3D Printed mm-Wave Filter for Spurious Suppression

advertisement

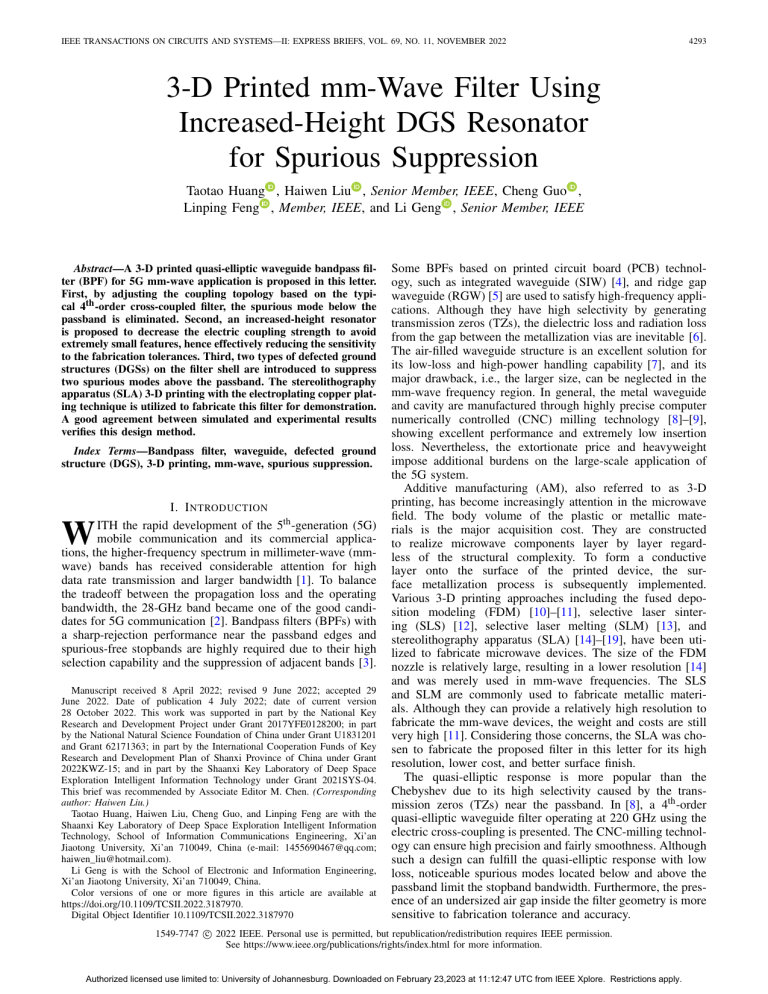

IEEE TRANSACTIONS ON CIRCUITS AND SYSTEMS—II: EXPRESS BRIEFS, VOL. 69, NO. 11, NOVEMBER 2022 4293 3-D Printed mm-Wave Filter Using Increased-Height DGS Resonator for Spurious Suppression Taotao Huang , Haiwen Liu , Senior Member, IEEE, Cheng Guo , Linping Feng , Member, IEEE, and Li Geng , Senior Member, IEEE Abstract—A 3-D printed quasi-elliptic waveguide bandpass filter (BPF) for 5G mm-wave application is proposed in this letter. First, by adjusting the coupling topology based on the typical 4th -order cross-coupled filter, the spurious mode below the passband is eliminated. Second, an increased-height resonator is proposed to decrease the electric coupling strength to avoid extremely small features, hence effectively reducing the sensitivity to the fabrication tolerances. Third, two types of defected ground structures (DGSs) on the filter shell are introduced to suppress two spurious modes above the passband. The stereolithography apparatus (SLA) 3-D printing with the electroplating copper plating technique is utilized to fabricate this filter for demonstration. A good agreement between simulated and experimental results verifies this design method. Index Terms—Bandpass filter, waveguide, defected ground structure (DGS), 3-D printing, mm-wave, spurious suppression. I. I NTRODUCTION ITH the rapid development of the 5th -generation (5G) mobile communication and its commercial applications, the higher-frequency spectrum in millimeter-wave (mmwave) bands has received considerable attention for high data rate transmission and larger bandwidth [1]. To balance the tradeoff between the propagation loss and the operating bandwidth, the 28-GHz band became one of the good candidates for 5G communication [2]. Bandpass filters (BPFs) with a sharp-rejection performance near the passband edges and spurious-free stopbands are highly required due to their high selection capability and the suppression of adjacent bands [3]. W Manuscript received 8 April 2022; revised 9 June 2022; accepted 29 June 2022. Date of publication 4 July 2022; date of current version 28 October 2022. This work was supported in part by the National Key Research and Development Project under Grant 2017YFE0128200; in part by the National Natural Science Foundation of China under Grant U1831201 and Grant 62171363; in part by the International Cooperation Funds of Key Research and Development Plan of Shanxi Province of China under Grant 2022KWZ-15; and in part by the Shaanxi Key Laboratory of Deep Space Exploration Intelligent Information Technology under Grant 2021SYS-04. This brief was recommended by Associate Editor M. Chen. (Corresponding author: Haiwen Liu.) Taotao Huang, Haiwen Liu, Cheng Guo, and Linping Feng are with the Shaanxi Key Laboratory of Deep Space Exploration Intelligent Information Technology, School of Information Communications Engineering, Xi’an Jiaotong University, Xi’an 710049, China (e-mail: 1455690467@qq.com; haiwen_liu@hotmail.com). Li Geng is with the School of Electronic and Information Engineering, Xi’an Jiaotong University, Xi’an 710049, China. Color versions of one or more figures in this article are available at https://doi.org/10.1109/TCSII.2022.3187970. Digital Object Identifier 10.1109/TCSII.2022.3187970 Some BPFs based on printed circuit board (PCB) technology, such as integrated waveguide (SIW) [4], and ridge gap waveguide (RGW) [5] are used to satisfy high-frequency applications. Although they have high selectivity by generating transmission zeros (TZs), the dielectric loss and radiation loss from the gap between the metallization vias are inevitable [6]. The air-filled waveguide structure is an excellent solution for its low-loss and high-power handling capability [7], and its major drawback, i.e., the larger size, can be neglected in the mm-wave frequency region. In general, the metal waveguide and cavity are manufactured through highly precise computer numerically controlled (CNC) milling technology [8]–[9], showing excellent performance and extremely low insertion loss. Nevertheless, the extortionate price and heavyweight impose additional burdens on the large-scale application of the 5G system. Additive manufacturing (AM), also referred to as 3-D printing, has become increasingly attention in the microwave field. The body volume of the plastic or metallic materials is the major acquisition cost. They are constructed to realize microwave components layer by layer regardless of the structural complexity. To form a conductive layer onto the surface of the printed device, the surface metallization process is subsequently implemented. Various 3-D printing approaches including the fused deposition modeling (FDM) [10]–[11], selective laser sintering (SLS) [12], selective laser melting (SLM) [13], and stereolithography apparatus (SLA) [14]–[19], have been utilized to fabricate microwave devices. The size of the FDM nozzle is relatively large, resulting in a lower resolution [14] and was merely used in mm-wave frequencies. The SLS and SLM are commonly used to fabricate metallic materials. Although they can provide a relatively high resolution to fabricate the mm-wave devices, the weight and costs are still very high [11]. Considering those concerns, the SLA was chosen to fabricate the proposed filter in this letter for its high resolution, lower cost, and better surface finish. The quasi-elliptic response is more popular than the Chebyshev due to its high selectivity caused by the transmission zeros (TZs) near the passband. In [8], a 4th -order quasi-elliptic waveguide filter operating at 220 GHz using the electric cross-coupling is presented. The CNC-milling technology can ensure high precision and fairly smoothness. Although such a design can fulfill the quasi-elliptic response with low loss, noticeable spurious modes located below and above the passband limit the stopband bandwidth. Furthermore, the presence of an undersized air gap inside the filter geometry is more sensitive to fabrication tolerance and accuracy. c 2022 IEEE. Personal use is permitted, but republication/redistribution requires IEEE permission. 1549-7747 See https://www.ieee.org/publications/rights/index.html for more information. Authorized licensed use limited to: University of Johannesburg. Downloaded on February 23,2023 at 11:12:47 UTC from IEEE Xplore. Restrictions apply. 4294 IEEE TRANSACTIONS ON CIRCUITS AND SYSTEMS—II: EXPRESS BRIEFS, VOL. 69, NO. 11, NOVEMBER 2022 Fig. 2. Electric field distributions of the spurious modes in the typical BPF I. (a) Mode A (capacitive iris resonance). (b) Mode B (TE101 ). (c) Mode C (TE210 ). Fig. 1. BPF I: typical fourth-order cross-coupling rectangular waveguide filter. (a) Geometry configuration and Coupling topology. (b) Simulated results in a wide frequency range. (c) Electric field distribution at 28 GHz. (Design parameters: a = 8.636, b = 4.318, w1 = 6.8, w2 = 8.48, l = 6, d12 = 4, d23 = 3.4, d34 = 4, d14 = 0.1, dS1 = d4L = 4.94, Units: mm). In this letter, based on the typical design in [8], a quasielliptic waveguide filter with extended spurious-free stopband and reduced sensitivity to fabrication tolerance is proposed by SLA 3-D printing. Three approaches are applied to optimize the filter performance. By adjusting the coupling topology, the spurious mode below the passband induced by the capacitive iris is firstly eliminated. To reduce the sensitivity to fabrication tolerances, an increased-height rectangular resonator is proposed, which can decrease the electric coupling strength between two resonators while having no effect on the filter response. Third, two types of defected ground structures (DGSs) are introduced on the filter shell to suppress two spurious modes above the passband, which can also facilitate the electroplating process to acquire a homogeneous conductive layer. The demonstration features a very low insertion loss and a highly selective with a good out-of-band rejection. II. T YPICAL C ROSS -C OUPLING F ILTER A typical fourth-order quasi-elliptic waveguide filter (BPF I) centered at 28GHz with 3-dB FBW of 7% and passband return loss of 20 dB is first depicted in Fig. 1. The filter is constructed with four dominant TE110 mode resonators and two ports using the standard WR-34 waveguide (8.636 mm × 4.318 mm). The resonant frequency of TE110 mode in a hollow metallic rectangular cavity can be determined by using the following formula [20]: c 1 1 ( )2 + ( )2 (1) fTE110 = 2 W L where c is the light velocity in vacuum, W and L are the width and length of the resonator, respectively. The frequency selectivity of the filter is improved by a cross-coupling topology employing folded construction that can generate two transmission zeros in the vicinity of the passband. The electric coupling M 14 is provided by a capacitive iris with a height of d14 , while the magnetic couplings M 12 , M 23 , and M 34 are realized by inductive irises with widths of d12 , d23 , and d34 , respectively [8]. The external coupling QeS and QeL are achieved by inductive irises with the width of dS1 and d4L , respectively. Based on the coupling matrix synthesis method [16], the un-normalized non-zero coupling coefficients and the external quality factors are calculated to be: M 12 = M 34 = 0.062, M 23 = 0.054, M 14 = −0.012, and QeS = QeL = 13.36. The simulated S-parameters and electric field distribution at 28 GHz are shown in Fig. 1 (b) and (c), respectively. As can be seen that apart from the desired passband, it also comprises three spurious bands, i.e. modes A, B, and C, their electric field distributions are displayed in Fig. 2. It can be found that mode A is the resonance induced by a small capacitive iris d14 , while mode B and mode C are caused by the degenerate mode TE101 and the higher-order mode TE210 in resonator-2 and -3, respectively. The excitation of the spurious modes may limit certain applications. Additionally, because of the very small value of its electric coupling coefficient M 14 (−0.012), the corresponding capacitive iris d14 given in Fig. 1 is only 0.1mm. Intuitively, such a small size is likely to be sensitive to fabrication tolerances and it is difficult for the metal solution to be uniformly plated on the surface of the resin body during plating. Furthermore, an inadequate capacitive iris is likely to result in the presence of a supporting structure to maintain stability during printing [12]–[13]. Here, we have developed an increased-height resonator filter with DGS to overcome the drawbacks mentioned above. III. P ROPOSED C ROSS -C OUPLING F ILTER To enhance the out-of-band performance and address the processing challenges posed by the inadequate capacitive iris, three improvements are introduced based on the BPF I, which is performed as follows. A. Suppression of Spurious Mode A As shown in Fig. 2 (a), mode A is generated by the capacitive iris resonance caused by the small electric coupling coefficient M 14 (0.012). To eliminate this mode, M 23 rather than M 14 as the negative electric coupling is preferred in our design (BPF II), as illustrated in Fig. 3. This is since coupling coefficient M 23 (0.054) is greater than M 14 (0.012), and accordingly, resulting in a larger capacitive iris from which mode A can be easily eliminated. Based on the coupling matrix theory [5], the location of the negative coupling in the coupling scheme topology has no effect on the response of the filter. Fig. 3 (b) demonstrates that with this coupling topology, the filter still exhibits a quasi-elliptic response, and mode A has been suppressed. In addition, with this type of solution, the capacitive iris can be enlarged to 0.6 mm. Authorized licensed use limited to: University of Johannesburg. Downloaded on February 23,2023 at 11:12:47 UTC from IEEE Xplore. Restrictions apply. HUANG et al.: 3-D PRINTED mm-WAVE FILTER USING INCREASED-HEIGHT DGS RESONATOR 4295 Fig. 5. (a) Coupling structure between resonator-2 and -3 under the electric coupling. (b) Extracted electric coupling coefficients as a function of d23 under three different h values. (c) Extracted electric coupling coefficients as a function of h under three different d23 values. Fig. 3. BPF II: BPF I with a coupling topology adjustment. (a) Geometry configuration and Coupling topology. (b) Simulated results in a wide frequency range. (Design parameters: a = 8.636, b = 4.318, w1 = 5.84, w2 = 8.22, l = 6.8, d12 = 3.76, d23 = 0.6, d34 = 3.76, d14 = 2.8, dS1 = d4L = 5.34, Units: mm). Fig. 6. Sensitivity analysis to capacitive iris tolerances (± 50 μm) of (a) BPF I and (b) BPF III. equation [21]: k23 = Fig. 4. BPF III: BPF II using an increased-height resonator. (Design parameters: a = 8.636, b = 4.318, w1 = 5.8, w2 = 8.2, l = 6.8, d12 = 3.76, d23 = 1, d34 = 3.76, d14 = 2.8, dS1 = d4L = 5.34, h = 0.982, Units: mm). B. Increased Capacitive Iris To further increase the size of the capacitive iris to reduce the sensitivity to fabrication tolerances so that it is physically realizable, an increased-height resonator is proposed and adopted. It was found that the electric coupling strength can be adjusted by changing the height of the resonator itself, whereas the resonant frequency of the dominant TE110 mode remains unchanged due to its zero wavenumbers in the z-direction, as represented in (1). Based on this property, the BPF III is designed using the increased-height resonators-2 and -3, as illustrated in Fig. 4. Note that the heights of resonators-1 and -4 keep the same with the standard waveguide since there is no effect on the magnetic coupling strength. Based on the above-mentioned description, the relationship between the electric coupling strength and the resonator height, as well as the size of the capacitive iris is further investigated. The electric coupling coefficient between two coupled resonators can be extracted by using the following f12 − f22 f12 + f22 (2) where f1 and f2 are the lower and higher resonance frequencies, respectively. They can directly be calculated from the eigenmode simulation. The coupling structure of resonators-2 and -3 under the electric coupling is shown in Fig. 5 (a), where d23 and h are the sizes of the capacitive iris and the height variation of the resonator, respectively. The simulated coupling coefficient curves versus different dimensions of the d23 and h are plotted in Fig. 5(b) and Fig. 5(c). It is clear from Fig. 5(b) that increasing h allows the slope of the electric coefficient k23 to be smaller. The k23 rises as h increases, as shown in Fig. 5(c). Therefore, filters using the resonator with increased height are expected to be less sensitive to fabrication tolerances. Subsequently, considering the convenience of the processing and the compactness of the overall 3-D geometry, a 1 mm capacitive iris was used to design the filter so that the sensitivity to fabrication tolerances can be further reduced. In this case, the total height of the resonators-2 and -3 is 5.3 mm (h = 0.982 mm). The sensitivity analysis to capacitive iris tolerances values of ± 50 μm (resolution of the SLA 3-D printer) in BPF I and BPF III are depicted in Fig. (6). As predicted, the BPF III using an increased-height resonator is far less sensitive to fabrication tolerance than the typical filter using the original height resonator. Authorized licensed use limited to: University of Johannesburg. Downloaded on February 23,2023 at 11:12:47 UTC from IEEE Xplore. Restrictions apply. 4296 IEEE TRANSACTIONS ON CIRCUITS AND SYSTEMS—II: EXPRESS BRIEFS, VOL. 69, NO. 11, NOVEMBER 2022 Fig. 7. Simulated S21 of the BPF II and BPF III. Fig. 10. Fig. 8. Simulated S21 of the BPF IV with different DGSs. BPF IV: BPF III with two types of DGSs. Fig. 11. 3-D printed filter. (a) Photograph of the prototype before surface metallization. (b) Photograph of prototype after electroless copper plating. can also facilitate the electroplating process, which allows the metal layer on the inner surface of the filter to be more homogeneous. Fig. 9. Surface current distributions of the resonators-2 and -3 in BPF IV. (a) TE110 . (b) TE101 . (c) TE210 . Moreover, to confirm that there is no effect of the resonator height on passband performance, the simulated responses of BPF II and BPF III are depicted in Fig. 7. It can be seen from the results that the responses of the two filters keep consistent with each other. C. Suppression of Spurious Modes B and C As illustrated in Fig. 2 (b) and (c), the spurious Modes B and C are induced by the TE101 mode and TE210 mode, respectively, and distributed within the resonators-2 and -3. To suppress those two modes, two types of DGSs are etched on the filter shell located at resonators-2 and -3, which is named BPF IV and shown in Fig. 8. The suppression principle by adding DGS is that the surface current of the spurious modes is disturbed and radiated while keeping the dominant mode intact. The surface current J s on the inner wall can be expressed using the following equation [20]: → J =− e ×H (3) s n → where − en and H are unit vector normal to the boundary and magnetic field, respectively. As can be seen from Fig. 9, DGS 2 intersects the currents of the TE101 on the sidewall in the x-direction, and DGS 1 is vertical with the currents on the upper surface of the TE210 . However, the dominant TE110 surface currents and two types of DGSs are always parallel and the current flowing paths are not cut so that there is no significant effect on the passband. Therefore, the spurious modes can be suppressed. Fig. 10 plots the responses of BPF IV with different DGSs, further verifying that Modes B and C are suppressed by DGSs 2 and 3, respectively. Furthermore, DGSs IV. FABRICATION AND M EASUREMENTS The filter prototype is first printed monolithically using the SLA 3-D printing process to generate a plastic body, and then metalized utilizing electroless and electroplating copper plating techniques. Compared with the multi-piece assembly structure, 3-D printing in one piece simplifies the design complexity and eliminates the additional losses caused by assembly and gaps. A ceramic-filled photosensitive resin is used to print the filter model using an SLA printer with a vertical resolution of 50 μm. Considering the thickness of the metalized layer on the device surface, the overall dimension of the internal air cavity is slightly enlarged before printing to compensate. Subsequently, a copper layer with a thickness of 10 μm is coated onto the resin surface using the electroless and electroplating plating process to form a metalized surface. It is noted that the thickness of the copper layer is over twenty times the skin depth (0.395 μm calculated at 28 GHz). A photograph of the fabricated filter before and after metallization is shown in Fig. 11. The proposed 3-D printed filter was measured with a vector network analyzer AV3672E under a thru-reflect-line (TRL) waveguide calibration. Fig. 12 shows the simulated and measured results of the filter, and excellent agreement among them can be observed. The measured passband insertion loss (IL) is 0.16 dB and the return loss (RL) is better than 20 dB. Note that the simulated S21 of the filter without DGSs is also given in Fig. 12(b) for a comparison. After adding DGSs, the IL only increased by less than 0.1 dB, which is acceptable. Fig. 13 plots the S21 of the filter over a wideband frequency range from 20 to 40 GHz. It can be found that the proposed filter effectively suppresses the spurious modes by adjusting the coupling topology and introducing DGSs, realizing an improved out-of-band rejection performance. Authorized licensed use limited to: University of Johannesburg. Downloaded on February 23,2023 at 11:12:47 UTC from IEEE Xplore. Restrictions apply. HUANG et al.: 3-D PRINTED mm-WAVE FILTER USING INCREASED-HEIGHT DGS RESONATOR 4297 By using the SLA 3-D printing technique, the prototype is fabricated. Excellent consistency is achieved between simulated and measured results. It implies the proposed waveguide filter can serve the 5G mm-wave applications well. R EFERENCES Fig. 12. Measured and simulated results of the filter. (a) Responses over the whole band. (b) Enlarged view of S21 over the passband. Fig. 13. Measured and simulated results of the filter. TABLE I C OMPARISON W ITH THE S TATE OF THE A RTS Finally, a comparison with state-of-the-art BPFs is listed in Table I. It indicates that the proposed 3-D printed filter exhibit not only a very low IL and excellent quasi-elliptic performance, but also a good spurious suppression. V. C ONCLUSION In this letter, a 3-D printed waveguide filter is proposed. Compared with the typical 4th -order cross-coupling filter, three spurious modes below and above the passband are suppressed by introducing the coupling topology adjustment and two types of DGSs on the filter shell, extending the spurious-free region. Moreover, an increased-height rectangular resonator is utilized to reduce the sensitivity to fabrication tolerances and accuracy. [1] A. Basaligheh, P. Saffari, S. R. Boroujeni, I. Filanovsky, and K. Moez, “A 28–30 GHz CMOS reflection-type phase shifter with full 360◦ phase shift range,” IEEE Trans. Circuits Syst. II, Exp. Briefs, vol. 67, no. 11, pp. 2452–2456, Nov. 2020. [2] Y. Wang, J. Li, L. Huang, Y. Jing, A. Georgakopoulos, and P. Demestichas, “5G mobile: Spectrum broadening to higher-frequency bands to support high data rates,” IEEE Veh. Technol. Mag., vol. 9, no. 3,pp. 39–46, Sep. 2014. [3] A. Monje-Real, N. J. G. Fonseca, O. Zetterstrom, E. Pucci, and O. Quevedo-Teruel, “Holey glide-symmetric filters for 5G at millimeterwave frequencies,” IEEE Microw. Wireless Compon. Lett., vol. 30, no. 1, pp. 31–34, Jan. 2020. [4] X. Chen and K. Wu, “Substrate integrated waveguide cross-coupled filter with negative coupling structure,” IEEE Trans. Microw. Theory Techn., vol. 56, no. 1, pp. 142–149, Jan. 2008. [5] M. S. Sorkherizi and A. A. Kishk, “Self-packaged, low-loss, planar bandpass filters for millimeter-wave application based on printed gap waveguide technology,” IEEE Trans. Compon., Packag., Manuf. Technol., vol. 7, no. 9, pp. 1419–1431, Sep. 2017. [6] J. Zheng et al., “Dual-band filtering power divider based on CSRRs loaded SIW cavity,” IEEE Trans. Circuits Syst. II, Exp. Briefs, vol. 69, no. 2, pp. 394–398, Feb. 2022, doi: 10.1109/TCSII.2021.3100568. [7] T. R. Jones, N. Vahabisani, E. T. Der, and M. Daneshmand, “Monolithic millimeter-wave air-filled waveguide resonator for filter applications,” IEEE Microw. Wireless Compon. Lett., vol. 29, no. 6, pp. 379–381, Jun. 2019. [8] J.-Q. Ding, S.-C. Shi, K. Zhou, D. Liu, and W. Wu, “Analysis of 220-GHz low-loss quasi-elliptic waveguide bandpass filter,” IEEE Microw. Wireless Compon. Lett., vol. 27, no. 7, pp. 648–650, Jul. 2017. [9] J.-Q. Ding, S.-C. Shi, K. Zhou, Y. Zhao, D. Liu, and W. Wu, “WR-3 band quasi-elliptical waveguide filters using higher order mode resonances,” IEEE Trans. THz Sci. Technol., vol. 7, no. 3, pp. 302–309, May 2017. [10] R. Dahle, P. Laforge, and J. Kuhling, “3-D printed customizable inserts for waveguide filter design at X-band,” IEEE Microw. Wireless Compon. Lett., vol. 27, no. 12, pp. 1080–1082, Dec. 2017. [11] D. Miek, S. Simmich, F. Kamrath, and M. Höft, “Additive manufacturing of E-plane cut dual-mode X-band waveguide filters with mixed topologies,” IEEE Trans. Microw. Theory Techn., vol. 68, no. 6, pp. 2097–2107, Jun. 2020. [12] M. Salek et al., “W-band waveguide bandpass filters fabricated by micro laser sintering,” IEEE Trans. Circuits Syst. II, Exp. Briefs, vol. 66, no. 1, pp. 61–65, Jan. 2019. [13] X. Wen et al., “An invar alloy SLM printed diplexer with high thermal stability,” IEEE Trans. Circuits Syst. II, Exp. Briefs, vol. 69, no. 3, pp. 1019–1023, Mar. 2022, doi: 10.1109/TCSII.2021.3120866. [14] M. D’Auria et al., “3-D printed metal-pipe rectangular waveguides,” IEEE Trans. Compon., Packag., Manuf. Technol., vol. 5, no. 9, pp. 1339–1349, Sep. 2015. [15] C. Guo, X. Shang, J. Li, F. Zhang, M. J. Lancaster, and J. Xu, “A lightweight 3-D printed X-band bandpass filter based on spherical dual-mode resonators,” IEEE Microw. Wireless Compon. Lett., vol. 26, no. 8, pp. 568–570, Aug. 2016. [16] X. Shang et al., “W-band waveguide filters fabricated by laser micromachining and 3-D printing,” IEEE Trans. Microw. Theory Techn., vol. 64, no. 8, pp. 2572–2580, Aug. 2016. [17] Y. Zhu, J. Li, and G.-L. Huang, “A lightweight 3-D printed dual-band high-gain slotted spherical antenna,” IEEE Antennas Wireless Propag. Lett., vol. 19, no. 4, pp. 552–556, Apr. 2020. [18] J. Li, C. Guo, J. Xu, and L. Mao, “Lightweight low-cost Ka-band 3-D printed slotted rectangular waveguide bandpass filters,” in Proc. IEEE Int. Symp. Antennas Propag. USNC/URSI Nat. Radio Sci. Meeting, 2017, pp. 2647–2648. [19] E. López-Oliver and C. Tomassoni, “3-D-printed dual-mode filter using an ellipsoidal cavity with asymmetric responses,” IEEE Microw. Wireless Compon. Lett., vol. 31, no. 6, pp. 670–673, Jun. 2021. [20] K. Zhang and D. Li, Electromagnetic Theory for Microwaves and Optoelectronics. Berlin, Germany: Springer-Verlag, 2008. [21] A. Iqbal, J. J. Tiang, C. K. Lee, N. K. Mallat, and S. W. Wong, “Dualband half mode substrate integrated waveguide filter with independently tunable bands,” IEEE Trans. Circuits Syst. II, Exp. Briefs, vol. 67, no. 2, pp. 285–289, Feb. 2020. Authorized licensed use limited to: University of Johannesburg. Downloaded on February 23,2023 at 11:12:47 UTC from IEEE Xplore. Restrictions apply.