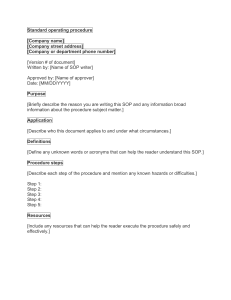

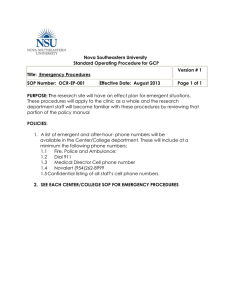

Topic 3: Apply (1) good documentation practice and (2) records keeping APH3011 Current Good Manufacturing Practice & Process Improvement (cGMPP) 1 Topic 3 – Part 2 learning objectives 1. Need for procedure documentation – SOP (is a very important documentation in cGMP) 2. A typical appropriate format of SOP 3. consequences of failure to follow standard operating procedure (SOP). 4. Deviation in Processes affecting SOPs 5. Change control management • changes and improvement in SOP which is affected by cGMP QMS processes. 2 What is procedure? E.g. SOP Type 1 of documentation - instructions (directions, requirements) • Regulatory Agencies require written (1) Quality Policy procedures for all systems and operations which impact the quality (1) Quality Manual/ Site and safety (ISPE) of pharmaceutical Master file – SMF/ QM products. (1) Procedures (SOP) • Standard Operating Procedures (SOPs) provide the main forum for the (1) Work Instructions/ work procedures, Forms, protocol, documentation of a company's master formulae, etc., (WI / WP) systems and operations. (2) – Records/ Reports • are therefore the most popular documents audited by Regulatory Agencies during GMP inspections. APH3011 – cGMPP 3 How do you know what SOP is required to established? In your plant? • Check against cGMP (PICs) requirements/ ICH or WHO guidance or any regulatory requirements. • Mandate by law for processing nuclear/ biological agents and toxins materials (e.g. MOH BATA) • (Critical) Process/ equipment and facilities that affects ISPE if not controlled. • Operation of Equipment/ Instruments which impacts to test and inspection results. APH3011 – cGMPP Where you manufacture? What you manufacture? Where you sell? written policies, procedures, protocols • • • • • • • • • • • • • • • Validation and qualification of processes, equipment and systems; Equipment assembly and calibration; Technology transfer; Maintenance, cleaning and sanitation; Personnel matters including signature lists, training in GMP and technical matters, clothing and hygiene and verification of the effectiveness of training; Environmental monitoring; Pest control; Records of each key process has Complaints; to be maintained. To discuss in Recalls; topic 3-2 Returns; Change control; Investigations into deviations and non-conformances; Internal quality/GMP compliance audits; Summaries of records where appropriate (e.g. product quality review); Supplier audits. APH3011 – cGMPP 5 In general for cGMP and some healthcare gmp codes (A)Technical & Analysis SOPs - Usually such critical “Work Process” requires, verification/ validation to formalise into SOP ensuring repeatable, reproducible, consistency and accurate as they affect product quality/ patient safety. APH3011 – cGMPP (B) QMS (procedural) “Management” SOPs 6 QMS (procedural) “Management” CATEGORY Such SOP can range from • Document and Record Control explain exactly which types of SOPs exist, what the outline is of each type of SOP and how the SOPs must be written. • Change Control • to performing management review. • Contract agreements • Training and Administration • Purchasing and inventory Management • Internal Auditing, Supplier Auditing • CAPA, Complaints handling & Recalls APH3011 – cGMPP 7 “TECHNICAL” (SOP) CATEGORY PROCEDURES 1. 2. 3. 4. 5. 6. Clear operating procedures should be available for key processes and major items of manufacturing and test equipment. Receipt of materials: for the receipt of each delivery of each starting material, (including bulk, intermediate or finished goods), primary, secondary and printed packaging materials Production methods and process preparation, operations and monitoring, maintenance and cleaning. Internal labelling, quarantine and storage of starting materials, packaging materials and other materials, as appropriate. Sampling, which include the methods and equipment to be used, the amounts to be taken and any precautions to be observed to avoid contamination of the material or any deterioration in its quality Testing materials and products at different stages of manufacture, describing the methods and equipment to be used. release and rejection procedures should be available for materials and products, and in particular for the certification for sale of the finished product by the Authorised Person(s). APH3011 – cGMPP Records of each key process has to be maintained. 8 What are the Components in an SOP? format No ONE right of an SOP, a good SOP generally contain the following Components 1. 2. 3. 4. 5. 6. 7. 8. Objectives Scope Responsibilities Procedures Materials/ Equipment Records Associated documents or References Appendices (if any) APH3011 – cGMPP should Some examples of SOP/ procedures/ protocol document section heading descriptions 1. Title: or name of the process / activity detailed by the SOP 2. Scope: The departments where the current SOP is applicable 3. Objectives: Overall objectives / purpose of the SOP 4. Procedures: Detailed procedures of the process / activity 5. Materials: All materials (chemicals / raw materials / packaging material) required to complete the procedures 6. Equipment: All equipment required to complete the procedures (Note: can be combined with Materials section to form “Materials and Equipment” section. 7. Records: Specify all records and forms that have to be completed as a result of performing the tasks. 8. Associated documents: Cross reference to all documents related to the tasks. E.g. MSDS, equipment datasheet, other SOPs, work instructions APH3011 – cGMPP 10 Not following / (Deviation from) – SOPs <Examples> • Use of non-approved SOP • Use of pre-dated, out-dated or backdated SOP and forms • Changes in Technical SOP not validated/ qualified before use. • Omits essential manufacturing processes • Alters procedures without being reviewed approved. APH3011 – cGMPP 11 Deviations from cGMP • Products – Mix-ups – Contamination/ Cross-contamination – Poor handling and improper storage – Loss / Lack of traceability – Poor documentation APH3011 – cGMPP 12 Deviations from cGMP • Production equipment – Major equipment is not tagged or labelled – Lack of status for equipment or not reflected in a centralized equipment log – Cleanliness of equipment is not checked prior to production – Major equipment or parts changed without proper change control – Equipment is not duly calibrated or maintained – Poorly maintained equipment log APH3011 – cGMPP 13 Deviations from cGMP • Environment – Environment condition not maintained to specifications (e.g.. Particle count, temperature, etc.) – Environment monitoring and control equipment not duly calibrated and/or maintained – Poorly maintained cleaning log – Waste material is not disposed of in a timely and hygienic manner – Environmental cleaning is not being performed according to pre-determined schedule and/or methods – Improper gowning/de-gowning APH3011 – cGMPP 14 What is DEVIATION? Why is it important to follow SOP? Baxter Heparin 2008 http://nolan-law.com/practice-areas/pharmaceuticals/baxter-heparin-contamination/ APH3011 – cGMPP 15 Consequences of failure to follow standard operating procedure (SOP) • Increase the chance of mix-up and errors in the manufacture of products. • Prone to mistakes • Impact on quality and safety of products manufactured as increased risk of having inconsistent quality of company’s product. • Production outcome different from expected thus affects production schedule, wastage of resources . • and causing hazards to working environment and personnel. These Deviation from SOP Increase risk of non-compliance with the cGMP requirements. – DEVIATION to requirements which may lead to …. Patient’s risk due to inadequate safety, quality or efficacy. APH3011 – cGMPP 16 Follow Up Actions to Deviations Alert relevant personnel (and QA) if a deviation may / can affect the process Record any deviation and action taken to correct deviation Carry out investigation through CAPA We will discuss CAPA in topic 7-2 One of the most critical importance of Good Manufacturing Practice is that People can admit a mistake at once without fears of being reprisal. This will ensure that any mistake can be identified and damage that could result are kept to a minimum. APH3011 – cGMPP 17 CHANGE CONTROL cGMPP APH 3011 18 PIC(s) Part II Chapter 13 SOP needed! Changes activity be tracked by e.g. change request/notification APH3011 – cGMPP 19 Deviation & Change Control Reference: WHO conference workshop 2009 Nanjing China APH3011 – cGMPP Is it different from deviation? Are changes allowed? 20 START Typical Change Control Process Initiate Change Request and fill up Change Control Request Form (CCF): • New / change, • rational, • preliminary impact assessment, • implementation plan Submit to supervisor who will do initial impact assessment CCB will: • Perform detail impact assessment (Regulatory, EHS, product efficacy & stability, quality, impact on downstream processing ) • Decide change classification • Decide extent of validation • Decide implementation & validation schedule CCB approves? Yes Pass Validation • • Submit to QA who will: • Record in Change Control Log (track change number) Update various document Perform training Fail - report CCB for discussion Write and submit Change Control Report to CCB CCB approves? No QA logs it down Change number Close Out Change Request Case closed Yes Forms the CCB: • Subject Matter Experts (E.g. Production, Engineering, R&D, Purchasing, QC • QA (QP) • Other stakeholders Implement Change No Supervisor approves? QA logs it down Change number Yes No END APH3011 – cGMPP Please note that change control process flow may differs from organization in accordance to cGMP requirements. 21 Change Control CC/Request Form or Notice) • • • • Current system (problem statement) Proposed new/changes and rationale Reasons and Justification Impact of the changes – Risk analysis – Results and data – impact assessment by various personnel • Change Control Board decision – Classification of changes – Validation extent and schedule CC Reference tracking or Change Control number or Document changes DC References Approved changes have the tracking reference indicated on affected change history table on controlled document. E.g. SOP APH3011 – cGMPP 22 Application of Change Control • cGMP processes: Throughout cGMP if any new or changes added affecting CPP & CQA – Raw materials – Process steps – Production equipment – Labelling and packaging – Analytical test procedures Self Directed learning Videos https://www.youtube.com/watch?v=InICcEBF5QM APH3011 – cGMPP 23 Application of Change Control Throughout cGMP - CPP & affecting CQA • Product/operation process related changes (e.g. CN - Change Notices) – Raw materials, solvent and any ingredient or component in bill of materials, process parameters, process control packaging materials labels and introduction of new product • Engineering Changes (e.g. ECN – Engineering Change Notices) – Changes in facility design, equipment type, hardware, maintenance, parameters, utilities. • System Changes – Software/Firmware or it’s configurations etc. – Controlled documents (e.g. Document CN): Standard operating procedures, Specification sheets, documentation forms and templates APH3011 – cGMPP 24 Possible Causes of Changes • • • • • Updates from experiences from developmental or transfer phases. Results of process monitoring or statistical process control. Audit/Inspection findings. Outcome of Continuous improvement processes (CIP) Strategic considerations. – Change of supplier of raw materials – Product/Technology transfers • Customer requests. • Regulator requirements (legal changes, official requirements) • Plant modifications to incorporate new processes or accommodate increased production volumes. APH3011 – cGMPP 25 Change Control Classification Major Moderate • Changes considered to • Changes considered to have a substantial have a moderate potential to have an potential to have an adverse effect on adverse effect on the “Quality” ISPE of a drug. “Quality” ISPE of a drug • Notification to agency is required. Minor Changes considered to have a minimal potential to have an adverse effect on the “Quality” ISPE drug. EXAMPLES • • • • • • A move to a different manufacturing site Changes in sterilization method Changes to processing steps Changes in source material Adding a new product Resignation and new appointment of Qualified person APH3011 – cGMPP • • A move to a different manufacturing site using preapproved test procedures Replacement of equipment with a different design that does not affect process methodology or process parameters • • • • • • Change / substitution of equipment part A move to a different site for labelling Tightening of acceptance criteria Change in packing style or secondary packing materials Format of labels, deletion of products Packing of batch size 26 Thanks that’s end of Part 2 for topic 3-1. Before we proceed to Topic 3-2 Records Please reflect what have we learnt 27 Self check Questions (1) • In a typical SOP template, what will be the section headings providing clarity to the reader? APH3011 – cGMPP 28 Self check Questions (2) Which of the following statement is not consider as deviation in cGMP. A. B. C. D. Use of pre-dated SOP. Raise change request for a Technical SOP and plan for pre-implementation validation and training after change approval. Omits essential manufacturing processes in approve SOP. Alters SOP without being approved by QA. APH3011 – cGMPP 29 Self check Questions (3) case study Watch this (25mins) video “You’ll Soon Feel Better” and identify the deviations from all 3 scenes. This is a remake of classic training video “You’ll Soon Feel Better” was produced for the Association of British Pharmaceutical Industries (ABPI) in 1987 to highlight what can happen when GMPs are not followed. Scene 1 Scene 2 Scene 3 Review the video : https://www.youtube.com/watch?v=e5hg9cieiEQ APH3011 – cGMPP 30 Self check Questions (4) 4a) What is CCB? APH3011 – cGMPP 31 Self check Questions (continue 4) 4b) Who should be members of CCB? APH3011 – cGMPP 32 Self check Questions (4 continue) 4c) What will be the steps after changes has been approved by CCB? APH3011 – cGMPP 33 Self check Questions (5) Major / Moderate / Minor? a) Changing the supplier of a certain cell culture media component. b) Changing the pH set point of production bioreactor from 7.2 to 7.15. c) Changing the make and model of a conductivity probe used in monitoring buffer preparation. d) Using a different template of datasheet to record inprocess control data. e) Version update of a software used in electronic documentation management. f) Introducing an additional step in personnel gowning procedure. APH3011 – cGMPP 34 Self direction learning – Do it yourself! Checklist Check you have understood the Learning Objectives of the topics Study tutorial questions. Check out PIC(s) 1 Chapter 4 & PIC(s) II Chapter 6, requirements of handling deviation is stated throughout PICS part 1 & II APH3011 – cGMPP 35