/sf)^0.20) For solid fin tubes arranged in, a staggered pattern, C4 = 0.11*(0.0 5*Pt/do)(-0.7*(lf/sf)^0.20) an inline pattern, C4 = 0.08*(0. 15*Pt/do)(-1.1*(lf/sf)^0.15) Where, lf = Fin height, in sf = Fin spacing, in Non-equilateral & row correction, C6: For fin tubes arranged in, a staggered pattern, C6 = 1.1+(1.8-2.1*e(-0.15*Nr^2))*e(-2.0*Pl/Pt) - (0.7*e(-0.15*Nr^2))*e(-0.6*Pl/Pt) an inline pattern, C6 = 1.6+(0.75-1.5*e(-0.70*Nr))*e(-2.0*(Pl/Pt)^2) Where, Nr = Number of tube rows Pl = Longitudinal tube pitch, in Pt = Transverse tube pitch, in Stud Tube Pressure Loss: For the stud tube pressure loss we will use the following method, The general equation for staggered or inline tubes, Dp = Nr*0.0514*ns((Cmin-d0-0.8*ls)/((ns*(Cmin-do-1.2*ls)2)0.555))1.8*G2*((Tg+460)/1460) Where, Dp = Pressure drop across tubes, inH2O Nr = Number of tube rows Cmin = Min. tube space, diagonal or transverse, in do = Outside tube diameter, in ls = Length of stud, in G = Mass gass velocity, lb/sec-ft2 Tg = Average gas Temperature, °F Correction for inline tubes, Dp = Dp*((do/Cmin)0.333)2 And, G = Wg/(An*3600) An = Le*Nt*(Pt-do-(ls*ts*rs)/12)/12 Where, Wg = Mass flow of gas, lb/hr An = Net free area of tubes, ft2 Le = Length of tubes, ft Nt = Number of tubes wide Pt = Transverse tube pitch, in ls = Length of stud, in ts = Diameter of stud, in rs = Rows of studs per foot CHAPTER 8 HEATER STACK DRAFT ANALYSIS Fired heaters come in numerous configurations and designs. These configurations include systems that are forced draft, induced draft or a combination of both, but many are natural draft. The natural draft designs will be discussed in this section. Regardless of the mechanics involved, the stacks purpose is the same, to safely disperse the products of combustion into the atmosphere. For environmental reasons, many stacks are required to discharge at a particular height. But in most cases they are designed only to meet the needs of the furnace or furnaces they are designed for. In the case of the natural draft furnace, the stack serves another purpose, that of assuring that the furnace stays below atmospheric pressure throughout the setting. For most stack designs, a gas velocity at the exit of about 15 to 25 ft/sec is sufficient to discharge the gasses into the atmosphere at a rate that will assure they disperse properly. Additionally, most natural stack are designed for 125% of the design flue gas flow to assure that if the furnace is operated above the design point that it will still operate safely. In this sketch, the area marked "A" is the height available, for the differences in the density of the ambient air and the flue gas, to create the draft required. Normally the draft required is that which will result in a slightly negative pressure at point "B". It should be noted that, for most heaters, the draft at point "C" required by the burners to induce combustion air is not considered in setting the stack height. The burners are normally sized to use only the draft in the firebox. Fig 10 draft in heater Pressure loss across stack entry: This pressure loss can normally be considered as a sudden entry since the area of the outlet gas plenum in the heater is usually much greater than the area of the inlet to the transition. A sudden entry pressure loss can be approximated by the following equation. Dp = 0.34 * Vh Where, Dp = Pressure drop, inH2O Vh = Velocity head at inlet area, inH2O Pressure loss across stack transition: This pressure loss can normally be considered as a gradual contraction since the area of the inlet and the outlet are usually close in area. A gradual contraction pressure loss can be approximated by the following equation. Dp = Ca * Vh Where, Dp = Pressure drop, inH2O Vh = Velocity head at outlet area, inH2O Ca = Coefficient based on included angle And the coefficient can be described as, Included Angle Ca 30 0.02 45 0.04 60 0.07 Pressure loss across stack damper: This pressure loss is normally accounted for by rule of thumb. This may be 0.5 or 0.25 velocity head. Assumed 0.25 Dp = 0.25 * Vh Where, Dp = Pressure drop, inH2O Vh = Average velocity head of stack, inH2O Stack friction loss: For the stack friction loss, the following equation is used Dp = (0.002989 * 0.018 * rg * Vg2) / Ds * Ls Where, Dp = Pressure drop, inH2O Vg = Average velocity of stack, ft/sec rg = Density of flue gas, lb/ft3 Ds = Stack diameter, ft Ls = Stack length, ft Stack draft gain: The draft gain will be taken based on the height, "A" on above sketch. Gd = (ra - rg)/5.2 * A Where, Gd = Draft Gain, inH2O rg = Density of flue gas, lb/ft3 ra = Density of ambient air, lb/ft3 A = Height of gas path, ft Pressure loss across stack exit: This pressure loss, since it normally exits to atmosphere, can be considered as a sudden exit. A sudden exit pressure loss can be approximated by the following equation. Dp = 1.0 * Vh Where, Dp = Pressure drop, inH2O Vh = Velocity head at inlet area, inH2O Velocity head of gas: Vh = Vg2 * rg / 2 / 32.2 / 144 * 27.67783 CHAPTER 9 DUCTING PRESSURE LOSS Fired heater designers utilize ducting for many purposes in a fired heater design. They are used for connecting flue gas plenums to stacks, distributing combustion air to burners, transferring flue gas to and from air preheat systems, etc. The pressure losses through ducting pieces may be individually analysed or the may be analysed as a system. Straight duct run friction loss: Dp = (0.002989 * Fr * rg * Vg2)*Le/De Where, Dp = Pressure drop, inH2O Fr = Moody friction factor rg = Average gas density, lb/ft3 Vg = Velocity of gas, ft/sec Le = Equivalent length of piece, ft De = Equivalent diameter of piece, ft And for round duct, De = Diameter And for rectangular duct, De = (2 * Width * Height)/(Width + Height) 90° Round section elbow loss: Dp = Vh * Cl Where, Vh = Velocity head of gas, inH2O Cl = Loss Coefficient From Table 90° Rectangular section elbow loss: Dp = Vh * Cl Where, Vh = Velocity head of gas, inH2O Cl = Loss Coefficient From Table Elbow of any degree turn loss: This may be used for a rectangular or round duct elbow of N ° turn. Dp = Vh * C90 * N/90 Where, Vh = Velocity head of gas, inH2O C90 = Loss coefficient from above for 90° turn N = Number of degrees of turn Sudden contraction loss: Dp = Vh * Cl Where, Vh = Velocity head of gas, inH2O Cl = Loss Coefficient From Table Gradual contraction loss: Dp = Vh * Cl Where, Vh = Velocity head of gas, inH2O Cl = Loss Coefficient From Table No contraction change of axis loss: Dp = Vh * Cl Where, Vh = Velocity head of gas, inH2O Cl = Loss Coefficient From Table Sudden enlargement loss: Dp = Vh * Cl Where, Vh = Velocity head of gas, inH2O Cl = Loss Coefficient From Table Gradual enlargement loss: Dp = Vh * Cl Where, Vh = Velocity head of gas, inH2O Cl = Loss Coefficient From Table Sudden exit loss: Dp = Vh * Cl Where, Vh = Velocity head of gas, inH2O Cl = Loss Coefficient From Table 90° Rectangular miter elbow loss: Dp = Vh * Cl Where, Vh = Velocity head of gas, inH2O Cl = Loss Coefficient From Table Draft gain or loss: The draft gain or loss will be taken based on the height of the upward or downward flow of the flue gas. If the flow is upward, the pressure loss is negative. Dp = (ra - rg)/5.2 * A Where, Dp = Draft gain or loss, inH2O rg = Density of flue gas, lb/ft3 ra = Density of ambient air, lb/ft3 A = Height of gas path, ft CHAPTER 10 BURNER TYPE AND SELECTION There are many aspects of burner design that need to be considered in conjunction with the design of a fired heater. The major considerations that shall be accounted for in burner selection and design are discussed below 10.1 DRAFT Burners are broadly categorized into two types : natural and forced draft. Burners are sized based on consideration of total air side pressure drop or draft loss across the burner. Natural draft burner The combustion air for natural draft burners is induced through the burner either by the negative pressure inside the firebox or by the fuel gas pressure educting the air through a venturi. Natural draft burners are the most found burner in general refinery service. Forced draft burner They operate with combustion air supplied at a positive pressure. The term “forced draft” is so designated because the combustion air or other oxygen source is normally supplied by mechanical means .They have higher available sir supply measured as higher air pressure compared to a natural draft burner. This can allow the use of smaller or few burners for the same equivalent heat release from a natural draft burner. 10.2 FLAME STABILITY Above all the other consideration a burner shall operate safely and be stable within the burner operating conditions. A stable flame is one where the root of the flame is firmly attached to the designed flame stabilization point( the region within a burner that acts as a continuous ignition zone for the flame), with no signs of the flame root jumping between other possible stability zones. The mixing of the combustion air with the fuel is critical to flame stability. Mixing energy can be provided by the fuel discharge velocity and its direction of flow. Natural draft burners have to rely more on fuel energy for mixing than do forced draft burner. They are more likely to have poorer mixing.in case of forced draft burner turbulence is created within the burner improving the mixing process and enhance flame stability. 10.3 DESIGN EXCESS AIR Perfect combustion is achieved when all the fuel is burned using only the theoretical amount of air. Perfect combustion cannot be achieved in a fired heater. Complete combustion is achieved when all the fuel is burned using the minimal amount of air above the theoretical amount of air needed to burn the fuel. With complete combustion, the fuel is burned at the highest combustion efficiency. Incomplete combustion occurs when all the fuel is not burned, which results in the formation of soot and smoke. Excess air is air supplied to the burner that exceeds the theoretical amount needed to burn the fuel. Combustion air requirements are based on the composition of the fuel used and the design of the burner. Fuels commonly used contain nitrogen, ash, oxygen, sulfur, carbon and hydrogen. When a fuel has a large volume of nitrogen that must be accepted along with the desired oxygen, more excess air should be provided. That excess air has a chilling effect on the flame. Some fuel particles fail to combine with oxygen and pass out of the stack unburned. Water vapor is a by-product of burning hydrogen. It too subtracts heat from the flame and becomes steam at flue gas temperature, passing out of the stack as vapor mixed with the combustion products. Natural gas contains more hydrogen and less carbon per unit of heat content than oil and consequently its combustion produces a great deal more water vapor which withdraws a greater amount of heat from the flame. Therefore gas efficiency is always slightly less than oil efficiency. Reducing excess air below design level will typically have following effects on emissions pollutant NOx SOx CO Combustible particulates Effect on excess air Decrease No change in total Sox, however less SO2 converted to SO3 Increase Increase Increase Table 2 effect of pollutant on excess air 10.4 COMBUSTION AIR PREHEAT The addition of heat to the combustion air increases the efficiency of the combustion process. Higher air preheat temperature will increase flame temperatures. This will increase the concentration of NOx in the flue gas while the mass will reduce. Hence the extent of air preheat at design conditions and consider this when specifying equipment for low emissions of NOx 10.5 TURBINE EXHAUST GAS The oxygen for the combustion of fuel in fired heater can be supplied by the flue gas streams such as the exhaust from a gas turbine . Gas turbine exhaust streams contain between 13 to 17 volume percent of oxygen at temperature between 454 ◦C and 565 ◦C .Burner can operate with oxygen content down to approximately 15 volume percent in turbine exhaust streams, below this level combustion can become unstable 10.6 COMBUSTION AIR ADJUSTMENT Burners are normally provided with airside control devices to adjust the air rate into the burner. Air registers or dampers are provided for this purpose. CHAPTER 11 AUXILIARY EQUIPMENT 11.1 AIR PREHEAT SYSTEM The air preheat system is used to preheat the combustion air going to the burners. Since it cools the flue gas further, while removing heat, it improves the efficiency of the furnace. Using an air preheat system will frequently result in overall efficiencies above 90%. Fig 11 Air preheat system Regenerative Air Heater The regenerative air heater is widely used in the boiler and power generation industry. For this reason, when the fired heater industry developed a need for air heaters, these designs were the first to be used. They consist of a setting enclosing a large rotor which holds baskets of heat exchange surface. This rotor causes the baskets to pass through the hot flue gas, where the material heats up, and then through the cold air, which it heats. Even though these were very good at exchanging large amounts of heat, they had a downside of leakage from the higher pressure side(air) to the lower pressure side(flue gas) and of course they have moving parts. The sketches below show the basics of this type air heater. Fig 12A regenerative air heater Fig 12C basket Fig 12B rotor Recuperative, Tubular Air Heater The recuperative air heater comes in a variety of types. The one shown below is designed to set atop the fired heater(in place of the stack). The air is drawn in across the shell side of the exchanger, then directed to the burners. After combustion, the flue gas travels through the heater and then the air heater on the tube side, where it exists to the artmosphere. Recuperative, Cast Tube Air Heater Fig 13 Recuperative, Tubular Air heater This recuperative air heater utilizes cast tubes and has become the most popular air heater in use. It has very low, if any leakage across the heat transfer surfaces. It is durable with no moving parts. If corrosion is a problem, the cold end units are usually glass tube. Fig 14 Recuperative, Cast Tube Air heater Heating Medium Air Heater This air heater comes Is part of a recirculating hot oil system which recovers heat from the flue gas exiting the fired heater and uses it to preheat the combustion air going to the burners. Fig 15 Heating medium air heater 11.2 SOOT BLOWER Soot blowers are becoming less and less important in the Petrochemical and Refinery industry during modern times. The reason for this is that generally, any component of the flue gases that can foul the tubes can also foul the air. So, as clean air requirements continue to get more stringent, the resulting cleaner fuels are less likely to foul the tubes. Retractable Soot Blower: The retractable blower gets it's name from the fact that the element that does the cleaning is retracted out of the hot gas stream when it is not in use. Since it has less nozzles than a fixed rotary blower, it can produce a better cleaning velocity for the same steam pressure. This type blower is used for the higher temperature and dirtier fuel applications. Fig 16 Retractable soot blower Fixed Rotary Soot Blower: Fig 17 Fixed rotary soot blower The rotary blower is in a fixed position and since the element is supported by the hangers at different points, the element requires less material than the retractable blower. This blower costs less than the retractable, but requires a greater volume of steam. This type blower is used for the lower temperature and cleaner fuel applications. Sootblower Recommendations: Under normal operating conditions, sootblower selection can be done as follows: A. Below 100 ppm vanadium or 25 ppm sodium or 2% sulphur in the fuel oil: Rotary sootblower to 1800°F gas temperature. Retractable sootblower above 1800°F. B. 100 to 200 ppm vanadium or 25 ppm sodium or 2% sulphur in the fuel oil: Rotary sootblower to 1300°F gas temperature. Retractable sootblower above 1300°F. Above 200 ppm vanadium or contents in excess of 25 ppm sodium or 2% sulphur in the fuel C. oil: Rotary sootblower to 1050°F gas temperature. Retractable sootblower above 1050°F. Under control conditions other factors may be used to modify sootblower selection. 11.3 FANS AND BLOWER Fans and blowers, as used in fired heater service, usually fall into one of the following categories. Forced Draft Fans Induced Draft Fans Purge Fans Each of these purposes are usually served by a different type fan. Forced Draft Fans: Forced draft (FD) fans are used in heater service to supply combustion air to the burner(s). They draw in oxygen rich ambient air and force it through the burner system for the combustion of fuel. They normally are not employed to move the flue gasses through the furnace setting, but in special cases, such as a positive pressure, single fan air preheat system, they may also provide the energy for this purpose. The FD fan is normally handling clean, ambient air. One exception is when the air preheater is located upstream of the FD fan. In this case it is handling hot clean air. When handling clean ambient air, the basic parameter of fan selection is the fan's efficiency Induced Draft Fans: Induced draft (ID) fans are generally used to pull the flue gas from the heater and discharge it to atmosphere directly or through an air preheater. Applications where this discharge is direct are unusual. An example might be where a fired heater was also being used as a waste gas flare. The normal use of the ID fan is on a two fan air preheat system. A single ID fan system might work but many factors would favor the FD fan single fan system over the ID fan. On two fan air preheat systems the fan selection is usually dictated by system pressure drop and type of fuel being burned. Centrifugal fans are almost always used since nothing but the wheel and shaft are actually exposed to the hot gas stream Purge Fans: The purpose of the purge fan is to discharge from a heater setting any potentially explosive gas mixtures prior to lighting of the burners. Purge fans are especially desirable on heaters that are shut down and relighted on a regular basis. Heaters employing FD or ID fans do not normally require additional purge fans. Running the FD or ID fan usually will purge the system. Natural draft heaters, however, are often fitted with purge blowers. When a cold heater experiences a light off failure, it can build up a potentially explosive gas mixture. As the heater setting is cold, there is no "natural draft" available to remove these gases. The purge fan is normally a small low pressure drop axial fan. It is important to protect these fans when they are not being used, since the radiant heat they may be exposed to would destroy the fan. A butterfly valve is often used to shut the fan off from the hot gases in the firebox. Some purge fan applications require the injection of purge air at multiple entry points. 11.4 DAMPERS, LOUVERS, & DIVERTERS Dampers and louvers can generally be broken down by the following types. Stack Damper: This is a basic device found on most heaters and furnaces. The stack damper is necessary to adjust the draft in a natural draft furnace. Even if the designer could calculate accurately enough to exactly predict the draft in the furnace, he would still over design the stack to take care of future modifications. This damper is normally not of a tight seal type, in fact it generally is manufactured with two or three inches of clearance around the perimeter. This damper would not normally be used to control combustion air, but rather to assure that too much draft is not available in the furnace. Too much draft would result in air leakages into the furnace which would result in reduced efficiency. Manual operation is normally used, but actuators can be used for automated operations. Fig 18 Stack Damper Butterfly Damper: Butterfly dampers are single blade, low leakage or minimum leakage dampers utilizing a round, square or rectangular blade. Butterfly dampers are well suited for on/off service or flow control balancing. Electric, pneumatic, hydraulic and manual gear actuators with pneumatic or electrical positioners can be used. Parallel Blade Louver: The parallel design is used primarily for isolation. The use of blade edge and jamb seals achieves minimal leakage past the closed damper. These dampers are used mostly in air preheat and heat recovery systems. They would be used where a tight shut off is required, such as isolating one unit from another in a multiple unit system. Electric, pneumatic, hydraulic and manual gear actuators with pneumatic or electrical positioners can be used. Opposed Blade Louver: The opposed design exhibits the best flow control characteristics with moderate leakage past the closed damper. This type damper would be necessary if the accuracy of the flow amount is required or if the flow pattern must be maintained, such as when entering a burner zone. Electric, pneumatic, hydraulic and manual gear actuators with pneumatic or electrical positioners can be used. Double Louvers: The double louver design utilizes two banks of blades. Zero flue gas leakage is achieved by pressuring the area between two closed banks of blades with seal air. The parallel/opposed configuration provides zero leakage yet retains good flow control characteristics. These dampers can be found in applications where fast bypass capability is required during an upset condition. Double louvers can also be found where overhead space is not available to install a slide gate damper. Slide Gate(Guillotine): Slide gate isolation dampers are available in low leakage and zero leakage designs utilizing either machine screws or chain drives. Slide gate dampers can be furnished with electrical actuators, air actuators or hydraulic actuators. Flow Diverter Dampers: Flow diverter dampers are utilized on many process and heat recovery systems to direct the flow in one or two directions. In a heat recovery system, the diverter damper would normally direct the gas to a waste heat recovery system or in a bypass mode through a silencer and stack. The diverter damper can also be furnished with a single end pivoted blade to direct the gas flow into one of the two outlets. The metallurgy of the damper is based on the design temperature and pressure of the system. CHAPTER 12 HEATER DESIGN AND ENGINEERING The engineering used in heater design can be mainly classified into following type 12.1 PROCESS/THERMAL ENGINEERING It mainly consists of burner design (type, numbers, burner circle diameter, etc) , radiant coil design (number of passes, coil diameter and length , pitch circle diameter, etc), convection coil design (number of passes, coil diameter and length ,number of rows, etc), refractory material and thickness , Anchoring system and stack sizing 12.2 MECHANICAL ENGINEERING It mainly consists of design of tube, design of fitting, design of tube supports, radiant , convection and header box sizing, hydro test calculations. 12.3 STRUCTURAL / CIVIL ENGINEERING It consists of load for radiant section, convection section and stack , support structure for pipping near heater area as per the project requirement, design of pipe support anchors , civil load data 12.4 ENVIRONMENTAL ENGINEERING It is mainly concerned with limitations for emission of NOx ,SOx , CO, particulate matter and unburnt hydrocarbon 12.5 INTERFACE ENGINEERING As the name suggest it involves interface within various departments involved in designing of fired heater. The departments are process, instrumentation, piping , civil , electrical and machinery. CHAPTER 13 LOAD DATA SHEET Having understood components, construction and working of fired heater I moved ahead to develop load data sheet which would help the company in preparing the project proposal at the initial stage of the project in cost estimation and visualizing the 2-D view of the heater. It would also help to find the potential problems that would occur at the time if erection of fired heater at sight and hence finding the solution so forth. I developed load data sheet for vertical cylinder heater as well as box heater. However , before starting the load data sheet I learnt how to interpret general arrangement diagram (GAD) and data sheet. Fig 19 tab 1 input sheet Fig 20 Tab 2 fired heater 2D diagram Fig 21 Tab 3 load calculation Fig 22 total weight calculation TIME LINE OF THE PROJECT 8 January– 12 February Basics of fired heater,components, standard followed , engineering involved , aid in live project 12 February– 12 March Understanding fired heater in detail, API 560 standard , John Zink Hamworthy handbook volume 1,2 and 3 12 March– 12 April Learn how to interpret GAD, data sheet an developing load data sheet for vertical cylindrical heater 12 April– 31 May Developing load data sheet for box heater, understanding heat transfer mechanism in fired heater, analysis of draft in stack, report preparation REFERENCES API 560 standard Book name : The John Zink Hamworthy Combustion Handbook, Second edition, Volume 1 – Fundamentals The John Zink Hamworthy Combustion Handbook, Second edition, Volume 2 – Design and Operation The John Zink Hamworthy Combustion Handbook, Second edition, Volume 3 – Applications Lobo & Evans, Heat Transfer in the Radiant Section of Petroleum Heaters, AICHE, Vol. 35, 1939 Last page Project Group Personal Details Name of the Student: Shah Vrund Bhavinkumar Permanent Address: D/2 Ganesh Park society , Nr. Kedar dham, Manjalpur, Vadodara , 390011 Email: vrund.smc17@sot.pdpu.ac.in Mobile no:8238677755