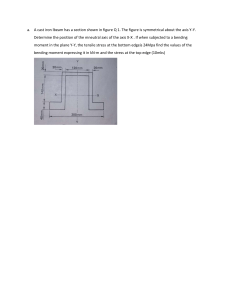

MSA University Faculty of Engineering Industrial Engineering Department Lectures Notes on Stress Analysis (Pure Bending) (DES 262: Mechatronics Eng. Students) (DES 352: Industrial Eng. Students) (Semester: Spring 2022) 1|Page Chapter IV Pure Bending The normal stresses and the curvature resulting from pure bending will be determined in this chapter. Objectives: • Considering the general principles of bending behavior. • Defining the deformations, strains, and normal stresses in beams subject to pure bending. • Analyzing members subject to eccentric axial loading, involving both axial stresses and bending stresses. • Reviewing beams subject to unsymmetric bending, i.e., where bending does not occur in a plane of symmetry. References: Ferdinand P. Beer, E. Russell Johnston Jr., John T. DeWolf, David F. Mazurek, “Mechanics of Materials”, 8th Edition-McGraw-Hill, 2020. Hibbeler, R. C – “Mechanics of materials” , Pearson, 10th ed., 2018. 2|Page 4.1 Introduction: This chapter and the following two analyze the stresses and strains in prismatic members subjected to bending. Bending is a major concept used in the design of many machine and structural components, such as beams and girders. This chapter is devoted to the analysis of prismatic members subjected to equal and opposite couples M and M’ acting in the same longitudinal plane. Such members are said to be in pure bending. The members are assumed to possess a plane of symmetry with the couples M and M’ acting in that plane. An example of pure bending is provided by the bar of a typical barbell. The bar carries equal weights at equal distances from the hands of the weight lifter. Because of the symmetry of the free-body diagram of the bar (Fig. a), the reactions at the hands must be equal and opposite to the weights. Therefore, as far as the middle portion CD of the bar is concerned, the weights and the reactions can be replaced by two equal and opposite 9.6 N.m couples (Fig. b), showing that the middle portion of the bar is in pure bending. 3|Page As interesting as the direct applications of pure bending, the results obtained will be used in the analysis of other types of loadings as well, such as eccentric axial loadings and transverse loadings. The Photo, shows a 300-mm steel bar clamp used to exert 600-N forces on two pieces of lumber as they are being glued together. Fig. 4.3a shows the equal and opposite forces exerted by the lumber on the clamp. These forces result in an eccentric loading of the straight portion of the clamp. In Fig. 4.3b a section CC’ has been passed through the clamp and a free-body diagram has been drawn of the upper half of the clamp, from which we conclude that the internal forces in the section are Fig. 4.3 Forces exerted on equivalent to a 600-N axial tensile force P and a clamp 72-N.m couple M. We can thus combine the knowledge of the stresses under a centric load and the results of the forthcoming analysis of stresses in pure bending to obtain the distribution of stresses under an eccentric load. This will be discussed later in this chapter. The results obtained from the direct applications of pure bending will be used in the analysis of other types of loadings, such as eccentric axial loadings and transverse loadings. 4|Page 4.2 SYMMETRIC MEMBER IN PURE BENDING: Internal Moment and Stress Relations: Consider a prismatic member AB possessing a plane of symmetry and subjected to equal and opposite couples M and M’ acting in that plane (Fig. a). We observe that if a section is passed through the member AB at some arbitrary point C, the conditions of equilibrium of the portion AC of the member require that the internal forces in the section be equivalent to the couple M (Fig. b). Thus, the internal forces in any cross section of a symmetric member in pure bending are equivalent to a couple. The moment M of that couple is referred to as the bending moment in the section. Following the usual convention, a positive sign will be assigned to M when the member is bent as shown in the above Figures. i.e., when the concavity of the beam faces upward, and a negative sign otherwise. Denoting by σx the normal stress at a given point of the cross section and by τxy and τxz the components of the shearing stress, we express 5|Page that the system of the elementary internal forces exerted on the section is equivalent to the couple M. The sum of the components of these forces in any direction is therefore equal to zero. Moreover, the moment of the couple is the same about any axis perpendicular to its plane, and is zero about any axis contained in that plane, then: x components: moments about y axis: moments about z axis: σx dA = 0 z σx dA = 0 (-y σx dA) = M (4.1) (4.2) (4.3) The minus sign in Eq. (4.3) is due to the fact that a tensile stress (σx > 0) leads to a negative moment (clockwise) of the normal force σx dA about the z axis. Once more, note that the actual distribution of stresses in a given cross section cannot be determined from statics alone. It is statically indeterminate and may be obtained only by analyzing the deformations produced in the member. 4.3 Deformations in a Symmetric Member in Pure Bending : We will now analyze the deformations of a prismatic member possessing a plane of symmetry. Its ends are subjected to equal and opposite couples M and M’ acting in the plane of symmetry. The member will bend under the action of the couples, but will remain symmetric with respect to that plane (Fig. 4.7). Fig. 4.7 Initially straight members in pure bending deform into a circular arc Moreover, since the bending moment M is the same in any cross section, the member will bend uniformly. Thus, the line AB along the upper face of the member intersecting the plane of the couples will have a constant curvature. In other words, the line AB will be 6|Page transformed into a circle of center C, as will the line A’B’ along the lower face of the member. Note that the line AB will decrease in length when the member is bent (i.e., when M > 0), while A’B’ will become longer. Suppose that the member is divided into a large number of small cubic elements with faces parallel to the three coordinate planes. These elements will be transformed as shown in Fig. 4.9 when the member is subjected to the couples M and M’. Since all the faces represented in the two projections of Fig. 4.9 are at 90º to each other, we conclude that γxy = γzx = 0 and, thus, that τxy = τxz = 0. Regarding the three stress components that we have not yet Fig. 4.9: (a) Longitudinal, vertical, (b) Longitudinal, horizontal section. discussed, namely, σy, σz, and τyz, we note that they must be zero on the surface of the member. This assumption is verified, both from experimental evidence and from the theory of elasticity, for slender members undergoing small deformations. We conclude that the only nonzero stress component exerted on any of the small cubic elements considered here is the normal component σx. Thus, at any point of a slender member in pure bending, we have a state of uniaxial stress. Recalling that, for M > 0, lines AB and A’B’ are observed, respectively, to decrease and increase in length, we note that the strain εx and the stress σx are negative in the upper portion of the member (compression) and positive in the lower portion (tension). 7|Page It follows from above that a surface parallel to the upper and lower faces of the member must exist where εx and σx are zero. This surface is called the neutral surface. The neutral surface intersects the plane of symmetry along an arc of circle DE (Fig. 4.10a), and it intersects a transverse section along a straight line called the Fig. 4.10: Neutral Axis Location neutral axis of the section (Fig. 4.10b). The origin of coordinates is now selected on the neutral surface, rather than on the lower face of the member, so that the distance from any point to the neutral surface is measured by its coordinate y. Denoting by ρ the radius of arc DE (Fig. 4.10a), by θ the central angle corresponding to DE, and observing that the length of DE is equal to the length L of the undeformed member, we write: L= ρθ Considering the arc JK located at a distance y above the neutral surface, its length L’ is: L’ = (ρ - y).θ Since the original length of arc JK was equal to L, the deformation of JK is: δ = L’ – L , then δ = (ρ - y)θ - ρθ = - yθ The longitudinal strain εx in the elements of JK is obtained by dividing δ by the original length L of JK. Write: 8|Page 𝜖𝑥 = 𝛿 𝐿 = −𝑦𝜃 𝜌𝜃 = −𝑦 𝜌 The minus sign is due to the fact that it is assumed the bending moment is positive, and thus the beam is concave upward. The strain εx reaches its maximum absolute value when y is largest. Denoting the largest distance from the neutral surface as c (corresponding to either the upper or the lower surface of the member) and the maximum absolute value of the strain as εm , we have: 𝑐 𝜖𝑚 = 𝜌 i.e: 𝜖𝑥 = −𝑦 𝑐 𝜖𝑚 equation…. (4.10) 4.4 STRESSES AND DEFORMATIONS IN THE ELASTIC RANGE: We now consider the case when the bending moment M is such that the normal stresses in the member remain below the yield strength σY (in the elastic range), and Hooke’s law for uniaxial stress applies. Assuming the material to be homogeneous, and denoting by E its modulus of elasticity, we have in the longitudinal x direction: 𝜎𝑥 = 𝐸. 𝜖𝑥 Recalling Eq. (4.10), and multiplying both members of that −𝑦 equation by E, we write: 𝐸𝜖𝑥 = 𝐸𝜖𝑚 𝑐 −𝑦 or: 𝜎𝑥 = 𝜎𝑚 equation…. (4.12) 𝑐 9|Page Where: σm denotes the maximum absolute value of the stress. This result shows that, in the elastic range, the normal stress varies linearly with the distance from the neutral surface (Fig. 4.11). It should be noted that, at this point, we do not know the location of the neutral surface, nor the maximum value σm of the stress. Both can be found if we recall the relations (4.1) and (4.3) which were obtained earlier from statics. Substituting first for σx from (4.12) into (4.1), we get: 𝒚 ∫ 𝝈𝒙 𝒅𝑨 = ∫(− 𝒄 𝝈𝒎 ) 𝒅𝑨 = − From which, it follows that: 𝝈𝒎 𝒄 ∫ 𝒚 𝒅𝑨 = 𝟎 ∫ 𝒚 𝒅𝑨 = 𝟎 This equation shows that the first moment of the cross section about its neutral axis must be zero. In other words, the neutral axis passes through the centroid of the section. We now recall Eq. (4.3): ∫ −𝑦𝜎𝑥 𝑑𝐴 = 𝑀 𝒚 ∫(−𝒚)(− 𝒄 𝝈𝒎 ) 𝒅𝑨 = 𝑴 OR: 𝜎𝑚 𝑐 ∫ 𝑦 2 𝑑𝐴 = 𝑀 we note that: I = y2 dA is the moment of inertia, or second moment, of the cross section with respect to a centroidal axis perpendicular to the plane of the couple M. Solving for σm, we write: And to obtain the normal stress σx at any distance y from the neutral axis: 10 | P a g e 𝝈𝒙 = 𝝈𝒎 = 𝑴𝒚 𝑰 𝑴𝒄 𝑰 The deformation of the member caused by the bending moment M is measured by the curvature of the neutral surface. The curvature is defined as the reciprocal of the radius of curvature ρ, and can be obtained by solving for 1/ρ: 𝜖𝑚 = ∴ Or: 11 | P a g e 1 𝜌 = 𝑐 𝜌 𝐸.𝜖𝑚 𝐸.𝑐 1 𝜌 → ∴ = = 𝜎𝑚 𝐸.𝑐 𝑀 𝐸.𝐼 1 𝜌 = = 𝜖𝑚 𝑐 1 𝑀.𝑐 𝐸𝑐 𝐼 Sample Problem 4.1 Given: The rectangular tube shown is extruded from an aluminum alloy for which σY = 275 MPa, σU = 415 MPa, and E = 73 GPa. Neglect the effect of fillets. Determine (a) the bending moment M for which the factor of safety will be 3.00. (b) The corresponding radius of curvature of the tube. Solution: (a) The bending moment M: 𝐼𝑥 = 120 mm 1 1 (80)(120)3 − (68)(108)3 = 𝟒. 𝟑𝟖𝒙𝟏𝟎𝟔 𝒎𝒎𝟒 12 12 80 mm 𝜎𝑢 415 = = 𝟏𝟑𝟖 𝑴𝑷𝒂 𝑓. 𝑠 3 Since σall < σY, the tube remains in the elastic range, we use the derived equations. 𝜎𝑎𝑙𝑙 = 𝜎𝑎𝑙𝑙 = 𝑀𝑐 , 𝐼𝑥 ∴ 138 = 𝑀𝑥60 4.38𝑥106 𝑀 = 10.1𝑥106 𝑁. 𝑚𝑚 = 𝟏𝟎. 𝟏 𝒌𝑵. 𝒎 (b) The corresponding radius of curvature of the tube. Since ∴ 1 𝜌 = Then: 12 | P a g e 1 𝜌 = 𝑀 𝐸.𝐼 10.1𝑥106 (𝑁.𝑚𝑚) (73𝑥103 𝑀𝑃𝑎)(4.38𝑥106 𝑚𝑚4 ) 𝜌 = 31.7𝑥103 𝑚𝑚 = 𝟑𝟏. 𝟕𝒎 t=6 mm 13 | P a g e 14 | P a g e Eccentric Axial Loading in a Plane of Symmetry One example of an eccentric loading is found in the shown press, in which the vertical forces exerted on the press cause an eccentric loading on the back column of the press. In this section, our analysis will be limited to members that possess a plane of symmetry, and it will be assumed that the loads are applied in the plane of symmetry of the member. (Fig. a). The internal forces acting on a given cross section may then be represented by a force F applied at the centroid C of the section and a couple M acting in the plane of symmetry of the member (Fig. b). The conditions of equilibrium of the free body AC require that the force F be equal and opposite to P′ and that the moment of the couple M be equal and opposite to the moment of P′ about C. F=P and M = Pd • Eccentric loading Stress due to eccentric loading found by superposing the uniform stress due to a centric load and linear stress distribution due a pure bending moment: x x centric x bending 15 | P a g e P My A I Where: A….. is the area of the cross section. I……is centroidal moment of inertia. and y…… is measured from the centroidal axis of the cross section. This relationship shows that the distribution of stresses across the section is linear but not uniform. Depending upon the geometry of the cross section and the eccentricity of the load, The combined stresses may all have the same sign, as shown in Fig. 4.41, Or some may be positive and others negative, as shown in Fig. 4.42. In the latter case, there will be a line in the section, along which σx This line represents the neutral axis of the section. = 0. We note that the neutral axis does not coincide with the centroidal axis of the section. 16 | P a g e Concept Application 4.7 An open-link chain is obtained by bending low-carbon steel rods of 12-mm diameter into the shape shown. Knowing that the 700 N chain carries a load of 700N, determine: (a) The largest tensile and compressive stresses in the straight portion of a link, 12 mm (b) The distance between the centroidal and the 16 mm neutral axis of a cross section. Solution: (a) The largest tensile and compressive stresses: The internal forces in the cross section are equivalent 700 N 16 mm to a centric force P and a bending couple M of magnitudes: P=700N M=Pd= 700x16 =11.2x103 N.mm The corresponding stress distributions are shown in parts a & b of the figure. The distribution due to the centric force P is uniform and equal to σ0 = P∕A. We have: 𝐴 = 𝜋 𝑐 2 = 𝜋𝑥(6)2 = 113.1 𝑚𝑚2 700 ∴ 𝜎𝑜 = = 6.2 𝑀𝑃𝑎. 113.1 66 MPa mm 6.2 MPa 𝜋 𝐼 = 4 𝑐 4 = 4 (6)4 = 1017.9𝑚𝑚4 c 𝑀𝑐 (11.2𝑥103 𝑁. 𝑚𝑚)𝑥(6𝑚𝑚) 𝜎𝑚 = = = 66 𝑀𝑃𝑎. 𝐼 1017.9𝑚𝑚4 17 | P a g e 72.2 MPa mm mm The distribution due to the bending couple M is linear with a maximum stress: σm = Mc∕I. We write: 𝜋 700 N - 66 MPa mm - 59.8 MPa mm Superposing the two distributions, we obtain the stress distribution corresponding to the given eccentric loading (Fig. c). The largest tensile and compressive stresses in the section are found to be, respectively: 𝝈𝒕 = 𝝈𝒐 + 𝝈𝒎 = 𝟔. 𝟐 + 𝟔𝟔 = 𝟕𝟐. 𝟐 𝑴𝑷𝒂. 𝝈𝒄 = 𝝈𝒐 − 𝝈𝒎 = 𝟔. 𝟐 − 𝟔𝟔 = −𝟓𝟗. 𝟖 𝑴𝑷𝒂. (b) The distance between the centroidal and the neutral axes: The distance y0 from the centroidal to the neutral axis of the section is obtained by setting σx = 0 in the equation: P My and solving for y0: x A 700 (11.2𝑥103 𝑁. 𝑚𝑚)𝑥(𝑦𝑜 ) 0= − 113.1 1017.9𝑚𝑚4 I 72.2 MPa mm ∴ 𝑦𝑜 = 700𝑥1017.9 = 𝟎. 𝟓𝟔𝒎𝒎 113.1𝑥 11.2𝑥103 σx yo - 59.8 MPa mm 18 | P a g e SAMPLE PROBLEM 4.8 Knowing that for the cast iron link shown, the allowable stresses are 30 MPa in tension and 120 MPa in compression, Determine: the largest force P which can be applied to the link. (Note: The T-shaped cross section of the link has previously been considered in Sample Prob. 4.2.) Solution: From Sample Prob. 4.2, we have the properties of Cross Section as: A = 3000 mm2; I=868x103 mm4 From the figure: d = (38) - (10) = 28 mm. Force and Couple at C: we replace P by an equivalent force-couple system at the centroid C as shown: Where: P = P and M = P (d) = P (28 mm) = 28P The force P acting at the centroid causes a uniform stress distribution (Fig. 1): 𝜎0 = 𝑃 𝑃 = = 0.333𝑥10−3 𝑃 (𝑐𝑜𝑚𝑝𝑟𝑒𝑠𝑠𝑖𝑜𝑛). 𝐴 3000 The bending couple M causes a linear stress distribution (Fig. b): 𝑀. 𝑐𝐴 28𝑃𝑥22𝑚𝑚 𝜎1 = = = 0.71𝑥10−3 𝑃 (𝑡𝑒𝑛𝑠𝑖𝑙𝑒) 3 𝐼 868𝑥10 𝑀. 𝑐𝐵 28𝑃𝑥38𝑚𝑚 𝜎2 = = = 1.226𝑥10−3 𝑃 (𝑐𝑜𝑚𝑝𝑟𝑒𝑠𝑠𝑖𝑣𝑒) 3 𝐼 868𝑥10 19 | P a g e Superposition: The total stress distribution (Fig. 3) is found by superposing the stress distributions caused by the centric force P and by the couple M. Since tension is positive, and compression negative, we have: 𝜎𝐴 = 𝑃 𝑀. 𝑐𝐴 + = −0.333𝑥10−3 𝑃 + 0.71𝑥10−3 𝑃 = 0.377𝑥10−3 𝑃 (𝑡𝑒𝑠𝑛𝑠𝑖𝑜𝑛). 𝐴 𝐼 𝜎𝐵 = 𝑃 𝑀. 𝑐𝐴 + = −0.333𝑥10−3 𝑃 − 1.226𝑥10−3 𝑃 = −1.559𝑥10−3 𝑃 (𝑐𝑜𝑚𝑝𝑟𝑒𝑠𝑠𝑖𝑜𝑛). 𝐴 𝐼 Largest Allowable Force: The magnitude of P for which the tensile stress at point A is equal to the allowable tensile stress of 30 MPa is found by writing: 0.377𝑥10−3 𝑃 = 30𝑀𝑃𝑎, ∴ 𝑃 = 79.6𝑥103 𝑁 = 𝟕𝟗. 𝟔𝒌𝑵. We also determine the magnitude of P for which the stress at B is equal to the allowable compressive stress of 120 MPa: 3 −1.559𝑥10−3 𝑃 = 120𝑀𝑃𝑎, ∴ 𝑃 = 77𝑥10 𝑁 = 𝟕𝟕𝒌𝑵. The magnitude of the largest force P that can be applied without exceeding either of the allowable stresses is the smaller of the two values So, the largest allowable force is: P=77kN. 20 | P a g e 4.8 UNSYMMETRIC BENDING ANALYSIS: • Our analysis of pure bending has been limited so far to members possessing at least one plane of symmetry and subjected to couples acting in that plane. • Members remain symmetric and bend in the plane of symmetry. • The neutral axis of the cross section coincides with the axis of the couple. • In both shown cases, the couple exerted on the section acts in the vertical plane of symmetry of the member and is represented by the horizontal couple vector M, and in both cases the neutral axis of the cross section is found to coincide with the axis of the couple. • Will now consider situations in which the bending couples do not act in a plane of symmetry. • Cannot assume that the member will bend in the plane of the couples. • In general, the neutral axis of the section will not coincide with the axis of the couple. • We propose to determine the precise conditions under which the neutral axis of a cross section of arbitrary shape coincides with the axis of the couple M as shown in Fig. 4.57, and both the couple vector M and the neutral axis have been assumed to be directed along the z axis. 21 | P a g e • The resultant force and moment from the distribution of elementary forces in the section must satisfy: Fx 0 M y M z M applied couple y 0 Fx x dA m dA c or 0 y dA Which mean that the neutral axis passes through centroid y M M z y m dA c or M σmI c I I z moment of inertia Which defines the stress distribution y 0 M y z x dA z m dA c or 0 yz dA I yz product of inertia Means that: the couple vector must be directed along a principal centroidal axis Superposition is applied to determine stresses in the most general case of unsymmetric bending: 22 | P a g e • Resolve the couple vector into components along the principle centroidal axes: M z M cos M y M sin • Superpose the component stress distributions: 𝜎𝑥 = − 𝑀𝑧 𝑦 𝐼𝑧 + 𝑀𝑦 𝑧 𝐼𝑦 • Along the neutral axis, 𝜎𝑥 = 0 = − 𝑠𝑜𝑙𝑣𝑖𝑛𝑔 𝑓𝑜𝑟 𝑦 , 𝑀𝑧 𝑦 𝐼𝑧 + 𝑀𝑦 𝑧 𝐼𝑦 = − (𝑀𝑐𝑜𝑠𝜃)𝑦 𝐼𝑧 + (𝑀𝑠𝑖𝑛𝜃)𝑧 𝐼𝑦 𝐼 ∴ 𝑦 = ( 𝑧 𝑡𝑎𝑛𝜃) 𝑧 𝐼𝑦 𝐼 𝑜𝑟 𝑡𝑎𝑛∅ = ( 𝑧 𝑡𝑎𝑛𝜃) 𝐼𝑦 Where: θ is the angle that the couple vector M forms with the same axis. Since Iz and Iy are both positive, ϕ and θ have the same sign. Furthermore, ϕ > θ when Iz > Iy, and ϕ < θ when Iz < Iy. Thus, the neutral axis is always located between the couple vector M and the principal axis corresponding to the minimum moment of inertia. 23 | P a g e Concept Application 4.8 A 180-N.m couple is applied to a wooden beam, of rectangular cross section 40 by 90mm, in a plane forming an angle of 30° with the vertical as shown. Determine: (a) The maximum stress in the beam and (b) The angle that the neutral surface forms with the horizontal plane. 180 N.m 90 mm 40 mm Solution: a. Maximum Stress: The components Mz and My of the couple vector are first determined: 𝑀𝑧 = 180 𝑁. 𝑚 𝑐𝑜𝑠30 = 155.9 𝑁. 𝑚 𝑀𝑦 = 180 𝑁. 𝑚 𝑠𝑖𝑛30 = 90 𝑁. 𝑚 Moments of inertia: 1 𝐼𝑧 = 𝑥40𝑥(90)3 1 = 2.43𝑥106 𝑚𝑚4 12 1 𝐼𝑦 = 𝑥90𝑥(40)3 1 = 0.48𝑥106 𝑚𝑚4 12 The largest tensile stress due to Mz occurs along AB and is: 𝜎1 = 𝑀𝑧 𝑦 𝐼𝑧 = (155.9𝑥103 𝑁.𝑚𝑚)𝑥45 2.43𝑥106 𝑚𝑚4 180 N.m 45 mm 20 mm = 2.89 𝑀𝑃𝑎. The largest tensile stress due to My occurs along AD and is: 𝜎2 = 𝑀𝑦 𝑧 𝐼𝑦 = (90𝑥103 𝑁.𝑚𝑚)𝑥20 0.48𝑥106 𝑚𝑚4 = 3.75 𝑀𝑃𝑎. The largest tensile stress due to the combined loading, therefore, occurs at A and is: 𝝈𝒎𝒂𝒙 = 𝝈𝟏 + 𝝈𝟐 = 𝟐. 𝟖𝟗 + 𝟑. 𝟕𝟓 = 𝟔. 𝟔𝟒 𝑴𝑷𝒂. The largest compressive stress has the same magnitude and occurs at E 24 | P a g e b. Angle of Neutral Surface with Horizontal Plane. The angle ϕ that the neutral surface forms with the horizontal plane is obtained from Eq. : 𝐼𝑧 2.43𝑥106 𝐼𝑦 0.48𝑥106 𝑡𝑎𝑛∅ = ( 𝑡𝑎𝑛𝜃) = 𝑡𝑎𝑛30 = 2.923 ∴ σmax c σmax t 25 | P a g e ∅ = 71.1° 4.9 General Case of Eccentric Axial Loading Analysis: • Consider a straight member subject to equal and opposite eccentric forces. • The eccentric force is equivalent to the system of a centric force and two couples. P centric force M y Pa M z Pb • By the principle of superposition, the combined stress distribution is: P Mz y M yz x A Iz Iy • If the neutral axis lies on the section, it may be found from: My Mz P y z Iz Iy A 26 | P a g e