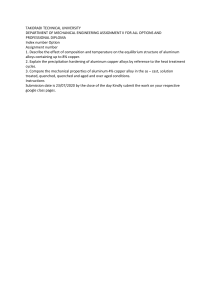

Journal of Alloys and Metallurgical Systems 2 (2023) 100010 Contents lists available at ScienceDirect Journal of Alloys and Metallurgical Systems journal homepage: www.journals.elsevier.com/journal-of-alloys-and-metallurgical-systems Metallurgical and mechanical investigation on FSSWed dissimilar aluminum alloy K. Anton Savio Lewisea, ⁎,1 ]] ]] ]]]]]] , J. Edwin Raja Dhasb, R. Pandiyarajanc, S. Sabarishd a Department of Aerospace Engineering, Karunya Institute of Technology and Sciences, Coimbatore 641114, India Department of Automobile Engineering, Noorul Islam Centre for Higher Education, Kumaracoil 629180, India c Department of Mechectronics Engineering, Agni College of Technology, Chennai 600130, India d Department of Mechanical Engineering, K.L.N. College of Engineering, Sivagangai 630612, India b A R T I C L E I N F O Keywords: Aluminum alloys Friction stir spot welding AA2024-T3 AA7075-T6 Dissimilar joint Microhardness Fractography A B S T R A C T The present work is the novel examination of influence of welding process parameters and material flow on the mechanical and microstructural characteristics during the FSSW of dissimilar AA2024/AA7075 joint were evaluated and compared with similar AA2024/AA2024 and similar AA7075/AA7075 FSSW joints. The microstructural and physical properties of two aluminum alloy joined through friction stir spot welding (FSSW) were examined. The aluminum alloys namely AA2024-T3 and AA7075-T6 were selected for the investigation owing to their typical and potential applications in aeronautical industry. The input parameters were tool rotational speed, plunge depth and dwell time (TRS 1800 rpm, 3.3 mm plunge depth and 45 s dwell time) were utilized. The microstructure of the welded specimen was investigated by scanning electron microscope and their chemical compositions were analyzed by energy-dispersive X-ray spectroscopy. The physical properties were investigated by Vickers microhardness survey and the specimen strength evaluated by tensile tests. The experimental investigation revealed the influence of the tool pin penetration and frictional heat on the microstructure, distribution of the grain structure affecting the microhardness and the tensile properties of the dissimilar joint. 1. Introduction Friction stir spot welding (FSSW) was a modified solid–state welding process derived from friction stir welding (FSW). The process involved a rotating tool with or without a protruding pin plunging into the weld specimen plates that overlap each other [1,2]. The pin tool was plunged to a predetermined depth for a set amount of dwell time and withdrawn after leaving behind a characteristic keyhole. The frictional heat generated by the rotating tool at the region where the tool contacts the specimen surface, caused the flow of material in the stir zone [3]. The welding input parameters such as tool geometry, tool rotation speed, dwell time, axial force, plunge depth typically influenced the flow of the material grains and distribution [4,5]. The flow of the material and resulting microstructure greatly influenced the possibilities of defects and porosities. These defects typically were detrimental to the physical properties and performance characteristics of the welded joint [6]. Several studies were carried out on the flow of material and respective ⁎ 1 metallurgical behavior during FSW is described [7]. The available literature on flow of material and subsequent investigations on microstructural and physical properties of dissimilar FSSW aluminum alloy joints was limited. The available studies presented many auxiliary insights in related approaches. The effect of FSSW process parameters of a similar aluminum alloy joint was investigated by use of software analysis in the weld zone [8]. The high compression force that followed the stirring action of an FSW AND FSSW tool led to compression of the materials in the stir zone and changes in the accumulated microstructure [9]. The effects of FSSW on similar aluminum alloy AA7075-T6 plates with two pin profiles were investigated to evaluate the damage the welding tool could bear at varying input conditions [10]. The increasing of sheet thickness at the joint region seemed to have positive effects on the improving the fatigue life of the specimen and tool life. The effect of refill FSSW on the aluminum alloy 5754-H22 and Ti6Al4V joint was performed to evaluate the microstructural and mechanical properties [11]. It was found that the refill FSSW was capable of effectively welding Corresponding author. E-mail address: kaslewise@gmail.com (K. Anton Savio Lewise). https://orcid.org/0000-0003-2616-3599 https://doi.org/10.1016/j.jalmes.2023.100010 Received 2 February 2023; Received in revised form 24 April 2023; Accepted 4 May 2023 Available online 5 May 2023 2949-9178/© 2023 The Author(s). Published by Elsevier B.V. This is an open access article under the CC BY-NC-ND license (http://creativecommons.org/licenses/ by-nc-nd/4.0/). K. Anton Savio Lewise, J. Edwin Raja Dhas, R. Pandiyarajan et al. Journal of Alloys and Metallurgical Systems 2 (2023) 100010 Table 1 Material composition of aluminum alloys (weight percentage). Aluminum alloy Cu (%) Zn (%) Fe (%) Mg (%) Ti (%) Mn (%) Al (%) AA2024-T3 AA7075-T6 4.9 1.6 0.142 5.6 0.239 0.5 1.28 2.5 0.0154 0.2 0.629 0.16 balance balance Table 2 Physical properties of aluminum alloys. Aluminum alloy Yield Strength (MPa) Tensile Strength (MPa) Elongation (%) Microhardness (HV) AA2024-T3 AA7075-T6 345 480 440 540 14 11 137 175 microstructure, physical properties and subsequent analysis on fracture of the welded specimens were not clear. It is clear that there exists a literature gap which investigate the relation between the microstructure, joint strength and weldig parameters such as tool rotational speed, dwell time and tool plunge depth during welding of dissimilar aluminium 2xxx and 7xxx series alloys. In the present work, the flow of material, microstructure, physical properties and fractography were studied for FSSW of dissimilar aluminum alloy AA2024-T3/AA7075-T6 joint. The upper and bottom plate interaction were studied. The experimental results were evaluated to comprehend the influences of grain dispersion and fracture crack propagation during failure. 2. Materials and methods Fig. 1. XRD analysis of aluminum alloys AA2024-T3 and AA7075-T6. 2.1. Materials overlap joints under optimized input conditions [12]. Reduction in heat input can lessen the creation of joint defects, and increasing tool rotation speed and dwell duration can increase a dissimilar joint strength and ductility [13]. Furthermore, the development of a defect-free connection with good mechanical characteristics can result from the right tool rotation speed and welding temperature, and the intermetallic compound formation at the joint interface has a significant impact on the joint strength [14]. The production of a sound dissimilar joint with good mechanical characteristics may also be achieved by optimising the tool geometry and process parameters, and the joint strength is determined by the grain structure and defect development in the joint [15]. It has also been stated that the microstructure and mechanical characteristics of the joint may be greatly influenced by the tool pin features, such as pin shape and pin length, and that optimising the tool pin features can result in the development of a high-quality joint [16]. The joint strength is determined by the dissimilar joint's microstructure and defect generation, and thus increasing welding speed can reduce joint strength while reducing welding speed can increase joint strength [17]. The nugget diameter was found to decrease when the tool rotating speed was increased, while the joint's hardness and ultimate tensile strength increased. when compared to other welding techniques, the FSSW is capable of generating a more homogenous microstructure [18]. The production of a strong dissimilar FSSW joint with good mechanical qualities necessitates optimising the tool pin profile, which can have an impact on the joint's microstructure and mechanical properties [19]. The ultimate tensile strength and joint elongation have been observed to increase with increasing tool rotating speed. The nugget diameter also decreased and the area of the heat impacted zone increased as the tool traverse and rotational speeds were increased [20]. It was discovered that the number of FSSW weld passes had a substantial impact on the microstructure and mechanical characteristics of joints made of different aluminium, with more passes producing finer grains, a more homogenous microstructure, and stronger joints [21]. The existing literature studies dealt with material flow or analysis of weld parameters of FSSW on weld joints. The analysis behind the The present work investigates a friction stir spot welded joint of two aluminum alloys AA2024-T3 and AA7075-T6. The microstructure of aluminum alloy AA2024-T3 was multifarious resulting in its elevated tolerance to cracks and fractures. This also led to increased microhardness levels but diminishes the weldability of the alloy. With copper being the principal alloying element of this aluminum alloy, it was widely used in the aircraft industry where their high strength is of great value. Aluminum alloy AA7075 in the T6 temper possessed highest strength among all the aluminum alloys making it extremely desirable for aircraft structural applications and high strength bracing components in performance automotive applications. Zinc was the primary alloying element of this aluminum alloy with other elements being copper and magnesium. The material compositions of the base aluminum alloys were evaluated by spectrochemical analysis (Table 1). The physical properties of these aluminum alloys were obtained from existing literature (Table 2). The microstructures of the aluminum alloys AA2024-T3 and AA7075-T6 were investigated X-ray diffraction (XRD) analysis. The XRD spectrometer used was X-Pert PRO by Panalytical systems with Cu target with fixed tube. The XRD analysis showed three dominant peaks for aluminum alloy AA2024-T3 at with the highest peak at 400 followed by two small peaks at 66.70, and 79.70 respectively (Fig. 1). The analysis presents a single peak observed at 400, for aluminum alloy AA7075-T6. The chemical composition of the base AA2024-T3 and AA7075-T6 alloys were analyzed by spectrochemical analysis and the highest composition elements of the alloys were analyzed for peak intensities by XRD analysis. The JCPDS database was inferred to determine the composition substances based on the X-Ray diffraction data. The variations of the microstructures were also exemplified by the respective peaks seen in Fig. 1. 2.2. Friction stir spot welding (FSSW) In the present study, the two-aluminum alloy AA2024-T3 and AA7075-T6 were used to fabricate lap joints by FSSW as schematically 2 K. Anton Savio Lewise, J. Edwin Raja Dhas, R. Pandiyarajan et al. Journal of Alloys and Metallurgical Systems 2 (2023) 100010 Fig. 2. (a) Working schematic representation of FSSW process; (b) Experimental setup of FSW AND FSSW machine. represented by Fig. 2(a). This was accomplished by customized vertical milling machine with a specialized fixture designed to hold the working specimens linearly. This modified machine was also capable of accommodating FSW (Fig. 2(b)). The friction stir spot weld was performed by a pin tool fabricated from D3 tool steel known for its high abrasion resistance and superior dimensional properties. The tool possessed a pin length of 2.5 mm with 3 mm diameter, while the tool shoulder had a diameter of 10 mm. FSSW experimental trials were performed with varied input process conditions such as tool rotational speed (800–2400 rpm), plunge depth (3–3.6 mm) and dwell time (30–60 s). The present experimental study yielded process parameters of tool rotational speed 1800 rpm, plunge depth of 3.3 mm and a dwell time of 45 s The FSSW process was essentially a three-stage process as the schematic shown in Fig. 2(a) [22]. The first stage started with the contact of rotating tool pin over the top surface of the aluminum alloy AA2024-T3 upper plate until when the tool pin contacted the top surface of the AA7075-T6 bottom plate. This stage resulted in plastic flow or stirring of the material facilitated by frictional heat generated by the tool pin. The next stage involved the plunging of the pin onto the bottom sheet resulting in active mixing of the materials in the upper and bottom plates. The downward motion of the tool aided in increasing the volume of the stirred material. During the next stage the tool shoulder met the upper plate thereby greatly increasing the stir zone and frictional heat generation. Majority of the material flow during the entire FSSW process had occurred at this stage where the steady downward motion of the tool pin forced the material in the stir zone upwards around the pin. The tool pin was retracted when the weld joint obtained was satisfactory. A total of nine welded specimens were fabricated. They included three specimens each with the combination of similar AA2024 welded joints, similar AA7075 welded joints and dissimilar AA2024/AA7075 welded joints. The different specimens were subsequently tested for their mechanical and microstructural characteristics. The mean values obtained for each set of the similar AA2024, AA7075 and dissimilar AA2024/ AA7075 specimens are discussed in Figs. 6 and 7, while the microstructures of the specimens with highest values among each specimen set are recorded in Figs. 5 and 9. The friction stir spot welded dissimilar aluminum alloy AA2024-T3/AA7075-T6 was evaluated for microstructural and physical characteristics. 3 K. Anton Savio Lewise, J. Edwin Raja Dhas, R. Pandiyarajan et al. Journal of Alloys and Metallurgical Systems 2 (2023) 100010 Fig. 3. (a) Micrograph of the top aluminum alloy AA2024-T3 plate after weld; (b) micrograph of the bottom aluminum alloy AA7075-T6 plate after weld; (c) micrograph of the FSSW weld zone. 2.3. Microstructure analysis welded specimen shown in Fig. 3(a) illustrates the regions that were characterized by EDAX analysis. The region near the stir zone and the heat affected zone of the aluminum alloy AA2024-T3 top plate was observed under with SEM-EDAX apparatus as seen in Fig. 3(b). The heat affected zone below the keyhole of bottom plate AA7075-T6 was also characterized as seen in Fig. 3(c) while the stir zone in the interfacial layer between the two plates were also observed in Fig. 3(b). The chemical compositions and the material information observed are presented in Table 3. The graphical representation of the EDAX data in Figs. 4(a), (b) and (c) illustrated the material composition of the base aluminum alloys AA2024-T3, AA7075-T6 and the FSSW specimen respectively. From the inference of Fig. 4, after the FSSW process, the material had undergone significant changes in element within the vicinity of the stir zone (Figs. 4(a), (b)). The interfacial layer between the base alloys exhibited material fusion and the joint exhibited elemental distribution changes (Fig. 4(c)). The distribution of the constituent elements of the weld joint post FSSW in Fig. 4(b) illustrated the flow of material greatly. The weld nugget zone of the joint possessed the redistributed elements due to the material flow which greatly enhanced the joint structure and impacted the properties of the welded specimen. Subsequent to the analysis of material composition of the welded specimen, the grain structure of specimen in interfacial region was The microstructural characteristics of the dissimilar aluminum alloy welded specimen were determined by scanning electron microscopy (SEM) (Thermo Scientific Apreo S) and subsequent Energy dispersive Xray analysis was performed to examine the intermetallic composition of the joint. The flow of the material and grain structure in the stir zone was evaluated for the weld specimens. The welded specimens had both length and width of 15 mm with 10 mm thickness. The surfaces of the welded specimens were prepared per ASTM E3 standard for the microscope analysis. Abrasive papers with differing grit size were utilized in initial surface preparation followed by polishing of the surface by alumina solution. The surfaces were subsequently subjected to etching by Keller’s reagent (ASTM E407). 3. Result and discussion 3.1. Metallurgical characterization of FSSW joints The metallurgical properties and composition of the base aluminum alloys AA2024-T3 and AA7075-T6 were evaluated by Energy-dispersive Xray spectroscopy at 15 kV for duration of 200 s. The macrograph of the 4 K. Anton Savio Lewise, J. Edwin Raja Dhas, R. Pandiyarajan et al. Journal of Alloys and Metallurgical Systems 2 (2023) 100010 Fig. 4. Material composition of (a) top aluminum alloy AA2024-T3 plate after FSSW; (b) bottom aluminum alloy AA7075-T6 plate after FSSW; (c) FSSW weld zone. Fig. 5. SEM analysis FSSW joints (a) interfacial zone; (b) WNZ; (c) region between HAZ and TMAZ; (d) TMAZ. studied by SEM analysis. The weld interface zone shown in Fig. 5(a) illustrates the friction stir zone in the region. Within the stir zone (SZ), fine grain structure was observed (Fig. 5(b)). This fine grain structure was attributed to the material flow caused by the FSSW process during the initial stage. The fine grain structure was also observed near the weld nugget zone (WNZ) [23,26,27]]. The heat affected zone (HAZ) of the interfacial joint was seen as the boundary that separated the coarse grain structure seen in the thermo mechanically affected zone (SZ in Fig. 5(c) and the TMAZ in Fig. 5(d)). The lower levels of weld joint microhardness observed in HAZ on both AA2024 and AA7075 base alloys, was a characteristic behavior observed in aluminium alloys welded by FSW and FSSW processes. 5 K. Anton Savio Lewise, J. Edwin Raja Dhas, R. Pandiyarajan et al. Journal of Alloys and Metallurgical Systems 2 (2023) 100010 Fig. 6. Weld specimen macrostructure and microhardness survey. The was due to the conflicting behavior of material over-ageing and work-hardening that lead to decreased strength with respect to the stir zone and the base alloys [16,24]. The welded specimens were heat treated by cold water cooling and artificially aged for 8 h at a temperature of 90 °C. The appearance of coarse grain structure was due to the lack of power dissipation during the welding caused by the higher innate microhardness level of the bottom AA7075-T6 aluminum alloy. The top plate AA2024-T3 had lower innate microhardness making it capable of facilitating better tool pin penetration. The grain structure distribution observed in the TMAZ was notably sparser than the neighboring HAZ and this was due to the obstructed material flow by the harder AA7075-T6. of the WNZ, HAZ and TMAZ of the welded specimen. The observed microhardness levels top AA2024-T3 and bottom AA7075-T6 plates were shown in Fig. 6. As the graph illustrated, the peak microhardness observed at the top AA2024-T3 plate was 132 HV in the HAZ near the WNZ and followed by another peak at 130 HV about 20 mm further from the stir zone beyond the HAZ. The peak microhardness observed for the bottom AA7075-T6 plate was 213 HV in the HAZ near the WNZ of the specimen. The microhardness observed in the WNZ for the weld specimen was 138 HV. The average microhardness values of the top and bottom plate showed variations to their original microhardness levels expressed in Table 2. This was the resultant effect of the influence of the frictional heat transfer in the plunge depth of the pin tool effectively stirring the material into dispersing the grains between the layers [22,25]. This resulted in AA2024-T3 gaining some improved microhardness and AA7075-T6 losing some microhardness level as the mixture of the materials in the WNZ becomes homogenous. Initially the smoother AA2024-T3 had allowed the pin tool to penetrate the specimen towards the bottom plate which had higher innate microhardness. This effect led the welded specimen to exhibit increased cohesive microhardness levels [19,21,24].(Table 4). 3.2. Microhardness analysis The microhardness levels were evaluated at various points on the surfaces of the welded specimens to determine the average microhardness level. Vickers microhardness test was conducted on the specimen on the surfaces of the top plate with intervals of 1 mm by a diamond indenter. The test load applied was 0.5 kgf for dwell time of 10 s at each survey point. The weld specimens were of the same dimensions as prepared for the microscopic analysis. The average microhardness distribution of the welded specimens is indicated in Fig. 7. The microhardness survey was conducted to establish the relationship between the strength distribution and the fracture of the weld specimen. The Vickers microhardness survey was conducted on the regions 3.3. Tensile analysis The tensile properties of the welded specimens were measured by subjecting to tensile test (ASTM E8 standard) by universal testing machine. The specimens were prepared by wire-cut process to obtain the 6 K. Anton Savio Lewise, J. Edwin Raja Dhas, R. Pandiyarajan et al. Journal of Alloys and Metallurgical Systems 2 (2023) 100010 Fig. 7. Tensile properties of welded specimen. Fig. 8. Tensile tested FSSW specimens (a) AA2024-T3/ AA2024-T3 joint; (b) AA7075-T6/ AA7075-T6 joint; (c) AA2024/AA7075 joint. standard test specimen geometry and were subsequently loaded until fracture of the specimen. The ultimate tensile strength, elongation and elastic modulus of the welded specimen were evaluated and compared with those of the base aluminum alloys AA2024-T3 and AA7075-T6 (Figs. 7a, b and c). The resulting fractured specimens were studied for their microstructure by fractographic analysis on various zones of the fractured material (Fig. 8). The fracture analysis was performed at scanning electron microscope using secondary electron mode. The Load vs Displacement curve in Fig. 7(d) illustrates the relation between the load applied and the deformation of the test specimens. The curve of the dissimilar AA2024/AA7075 FSSW specimen indicates the reduced level of displacement during loading that corresponds to the lowered elongation of the dissimilar specimens compared to the similar AA2024/ AA2024, AA7075/AA7075 FSSW specimens. This was observed to be in accordance to the inferences from Figs. 7(a), (b) and (c). The observed values are listed in Table. As represented by the illustration, the UTS of the welded specimen were seen to be improved up to 15%. The yield strength of the specimen has also gained improvement albeit it being minor. The percentage of elongation of the welded specimen was observed to be lower than the 7 K. Anton Savio Lewise, J. Edwin Raja Dhas, R. Pandiyarajan et al. Journal of Alloys and Metallurgical Systems 2 (2023) 100010 Fig. 9. Fractography of the welded joint (a) top surface; (b) bottom surface; (c) interfacial zone; (d) crack propagation; (e) WNZ of AA2024-T3; (f) WNZ of AA7075T6. Table 3 Material composition of the FSSW specimen. Specimen C (%) O (%) Na (%) Mg (%) Al (%) Mn (%) Cu (%) Cr (%) Zn (%) AA2024-T3 AA7075-T6 Welded specimen 6.20 5.30 3.36 16.21 15.45 2.60 – 1.75 – 2.14 1.45 1.95 69.65 72.10 83.78 – 0.34 – 1.27 3.60 1.73 0.20 – 4.33 0.90 base aluminum alloys because of the improved overall microhardness has reduced the ductility of the specimen [14–16]. The aluminum alloy AA2024-T3 top surface of the welded specimen is observed in Fig. 9(a) which showed the stirred surface. The broken bottom plate was observed in Fig. 9(b) which showed its coarse microstructure in contrast with its finer counterpart seen in Fig. 9(a). The interfacial region of the fractured specimen was observed in Fig. 9(c) which showed the cracks formed within the region during fracture. The cracks observed in the interface region were not as profound as observed in Fig. 9(d) which showed the crack propagated in the HAZ of 3.4. Fractography The tensile tested specimens were illustrated in Fig. 8. The fractography of the weld specimen was evaluated by scanning electron microscope. 8 K. Anton Savio Lewise, J. Edwin Raja Dhas, R. Pandiyarajan et al. Journal of Alloys and Metallurgical Systems 2 (2023) 100010 Table 4 Tensile properties of the tested specimens. Ultimate Tensile Strength (MPa) Std. Dev. Mean (MPa) Elastic Modulus (GPa) Std. Dev. Mean (MPa) Elongation (%) Std. Dev. Mean (MPa) 14.65 14.75 15 16.7 17 16.35 18.25 18.15 18.45 0.180278 14.8 0.1 11.6 7.867 16.6833 0.104083 11.83 0.05 7.75 0.152753 18.2833 0.125831 12.13 7.8 7.9 7.9 7.8 7.7 7.75 6.9 6.95 6.95 0.057735 0.32532 11.5 11.7 11.6 11.8 11.95 11.75 12 12.25 12.15 0.028868 6.933 the weld specimen. The interfacial region possessed higher levels of microhardness and the WNZ possesses improved tensile properties thereby leading to reduced crack formation in that region [25,26]. The HAZ and the TMAZ were most affected by the tensile stress and were subsequently fractured as evidenced in Fig. 9(d). The WNZ of AA2024-T3 and AA7075-T6 can be observed in Figs. 9(e) and (f) showed the fractured surfaces on either plate’s side. The cohesive distribution of the material in the AA2024-T3 was in contrast to the observation in the WNZ of the AA7075-T6 of the weld specimen [13,23]. [2] G. DijuSamuel, J.E.R. Dhas, Influence of tool pin in friction stir welding on activated carbon reinforced aluminium metal matrix composite, IOP Conf. Ser.: Mater. Sci. Eng. 247 (1) (2017) 12015. [3] R. Pandiyarajan, P. Maran, S. Marimuthu, M.P. Prabakaran, Investigation on mechanical properties of ZrO2, C and AA6061 metal matrix composites, Adv. Mater. Process. Technol. (2020), https://doi.org/10.1080/2374068X.2020.1810946 [4] R. Suryanarayanan, V.G. Sridhar, Effect of process parameters in pinless friction stir spot welding of Al 5754-Al 6061 alloys, Metallogr. Microstruct. Anal. 9 (2) (2020) 261–272. [5] K. Anton Savio Lewise, J. Edwin Raja Dhas, FSSW process parameter optimization for AA2024 and AA7075 alloy, Mater. Manuf. Process (2021), https://doi.org/10. 1080/10426914.2021.1962532 [6] L. Tong, J. Xie, L. Liu, G. Chang, O.O. Ojo, Microscopic appraisal and mechanical behavior of hybrid Cu/Al joints fabricated via friction stir spot welding-brazing and modified friction stir clinching-brazing, J. Mater. Res. Technol. 9 (6) (2020) 13239–13249. [7] Y. Yan, Y. Shen, H. Lei, J. Zhuang, Influence of welding parameters and tool geometry on the morphology and mechanical performance of ABS friction stir spot welds, Int. J. Adv. Manuf. Technol. 103 (5) (2019) 2319–2330. [8] S.S. Mahapatra, et al., Investigation of weld zone obtained by friction stir spot welding (FSSW) of aluminium-6061 alloy, Mater. Today Proc. 18 (2019) 4491–4500. [9] R. Pandiyarajan, P. Maran, S. Marimuthu, K. Arumugam, Mechanical and metallurgical characterization of friction stir welded AA6061-ZrO2-C hybrid MMCs, Mater. Today Proc. 19 (2019) 256–259. [10] M. Balakrishnan, C. Leitão, E. Arruti, E. Aldanondo, D.M. Rodrigues, Influence of pin imperfections on the tensile and fatigue behaviour of AA 7075-T6 friction stir lap welds, Int. J. Adv. Manuf. Technol. 97 (5) (2018) 3129–3139. [11] G.S. Vacchi, et al., Refill friction stir spot welded AA5754-H22/Ti-6Al-4V joints: microstructural characterization and electrochemical corrosion behavior of aluminum surfaces, Mater. Today Commun. 22 (2020) 100759. [12] A.N. Ashong, M. Lee, S.-T. Hong, Y.S. Lee, J.H. Kim, Refill friction stir spot welding of dissimilar AA6014 Al alloy and carbon-fiber-reinforced polymer composite, Met. Mater. Int. 27 (4) (2021) 639–649. [13] H. Su, C. Chen, J. Li, J. Ma, Effect of process parameters on microstructure and mechanical properties of dissimilar aluminum alloy joints by friction stir spot welding, J. Mater. Process. Technol. 267 (2019) 43–54. [14] M.A. Ahmed, A.H. Ahmed, A.A. Ali, Microstructure and mechanical properties of dissimilar aluminum alloy joints by friction stir welding, J. Mater. Eng. Perform. 29 (2020) 4845–4856. [15] F.M. Mahmoud, E.A. Abdel-Aziz, A.M. Hussein, Improving the mechanical properties of dissimilar aluminum alloys FSSW joints by SiC nanoparticles, J. Mater. Eng. Perform. 29 (2020) 8755–8767. [16] Y. Yan, Y. Shen, H. Lei, J. Zhuang, Influence of welding parameters and tool geometry on the morphology and mechanical performance of ABS friction stir spot welds, Int. J. Adv. Manuf. Technol. 103 (5) (2019) 2319–2330. [17] S.R. Kummari, S.S. Prasad, B.S. Murty, Mechanical and metallurgical characterization of dissimilar Al alloys joints produced by friction stir welding, J. Mater. Res. Technol. 10 (1) (2021) 24–34. [18] R. Kumar, A. Kumar, A. Kumar, V. Kumar, Effect of rotational speed on microstructure and mechanical properties of dissimilar aluminum alloys AA6061-T6 and AA7075-T6 friction stir spot welded joints, J. Manuf. Process. 62 (2021) 185–192. [19] R.M. Mohd Jani, N.A. Ariffin, M.Z. Omar, M.Z. Abdullah, M.Z. Nuawi, Effect of tool pin profile on mechanical properties and microstructure of FSSW of dissimilar aluminum alloys, J. Mech. Eng. Res. Dev. 43 (1) (2020) 14–23. [20] A.M.A. Hussein, A.M.M. Ali, M.S.A. Serry, A.A.M. Alaskari, Influence of tool traverse speed and rotational speed on the mechanical properties and microstructure of dissimilar AA6061-T6 and AA7075-T6 friction stir spot welded joints, J. Mater. Res. Technol. 9 (5) (2020) 9781–9791. [21] S. Vidyasagar, A. Balaji, S.M. Sharif, R. Uthayakumar, Influence of multi-pass friction stir spot welding on microstructure and mechanical properties of dissimilar aluminum alloy joints, J. Mater. Res. Technol. 10 (2) (2021) 449–459. 4. Conclusion The dissimilar aluminum alloy AA2024-T3/AA7075-T6 joint was successfully welded by friction stir spot welding process with the process parameters. The welded specimens were subjected to microstructural characterization and analysis of physical properties and fractography. • The dissimilar alloy joint was welded devoid of macroscopic por• • • osities and superficial defects. Satisfactory interfacial bonding was obtained due to better tool pin penetration. The material flow within the specimen resulted in redistribution of grain structure and improved particle homogeneity. This was the resultant effect of softer aluminum alloy AA2024-T3 enabling better distribution of friction heat within the interfacial layer. The improved average microhardness of the specimen was attributed to AA7075-T6 possessing higher innate microhardness and during the material stirring greatly affecting the stir zone. This effect reduced the percentage of elongation of the welded specimen due to reduced ductility of the weld specimen. The UTS of the welded specimen however was improved due to the frictional heat tempering the material mixture within the interfacial layer of the weld specimen. An improvement of 7.1% was observed between the microhardness observed in AA2024-T3 and the WNZ of the dissimilar weld specimen. Declaration of Competing Interest The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper. References [1] E.T. Akinlabi, A.S. Osinubi, N. Madushele, S.A. Akinlabi, O.M. Ikumapayi, Data on microhardness and structural analysis of friction stir spot welded lap joints of AA5083-H116, Data Br. 33 (2020) 106585. 9 K. Anton Savio Lewise, J. Edwin Raja Dhas, R. Pandiyarajan et al. Journal of Alloys and Metallurgical Systems 2 (2023) 100010 [22] J. Chi-Sung, H. Sung-Tae, K. Yong-Jai, C.H.O. Hoon-Hwe, H.N. Han, Material properties of friction stir spot welded joints of dissimilar aluminum alloys, Trans. Nonferrous Met. Soc. China 22 (2012) s605–s613. [23] R. Pandiyarajan, P. Maran, S. Marimuthu, K.C. Ganesh, Mechanical and tribological behavior of the metal matrix composite AA6061/ZrO 2/C, J. Mech. Sci. Technol. 31 (10) (2017) 4711–4717. [24] M. Li, C. Zhang, D. Wang, L. Zhou, D. Wellmann, Y. Tian, Friction stir spot welding of aluminum and copper: a review, Materials 13 (1) (2020) 156. [25] H. Zhang, et al., Effect of tool plunge depth on the microstructure and fracture behavior of refill friction stir spot welded AZ91 magnesium alloy joints, Int. J. Miner. Metall. Mater. 28 (4) (2021) 699–709. [26] T.W. Nelson, R.J. Steel, W.J. Arbegast, In situ thermal studies and post-weld mechanical properties of friction stir welds in age hardenable aluminium alloys, Sci. Technol. Weld. Join. 8 (4) (2003) 283–288. [27] K. Takaya, Y. Harada, S. Kumai, K. Kitayama, Microstructure of joint interface and mechanical properties in high-speed solid-state welded 2024 aluminum alloy stud and 6N01 aluminum alloy plate, Keikinzoku 62 (10) (2012) 370–376. 10