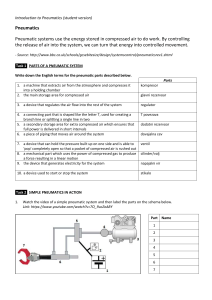

PNEUMATICS & HYDRAULICS Fluid Power System Fluid is a substance that has definite mass and volume at constant temperature and pressure; however, it has no definite shape. It takes the shape of the vessel in which it is put. Further, a fluid has minimum resistance to flow. The two most important fluids of our interest are oil and air. These fluids under normal conditions have no inherent power and have to be converted into power sources by pressurising them. Then the energy stored in pressurised fluids can be conveyed to actuating devices to perform some useful work. The generation of fluid power, as it is defined and understood today, is possible through the use of pumps and compressors which create high pressures within a confined system and use relatively small quantity of fluid. The branch of fluid power system, which uses incompressible oil for energy transmission, is called hydraulics. The branch of fluid power system, which uses compressible air for energy transmission, is called pneumatics. The two branches are quite different in behaviour and performance and hence are to be treated separately. Fluid power systems are used widely due to their ability to do useful work economically and efficiently. Perhaps the greatest advantage of these systems is the flexibility with which power can be distributed and applied easily to the point of work. With fluid power, there is no need for belts, chains, clutches, brakes, cams or levers; hence no measures required to protect the personnel from the accidents these devises may course. In other words, machines can be designed primarily to perform, the required tasks rather than bothering about the ways to transmit power to them. Fluid power systems also face limitations, and a major problem facing them is contamination of the fluid medium. Hydraulic Power System The basic elements of a hydraulic system are depicted in Figure 1. In the hydraulic transmission of energy, a pump is used as the power source to raise the pressure of an oil medium to the required level almost instantaneously. Then the energy stored in the pressurised oil is transmitted through piping in a controlled manner to a hydraulic actuator to perform some useful work. A hydraulic system is designed as a high-pressure system and hence is capable of generating a force of large magnitude economically. Figure 1 A major advantage of hydraulic systems is that they can easily generate linear motion through the basic actuator, cylinder. Speed control is also achieved easily by regulating the volumetric flow rate of oil to the actuator. Precise control of speed even at low values is another advantage of a hydraulic system. Pneumatic Power System The basic elements of a pneumatic system are depicted in Figure 2. In the pneumatic transmission of energy, a compressor is used as the power source to raise the pressure of the air to the required level quite slowly. Page 1 of 6 The slow response of an air compressor necessitates storage of compressed air at the required pressure in a receiver tank. The energy stored in the compressed air is transmitted through piping in a controlled manner to a pneumatic actuator to perform some useful work. Figure 2 A great advantage of pneumatic systems is that, like hydraulic systems, they can easily generate linear motion through the basic actuator, cylinder. Speed control is also achieved easily by using flow control valves. However, pneumatic systems are not suitable for obtaining uniform motion. Operating pressures in pneumatics are generally much lower than those used in hydraulics. Pneumatic systems are generally designed as low-pressure systems and hence are capable of generating only smallmagnitude forces economically unlike hydraulic systems. Overall Power System A combined power system representation is given in Figure 3 to present an overall picture of various types of power system and their inter-relations. Figure 3 Page 2 of 6 Introduction to Pneumatics Fluid power in the form of compressed air fulfilled the need for an energy transmission system -with muscle, which could easily be customised as per the needs of automated machinery. Tremendous amount of compressed air is used throughout industry due to its versatility and simplicity in application. Many unique characteristics of air make it more suitable to fulfil various needs of industrial applications than other energy media. The ‘pneumatic muscle’ power has managed to find its place between low-cost automation and hightech applications, affirming its innovative capability. Pneumatics not only includes the cylinder and directional control valves, it also encompasses a wide range of diversified components such as sensors, processors, various types of actuators, and extensive accessories and auxiliary components. Pneumatics – Definition The study of pneumatics deals with systems operated with air or other gaseous media to impart power or to control power. The term ‘pneumatics’ is derived from the Greek word pneuma, meaning wind or breath. Hence pneumatics may be defined as the study of movement of air. Pneumatic power is the power that is transmitted by pressurised air. It may be used to power machines or to control or regulate machines. Figure 4 Compressed Air for Transmitting Power A simplified pneumatic system with only three blocks is given in Figure 4. In industry, the pneumatic medium usually employed for transmitting power is the highly compressible air. Since gaseous substances are compressible in the ratio of decrease in volume to increase in pressure, a compressor is used as an energy source. The compressed air is then prepared or treated in several stages to remove undesirable contaminants present in it and stored in a tank called receiver tank. Other issues of concern at this stage are the distribution of compressed air, regulation of pressure and introduction of fine mist of lubricating oil in the compressed air. The compressed air medium is subsequently used to do work in a controlled manner by allowing it to expand back to the atmospheric pressure. The work done in this expansion is transmitted to a load surface such as a piston or a vane, which will be moved by the expanding air with a force equal to the product of the air pressure acting on the piston and area of the piston (force = pressure x area). The function of a pneumatic system can be simply summed up as follows: Applying a force to a gaseous fluid like air and transmitting pneumatic pressure all through the fluid, and then converting the stored energy back into mechanical force before work could be done. Page 3 of 6 Economical Pressure in Pneumatics Pneumatic systems have been developed as low-pressure systems in comparison to hydraulic power systems. Pneumatic air consuming devices such as valves and cylinders are designed for a maximum operating pressure of 8 to 10 bar. However, practical experience has shown that 6 bar is the ideal pressure for the economical operation of pneumatic systems. This pressure allows for: • • • • compressors to be relatively simple and cheaper, installation cost of pipe system to be kept minimum, valves and cylinders to be kept to reasonable dimensions, minimum wear and maximum efficiency. Pressure Scales Two pressure scales are utilised to measure pressure in fluid power systems: a gauge scale [bar(g) or bar] and an absolute scale [bar(a)]. The gauge pressure measures the pressure with reference to the atmosphere but does not include the pressure exerted by the atmosphere. It is the pressure above atmospheric pressure regardless of the altitude. Zero gauge pressure is the atmospheric pressure. The absolute pressure scale begins at the point where there is complete absence of pressure (zero absolute pressure). Gauge pressures may be converted to absolute pressure by adding the atmospheric pressure [i.e. 1.013 bar(a) or 14.7 psia] to the gauge reading. Absolute pressures are to be used in calculations. The relationship between absolute pressure and gauge pressure is illustrated graphically in Figure 5. A vacuum is any pressure condition with a pressure less than the atmospheric pressure. In measuring a vacuum, absolute zero or atmospheric pressure may be used as the reference. Thus a vacuum of 0.4 bar is equal to 0.6 bar(a). Because pressure is an indication of molecular energy and movement, and we do not know how to take away all the molecules from any space, zero absolute pressure is physically impossible, although we can attain very low pressures. Figure 5 Page 4 of 6 Page 5 of 6 Pneumatic Applications Pneumatic systems have been in use within the industrial processes since the Second World War and as such have set up a strong presence in modern industry. Continuous research and development of pneumatic power technology has significantly expanded and augmented its applications to many areas hitherto unknown for adopting pneumatics. Amongst many applications and users of pneumatic systems, few are outlined below: 1. Aircraft manufacturers 2. Cement plants 3- Chemical plants 4. Coal mines 5. Cotton mills 6. Dairies 7. Distilleries 8. Forge shops 9. Foundries 10. Machine tool manufacturers 11. Material conveying 12. Metal forming 13- Oil refineries 14. Paper mills 15. Printing 16. Space exploration 17. Steel mills 18. Vehicle manufacturing An air-equipment presents no sparks in explosive atmospheres; therefore, it can be utilised in oil refineries, chemical plants and other plants that have the problem of explosive atmosphere. Airequipment can be employed under wet and humid conditions because there is no electric shock hazard. The ever-increasing number of pneumatic applications is due to research investments by the component manufacturers and the efforts of creative people who design and develop flexible and efficient pneumatic control systems. Perhaps, a major factor that contributed to the speedy growth of pneumatic applications was the development of symbols and standards that have become widely accepted and used throughout the manufacturing and processing industries all over the world. Page 6 of 6