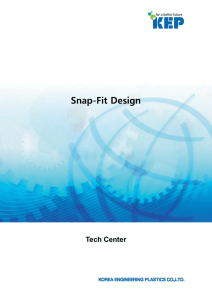

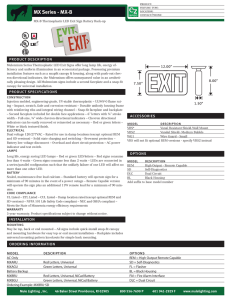

Available online at www.sciencedirect.com Availableonline online atwww.sciencedirect.com www.sciencedirect.com Available Availableatonline at www.sciencedirect.com ScienceDirect ScienceDirect ScienceDirect ScienceDirect Procedia CIRP 00 (2018) 000–000 ProcediaCIRP CIRP00 00(2017) (2018)000–000 000–000 Procedia Procedia CIRP 79 (2019) 113–118 www.elsevier.com/locate/procedia www.elsevier.com/locate/procedia www.elsevier.com/locate/procedia 12th 2018, 12thCIRP CIRPConference ConferenceononIntelligent IntelligentComputation ComputationininManufacturing ManufacturingEngineering, Engineering,18-20 CIRPJuly ICME '18 12th CIRP Conference on Intelligent Computation in Manufacturing Engineering, CIRP ICME '18 Gulf of Naples, Italy Design Conference, 2018, Nantes, Methodology28th forCIRP design process of aMay snap-fit jointFrance made by additive Methodology for design process of a snap-fit joint made by additive A new methodology to analyzemanufacturing the functional and physical architecture of manufacturing a a a a a, existing products for an assembly oriented product family identification Emilio A. Ramírez a, Fausto Caicedoa, Jorge Hurela, Carlos G. Helgueroa, Jorge Luis Amayaa,* Emilio A. Ramírez , Fausto Caicedo , Jorge Hurel , Carlos G. Helguero , Jorge Luis Amaya * Paul Stief *, Jean-Yves Dantan, Alain Etienne, Ali Siadat ESPOL Polytechnic University, Advanced Machining and Prototyping Laboratory CAMPRO, Faculty of Mechanical and Production Sciences Engineering a ESPOL Polytechnic University, Advanced and Prototyping Laboratory CAMPRO, of Mechanical andEcuador Production Sciences Engineering FIMCP, Campus Machining Gustavo Galindo Km 30.5 Vía Perimetral, P.O. BoxFaculty 09-01-5863, Guayaquil, FIMCP, Campus Gustavo Galindo Km 30.5 Vía Perimetral, P.O. Box 09-01-5863, Guayaquil, Ecuador Écoleauthor. Nationale d’Arts etE-mail Métiers, Arts et jorge-luis.amaya@espol.edu.ec Métiers ParisTech, LCFC EA 4495, 4 Rue Augustin Fresnel, Metz 57078, France * Corresponding Tel.:Supérieure +593-42-269-295. address: * Corresponding author. Tel.: +593-42-269-295. E-mail address: jorge-luis.amaya@espol.edu.ec a * Corresponding author. Tel.: +33 3 87 37 54 30; E-mail address: paul.stief@ensam.eu Abstract Abstract The use of additive manufacturing (AM) technology has been widely adopted due to its facility to produce highly complex Abstract The use ofNevertheless, additive manufacturing (AM) technology has been widelylimitations adopted due to its facility producecapabilities highly complex elements. elements fabricated by AM have dimension regarding printerstobuilding (e.g. elements. Nevertheless, elements fabricated by AM have dimension limitations regarding printers building capabilities (e.g. more volumetric than printers building chamber). potential solution to divide elements in sections, the which are Inelements today’s business environment, thethe trend towards more product varietyAand customization is is unbroken. Due to this development, need of elements more volumetric than printers building chamber). A potential is to divideTo elements in sections, which are later 3D-printed and joined usingthe snap-fits. The present work an AMsolution design methodology fordesign elements´ couplingproduction by snapagile and reconfigurable production systems emerged to cope with proposes various products and product families. and optimize later 3D-printed joinedthe using snap-fits. The present work proposes ananalyze AM design methodology for elements´ coupling by snapsystems as A well as and todivision choose optimal product matches, product analysis to methods arethe needed. Indeed, design most ofinthe known methods aim to fit joints. model and parts assembly case study is presented parts mating terms of joining features fit joints. Asupport model division and partsonassembly caselevel. study is presented tofamilies, analyze however, the parts may mating design inin terms features analyze a product or one product family the physical Different product differ largely termsofofjoining the number and resistance, material consumption and printing times. resistance, support and printing times. and choice of appropriate product family combinations for the production nature ofThe components. This factconsumption impedes anB.V. efficient comparison © 2018 Authors.material Published by Elsevier © 2018AThe The Authors. Published by Elsevier B.V. committee Peer-review under responsibility ofElsevier the scientific of the 12th Conference on Intelligent Computation in Manufacturing system. new methodology is proposed to analyze existing products in CIRP view of their functional and physical architecture. The aim is to cluster © 2019 Authors. Published by B.V. Peer-review under responsibility of the scientific committee of the 12th CIRP Conference on Intelligent Computation inof Manufacturing Engineering. these products in new assembly oriented product families for the optimization of existing assembly lines and the creation future reconfigurable Peer-review under responsibility of the scientific committee of the 12th CIRP Conference on Intelligent Computation in Manufacturing Engineering. Engineering. assembly systems. Based on Datum Flow Chain, the physical structure of the products is analyzed. Functional subassemblies are identified, and method, Additive manufacturing, a Keywords: functionalDesign analysis is performed. Moreover, aSnap-fit hybrid functional and physical architecture graph (HyFPAG) is the output which depicts the Keywords: Design method, Additive manufacturing, Snap-fit similarity between product families by providing design support to both, production system planners and product designers. An illustrative example of a nail-clipper is used to explain the proposed methodology. An industrial case study on two product families of steering columns of precision. potential solution is to divide the elements in 1. Introduction thyssenkrupp Presta France is then carried out to give a first industrial evaluation of theA approach. precision. Aproposed potential solution is to elements in 1. Introduction sections, which are later 3D-printed anddivide joinedthe using snap-fits. © 2017 The Authors. Published by Elsevier B.V. sections, which are later 3D-printed and joined using snap-fits. Snap-fits joints are mechanical features for part mating Additiveunder manufacturing (AM) a layer-by-layer fabrication Peer-review responsibility of theisscientific committee of the 28th CIRP Design Conference 2018. Snap-fits joints deformation, are mechanical featuresa flexible for part element mating Additive used manufacturing (AM) is a layer-by-layer fabrication based on material in which technology to construct computer-aided designs (CAD) based on material deformation, in which a flexible element technology used to construct computer-aided designs (CAD) deflects during the assembly and fixes in the mating Keywords: Assembly; Design The method; identification models or prototypes. useFamily of AM technology has been deflects duringAlthough the assembly and fixessnap-fit in the mating models or prototypes. Thefacility use oftoAM technology been component. traditional design widely adopted due to the produce highly has complex component. Although traditionalfor polymer snap-fit injection design widely adopted due to the facility to produce highly complex methodologies have been developed elements compared to conventional fabrication processes. methodologies have studies been developed for polymer injection elements compared to conventional fabrication processes. applications, other have reported that additiveDue to AM technology development, it is possible to applications, studies have additiveDue to AM technology it is possible(e.g. to 1.manufacture Introduction of the product other range and characteristics and/or manufactured snap-fits joints have reported a manufactured similarthat behavior to products with adevelopment, growing list of materials manufactured snap-fits joints have a similar behavior to manufacture products with a growing list of materials (e.g. injected features and that previous developed design rules for assembled in this system. In this context, the main challenge in polymers, metal powder, ceramics) depending of model’s injected features and that previous developed design rules for polymers, metal ceramics) depending of model’s dimensioning applicable [3].not only to cope with single Due to requirements the powder, fast and development in the domain of modelling and are analysis is now functional AM technology capabilities. dimensioning are applicable [3]. oris existing functional requirements AM technology The objective of this article to present a systematic communication and an and ongoing trend of capabilities. digitization and products, a limited product range product families, Even though recent advances on AM permit process The objective of this article toand present a systematic Even though recent advances on AM permit process procedure forable snap-fit feature elements coupling digitalization, manufacturing enterprises are facing feasibility, important but also to be to analyze anddesign toiscompare products to define stability on industrial applications and economic procedure snap-fit feature design and mating elementsparts, coupling stability on and economic feasibility, based on for operating of the part challenges inindustrial today’s applications market a continuing new product families. Itconditions can be observed that classical existing elements manufactured by AMenvironments: technology have dimension based on printing operating conditions of technology the matingused, parts, part elements manufactured by AM technology have dimension geometry, material and AM in order limitations regarding printers building capacities times and work tendency towards reduction of product development and product families are regrouped in function of clients or features. geometry, printing material and AM technology used, in order limitations regarding printers building capacities and work to avoid the use of fasteners or adhesives as joining methods. piece volumes [1].lifecycles. In addition, there is an increasing shortened product However, assembly oriented product families are hardly to find. to avoid the use of fasteners or adhesives as joining methods. piece volumes [1]. have proposed Additionally, procedure the Previous studies of parts demand of customization, being at the thedivision same time in a greater global On the product the familyproposed level, products differ considers mainly in two Additionally, the proposed procedure considers the Previous studies have proposed the division of parts greater subdivision of a single element, accounting general Design for than the printer building chamber on a voxelization competition with competitors all overbased the world. This trend, main characteristics: (i) element, the number of components and (ii) the subdivision of a single accounting general Design for than the with printer building chamber based onmodel a voxelization Manufacturing and Assembly (DFMA) criteria’s, which bases method, an interlocking approach to final assembly which is inducing the development from macro to micro type of components (e.g. mechanical, electrical, electronical). Manufacturing and Assembly (DFMA) criteria’s, which bases method, with an this interlocking to final model assembly on multiple-part design for ease of manufacturing and ease of [2]. However, joining approach method have been reported as markets, results in diminished lot sizes due to augmenting methodologies mainly single onClassical multiple-part design forconsidering ease of manufacturing andproducts ease of [2]. However,forthis joining method have that beenrequire reported as assembly. inappropriate hollow objects and models further product varieties (high-volume to low-volume production) [1]. or solitary, already existing product families analyze the assembly. inappropriate for hollow objects and models that require further To cope with this augmenting variety as well as to be able to product structure on a physical level (components level) which 2212-8271possible © 2017 The optimization Authors. Published by Elsevier B.V. identify potentials in the existing causes difficulties regarding an efficient definition and 2212-8271 ©under 2017responsibility The Authors. of Published by Elsevier B.V.of the 11th CIRP Conference on Intelligent Computation in Manufacturing Engineering. Peer-review the scientific committee production system, it is important to have a precise knowledge comparison of different product families. Addressing this Peer-review under responsibility of the scientific committee of the 11th CIRP Conference on Intelligent Computation in Manufacturing Engineering. 2212-8271©©2017 2019The The Authors. Published by Elsevier 2212-8271 Authors. Published by Elsevier B.V. B.V. Peer-reviewunder underresponsibility responsibility scientific committee of the CIRP Conference on 2018. Intelligent Computation in Manufacturing Engineering. Peer-review of of thethe scientific committee of the 28th12th CIRP Design Conference 10.1016/j.procir.2019.02.021 114 Emilio A. Ramírez et al. / Procedia CIRP 79 (2019) 113–118 E. A. Ramírez et al. / Procedia CIRP 00 (2018) 000–000 2. General Snap-fit design procedures: from traditional manufacturing to AM Most studies in snap-fit applications focus on a feature-level design methodology; this means them often consider the dimensioning of the deformable beam of the joint and the locking mechanisms for diverse snap-fit types and crosssectional areas [4]. For instance, software-based tools have been developed for snap-fit selection and optimization and for feature evaluation and machinery dimensioning for consumer products applications [5]. Furthermore, industry manufacturers have developed snap-fit feature-dimensioning guidelines; however, these design methodologies do not consider the location and orientation of snap-fit features nor additional elements of the joint mechanism [6, 7]. Early studies have been made regarding a methodical procedure for an integral snap-fit joint design [8]; which considers the locating features for part-mating positioning, the snap-fit dimensioning and locking features, and additional enhancement features design for assembly and disassembly enablers, among other characteristics. Concerning AM technologies, recent studies have stated that the working principles of traditional snap-fit design prove to be independent of the manufacturing process and have proposed additive manufactured snap-fit design guidelines in which previous methodology needs to be adapted to the restrictions of the new manufacturing technology [3]. Seepersad, et al. [9] states that current design guides often focus exclusively on process limitations instead of evaluating the possible advantages in part fabrication, and, although this can contribute to a poor utilization of the new manufacturing technologies capabilities, there is still the need for an in-depth evaluation of design conditions or principles. One of the many considerations in AM applications is the orientation of the printed pieces relatively to the building plates, as the discrete characteristic of the layer-by-layer fabrication process is a source for anisotropic properties. Previous studies have developed a systematic approach for part orientation based on a qualitative analysis of the concept designs [1]. The available literature seems to suggest the need of further studies in developing design guidelines for integral snap-fit joint fabrication adapted to some of the current fabrication characteristics of AM technology. This present study does not propose an exhaustive analysis for process characteristics regarding a specific AM technology, but accounts for the general considerations and the limitations that seemed to have the most relevance. made separately and there has been no formal integration between both design stages. Consequently, our study considers the integration of the conceptual and detail design, on which the results for the conceptual stages are used on the design phases. The proposed design methodology for Snap-fit systems design process made by AM technology is shown on Fig. 1. The flowchart starts with the input variables of performance and manufacturing conditions labeled as Design Specifications. The conceptual design stage includes the part mating design and the Snap-fit systems type selection and location. The detail design section is formed by three independent procedures, which are material deflection limits calculation based on the joint performance conditions, deflection mechanism geometry dimensioning, and, retention mechanism geometry dimensioning. 3. Additive-manufactured Snap-fit design process Methodology A systematic procedure for additive-manufactured snap-fit systems can be developed accounting for general design guidelines. Common design methodologies are formed by four main stages: performance conditions or design specifications, conceptual design, detail design, and lastly a design validation stage. Once design process has been validated, the final product can be manufactured. Previous studies have established methodologies for Snapfit systems design in a conceptual framework and in a detail design framework [8]; however, these approaches have been Fig. 1. Proposed methodology of design process for snap-fit joint. Emilio A. Ramírez et al. / Procedia CIRP 79 (2019) 113–118 E. A. Ramírez et al. / Procedia CIRP 00 (2018) 000–000 A design validation stage is also considered to give a feedback to both conceptual and detail design phases. This validation is formed by a feature deformation analysis based on material limits and deflection mechanism geometry, an ergonomics check for ease of part mating based on assembly and disassembly forces, and a final evaluation of the retention features for the snap-fit joint. The final stage of the process corresponds to the 3D printing manufacturing of the pieces with the added designed and validated snap-fit joints. Each node of the flowchart is detailed on the following sections. Before describing the methodology in detail, it is necessary to know that the design process could be linear from an ideal standpoint but is iterative in most cases. Considering that the iterative condition could occur in the detail design or design validation stages, the initial design is subject to change. 3.1. Performance Conditions The present study focuses on four main design specifications or performance conditions of the snap-fit system, which are AM technology, printing material, model geometry and snap-fit performance conditions. These restrictions are considered as input variables to the methodology and will not change during the design process. AM technology considerations refers to machinery specific constraints. Parameters such as printing layer thickness and building chamber dimensions affect directly to the model partitioning in the part mating design stage. Also, it is important to evaluate the printing procedure beforehand to know the limitations on small features printing and the need of support structures, as this result could impact in the posterior dimensioning of the snap-fit system. Regarding printing material, mechanical properties characterization is needed for the detail design stages such as in material deformation limits calculation and deflection and retention mechanisms dimensioning. Overall model geometry needs to be accounted as it can limit the partitioning approach and the location of the snap-fit features due to aesthetic or functional requirements. Model wall thickness and weight influence the final joining design. The last design specification considered in the proposed design process corresponds to the performance condition of the snap-fit system. This input refers to operational restraints such as in the need of a permanent joint, or if the joint will be subject to frequent assembly and disassembly motions. These requirements can influence both conceptual and detail design stages. 3.2. Conceptual Design After the definition of the input parameters to be used, the conceptual design stages take place. This preliminary design constitutes the initial framework for the mating features. 3.2.1. Part Mating Design This first conceptual design stage refers to the subdivision of the initial model. As stated before, a primary partitioning method can be selected based on the general model configuration, and the building chamber volume of the printer. 115 Although, current 3D printing capabilities offers manufacturing advantages over traditional manufacturing methods, the final printing approach can be further optimized by accounting for the additive manufacturing technology characteristics. A possible method of optimization is to consider the part printing orientation of the model sections. From the primary partitioning, the designer can evaluate the subdivision according to an efficient partitioning approach, which depends on support material utilization and printing times, and offers a quantitative validation. Both considerations of the efficient partitioning approach can be competing measures, as one orientation can use less support material but complete in a greater printing time. The anisotropy of the parts associated with the 3D-printer building directions could be a considerable restriction; therefore, the printing approach, as well as model wall thickness and model overhangs, can also affect the selected partitioning method and the posterior snap-fit features location. 3.2.2. Snap-fit System Type and Location selection The snap-fit system, as an assembly mechanism, consists on locking features, locating features and enhancement features [8]. Locking features are responsible for restricting the movement between mating parts in the assembly direction (i.e. one degree of freedom DOF). The most common types of locking features are the cantilever, torsional and annular snapfit joints. The locking feature can be further divided in two mechanisms: the deflection mechanism and the retention mechanism. The deflection mechanism is chosen based on the mating part geometry and is deflected to couple the retention mechanism. Depending the desired operational deflection, it will have a different mechanical behavior and resistance. The retention mechanism is defined by the assembly/disassembly operation and it produces the interference between the mating parts. According to the snap-fit joint type, the location of the locking feature should be oriented in order to distribute the principal stresses along the most resistant building direction. Locating features (e.g. locators, catches) are used to constraint the remaining DOF, guide the locking features, and establish a reference between the mating parts. Enhancement features are the attributes of locking and location features that ease the performance of the snap-fit joint and the manufacturing (e.g. assembly or disassembly aid). 3.3. Detail Design With the results of the conceptual design stages, in depth analysis of the used material and the dimensioning of the snapfit features is considered in the detail design stages. For the following subsections, a general guideline for feature design is proposed, the authors encourage the review of available literature [6, 7, 10], regarding general snap-fit features design. 3.3.1. Material Deformation Limits For establishing material deformation limits, a primary design strain of the joint can be considered depending on the Emilio A. Ramírez et al. / Procedia CIRP 79 (2019) 113–118 E. A. Ramírez et al. / Procedia CIRP 00 (2018) 000–000 116 presence of a definite yield point in the printing material stressstrain curve. The need of material characterization data in this stage is crucial as it can affect the posterior joint deformation validation, thus compromising the previous conceptual design. In addition, the performance conditions of the joint, such as the number of cycles for frequent assembly and disassembly motions, or the position of the snap-fit features relatively to the part walls, affect as a factor to the prior design strain. Furthermore, this factor will also vary if the material has a flexible or brittle behavior. The maximum permissible strain of the joint is equal to the design strain divided by a stress concentration factor. This stress concentration is located in the interface of the snap-fit and the wall where it is mounted, acting in the surface subjected to bending deformation. For diminishing the effects of stress concentration, literature suggests the use of fillets of a value of 50% the snap-fit feature thickness, which produces a stress concentration factor of 1.5 in these interfaces. 3.3.2. Deflection Mechanism Dimensioning The geometry of the deflection mechanism can be defined as a function of the snap-fit feature thickness; however, the available literature lacks in information for the proper selection of this dimension. Nevertheless, an initial design value can be selected based on the positioning of the feature relatively to the part wall where it is mounted. If the feature extends from a wall, the feature thickness can equal to the wall thickness. For features protruding from a wall, literature suggests a factor of 50% to 60% of wall thickness for feature thickness values, based on tests for filling and flow problems, as well as cooling problems, on injection molding applications [10]. 3.3.3. Retention Mechanism Dimensioning The final dimensioning stage is the definition of the retention mechanism, which is comprised of a sloped surface that engages the part during the mating procedures and permits or inhibits the removal of the parts. The overhang of the retention mechanism can be defined as a function of the feature length to thickness ratio. Common values for insertion angles tends to be less than 45 degrees, as greater values make the joining difficult to assembly. For the disassembly interfaces, the angles will vary depending if the joint needs to be releasing or non-releasing. Typical angular values of the sloped removal surfaces for nonreleasing joints are above 80 degrees. For a releasing joint, an additional consideration is the presence of external loads along the mating directions. If no loads are present, the retention angle can be equal to a threshold value that accounts for part weight effects and is a function of the material friction coefficient. If external loads are applied, the retention angle should have a value in between the threshold value and 80 degrees. 3.4. Design Validation The design validation stages are of great importance as it compromises a series of tests or performance conditions evaluation to ensure the successful application of the snap-fit joint system in the final part joining, prior to the additive manufacturing production. 3.4.1. Deformation Validation The deformation validation stage compares the strain obtained while deflecting the snap-fit feature with the permissible feature strain defined on the material deformation limits. The feature strain depends on the snap-fit feature type geometry. For some feature configurations, as in cantilever snap-fit joints, the feature deflection and strain and can be obtained based on beam theory calculations. Additional factors of feature positioning relatively to part wall and corrections factors due to mating parts deflection in finite element simulation should also be considered for a final strain value calculation. If the final strain on the features is greater than the permissible strain limits, corrections should be made on the conceptual design stages or on the snap-fit feature geometry values, depending on the amount of the difference. For small deviations, a simple feature dimension correction can be sufficient, but for greater values a more in-depth analysis of the feature location and/or part mating orientation is needed. In the flowchart, the unacceptable condition is connected to the part mating design as it corresponds to the worst-case scenario. 3.4.2. Assembly and Disassembly forces calculation The force needed to deflect the snap-fit features depends on feature geometry and type. As this deflection force acts on the sloped surfaces of the joint during the union or removal of the parts, the assembly and disassembly forces are calculated as the projected force along the mating or release direction. The assembly and disassembly forces are a function of the deflection force, material friction coefficient and the effective angle of the slope considering mating simulations correction factors. This correction factor accounts for actual part deformation, as the general equations assumes that the only deformable element is the snap-fit feature. The available literature [6, 7, 10] have additional information regarding calculation formulas. 3.4.3. Ergonomics Validation The ergonomics validation is made with the results from the assembly forces calculation. This validation consists on the comparison of the force needed to join the parts and acceptable forces for manual assembly. Lee and Gu [11] reported a mean value of roughly 81 N for acceptable insertion forces in manual assembly of small connectors, and a mean maximum force of 141 N. It is also noted that acceptable and maximum coupling forces depend on the posture and size of the mating parts. If the assembly forces surpass the acceptable insertion forces, the proposed methodology suggest the evaluation of the predefined snap-fit feature dimensions. A possible correction approach is to vary the feature width as it does not affect the feature deflection results but lowers the required deflection forces. Emilio A. Ramírez et al. / Procedia CIRP 79 (2019) 113–118 E. A. Ramírez et al. / Procedia CIRP 00 (2018) 000–000 3.4.4. 117 Retention Performance Evaluation The final design evaluation corresponds to the comparison of the calculated disassembly forces to the expected joint feature resistance. If the disassembly forces are not greater enough to ensure a reliable joint, the retention angle should be increased thus increasing the retention capability. This correction does not interfere with the general feature dimensioning. An additional consideration in this phase is the resistance of the sloped area, as it can fail by shear forces during part releasing. 3.5. Additive Manufacturing Test Once the detail design has been validated, the final stage of the proposed methodology is the 3D-printing of the model parts and physical assembly procedures. 4. Case Study: A 1-gallon plastic container The printing of a 1-gallon plastic container is considered for evaluation of the design methodology. The design specifications for the manufacturing of the model are based on MultiJet Printing technology using ABS (Acrylonitrile Butadiene Styrene) plastic for model part construction, with the utilization of permanent joints that does not affect the overall outward appearance. The 3D-printer used for the construction of the elements was a 3DSystems ProJet 3510 SD, with a building chamber of 298.45x185.42x208.78 mm for the X, Y and Z directions respectively. The model gross dimensions are 277x115x206 mm, but the selected printing equipment needs an additional 5.48 mm for a removable base in the Z building direction, therefore, the model does not fit in the building chamber and needs to be printed in sections. For the part mating design, three alternatives for model division were tested: a 2-part division, a 3-part division and a 6-part division, which are shown on Fig. 2. These approaches were evaluated in terms of support material consumption and estimated printing time, giving more importance on material economy. The results for support material consumption and estimated printing times of each alternative are reported on Table 1, the percentages shown for support material reduction are compared to the original model support requirements, obtained from the printer software. The first division approach (2-part division) was discarded due to the relatively low performance in terms on material economy. Although the 3-part division have a better overall performance in printing times and support material reduction, further analysis of the part geometries indicate that the snap-fit joints could not be located perpendicular to the building direction, resulting in poor mechanical performance of the deflection mechanisms. Additionally, this type of division affected the overall model aesthetic with divisions along symmetry planes. Even though the estimated printing times for the 6-part division were longer that the other alternatives, it accounts for a better snap-fit joints location compared to the previous alternatives, with a relatively good support material economy. Also, this approach took advantage on the model surfaces and details to have a clean division. Fig. 2. Mating Part Design: Model division alternatives. Table 1. Support Material consumption for model division alternatives Division alternatives Support Material Reduction* Estimated Printing Time (hours) Alternative A: 2-part Division 66% 66 Alternative B: 3-part Division 74% 62 Alternative C: 6-part Division 73% 84 * Compared to original model support material requirements. The part mating sequence for the 6-part division starts with the union of the parts C2 and C3 (Fig. 2). Both parts then lock to the part C1, followed by the part C4. The remaining parts (C5 and C6) are first joined together, and the locked to the main body. Loop-style cantilever locks were considered for the snap-fit systems, and they were located in the parts perpendicular to the printing building directions, in order to distribute the deflection forces along the construction layers. Different sets of locators and catches were designed to restrict additional DOF for all the mating parts. An example of the designed snap-fit system, regarding locks (deflection mechanism and retention mechanisms), locators and catches, can be seen on Fig. 3, for the mating interfaces of parts C2 and C5. The deflection mechanism design was based on a special case of snap-fit extended from a wall. Instead of extending the features from the wall, they were designed to extend parallel to the wall, thus preserving the outside model appearance and locating all mating features inside the body. From the required performance conditions of the snap-fit system, and building material, the maximum allowable strain was calculated and compared to the design strain obtained by the feature dimensions, in order to make a first validation of the deflection mechanism geometry. The assembly and disassembly forces were calculated based on the available literature [6, 7, 10]. A value of nearly 3.3 N per feature for insertion forces was determined, which is less than the acceptable insertion forces [11], thus proving to be acceptable for the ergonomics validation stage. For the final design validation stage, the retention mechanism was evaluated mainly for shear stresses. Emilio A. Ramírez et al. / Procedia CIRP 79 (2019) 113–118 E. A. Ramírez et al. / Procedia CIRP 00 (2018) 000–000 118 Fig. 3. Examples for locks, locators and catches features. By accounting for part surfaces and geometries, the final part mating and division approach resulted in a clean division which does not affect the final model aesthetics and can ease the location of the snap-fit system features. Although there was a substantial reduction in support material consumption compared to the original model, the printing times augmented in the final part division iteration. Even though the economic analysis is out of the scope of this study, the final mating design iteration yielded an additional reduction in printing costs. Further analysis for manufacturing cost regarding cost of material and cost of equipment utilization is needed. The inclusion of the snap-fit system to the model parts had an increase of 2.1% of part material utilization, which had little effect on the overall part weight. Additionally, in some cases these features served as stiffeners for vertical extended plates such as in part C2, as shown on Fig. 3. Future works aims to include a more in-depth analysis regarding design specifications for the proposed methodology. Additionally, the inclusion of a more detailed process for detail design stages is needed in order to formally include finite element analysis for deflection corrections and final assembly and disassembly forces calculation. Acknowledgements The authors would like to thank the Advanced Machining and Prototype Laboratory CAMPRO, from ESPOL Polytechnic University. References Fig. 4. 1-gallon plastic container made by AM: (a) Printed parts, Final model assembly (b) Isometric view and (c) Lateral view, Joints and locators for parts (d) C2 and C5, and (e) C1 and C2. A final analysis for the model parts was to evaluate the impact of the addition of the additional features of locks, locators and catches. The inclusion of the snap-fit system represents an increase of 2.1% for part material utilization, an increase of 1.8% for support material utilization, and an increase of 3.5% of the overall estimated printing time. With the validated design, the parts were 3D-printed and then assembled following the joining procedure described. Images of the printed parts and model assembly are shown on Fig. 4. 5. Conclusions The employment of the proposed methodology for snap-fit systems design permitted to 3D-print and assemble a model of a 1-gallon plastic container that could not be printed in a single job due to 3D-printing building chamber limitations. [1] Leutenecker-Twelsiek B, Christoph K, Meboldt M. Considering Part Orientation in Design for Additive Manufacturing. Procedia CIRP, 50, 2016; 408-413. [2] Song, P, Fu Z, Liu L, Fu CW. Printing 3D objects with interlocking parts. Computer Aided Geometric Design 2015; 35-36: 137-148. [3] Klahn C, Singer D, Meboldt M. Design Guidelines for Additive Manufactured Snap-Fit Joints. Procedia CIRP, 50, 2016; 264-269. [4] Ruan T, Luscher AF. A Web-Based Design Tool for Snap-Fit Features. ASME International Design Engineering Technical Conferences and Computers and Information in Engineering 2005; 937-945. [5] Brock JM, Wright PK. Design Tool for Injection Molded Snap Fits in Consumer Products. Journal of Manufacturing Systems 2002; 21: 32-39. [6] BASF Corporation, Snap-fit design manual. 2007. [7] Bayer Material Science LLC. Snap-fit joints for plastics - a design guide. Pittsburg 2013. [8] Genc S, Messler RW, Gabriele GA. A systematic approach to integral snapfit attachment design. Research in Engineering Design 1998; 10 (2): 84-93. [9] Seepersad CC, Allison J, Sharpe C. The need for effective design guides in additive manufacturing. Proceedings of the International Conference on Engineering Design, ICED 2017; 5 (DS87-5): 309-316. [10] Bonenberger PR. The first snap-fit handbook: Creating and managing attachments for plastics parts. Hanser Publications 2016. [11] Lee K, Gu K. Required forces in manually inserting a small object. Yamamoto, Sakae; New Ergonomics Perspective: Selected papers of the 10th Pan-Pacific Conference on Ergonomics 2014; 91-94; CRC Press.