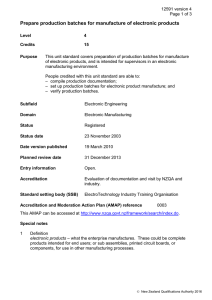

Medicines Control Authority of Zimbabw e QUALITY INFORMATION SUMMARY (QIS) FOREWORD The Quality Information Summary (QIS) template should be completed to provide a condensed summary of the key quality information for product dossiers (PDs) containing APIs of synthetic or semi-synthetic origin and their corresponding products that are. submitted to the MCAZ for registration. The QIS constitutes part of the registration PD. The QIS provides an accurate record of technical data in the PD at the time of registration and thereafter serves as an official reference document during the course of GMP inspections, and variation (amendment) assessments performed by the MCAZ. The QIS is a condensed version of the Quality Overall Summary – Product Dossier (QOS-PD) and represents the final, agreed upon key information from the PD review (inter alia identification of the manufacturer(s), API/FPP specifications, stability conclusions and relevant commitments). The QIS template is structured to permit the rapid assembly of the QIS by copying requisite information from the corresponding portions of the QOS-PD submitted with the original PD. It is acknowledged that the numbering of the sections may not be entirely sequential. Those sections not considered necessary to be included in the QIS have been removed (e.g., 2.3.S.5 Reference Standards or Materials) and the remaining sections have retained their numbering to be consistent with the original PD. For original PDs, the QIS should be provided in MS-Word format at the time of PD submission. The QIS should be revised and submitted with the change history (see table at the end of the template) each time additional data is provided during the assessment process. If no revision is necessary due to no change in the information, a statement should be made to this effect in the covering letter. For amendments, the QIS should be completed in its entirety (regardless of the proposed change), it should include information on all strengths, with any changes highlighted and it should be provided at the time of submission of such amendments. When completing the QIS template, this covering Foreword should be deleted. QUALITY INFORMATION SUMMARY (QIS) <Dossier Reference Number(s) e.g. H999> Page 1 of 16 (QIS) (2012-02-20) Medicines Control Authority of Zimbabw e INTRODUCTION (a) Summary of product information: Non-proprietary name of the finished pharmaceutical product (FPP) VetAg Wound Oil Proprietary (Trade) name of the finished pharmaceutical product (FPP) N/A International non-proprietary (generic) name(s) of the active pharmaceutical ingredient(s) (API(s)), including form (salt, hydrate, polymorph) 1. Applicant name and address Aherechem (Pvt) Ltd, 356 Esap Way, Willowvale, Harare, Zimbabwe Dosage form Oily liquid, light blue Reference Number(s) N/A Strength(s) Deltamethrin, 1mg/g; Chlorfenvinpho s, 1mg/g Route of administration Topical LamaVet Wound Oil is a ready-to-use, combined insecticidal and antimicrobial topical application liquid for the following applications: Screw-worm remedy Active against bacteria and fungi for wound treatment Control of ticks, fleas and lice Capabilities of repelling flies Preventing or eliminating maggot infestations due to fly-strike Name: Adherechem (Pvt) Ltd Proposed indication(s) Contact information Deltamethrin Technical, 98% min. 2. Chlorfenvinphos Technical, 92% min. Phone: +263 773 085 519, +263 771 332 880; +263 775 735 713; +263 773 404 166 Fax: N/A Email: lamas@zol.co.zw; info@lamas.co.zw (b) Administrative Summary: Reference number e.g. H999 N/A <Dossier Reference Number(s) e.g. H999> Page 2 of 16 (QIS) (2012-02-20) Medicines Control Authority of Zimbabw e Applicant’s date of preparation or revision of the QIS 30 April 2023 Internal version and/or date of acceptance (MCAZ use only) Related dossiers (e.g. FPP(s) with the same API(s) submitted to the Prequalification Programme by the applicant): Reference number (eg H999) N/A Prequalified (Y/N) API, strength, dosage form (eg. Abacavir (as sulphate) 300 mg tablets) Deltamethrin, 98% min., powder Chlorfenvinphos, 92% min., liquid API manufacturer (including address) 2.3.S DRUG SUBSTANCE (or ACTIVE PHARMACEUTICAL INGREDIENT (API)) (NAME, MANUFACTURER) Indicate which option applies for the submission of API information: 1. Deltamethrin 2. Chlorfenvinphos Name of API: Name of API manufacturer: □ Certificate of suitability to the European Pharmacopoeia (CEP) □ □ Full details in the PD 2.3.S.2 Manufacture (name, manufacturer) 2.3.S.2.1 Manufacturer(s) (name, manufacturer) (a) Name, address and responsibility (e.g. fabrication, packaging, labelling, testing, storage) of each manufacturer, including contractors and each proposed production site or facility involved in these activities: Name and address (including block(s)/unit(s)) Adherechem (Pvt) Ltd Responsibility APIMF/CEP number (if applicable) Packaging, labelling, testing and storage 2.3.S.4 Control of the API (name, manufacturer) 2.3.S.4.1 Specification (name, manufacturer) <Dossier Reference Number(s) e.g. H999> Page 3 of 16 (QIS) (2012-02-20) Letter of access provided? Medicines Control Authority of Zimbabw e (a) API specifications of the FPP manufacturer: Standard (e.g. Ph.Int., Ph.Eur., BP, USP, House) Specification reference number and version Test Acceptance criteria Analytical procedure (Type/Source/Version) Description Identification Impurities Assay etc. 2.3.S.6 Container Closure System (name, manufacturer) (a) Description of the container closure system(s) for the storage and shipment of the API: 2.3.S.7 Stability (name, manufacturer) 2.3.S.7.1 Stability Summary and Conclusions (name, manufacturer) (c) Proposed storage conditions and re-test period: Container closure system Storage statement Re-test period* * indicate if a shelf-life is proposed in lieu of a re-test period (e.g. in the case of labile APIs) 2.3.P DRUG PRODUCT (or FINISHED PHARMACEUTICAL PRODUCT (FPP)) 2.3.P.1 Description and Composition of the FPP (a) Description of the FPP: LamaVet Wound Oil is a ready-to-use, combined insecticidal and antimicrobial topical application liquid for the following applications: Screw-worm remedy. Active against bacteria and fungi for wound treatment. Control of ticks, fleas and lice. <Dossier Reference Number(s) e.g. H999> Page 4 of 16 (QIS) (2012-02-20) Medicines Control Authority of Zimbabw e Capabilities of repelling flies. Preventing or eliminating maggot infestations due to fly-strike. It is a light blue oily liquid free from visible impurities packed in 500ml HDPE bottles with a tamper-proof lid. (b) Composition of the FPP: (i) Composition, i.e. list of all components of the FPP and their amounts on a per unit basis and percentage basis (including individual components of mixtures prepared in-house (e.g. coatings) and overages, if any): Component and quality standard (and grade, if applicable) Function Strength (label claim) Deltamethrin, 0.1% (m/v) Chlorfenvinphos, 0.1% (m/v) Quant. per Unit % 200ml Wound Oil Deltamethrin Insecticide API 0.2041 0.10 Chlorfenvinphos Insecticide API 0.2128 0.10 Tar Acid Antiseptic 1.0000 0.50 Linseed oil Diluent Gum rosin Processing Aid & Binder Turpentine Solvent 73.2000 36.60 White oil Diluent 20.0000 10.00 Blue dye Colour 0.0200 0.01 Total 97.7632 48.89 7.6000 3.80 200.0000 100.0000 (ii) (c) Composition of all components purchased as mixtures (e.g. colourants, coatings, capsule shells, imprinting inks): N/A Description of accompanying reconstitution diluent(s), if applicable: N/A 2.3.P.2.2.1 Formulation Development (b) Information on primary (submission, registration, exhibit) batches including comparative bioavailability or biowaiver, stability, commercial: (i) Summary of batch numbers: <Dossier Reference Number(s) e.g. H999> Page 5 of 16 (QIS) (2012-02-20) Medicines Control Authority of Zimbabw e Batch number(s) of the FPPs used in Bioequivalence or biowaiver Dissolution profile studies Stability studies (primary batches) Batches Packaging N/A N/A PS-20-100-025 PS-20-100-026 PS-20-100-027 500ml HDPE 500ml HDPE Bottle 500ml HDPE Bottle Bottle Stability studies (production batches) PS-20-100-028 500ml HDPE Bottle Validation studies (primary batches) if available PS-20-100-025 Batches 500ml HDPE Packaging Bottle PS-20-100-031 Validation studies (at least the first three consecutive production batches) or code(s)/version(s) for process validation protocol(s) Batches Packaging <Dossier Reference Number(s) e.g. H999> Page 6 of 16 PS-20-100-029 500ml HDPE Bottle PS-20-100-030 500ml HDPE Bottle PS-20-100-026 500ml HDPE Bottle PS-20-100-027 500ml HDPE Bottle PS-20-100-033 PS-20-100-032 (QIS) (2012-02-20) Medicines Control Authority of Zimbabw e (ii) Summary of formulations and discussion of any differences: Relevant batches Component and quality standard (e.g. NF, BP, Ph.Eur, in-house) Compa rative bioavail ability or biowaiv er Pilot/Process Validation Production/Commercial (2.3.P.1) <Batch nos. and sizes> PS-20-100-028-100kg PS-20-100-029-100kg PS-20-100-030-100kg Theor. % quantity per batch (kg) <Batch nos. and sizes> a) PS-20-100-031-200kg b) PS-20-100-032-200kg c) PS-20-100-033-200kg Theor. % quantity per batch (kg) Stability/Primary Theor. quantit y per batch (kg) <Batch nos. and sizes> a) PS-20-100-025-5kg b) PS-20-100-026-5kg c) PS-20-100-027-5kg % Theor. % quantity per batch (kg) Deltamethrin Tech., 98% min. Chlorfenvinp hos Tech., 92% min. High Boiling Tar Acid N/A N/A 0.0051 0.1 0.1020 0.1 0.2041 0.1 N/A N/A 0.0054 0.1 0.1087 0.1 0.2174 0.1 N/A N/A 0.0250 0.5 0.5000 0.5 1.0000 0.5 Linseed Oil N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A 2.4440 0.1900 1.8300 0.5000 0.0005 48.89 48.8793 3.8000 36.6000 10.0000 0.0100 48.89 101.5585 3.8000 73.2000 20.0000 0.0200 48.89 Gum Rosin Turpentine White Oil Blue Dye <Batch nos. and sizes> Total 5.0000 3.8 36.6 10 0.01 100 3.8 36.6 10 0.01 100.0000 100.0000 3.8 36.6 10 0.01 200.0000 2.3.P.3 Manufacture 2.3.P.3.1 Manufacturer(s) (a) Name, address and responsibility (e.g. fabrication, packaging, labelling, testing, holder of the national manufacturing authorization of the FPP) of each manufacturer, including contractors and each proposed production site or facility <Dossier Reference Number(s) e.g. H999> Page 7 of 16 (QIS) (2012-02-20) 100 Medicines Control Authority of Zimbabw e involved in manufacturing and testing: Name and address (include block(s)/unit(s)) Adherechem (Pvt) Ltd Responsibility Packaging, labelling and testing 2.3.P.3.2 Batch Formula (a) List of all components of the FPP to be used in the manufacturing process and their amounts on a per batch basis (including components of mixtures prepared in-house (e.g. coatings) and overages, if any): Strength (label claim) Master production document reference number and/or version Proposed commercial batch size(s) (e.g. number of dosage units) Component and quality standard (and grade, if applicable) Deltamethrin Chlorfenvinphos Tar Acid Linseed oil Gum rosin Turpentine White oil Blue dye TOTAL LamaVet Wound Oil Deltamethrin, 0.10% m/v Chlorfenvinphos, 0.10% m/v MPD-VET-22003, Version: 01 200kg % Mass/Mass Quantity per batch (kg/batch) 0.1000 0.1000 0.5000 48.8900 3.8000 36.6000 10.0000 0.0100 0.2041 0.2128 1.0000 97.7632 7.6000 73.2000 20.0000 0.0200 100.0000 200.0000 2.3.P.3.3 Description of Manufacturing Process and Process Controls (a) Flow diagram of the manufacturing process: <Dossier Reference Number(s) e.g. H999> Page 8 of 16 (QIS) (2012-02-20) Medicines Control Authority of Zimbabw e Flow Diagram of the LamaVet Wound Oil Manufacturing Process (b) Narrative description of the manufacturing process, including equipment type and working capacity, process parameters: (i) (ii) (iii) (iv) (v) (vi) (vii) (viii) Measure linseed oil into mixing tank. Heat to 70 OC. Slowly mix in gum rosin until dissolved. Mix in Deltamethrin and Chlorfenvinphos. Stop heating and allow the solution to cool to about 45 oC. Mix in turpentine followed by HBTA & White oil. Add blue dye and mix until homogeneous. Let cool and take 500ml sample for analysis 2.3.P.3.4 Controls of Critical Steps and Intermediates (a) Summary of controls performed at the critical steps of the manufacturing process <Dossier Reference Number(s) e.g. H999> Page 9 of 16 (QIS) (2012-02-20) Medicines Control Authority of Zimbabw e and on isolated intermediates: Step (e.g. granulation, compression, coating) Heating and Melting Mixing Controls a) b) c) d) a) b) c) d) e) f) g) Drug substance particle size Equipment Scale Temperature Blending time Blending speed Blending homogeneity of the drug substance Assay Content uniformity Appearance Specific gravity 2.3.P.3.5 Process Validation and/or Evaluation (a) Summary of the process validation and/or evaluation studies conducted and/or a summary of the proposed validation protocol for the critical steps or critical assays used in the manufacturing process (e.g. protocol number, parameters, results): Document code(s) for the process validation protocol(s) and/or report(s) (including reference number/version/date): Refer to Process Validation Protocol, Document Number PRPV-221021and the Process Validation Report, Document Number PV-221003in Module 3 2.3.P.5 Control of FPP 2.3.P.5.1 Specification(s) (a) Specification(s) for the FPP: Standard (e.g. Ph.Int., BP, USP, House) In-HouseAdherechem Specification reference number and version PS-20-22403 Test Description Acceptance criteria (release) Oily liquid, free from invisible impurities <Dossier Reference Number(s) e.g. H999> Page 10 of 16 Acceptance criteria (shelf-life) Oily liquid, free from invisible impurities (QIS) (2012-02-20) Analytical procedure (type/source/versio n) Visual Medicines Control Authority of Zimbabw e Standard (e.g. Ph.Int., BP, USP, House) In-HouseAdherechem Specification reference number and version PS-20-22403 Test Acceptance criteria (release) Assay Deltamethrin 0.095 – 0.12% (m/v) Acceptance criteria (shelf-life) Analytical procedure (type/source/versio n) 94.0-106% of labelled amount of Deltamethrin 333/WP/M/3, CIPAC Handbook L, p.45, 2006 Chlorfenvinphos 0.095 – 0.12% (m/v) 94.0-106% of labelled CIPAC Method amount of Chlorfenvinphos 88/1/M/1.3; 1A p. 1131) Colour Light blue Light blue Visual Odour Characteristic Characteristic Visual Specific Gravity 0.923 – 0.933 0.923 – 0.933 CIPAC Method F MT 3 2.3.P.7 Container Closure System (a) Description of the container closure systems, including unit count or fill size, container size or volume: Description (including materials of construction) Container: Round, opaque, high density polyethylene (HDPE) jars Closure: Round, opaque, polypropylene (PP) lid Strength Unit count or fill size Deltamethrin, Bottles of 10's 1mg/g; Chlorfenvinphos, 1mg/g Container size 500ml bottles 2.3.P.8 Stability 2.3.P.8.1 Stability Summary and Conclusions (c) Proposed storage statement and shelf-life (and in-use storage conditions and in-use period, if applicable): Container closure system HDPE Bottle with a PP lid Storage statement Store below 30°C (room temperature) in closed, original <Dossier Reference Number(s) e.g. H999> Page 11 of 16 Shelf-life 2 years from the date of manufacture (QIS) (2012-02-20) Medicines Control Authority of Zimbabw e container in a dry well-ventilated area, out of direct sunlight 2.3.P.8.2 Post-approval Stability Protocol and Stability Commitment (a) Stability protocol for Primary stability batches (e.g. storage conditions (including tolerances), batch numbers and batch sizes, tests and acceptance criteria, testing frequency, container closure system(s)): Parameter Storage condition(s) (◦C, % RH) Batch number(s) Batch size(s) Tests and acceptance criteria Testing frequency Number of batches per strength and batch sizes Container closure system(s) Tests and acceptance criteria (b) Details 30ºC±2ºC / 75% ±5%RH B/Nos: PS-20-100-013, PS-20-100-014 & PS-20-100-015 20kg Appearance Jelly, free from invisible impurities Assay Deltamethrin: 0.020 +0.001% (m/m) Chlorfenvinphos: 0.20 +0.01% (m/m) Odour Characteristic Colour Pale Blue Odour Characteristic Drop Point 35-45 oC 0, 3, 6, 9, 12, 18, 24, 36 months First three production batches (200kg) each of the same strengths will be added to the stability programme HDPE Dixie Jar Stability tests described in 2.3.P.5.1 Stability protocol for Commitment batches (e.g. storage conditions (including tolerances), batch numbers (if known) and batch sizes, tests and acceptance criteria, testing frequency, container closure system(s)): Parameter Storage condition(s) (◦C, % RH) Batch number(s) Batch size(s) Tests and acceptance criteria Details 30ºC±2ºC / 75% ±5%RH B/Nos: PS-20-100-013, PS-20-100-014 & PS-20-100-015 20kg Appearance Jelly, free from invisible impurities Assay Deltamethrin: 0.020 +0.001% (m/m) Chlorfenvinphos: 0.20 +0.01% (m/m) <Dossier Reference Number(s) e.g. H999> Page 12 of 16 (QIS) (2012-02-20) Medicines Control Authority of Zimbabw e Testing frequency Number of batches per strength and batch sizes Container closure system(s) Tests and acceptance criteria (c) Odour Characteristic Colour Pale Blue Odour Characteristic Drop Point 35-45 oC 0, 3, 6, 9, 12, 18, 24, 36 months First three production batches (200kg) each of the same strengths will be added to the stability programme HDPE Dixie Jar Stability tests described in 2.3.P.5.1 Stability protocol for Ongoing Batches (e.g. storage conditions (including tolerances), number of batches per strength and batch sizes, tests and acceptance criteria, testing frequency, container closure system(s)): Parameter Storage condition(s) (◦C, % RH) Batch number(s) Batch size(s) Tests and acceptance criteria Testing frequency Number of batches per strength and batch sizes Container closure system(s) Tests and acceptance criteria Details 30ºC±2ºC / 75% ±5%RH B/Nos: PS-20-100-013, PS-20-100-014 & PS-20-100-015 20kg Appearance Jelly, free from invisible impurities Assay Deltamethrin: 0.020 +0.001% (m/m) Chlorfenvinphos: 0.20 +0.01% (m/m) Odour Characteristic Colour Pale Blue Odour Characteristic Drop Point 35-45 oC 0, 3, 6, 9, 12, 18, 24, 36 months First three production batches (200kg) each of the same strengths will be added to the stability programme HDPE Dixie Jar Stability tests described in 2.3.P.5.1 i) Expiration dates may be extended based upon room temperature stability data from a minimum of three production batches. ii) If, in these post-approval stability studies, any lots are found to fall outside the approved specifications, these lots may be withdrawn from the market. iii) Deviations that do not affect the safety and efficacy of the product will be promptly discussed between the applicant and the reviewing division at MCAZ and must be reported to the MCAZ. 2.3.P.8.3 Stability Data <Dossier Reference Number(s) e.g. H999> Page 13 of 16 (QIS) (2012-02-20) Medicines Control Authority of Zimbabw e (c) Bracketing and matrixing design for commitment and/or continuing (i.e. ongoing) batches, if applicable: The actual stability results (i.e., raw data) can be found in Module 3.2.P.8.3. WRITTEN COMMITMENTS OF THE MANUFACTURER API If applicable (primary stability study commitment): The Applicant (or API manufacturer) undertook in writing (date of letter of commitment) to continue long-term testing of <INN of API> for a period of time sufficient to cover the whole provisional re-test period (period ending month/year) and to report any significant changes or out-of-specification results immediately to MCAZ for the following batches : <Batch numbers, manufacturing dates, batch size, primary packing materials> If applicable (commitment stability studies): Since stability data on three production scale batches were not provided with the application, the remaining number of production scale batches should be put on long-term stability testing and the data should be provided as soon as available. Any significant changes or out-of-specification results should be reported immediately to MCAZ. The approved stability protocol should be used for commitment batches. API option 2 - CEP The Applicant provided a commitment in writing (date of letter of commitment) to inform MCAZ in the event that the CEP is withdrawn. Note that withdrawal will require additional consideration of the API data requirements to support the dossier. API option 3 - full details in the PD (ongoing stability study commitment) The Applicant undertook in writing (date of letter of commitment) a commitment regarding ongoing stability studies. Unless otherwise justified, at least one batch per year of the product will be included in the stability programme (unless none is produced during that year). The stability protocol will be that which was approved for primary batches (or the protocol was submitted for assessment). Out-ofspecification results or significant atypical trends should be investigated. Any confirmed significant change, out-of-specification result, or significant atypical trend should be reported immediately to MCAZ. The possible impact on batches on the market should be considered in consultation with MCAZ inspectors. FPP If applicable (primary stability study commitment): The Applicant undertook in writing (date of letter of commitment) to continue long-term testing of < FPP reference number, trade name (INN of API), strength, pharmaceutical form> for a period of time sufficient to cover the whole provisional shelf-life (period ending month/year) and to report any out-ofspecification results or significant changes immediately to WHO for the following batches : <Batch numbers, manufacturing dates, batch size, primary packing materials > If applicable (commitment stability studies): <Dossier Reference Number(s) e.g. H999> Page 14 of 16 (QIS) (2012-02-20) Medicines Control Authority of Zimbabw e Since stability data on three production scale batches was not provided with the application, the Applicant undertook in writing, (date of letter of commitment) to put the remaining number <e.g. additional two (2)> production scale batches of < FPP reference number, trade name (INN of API), strength, pharmaceutical form, primary packing material> on long-term stability testing. Any out-ofspecification results or significant changes during the study should immediately be reported to MCAZ. The approved stability protocol should be used for commitment batches. If applicable (the proposed commercial batch size is 200 000 units (x units) or less) The Applicant undertook in writing (date of letter of commitment) to place the first three batches of any production size larger than x units on stability. The stability protocol will be that which was approved for primary batches (or the protocol was submitted for assessment). Out-of-specification results or significant atypical trends will be investigated. Any confirmed significant change, out-of-specification result, or significant atypical trend will be reported immediately to MCAZ. Ongoing stability study commitment The Applicant undertook in writing (date of letter of commitment) a commitment regarding ongoing stability studies. Unless otherwise justified, at least one batch per year of the product manufactured in every primary packaging type will be included in the stability programme (unless none is produced during that year). The stability protocol will be that which was approved for primary batches (or the protocol was submitted for assessment). Out-of-specification results or significant atypical trends should be investigated. Any confirmed significant change, out-of-specification result, or significant atypical trend should be reported immediately to MCAZ. The possible impact on batches on the market should be considered in consultation with MCAZ inspectors. If applicable (validation of production batches) Since validation data on production scale batches of not less than three (3) consecutive batches of <FPP reference number, trade name (INN of API), strength, pharmaceutical form, primary packing material> were not provided with the application, the Applicant submitted a written commitment (date of letter of commitment) that a validation report —in accordance with the details of the validation protocol provided in the dossier— would be made available as soon as possible for evaluation by assessors or for verification by the MCAZ inspection team. The approved validation protocol should be used for commitment batches. <Dossier Reference Number(s) e.g. H999> Page 15 of 16 (QIS) (2012-02-20) Medicines Control Authority of Zimbabw e Change History Date of preparation of original QIS: Date of revised version Section (e.g. S.2.1) <Dossier Reference Number(s) e.g. H999> Page 16 of 16 Revision (QIS) (2012-02-20)