[1]

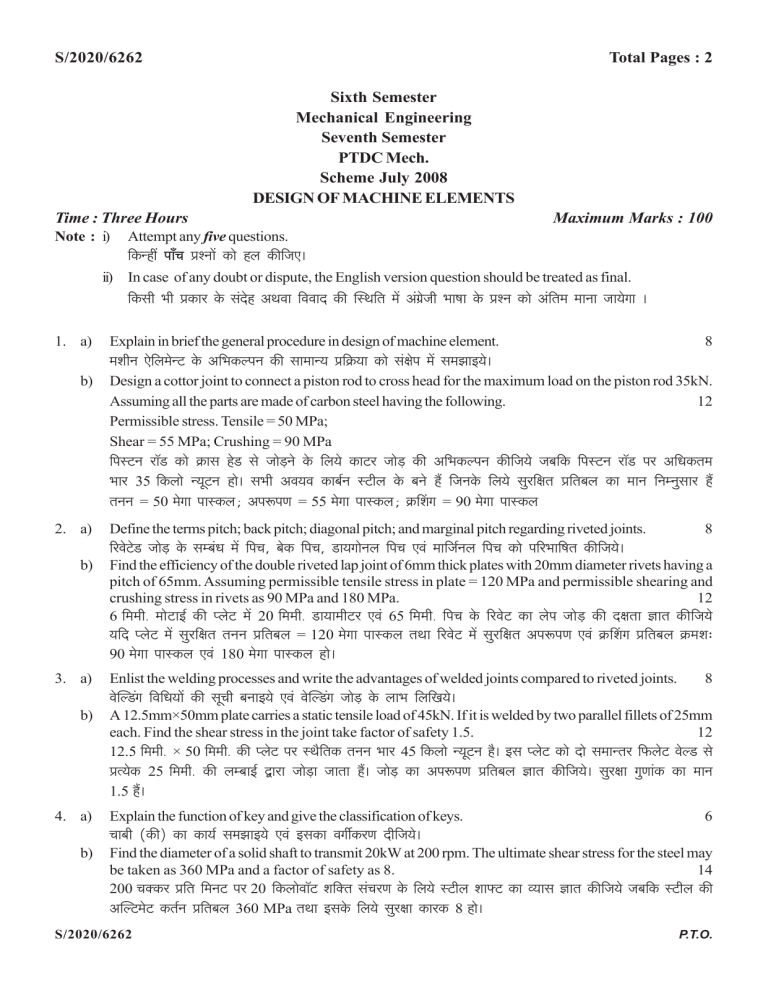

S/2020/6262

Total Pages : 2

Sixth Semester

Mechanical Engineering

Seventh Semester

PTDC Mech.

Scheme July 2008

DESIGN OF MACHINE ELEMENTS

Time : Three Hours

Note : i)

Maximum Marks : 100

Attempt any five questions.

{H$Ýht nm±M àíZm| H$mo hb H$s{OE&

ii) In case of any doubt or dispute, the English version question should be treated as final.

{H$gr ^r àH$ma Ho$ g§Xoh AWdm {ddmX H$s pñW{V ‘| A§J«oOr ^mfm Ho$ àíZ H$mo A§{V‘ ‘mZm Om¶oJm &

1. a)

Explain in brief the general procedure in design of machine element.

8

‘erZ Eo{b‘oÝQ> Ho$ A{^H$ënZ H$s gm‘mݶ à{H«$¶m H$mo g§jon ‘| g‘PmB¶o&

b)

Design a cottor joint to connect a piston rod to cross head for the maximum load on the piston rod 35kN.

Assuming all the parts are made of carbon steel having the following.

12

Permissible stress. Tensile = 50 MPa;

Shear = 55 MPa; Crushing = 90 MPa

{nñQ>Z am°S> H$mo H«$mg hoS> go Omo‹S>Zo Ho$ {b¶o H$mQ>a Omo‹S> H$s A[^H$ënZ H$s{O¶o O~{H$ {nñQ>Z am°S> na A{YH$V‘

^ma 35 {H$bmo ݶyQ>Z hmo& g^r Ad¶d H$m~©Z ñQ>rb Ho$ ~Zo h¢ {OZHo$ {b¶o gwa{jV à{V~b H$m ‘mZ {ZåZwgma h¢

VZZ = 50 ‘oJm nmñH$b; Anê$nU = 55 ‘oJm nmñH$b; H«$qeJ = 90 ‘oJm nmñH$b >

2. a)

Define the terms pitch; back pitch; diagonal pitch; and marginal pitch regarding riveted joints.

8

[adoQ>oS> Omo‹S> Ho$ gå~§Y ‘| {nM, ~oH$ {nM, S>m¶JmoZb {nM Ed§ ‘m{O©Zb {nM H$mo n[a^m{fV H$s{O¶o&

b)

3. a)

Find the efficiency of the double riveted lap joint of 6mm thick plates with 20mm diameter rivets having a

pitch of 65mm. Assuming permissible tensile stress in plate = 120 MPa and permissible shearing and

crushing stress in rivets as 90 MPa and 180 MPa.

12

6 {‘‘r. ‘moQ>mB© H$s ßboQ> ‘| 20 {‘‘r. S>m¶m‘rQ>a Ed§ 65 {‘‘r. {nM Ho$ [adoQ> H$m bon Omo‹S> H$s XjVm kmV H$s{O¶o

¶{X ßboQ> ‘| gwa{jV VZZ à{V~b = 120 ‘oJm nmñH$b VWm [adoQ> ‘| gwa{jV Anê$nU Ed§ H«$qeJ à{V~b H«$‘e…

90 ‘oJm nmñH$b Ed§ 180 ‘oJm nmñH$b hmo& >

Enlist the welding processes and write the advantages of welded joints compared to riveted joints.

8

dopëS>¨J {d{Y¶m| H$s gyMr ~ZmB¶o Ed§ dopëS>¨J Omo‹S> Ho$ bm^ {b{I¶o&

b)

4. a)

A 12.5mm×50mm plate carries a static tensile load of 45kN. If it is welded by two parallel fillets of 25mm

each. Find the shear stress in the joint take factor of safety 1.5.

12

12.5 {‘‘r. × 50 {‘‘r. H$s ßboQ> na ñW¡{VH$ VZZ ^ma 45 {H$bmo ݶyQ>Z h¡& Bg ßboQ> H$mo Xmo g‘mÝVa {’$boQ> doëS> go

à˶oH$ 25 {‘‘r. H$s bå~mB© Ûmam Omo‹S>m OmVm h¢& Omo‹S> H$m Anê$nU à{V~b kmV H$s{O¶o& gwajm JwUm§H$ H$m ‘mZ

1.5 h¢& >

Explain the function of key and give the classification of keys.

6

Mm~r (H$s) H$m H$m¶© g‘PmB¶o Ed§ BgH$m dJuH$aU Xr{O¶o&

b)

Find the diameter of a solid shaft to transmit 20kW at 200 rpm. The ultimate shear stress for the steel may

be taken as 360 MPa and a factor of safety as 8.

14

200 M³H$a à{V {‘ZQ> na 20 {H$bmodm°Q> e{³V g§MaU Ho$ {b¶o ñQ>rb emâQ> H$m ì¶mg kmV H$s{O¶o O~{H$ ñQ>rb H$s

ApëQ>‘oQ> H$V©Z à{V~b 360 MPa VWm BgHo$ {b¶o gwajm H$maH$ 8 hmo&

S/2020/6262

P.T.O.

[2]

5. a)

Explain the working principle of any one type of clutch with the help of neat sketch.

8

ñdÀN> {MÌ H$s ghm¶Vm go {H$gr EH$ àH$ma Ho$ ³bM H$s H$m¶©H$mar {gÕm§V kmV H$s{O¶o&

b)

For a single plate clutch both surfaces working have inner and outer radius 160 mm and 240 mm respectively.

Maximum pressure it can carry is 0.35N/mm2 and co-efficient of friction is 0.29 find the power transmitted by

the clutch at 1900 rpm.

12

EH$ EH$b ßboQ> ³bM {OgH$s XmoZmo gVh {H«$¶merb h¢ H$s Am§V[aH$ Ed§ ~mhar {ÌÁ¶m H«$‘e… 160 {‘.‘r. Ed§ 240 {‘.‘r.

h¢& ¶h A{YH$V‘ 0.35 ݶy./{‘‘r2 Xm~ gh gH$Vr h¡ Ed§ BgH$m Kf©U JwUm§H$ 0.29 h¢& Vmo ³bM Ûmam 1900 M³H$a

à{V. {‘ZQ> na nmao{eV e{³V kmV H$amo&

6. a)

b)

Explain “Bearing characteristic Number” and its effect on performance of journal bearing.

8

“~r¶[a¨J Ho$ao³Q>[apñQ>H$ Zå~a g‘PmB¶o” Ed§ OaZb ~r¶[a¨J na’$m‘}Ýg na BgH$m à^md {b{I¶o&

Select a single row, deep grove ball bearing for a radial load of 4200 N and axial load of 5000N. Operating

at 1550 rpm for an average life of 5 years at 8 hours per day. Assume uniform steady load.

12

EH$b H$Vma Jham J«yd ~mb {~¶[a¨J H$m MwZmd H$s{O¶o ¶{X ao{S>¶b ^ma 4200 N Ed§ Ajr¶ ^ma 5000N h¢& ¶h EH$

g‘mZ ^ma na 1550 M³H$a à{V. {‘ZQ> na H$m¶© H$aVr h¢. BgH$s Am¡gV Am¶w 8 K§Q>m à{V{XZ H$s Xa go 5 df© h¢&

7. Write note on any four of the following :

a) Types of threads

b) Factors affecting selection of materials

c) Classification of clutch

d) Wahl’s factor

e) Bolt of uniform strength

4×5=20

{ZåZ{b{IV ‘| go {H$Ýht Mma na {Q>ßnUr {b{I¶o …

A) My{‹S>¶mo§ Ho$ àH$ma

~) nXmW© M¶Z H$mo à^m{dV H$aZo dmbo H$maH$

g) ³bM H$m dJuH$aU

X) dmëg ’o$³Q>a

B) g‘mZ gm‘϶© H$m ~moëQ>

Y

S/2020/6262