Electric Power Systems Research 216 (2023) 109009

Contents lists available at ScienceDirect

Electric Power Systems Research

journal homepage: www.elsevier.com/locate/epsr

A model-based EVs charging scheduling for a multi-slot Ultra-Fast Charging

Station

Ciro Attaianese, Antonio Di Pasquale ∗, Pasquale Franzese, Diego Iannuzzi, Mario Pagano,

Mattia Ribera

Department of Electrical Engineering and Information Technology, University of Naples Federico II, Via Claudio 21, Naples, 80125, Italy

ARTICLE

INFO

Keywords:

Electric Vehicle

Charging slot

High charging power

Optimal strategy

Energy storage systems

Energy efficiency

ABSTRACT

The scientific literature is paying particular attention to Ultra-Fast Charging Stations (UFCSs) that can make

charging times of Electric Vehicles (EVs) comparable with the refuelling time of internal combustion engine

vehicles. In this context, scheduling charging algorithms to manage the available resources deserve significant

attention. This paper proposes an online scheduling algorithm for UFCSs equipped with Battery Energy Storage

Systems. The charging profile is obtained by considering the power and energetic constraints related to

both infrastructure and EVs. The constraints are assessed according to the efficiency of the infrastructure,

for which a power losses estimation approach was proposed and then detailed for the UFCS realized at our

department. Even, the dependence of the maximum EV charging rate on the State of Charge (SoC) is considered.

These aspects are usually neglected. Thus, starting from the measurements of the maximum charging rate for

two commercial EVs, numerical simulations were performed using the proposed algorithm according to two

different scheduling policies, i.e., the not-preemptive ‘First Come Best Served’ and the preemptive ‘Round

Robin SoC’. The numerical results highlight the difference between the two policies regarding the allocation

of resources among vehicles and how the SoC of the BESS affects the overall charging profiles.

1. Introduction

The growing development of the electric vehicle (EV) market emphasizes the need for charging infrastructures technologically efficient

and widespread throughout the territory. Currently, the EV market

and the reference technical literature are paying particular attention

to charging infrastructures capable of managing high charging power

to make charging times comparable to those of the internal combustion engine vehicles. In this context, the Ultra-Fast Charging Stations

(UFCSs) represent one of the most interesting technological solutions,

because they have the capability to charge the EV on-board battery up

to 80% of the State of Charge (SoC) in less than ten minutes [1]. Due

to the pulsed nature of the EV charging process, UFCSs can represent

critical loads for AC distribution grids. Indeed, DC fast chargers are

able to reach rated powers of 350 kW. This may compromise the

stability of the AC power grid [2]. In order to mitigate the effects

of the Ultra-Fast recharge, researchers proposed several solutions in

terms of topologies, architectures, and connections to the grid. For

instance, in [3] authors proposed to connect the infrastructure directly

to the MV grid through a LV/MV transformer. In [4] authors analysed

several solutions to enhance grid stability, such as Smart charging, which

is based on a smart managing of the EV charging process thanks to

the exchange of information among charging companies and utility

operators. Another solution consists in conceiving the UFCS as Microgrid

Ecosystem, in which both Energy Storage Systems (ESSs) and Renewable

Energy Sources (RESs) are used to support the charging process, in such

a way to level the power drawn from the AC grid, and at the same

time to offer services to the AC grid. Even, the authors in [5] exploited

the flexibility and dispatchability of EVs to mitigate the effects on

voltage fluctuations and grid stability due to the uncertainty of the

RESs energy production. Furthermore, it has to be highlighted that the

charging infrastructures can be equipped with multiple slots, which allow charging more EVs simultaneously. This gives rise to several issues

concerning the charging power profiles of each EV and, particularly,

how to share the available energy among more EV owners. Indeed,

in the recent years, the EV charging scheduling problem has receiving

a great deal of attention and several algorithms have been proposed.

According to their features, they can be classified as either offline or

online using both not-preemptive and preemptive scheduler policies.

The offline algorithm requires a huge amount of available data, such

as future time arrival, energy demands and time departure of EVs,

they are formulated in terms of Optimal Power Flow (OPF) problems,

∗ Corresponding author.

E-mail address: antonio.dipasquale@unina.it (A. Di Pasquale).

https://doi.org/10.1016/j.epsr.2022.109009

Received 29 July 2022; Received in revised form 26 October 2022; Accepted 19 November 2022

Available online 1 December 2022

0378-7796/© 2022 Elsevier B.V. All rights reserved.

Electric Power Systems Research 216 (2023) 109009

C. Attaianese et al.

Moreover, [14] considered a preemptive scheduling problem with

commitment requirement. If the scheduler (i.e., the UFCS) is not able

to complete the accepted job by its deadline, then it receives a penalty,

i.e., the scheduler loses the profit corresponding to its job. Under these

assumptions, the work presented an online algorithm, formulated in

terms of competitive ratio, that allows maximizing the scheduler’s profits. Also [15] addressed the problem of online EV charging scheduling

with on-arrival commitment, where the optimal charging rate aims

at maximizing social welfare. It is assumed that, upon its arrival, the

EV communicates its departure time, charging demand, willingness to

pay and maximum instantaneous charging rate. In [16], the authors

proposed a combined approach: an offline pricing method combined

with an online scheduling algorithm, based on a model predictive

control, which aims to approximate the offline minimum-cost solution.

As highlighted by the aforementioned literature, several works tackled the EV charging scheduling problem in online scenarios, with

different objectives and sets of constraints. However, none of the above

works considered the actual behaviour of the UFCS infrastructure to

assess power and energy capacity constraints (ESS). Even though the

variability of the efficiency is taken into account in some analytical

problem formulations, there is no work that assessed and used the UFCS

power-SoC-dependent efficiency to find the optimal EV charging rate.

In addition, another critical point is represented by the instantaneous

maximum charging rate of EVs. Typically, it is assumed as a constant

rated value. However, it is more appropriate to consider the maximum

rate as a function depending on the SoC of the vehicle. Indeed, as

pointed out by the typical charging profiles reported in [17], car manufacturers usually limit the maximum charging power of the vehicle for

high value of SoC in order to preserve the State of Health (SoH) of the

EV battery. Thus, energy efficiency variability and a not-constant maximum charging rate may significantly affect the scheduler’s decisions,

especially in an online on-arrival commitment scenario.

Hence, in the present work, the authors propose an online EV

charging scheduling strategy based on the power losses modelling of

the UFCS to take into account the efficiency dependence on operating

conditions during the scheduling decision. Furthermore, it is assumed

that upon the arrival the vehicle announces its maximum charging rate

(i.e., SoC-Power characteristic) and its energy demand. The charging infrastructure has no information about future arrivals and demands. The

proposed algorithm takes into account the actual power-dependent efficiency of the infrastructure, which was assessed on the UFCS realized

at the laboratory of Electrical Engineering and Information Technology

Department (DIETI) of the University of Naples Federico II. Secondly,

a measuring campaign was carried out, on the abovementioned charging station, in order to determine the maximum charging SoC-Power

characteristic for two commercial EVs. The obtained charging curves

were used to validate the effectiveness of the algorithm. It has been

formulated as a minimization problem, which aims to minimize the

charging time of EVs according to two possible policies based on the

not-preemptive First Come First Served (FCFS) [18] and the preemptive

Round Robin (RR) [19] algorithms.

Thus, the main novelties introduced by this work can be summarized as follows:

Nomenclature

𝛼

𝜂AFE

𝜂BESS

𝜂SABi

𝑓𝑠 , 𝑇𝑠

E BESS

E EVi

I SAB,max

I BESS

I EVi

k

OCV BESS

OCV EVi

P BESS,ch

P BESS,dis

P ENi

P SAB,max

P AFE

P EVi

P EV

P grid

P SAB,in

P SAB,out

RBESS

REVi

SoC BESS

SoC EVi

V BESS

V EVi

V grid

AFE

BESS

EVi

SABi

Power contribution of the EV1 in PEV

Efficiency of the AFE

Discharge efficiency of the BESS

Efficiency of the SABi

Switching Frequency and Period of SAB

Nominal capacity of battery of the BESS

Nominal capacity of battery of the EVi

Maximum Current of the SAB

Current of the BESS

Current of the EVi

Power contribution of the AFE in PEV

Open Circuit Voltage of battery of the BESS

Open Circuit Voltage of battery of the EVi

Charging Power of the BESS

Discharging Power of the BESS

Upper bound of power for the EVi due to

the station’s energy constraint

Maximum Power of the SAB

Output Power of the AFE

Power supplied to the EVi

Power supplied to all vehicles

Installed Power of the Grid

Input Power of the SABi

Output Power of the SABi

Internal battery resistance of the BESS

Internal battery resistance of the EVi

State of Charge of the BESS

State of Charge of the EVi

Voltage of the BESS

Voltage of the EVi

Peak grid phase voltage

Active Front End converter

Battery Energy Storage System

𝑖th Electric Vehicle

𝑖th Single H-Active Bridge converter

which aim to minimize, for instance, both charging and production

costs [6]. The main drawback of such algorithms is that information

may be not available or too expensive to obtain. To overcome these

limitations, online algorithms were introduced since they do not require

any future information but only rely on the current and past EV

profiles, including the arrival and departure times, and the charging

demand of EVs [7]. They are formulated as a constrained optimization

problem in which the optimum charging rate that minimizes costs,

or alternatively maximizes profits, can be achieved through an online

linear programming technique [8], or heuristic techniques [9]. It has

to be noted that the above mentioned approaches require a significant

computational effort, therefore also many online algorithms, which

assume the future information of EVs predictable, such as Whittle’s

index policy [10], the earliest deadline first (EDF) and the least laxity

first (LLF) [11,12] were investigated. However, in [13] a low-complex

algorithm is proposed, that does not require any future information.

The adaptive EV charging is formulated as a feasibility problem that

aims at meeting EVs energy demands before their deadlines while

satisfying charging rate and power constraints. The proposed algorithm

is called Smoothed Least-Laxity-First (SLLF) since it is based on the

LLF and overcomes its limitations concerning the oscillations in the

charging rate and improves its success rate.

• an online EV charging scheduling algorithm, which takes into account both the power losses modelling of the UFCS, and the variability of the EVs’ maximum charging rate according to their state

of charge (i.e., the SoC-Power characteristics of each vehicle);

• the experimental determination of the maximum charging SoCPower characteristic for two commercial EVs;

• the comparison between two alternative scheduling algorithms

(i.e., FCFS and RRS).

The rest of the paper is organized as follows: Section 2 presents the

topology of the UFCS realized at the DIETI. In this section the efficiencies of the infrastructure subsystems are discussed as well. Section 3

provides a brief overview of the scheduling policies, i.e., FCFS and RR.

2

Electric Power Systems Research 216 (2023) 109009

C. Attaianese et al.

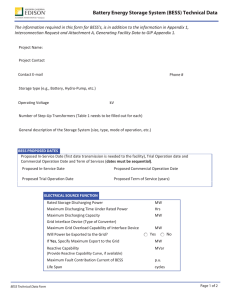

Table 1

Rated values.

In Section 4 the proposed charging scheduling strategy is described. In

Section 5 the measured charging profiles for the two commercial EVs

and the numerical results for the proposed scheduling algorithm are

discussed. Finally, Section 6 provides the conclusions.

Parameters

AC rated voltage

DC voltage range

Rated power

Switching frequency

IGBT rated voltage

Cooling

2. The UFCS structure and operating mode

The expected time target of an UFCS to charge EV battery up

to 80% is 10–15 min. Charging slots operate in a voltage range of

450–1000 V DC, with an operating current value up to 450 A [20].

These infrastructures require to be connected to Low Voltage (LV) or

Medium Voltage (MV) three-phase distribution grid. Typically, when

equipped with multiple charging slots, also local energy sources have

to be integrated in the infrastructure in order to reduce the amount

of power delivered from the AC grid, since it is not always possible

to have a strong grid connection [21]. Therefore, in presence of BESSs

and/or RESs, UFCSs look like smart grids. Figs. 1(a) and 1(b) show a

schematic representation and a view of the UFCS realized at the DIETI

Lab, respectively. The infrastructure is connected to the AC three-phase

grid (400 V∕50 Hz) with a 50 kW AC/DC grid-tied power converter and

it is equipped with a BESS on DC common bus, to reach the rated power

up to 350 kW useful for charging two EVs simultaneously. The UFCS,

as shown in Fig. 1(a), consists of the following main subsystems:

DC voltage range

Output Voltage AC side

Rated Power

Max duty cycle

Max current

IGBT rated voltage

Rated frequency

Cooling

DC input voltage (peak)

DC Rated current

Rated Power

Diode Voltage

400

510–720

50

4

1200

[V]

Square wave

[kW]

–

[A]

[V]

[kHz]

Water

510–720

160

0.5

420

1200

2.6

[V]

[A]

[kW]

[V]

720

400

160

1200

SAB (Medium Frequency Transformer)

Rated active power

Rated Apparent Power

Primary rated voltage

Secondary rated voltage

Max Current at secondary side

Rated frequency

Coil Ratio

Weight

Primary/Secondary Coils Resistance

Total Power Losses

Iron Core

[kW]

160

[kVA]

234

[V]

700

[V]

735

[A]

400

[kHz]

2.6

–

1∕1.05

[kg]

42

[m𝛺]

1, 49∕1, 41

[W]

490

Ferroxube 3C95F/60

BESS

Voltage range

Rated capacity

N modules

Battery technology

[V]

500–710

[Ah]

128

–

168𝑠2𝑝

Lithium Ion - NMC

LC filter

Rated DC current

Max DC voltage

Inductance

Capacitance

Current ripple (peak-peak) at 5.4 kHz

with 𝛼 partial power factors of EVs. According to the following definitions of efficiency:

𝑃

𝑃AFE

, 𝜂BESS,dis = BESS,dis

𝑃grid

𝑃BESS

𝛼𝑃

(1−𝛼)𝑃EV

𝜂𝑆𝐴𝐵1 = 𝑃 EV , 𝜂𝑆𝐴𝐵2 = 𝑃

SAB1 ,in

SAB2 ,in

[V]

[V]

[kW]

[kHz]

[V]

Water

SAB (Diode Rectifier)

In the single configuration, the UFCS allows charging two EVs,

equipped with a battery having a rated voltage up to 450 V. In this

case, according to Fig. 1(a), the switches 𝐾𝑎 and 𝐾𝑏 are closed and 𝐾𝑠

is open. Moreover, when the two SABs work independently, the UFCS is

able to charge two EVs at the rated power of 160 kW. The main features

of this converter are highlighted in Fig. 2.

The instantaneous active power of AFE, 𝑃AFE , and BESS, 𝑃BESS,dis ,

are divided into the two independent power channels. The resultant

charging profile, 𝑃EV , is the sum of time-power demand of each EV:

{

𝑃EV = 𝑃EV1 + 𝑃EV2

(1)

𝑃EV1 = 𝛼𝑃EV , 𝑃EV2 = (1 − 𝛼) 𝑃EV

𝜂AFE =

Value

SAB (H-bridge converter)

• AC/DC four-quadrant grid-tied converter, consisting of the input

LV isolation transformer and the Active Front End converter

(AFE);

• BESS;

• Two DC/DC converters (SAB), each one consisting of a H-Bridge

converter, a medium frequency isolation transformer, a diode

rectifier and a LC filter; they can work independently or in the

twin configuration with the outputs connected in series.

⎧

⎪

⎨

⎪

⎩

Unit

AFE

[A]

[V]

[mH]

[mF]

[A]

400

950

1

1

7

max, 400 A max), by connecting the two SAB converters in series. In

this configuration, (2) and (4) are still valid with 𝛼 = 1.

In Fig. 3 the working area of the station is reported. The orange line

refers to the twin mode, whereas the blue line refers to the single.

(2)

2.1. Efficiency assessment

where

⎧

⎪

⎨

⎪

⎩

)

(

𝜂AFE = 𝜂AFE 𝑃grid , 𝑉BESS

(

)

𝜂BESS,dis = 𝜂BESS,dis 𝑃BESS

(

)

𝜂SABi = 𝜂SABi 𝑃EVi , 𝑉EVi , 𝑉BESS

The estimation of UFCS efficiency is based on the computation

of power losses of each subsystem. The following power losses are

considered:

(3)

(4)

– AFE: IGBT and Diode conductive losses; IGBT commutation losses

[22,23];

– SAB: IGBT and Diode conductive losses; IGBT commutation losses;

transformer conductive and iron losses [23,24];

– BESS: joule losses.

where EV0 means no presence of EVs. Alternatively, in single configuration, the UFCS allows charging a single EV equipped with a battery

of 600–800 V. The switches 𝐾𝑎 and 𝐾𝑏 are open and 𝐾𝑠 is closed. The

UFCS is able to charge the EV at a full power up to 320 kW (800 V

The losses are estimated considering the electrical features of the

semiconductor devices and medium frequency transformer according

to the data shown in Table 1, and the typical SAB voltage and current

waveforms depicted in Fig. 2. The latter refer to the case of square wave

The instantaneous efficiency of the UFCS during EVs or BESS charging

are respectively:

1,2)

𝜂𝑈(𝐸𝑉

=

𝐹 𝐶𝑆

𝑃EV

𝑃AFE + 𝑃BESS,dis

0)

𝜂𝑈(𝐸𝑉

=

𝐹 𝐶𝑆

𝑃BESS,ch

𝑃AFE

3

Electric Power Systems Research 216 (2023) 109009

C. Attaianese et al.

Fig. 1. (a) Block diagram of UFCS scheme and power flows, (b) view of UFCS at DIETI lab.

Fig. 3. UFCS working Area: DC output in terms of current (blue line) and power

(orange line).

UFCS efficiency as a function of the EV charging power for minimum,

intermediate and maximum BESS voltage value. The two groups of

curves represent the lower and upper bounds of operating working area

during a fast charge of an EV with 400 V rated voltage. The curves

show, clearly, that the efficiency strongly depends on EV power and

voltage, whereas they are weakly dependent on the BESS voltage.

Fig. 2. Single Active Bridge DC/DC converter, power losses flow, voltage and current

of primary side.

modulation in Zero Voltage Switching condition with phase-shift technique at fixed frequency of 2.6 kHz. This is the modulation technique

implemented on each SAB converter.

2.2. UFCS operating mode

The obtained UFCS efficiency waveforms as a function of EV charging power, BESS and EV voltage values (i.e., 𝑉BESS , 𝑆𝑜𝐶EV , respectively)

are highlighted in Fig. 4. Two groups of curves are represented according to 𝑆𝑜𝐶EV equal to 20% and 80%. Each group of curves highlights

A Peak Shaving (PS) power management strategy has been implemented. The strategy limits the active power supplied by the grid

to the rated value of 50 kW during all the phases of the ultra-fast

charging processes. Therefore, higher power peak requirements are

4

Electric Power Systems Research 216 (2023) 109009

C. Attaianese et al.

Fig. 4. UFCS efficiency on EV power for different values of 𝑆𝑜𝐶EV and 𝑉BESS , and with vehicle rated voltage 400 V.

Fig. 5. Representative peak shaving strategy: 𝑆𝑜𝐶BESS (blue line), 𝑃EV (orange line),

𝑃grid (green line).

supplied by the BESS, in the respect of threshold limits (i.e., 𝑆𝑜𝐶min ≤

𝑆𝑜𝐶BESS ≤ 𝑆𝑜𝐶max ). In Fig. 5, the representative peak shaving strategy

is highlighted for two consecutive charging processes. The grid power

is constantly set to 50 kW (i.e., dotted green line). 𝑆𝑜𝐶BESS , (i.e., blue

line) decreases or increases according to the difference between EV and

grid power.

Fig. 6. Schemes representative of priority algorithms.

Fig. 6 provides an example of how the abovementioned algorithms

work, in particular it highlights the differences in terms of priority

management.

The management of EV charging is a scheduling problem in which

the energy demands of vehicles are the processes, and the energy

available from the grid and the BESS represents the shared resource.

The most prioritized process is the EV charging which benefits from the

most resources under operating constraints. Less prioritized processes

can use only, if present, the residual energy.

In Section 4, the proposed model-based scheduling algorithm is

described. The analytical formulation of such an algorithm includes

both the just introduced scheduling policies in a revised version. In

detail, the policy inspired by the FCFS will be called ‘First Come Best

Served’ FCBS, since the Multi-slot charging station allows charging

more EVs simultaneously. Thus, according to the FCBS, the first vehicle

benefits from most of the shared resources, but the residual can be

used to start charging the less prioritized vehicles. Moreover, The policy

inspired by the RR will be called ‘Round Robin SoC’ (RRS). This policy

will be applied providing a cyclical exchange of priorities among EVs,

in terms of increase in SoC instead of considering time: when the SoC

of the vehicle with the highest priority increases of a fixed 𝛥𝑆𝑜𝐶, this

EV loses its priority and becomes the vehicle with the lowest priority.

3. Scheduling policies for an UFCS

The problem of managing the EVs recharge in a multislot UFCS

addresses two issues: the scheduling strategy for the infrastructure and

the planning of EV charging power profiles. The scheduling strategy

concerns the arrangement of the deadline-constrained charging processes in presence of limited resources. The power profile planning

concerns the strategy with which the right amount of resources are

assigned (i.e., the service offered to each EV). This problem is a typical

‘job scheduling’ with a priority mechanisms.

The ‘job scheduling’ theory has a strong application in computer

science, where the processes executed by a CPU must be managed.

The main scheduling algorithms are categorized as preemptive and notpreemptive. In computing, the word preemption denotes the possibility

for the scheduler to temporarily interrupt an executing task, and resume

it at a later time. In this framework, as pointed out by [25], FCFS

and RR are two of the most common scheduling policies, whose main

features are reported below:

• the FCFS is a not-preemptive algorithm. The priority is fixed and

it is given to the process with earlier arrival time. The subsequent

processes increase their priority when the previous processes are

completed.

• the RR is a particular preemptive algorithm that executes the

charging processes in order of arrival, like the FCFS, but preempts

the running process, placing it at the end of the queue of pending

processes, if execution takes longer than the set ‘‘amount of

time’’, and allowing the execution to continue to the next pending

process.

4. Model-based EV charging scheduling strategy

In this Section, a model-based strategy for planning the power

profiles of a multi-slots UFCS is proposed. The goal is minimizing

the EV charging time (i.e., power maximization) taking into account

the constraints on both power (i.e., supplying and charging limits)

and energy. This strategy can be adopted for an arbitrary number

of charging slots and vehicles. As explained below, in the case of

several vehicles, the scheduling problem needs to establish a priority

5

Electric Power Systems Research 216 (2023) 109009

C. Attaianese et al.

(𝑘)

• Maximum power constraint of UFCS (𝑃SAB,max

): it represents

the maximum deliverable power of the SAB converter (it depends

on the infrastructure rate). The value of this power constraint is:

mechanism among the EVs. Therefore, the fundamentals of the strategy

are:

1. in the presence of a single EV, it has the highest priority, so

the planning of its charging profile is based on the status of the

infrastructure, in terms of available power and energy from grid

and BESS;

2. in the presence of multiple EVs, a priority algorithm has to

be considered. The charging profile of the EV with the highest

priority is determined as in the case of a single EV. The planning

of the charging profile of EVs with lower priority has to consider

power and energy values already assigned to the vehicles with

higher priority. Hence, EVs with lower priorities are subject to

more restrictive constraints than EVs with higher priorities.

(𝑘)

(𝑘) (𝑘)

𝑃SAB

= 𝐼SAB,max ⋅ 𝑉BESS

𝜂SAB

i

where the product between the maximum deliverable current and

(𝑘)

the input voltage (𝑉BESS

) is the theoretical maximum input power

of the SAB at the time interval considered.

(𝑘)

• Energy constraint of UFCS (𝑃EN

): it takes into account the

i

amount of energy available within the BESS. It must be imposed

to ensure that: i) the BESS contains energy enough to supply

the energy demanded by the 𝑖th EV during the 𝑘th interval; ii)

the energy demanded by EVi does not limit the power already

scheduled for the EVs with higher priority. Indeed, the power

supplied to the 𝑖th EV could fully discharge the BESS ahead of

schedule and, as a consequence, it will not be able to feed the

charging profiles already assigned to other EVs.

The residual energy within the BESS at the 𝑘th time interval

(𝑘)

(𝐸BESS

) can be calculated according to the following expression:

4.1. Problem formulation

The problem of scheduling the charging profile for the 𝑖th EV

arriving at the UFCS can be modelled according to the following

minimization problem:

{

𝑃EVi (𝑡) ≤ 𝑃EVi ,max (𝑡)

min 𝑡EVi ,ch such that

(5)

𝑃EV

𝑃EVi (𝑡) ≤ 𝑃SAB,max (𝑡)

(𝑘)

(0)

𝐸BESS

= 𝐸BESS

−

min 𝑡EVi ,ch

(𝑘)

𝑃EV

i

(ℎ)

𝑃BESS,dis

i

(6)

(𝑘)

(𝑘)

𝑃EV

≤ 𝑃EN

i

i

Eq. (6) is obtained by the discretization of (5), for instance through

the forward Euler method, in which the sample time, 𝛥𝑇 , can be chosen

according to the desired levels of accuracy and 𝑘 is the integer index

of the discrete time, such that 𝑡𝑘+1 = 𝑡𝑘 + 𝛥𝑇 . Hence, the problem can

be stated as follows:

(𝑘)

, 𝑃 (𝑘) }

, 𝑃 (𝑘)

max {𝑃EV

,max SAB,max EN

(7)

i

i

The terms in (7) can be assessed as follows:

i

i

(𝑘)

where 𝑉EV

is the terminal battery voltage at maximum battery

i

current value. In order to calculate the voltage, the zero order

battery mathematical model can be used:

i

i

(𝑘)

(𝑘−1)

𝑆𝑜𝐶EV

= 𝑆𝑜𝐶EV

+

i

i

i

(𝑘) (𝑘)

𝑉EV

𝐼

i EVi

𝐸EVi

(ℎ)

𝜂SAB

(12)

𝛥𝑇

(ℎ)

− 𝑃grid 𝜂AFE

(13)

q

(ℎ)

∑𝑘end −1

𝑃BESS,dis

ℎ=𝑘

𝜂BESS

(𝑘)

= 𝐸BESS

−

𝑘end

= max {𝑘end,j }

i

(𝑘)

(𝑘)

(𝑘)

𝑉EV

= 𝑂𝐶𝑉EVi (𝑆𝑜𝐶EV

) − 𝑅EVi ⋅ 𝐼EV

=

𝐸̂ i(𝑘)

(𝑘)

𝑃EN

=

(8)

i

(ℎ)

𝜂BESS

(ℎ)

𝛥𝑇

(14)

∀𝑗 ∈ 𝑛(𝑘)

where 𝑘𝑒𝑛𝑑,𝑗 , is the steps in which the 𝑗th EV will complete its

recharge or its priority will change. In other words, 𝐸̂ i(𝑘) consists

(𝑘)

in the total energy 𝐸BESS

decreased of the amount of BESS energy

already assigned to the EVs with higher priority. Here the nature

of the employed priority policy lies. Indeed, according to the

FCBS or the RRS, the vehicles are sorted from the one with the

highest priority to the one with the lowest priority. According to

this sorting, the energy constrain is assigned. The latter can be

formulated more conveniently in terms of power as follows:

(𝑘)

): The EV on-board Bat• Maximum EV power demand (𝑃EV

i ,max

tery Management System (BMS) communicates to the charging

infrastructure the maximum value of current that the vehicle can

draw, which depends on the on-board battery’s technology, sizing

and 𝑆𝑜𝐶EV . It is remarkable that in order to preserve the battery

State of Health, the BMS could define values quite lower than the

(𝑘)

rated one. Thus, the constraint 𝑃EV

at the 𝑘th time interval

i ,max

can be formulated as follows:

(𝑘)

(𝑘)

(𝑘)

𝑃EV

= 𝐼EV

⋅ 𝑉EV

,max

,max

ℎ=0

It should be noted that 𝑛(ℎ) in (13) is the subset of EVs with higher

priority than EVi at the ℎth step, therefore the number of elements

of 𝑛(ℎ) represents the number of operating SAB converters at each

step. Furthermore, when the there is no vehicle in charge, the

power supplied by the grid is used to charge the 𝐵𝐸𝑆𝑆, therefore,

according to (13) 𝑃BESS,dis becomes negative.

The energy constraint consists of the amount of energy that the

UFCS makes available to the 𝑖th EV according to the priority

policy (e.g., FCBS or RRS). Indeed, if at the 𝑘th step EVi has the

highest priority, the available energy of the BESS would be the

(𝑘)

entire 𝐸BESS

. More in general, for each vehicle, the amount of

available energy from the station (𝐸̂ i(𝑘) ) is defined as follows:

i

i

(ℎ)

𝑃BESS,dis

(ℎ)

∑ 𝑃EVq

𝑞∈𝑛(ℎ)

(𝑘)

(𝑘)

𝑃EV

≤ 𝑃EV

,max

(𝑘)

(𝑘)

𝑃EV

≤ 𝑃SAB,max

𝑘−1

∑

in which the sum represents the gross energy supplied by the BESS

(ℎ)

and the quantity 𝑃BESS,dis

is given by the difference between the

total input power to all the operating SAB converters at the ℎth

step, and the power supplied by the grid:

The objective function seeks to minimize the EVs charging time (𝑡EVi ,ch )

to release the charging slot as soon as possible. The goal is pursued

by maximizing the charging power, taking into account the constraints

on maximum EV and slot charging rate, (𝑃EVi ,max (𝑡)) (𝑃SAB,max (𝑡)) respectively. Moreover, 𝑃EN (𝑡) is a power constraint depending on energy

available from BESS and EV, as well as on the scheduling policy. It is

to underline, the constraints are time variant due to their dependence

on 𝑆𝑜𝐶EV and 𝑆𝑜𝐶BESS . Therefore, in order to solve it numerically, the

following discrete model has to be considered:

⎧

⎪

⎪

such that ⎨

⎪

⎪

⎩

(11)

i

𝐸̂ i(𝑘)

𝛥𝑇

(𝑘)

(𝑘)

𝜂BESS

𝜂SAB

(15)

i

(𝑘)

where 𝑃EN

represents the EV charging power that would consume

i

̂ (𝑘)

𝐸i

(𝑘)

𝜂BESS

the whole 𝐸̂ i(𝑘) in a single time interval. The quantity 𝛥𝑇

is the power that the BESS would supply to run out the energy

available for the 𝑖th EV.

(9)

Eventually, noteworthy is that the priority policies affect only the

assessment of the energy constraint. Indeed, the latter determines the

distribution of the shared resources, whereas the other constraints refer

to the technical limitations in terms of instantaneous power.

⋅ 𝛥𝑇

(10)

where for the current the passive sign convention was adopted.

6

Electric Power Systems Research 216 (2023) 109009

C. Attaianese et al.

Table 2

EVs Data.

4.2. Constraint numerical assessment

The numerical assessment of the constrains is mandatory for formulating the proposed strategy. The first constraint 𝑃𝐸𝑉 i,𝑚𝑎𝑥 can be

(𝑘)

easily calculated by replacing (9) in (8), where 𝐼EVi ,max and 𝑆𝑜𝐶EV

are

i

known. Hence:

(

)

(𝑘)

(𝑘)

(𝑘)

(𝑘)

𝑃EV

=𝐼EV

⋅ 𝑂𝐶𝑉EV

𝑆𝑜𝐶EV

+

i ,max

i ,max

i

i

(16)

[

]2

(𝑘)

− 𝑅EVi ⋅ 𝐼EV

,max

i

(𝑘)

The second constraint 𝑃𝑆𝐴𝐵i,𝑚𝑎𝑥

, as highlighted by (11) depends on the

(𝑘)

quantity 𝑉BESS

. It can be calculated according to the battery model by

(𝑘)

considering the current (𝐼BESS

) that the BESS should deliver so that SABi

supplies the maximum current (𝐼SAB,max ). Hence the problem can be

formulated as reported below:

⎧

⎪

⎨

⎪

⎩

(𝑘)

(𝑘)

𝑃grid ⋅𝜂AFE (𝑉BESS )

∑

(𝑘)

(𝑘)

𝐼BESS

= 𝐼SAB,max + 𝑞∈𝑛(ℎ) 𝐼𝑆𝐴𝐵

−

(𝑘)

q

𝑉BESS

(

)

(

)

(𝑘)

(𝑘)

(𝑘)

(𝑘)

𝑉BESS

= 𝑂𝐶𝑉 𝑆𝑜𝐶BESS

− 𝑅BESS ⋅ 𝐼BESS

𝑉BESS

Parameters

Unit

EV1

EV2

Rated discharge power

Specific energy

Consumption

Autonomy (WLTO)

Nominal battery capacity

Nominal battery voltage

Max charge power

Full charge time

Propulsion type

[kW]

[kWh/100 km]

230

22.3

150

17.2

[km]

[kWh]

[V]

[kW]

[min]

–

330

71

450

130

30

IM

520

77

400

130

50

BR

Table 3

Case studies.

(17)

Quantity

Unity

Case A

Case B

Arrival time EV1

Arrival time EV2

𝑆𝑜𝐶EV10

𝑆𝑜𝐶EV20

𝑆𝑜𝐶EV,max

𝑆𝑜𝐶BESS0

[min]

[min]

[pu]

[pu]

[pu]

[pu]

0

2

0.4

0.2

0.8

0.8

0.5

(𝑘)

in which 𝐼SAB

can be calculated as following:

q

(𝑘)

=

𝐼SAB

q

(𝑘)

𝑃EV

q

and slots since it is based on the analytical model obtained for the

charging station installed at the DIETI. However, this does not affect

the goodness of the obtained results, which aim to show how to

deal with EV charging scheduling problems taking into account the

dependence of the efficiency on the power and the SoCs (i.e., voltages),

and SoC-dependent EV maximum charging rate.

(18)

(𝑘)

(𝑘)

𝑉BESS

𝜂EV

q

(𝑘)

(𝑘)

It worth noting that the cross dependence of 𝐼BESS

and 𝑉BESS

makes

non-linear. Furthermore, calculated the BESS voltage, the maximum

power of the UFCS can be defined according to the following non-linear

system:

( (𝑘)

)

⎧

𝑃SAB ,𝑚𝑎𝑥

(𝑘)

(𝑘)

i

⎪ 𝑃 (𝑘)

=

𝐼

⋅

𝑉

⋅

𝜂

SAB,max

(𝑘)

SABi ,𝑚𝑎𝑥

BESS

SABi

𝑉EV

⎪

i

(19)

⎨

(𝑘)

(

)

𝑃SAB ,𝑚𝑎𝑥

⎪ 𝑉 (𝑘) = 𝑂𝐶𝑉 (𝑘) 𝑆𝑜𝐶 (𝑘) − 𝑅 ⋅

i

EVi

(𝑘)

EVi

EV

EVi

⎪

𝑉EV

⎩

i

5.1. EV charging current profiles

In order to validate the strategy in a real scenario, the maximum

power demand profile (i.e., 𝑃EV,max ) and the 𝑆𝑜𝐶 − 𝐼 characteristic

of two commercial EVs were evaluated in a preventive experimental

measurement campaign. The most relevant features of both vehicle are

reported in Table 2.

The two vehicles were charged separately, from values of SoC close

to zero up to 100%, with the BESS full charged. The measurements,

in terms of absorbed current, EV battery voltage, and absorbed power

are reported in Fig. 7. It can be noted that the two charging modes as

a function of 𝑆𝑜𝐶EV are different. The maximum power requirements

of EV2 begins to decrease for values of 𝑆𝑜𝐶EV around 40%, whereas

EV1 keeps a constant power (i.e., 120 kW) up to 65% of 𝑆𝑜𝐶EV . These

behaviours depend on the strategies imposed by the two car makers

in order to manage the on-board battery temperature (i.e., to preserve

battery lifetime).

Eqs. (17) and (19) need to be solved using a numerical method. In this

work, the fixed point iteration has been chosen.

(𝑘)

(𝑘)

reported in (15) depends on 𝑉BESS

. It can

Also the constraint 𝑃EN

i

be calculated by solving, once again with the fixed point iteration, the

non-linear system:

⎧

⎪

⎨

⎪

⎩

(

)

(𝑘)

(𝑘)

(𝑘)

𝑉BESS

= 𝑂𝐶𝑉BESS 𝑆𝑜𝐶BESS

− 𝑅BESS ⋅ 𝐼BESS

(

)

(𝑘)

̂

𝐸i

∑

(𝑘)

(𝑘)

(𝑘)

(𝑘)

𝐼BESS

=

(𝑘) ⋅ 𝜂BESS 𝑉BESS +

𝑞∈𝑛(ℎ) 𝐼𝑆𝐴𝐵 −

𝛥𝑇 ⋅𝑉BESS

q

(𝑘)

(𝑘)

𝑃grid ⋅𝜂AFE (𝑉BESS )

(𝑘)

𝑉BESS

(20)

(𝑘)

𝐼BESS

where

represents the current that the BESS should deliver, in one

time interval, in order to supply the whole 𝐸̂ i(𝑘) to 𝑖th vehicle.

5.2. FCBS vs RRS

5. Numerical results

Two case studies, i.e., Case A and Case B, were analysed. The assumed operating conditions are given in Table 3, which shows that the

two scenarios differ only in the BESS initial 𝑆𝑜𝐶 (𝑆𝑜𝐶BESS0 ), whereas

EVs arrival times, initial and final SoC (𝑆𝑜𝐶EV10 , 𝑆𝑜𝐶EV20 , 𝑆𝑜𝐶EV,max )

were kept the same.

Figs. 8 and 9 show the resulting charging profiles obtained according to the two alternative priority policies discussed above.

For the sake of clarity, the power profiles are marked with:

Matlab®

The model-based strategy was implemented in

2019b.

A sample time of 1 min was assigned since it represents a good

compromise between calculation effort and accuracy. The numerical

results aim at assessing the behaviour of the modelled infrastructure

(i.e., DIETI UFCS) according to the two proposed alternative priority

algorithms, i.e., FCBS and RRS. The case studies aim to show how

initial conditions on EVs SoC 𝑆𝑜𝐶BESS , and the management of the

priority can affect the resultant charging power profiles. Furthermore,

the numerical validation of the strategy exploited the EV maximum

charging rate obtained from the measures carried out on the DIETI

UFCS for two different commercial EVs.

It has to be highlighted that the proposed algorithm was formulated

for an arbitrary number of vehicles and slots of the UFCS, nevertheless, the following numerical analysis focuses on only two vehicles

• square-shaped marker, when the curve is limited by the EV maximum power constraint (𝑃EV,max );

• triangle-shaped marker, when the curve is limited by the SAB

maximum power constraint (𝑃EV,max );

• circle-shaped marker, when the curve is limited by the energy

constraint (𝑃EN ).

7

Electric Power Systems Research 216 (2023) 109009

C. Attaianese et al.

Fig. 8. FCBS Vs RR — Case A.

As a consequence, the charging power profile available for the EV2 can

be calculated by using only the residual BESS energy. This means that

the charging profile assigned to EV1 is a constraint for charging EV2 .

In case of FCBS algorithm, the residual BESS energy allows to charge

EV2 at its maximum power only for the first two minutes (Fig. 9(a)).

Later, the charge process stops and resumes only when EV1 is fully

charged. So, being 𝑆𝑜𝐶BESS low, the slots charges EV2 by the grid power

(i.e. 50 kW).

RRS algorithm varies cyclically EV priority during the charging

phase. In detail, each EV holds the priority for a time interval related at

increasing its SoC of 20%. The solution provided by the RR algorithm

highlights the following charging modes:

Fig. 7. Experimental values of current (a), voltage (b) and power (c) referring to the

charge of two different vehicles.

In Case A, when the BESS initial SoC is 0.8, the UFCS charges

simultaneously the two EVs. Noteworthy is that the FCBS and RRS

algorithms give the same results. Indeed, Fig. 8(a) shows that the active

constraint over the entire charging phase is 𝑃EV,max , since as pointed out

by Fig. 8(b) the BESS is not fully discharged at the end of the recharge

of both vehicles. As a consequence, the charging profiles of Fig. 8(a)

are equivalent to the power profiles of Fig. 7 in the SoC range [0, 0.8].

UFCS maximum power constraint (i.e., 𝑃SAB,max ) does not act, being

higher than the two 𝑃EV,max .

More relevant is Case B. As a consequence of the lower BESS

initial SoC, the priority algorithms give different results. The results are

highlighted in Fig. 9, in which Figs. 9(a) , 9(c), 9(e) and 9(g) focus on

the results of the FCBS algorithm, whereas Figs. 9(b), 9(d), 9(f) and 9(h)

relate to the RRS algorithm. Figs. 9(a) and 9(b) point out the charging

power profile of the two EVs. Figs. 9(c) and 9(d) show the value of the

energy constraint, whereas Figs. 9(e) and 9(f) highlight the behaviour

of 𝑆𝑜𝐶EV1 , 𝑆𝑜𝐶EV2 and 𝑆𝑜𝐶BESS . Furthermore, in Figs. 9(g) and 9(h)

it is shown the behaviour of the UFCS in terms of efficiency, which is

computed according the approach explained in Section 2.

The analysis of the results highlights the differences between the

adoption of the two alternative strategies. In Case B, more constraints

are active over the entire charging phase. In case of FCBS, the EV1

(solid blue line) has the highest priority over its entire charging phase.

Therefore, the UFCS makes available to EV1 the full BESS energy and

the grid power. The charge of EV1 is the fastest as it is possible. The

parameters for charging EV1 are calculated at its arrival at the station.

• 0 min ≤ 𝑡 ≤ 4 min: the charging power profiles and the values

of 𝑃EN are equivalent to those of the FCBS, where EV1 has the

priority. At the time (𝑡 = 4 min) EV1 ’s SoC is increased by +20%

and, hence, the algorithm assign the priority to EV2 .

• 4 min < 𝑡 ≤ 7 min: all the UFCS energy is available for

EV2 . Thus, EV2 can be charged at its maximum power value.

This estimated time horizon of priority uses a limited amount

of 𝑆𝑜𝐶BESS , therefore also EV1 can be charging at its maximum

power value.

• 7 min < 𝑡 ≤ 12 min: EV1 gets the highest priority again; the

amount of BESS energy is not enough for charging both the

vehicles at their maximum powers. Initially, EV1 charges at its

maximum power, whereas EV2 is not charged; three minutes later,

the energy constraint limits the charging power. At 𝑡 = 10 min the

BESS is fully discharged, therefore the charging continues using

only the grid power.

• 12 min < 𝑡 ≤ 49 min: EV1 and EV2 are charged alternatively,

according to the assigned priority.

Table 4 shows the comparison between the two proposed priority algorithms, in terms of charging time and average supplied power. If the

8

Electric Power Systems Research 216 (2023) 109009

C. Attaianese et al.

Fig. 9. FCBS Vs RRS — Case B.

𝑆𝑜𝐶BESS0 is high, the two priority algorithms produce no differences. If

the BESS is only partially charged, the FCBS algorithm, as expected,

favours unequivocally the first arrived vehicle. On the contrary, the

RRS allows a fairer sharing of resources. Indeed, Fig. 9(f) discloses that,

for instance, EV2 reaches 𝑆𝑜𝐶 = 0.51 at 𝑡 = 19 min whereas according

to Fig. 9(e) it reaches the same value at 𝑡 = 28 min. Therefore,

if the owner of EV2 was not interested in fully charging its vehicle

or if 𝑆𝑜𝐶EV20 was higher, the RRS policy would provide a significant

improvement in the service offered to second vehicle.

Table 4

Priority policies comparison.

6. Conclusion

depends on the SoC. Such an algorithm is formulated as an optimization

problem, whose objective function is the minimization of charging time

for each vehicle. This aim is pursued by taking into account power and

energy constraints referring to both EVs and charging stations. Two

priority policies based on the non-preemptive FCFS and the preemptive RR are proposed. Thus, the effectiveness and the features of the

proposed approach is pointed out by numerical results, which exploit

Case A

FCBS

TEV 1 [min]

TEV 2 [min]

PEV1 ,avg [kW]

PEV2 ,avg [kW]

This paper proposes an online model-based strategy to schedule the

EV charging power profiles for a UFCS equipped with several charging

slots. The algorithm was formalized by accounting for the dependence

of the UFCS efficiency on operating power and voltage values. It also

takes into account that the EV instantaneous maximum charging rate

9

16

21

106.22

91.80

Case B

RR

FCBS

RR

16

48

110.84

39.73

29

49

60.67

39.31

Electric Power Systems Research 216 (2023) 109009

C. Attaianese et al.

the power losses model obtained for the UFCS installed at the DIETI

and the maximum charging rates measured for two commercial EVs.

Future studies will concern the experimental validation of the proposed algorithm through its implementation on the actual charging

infrastructure. In addition, other scheduling strategies and priority

policies will be considered.

[7] Y. Cao, H. Wang, D. Li, G. Zhang, Smart online charging algorithm for electric

vehicles via customized actor–critic learning, IEEE Internet Things J. 9 (1) (2021)

684–694.

[8] L. Guo, K.F. Erliksson, S.H. Low, Optimal online adaptive electric vehicle

charging, in: 2017 IEEE Power & Energy Society General Meeting, IEEE, 2017,

pp. 1–5.

[9] M. Alonso, H. Amaris, J.G. Germain, J.M. Galan, Optimal charging scheduling

of electric vehicles in smart grids by heuristic algorithms, Energies 7 (4) (2014)

2449–2475.

[10] Z. Yu, Y. Xu, L. Tong, Deadline scheduling as restless bandits, IEEE Trans.

Automat. Control 63 (8) (2018) 2343–2358.

[11] A. Subramanian, M.J. Garcia, D.S. Callaway, K. Poolla, P. Varaiya, Real-time

scheduling of distributed resources, IEEE Trans. Smart Grid 4 (4) (2013)

2122–2130.

[12] J.A. Stankovic, M. Spuri, K. Ramamritham, G. Buttazzo, Deadline scheduling

for real-time systems: EDF and related algorithms, vol. 460, Springer Science &

Business Media, 1998.

[13] N. Chen, C. Kurniawan, Y. Nakahira, L. Chen, S.H. Low, Smoothed least-laxityfirst algorithm for electric vehicle charging∶ online decision and performance

analysis with resource augmentation, IEEE Trans. Smart Grid 13 (3) (2021)

2209–2217.

[14] S. Chen, L. Tong, T. He, Optimal deadline scheduling with commitment, in: 2011

49th Annual Allerton Conference on Communication, Control, and Computing

(Allerton), IEEE, 2011, pp. 111–118.

[15] B. Alinia, M.H. Hajiesmaili, N. Crespi, Online EV charging scheduling with

on-arrival commitment, IEEE Trans. Intell. Transp. Syst. 20 (12) (2019)

4524–4537.

[16] Z.J. Lee, J.Z. Pang, S.H. Low, Pricing EV charging service with demand charge,

Electr. Power Syst. Res. 189 (2020) 106694.

[17] P3 Charging Index Report 07/22 – Comparison of the fast charging capability

of various electric vehicles, https://www.p3-group.com/en/p3-charging-indexcomparison-of-the-fast-charging-capability-of-various-electric-vehicles-from-ausers-perspective_07-22. (Available [online], accessed: July 22, 2022).

[18] U. Schwiegelshohn, R. Yahyapour, Analysis of first-come-first-serve parallel job

scheduling, in: SODA, vol. 98, Citeseer, 1998, pp. 629–638.

[19] T. Balharith, F. Alhaidari, Round robin scheduling algorithm in CPU and cloud

computing: a review, in: 2019 2nd International Conference on Computer

Applications & Information Security, ICCAIS, IEEE, 2019, pp. 1–7.

[20] L. Rubino, C. Capasso, O. Veneri, Review on plug-in electric vehicle charging

architectures integrated with distributed energy sources for sustainable mobility,

Appl. Energy 207 (2017) 438–464.

[21] A. Ahmad, Z. Qin, T. Wijekoon, P. Bauer, An overview on medium voltage grid

integration of ultra-fast charging stations: Current status and future trends, IEEE

Open J. Ind. Electron. Soc. (2022).

[22] J.K. Murali, V. Chandrasekar, S. Mohan, et al., Analysis, estimation and

minimization of power loss in CCM operated PSFB converter, in: 2016 IEEE

International Conference on Power Electronics, Drives and Energy Systems,

PEDES, IEEE, 2016, pp. 1–5.

[23] D. Gravoc, M. Purschel, IGBT power losses calculation using the data-sheet

parameters, Infineon Tech. AG, Neubiberg, Germany, 2009, p. 17.

[24] Z. Emami, M. Nikpendar, N. Shafiei, S.R. Motahari, Leading and lagging legs

power loss analysis in ZVS phase-shift full bridge converter, in: 2011 2nd

Power Electronics, Drive Systems and Technologies Conference, IEEE, 2011, pp.

632–637.

[25] M. Chetto, Real-Time Systems Scheduling 1: Fundamentals, vol. 1, John Wiley

& Sons, 2014.

CRediT authorship contribution statement

Ciro Attaianese: Conceptualization, Methodology, Writing –

original draft, Writing – review & editing, Supervision. Antonio

Di Pasquale: Conceptualization, Methodology, Software, Writing

– original draft, Writing – review & editing. Pasquale Franzese:

Conceptualization, Methodology, Software, Writing – original draft.

Diego Iannuzzi: Conceptualization, Methodology, Writing – original

draft, Writing – review & editing, Supervision. Mario Pagano:

Conceptualization, Methodology, Writing – original draft, Writing

– review & editing, Supervision. Mattia Ribera: Software.

Declaration of competing interest

The authors declare that they have no known competing financial

interests or personal relationships that could have appeared to

influence the work reported in this paper.

Data availability

The data that has been used is confidential.

References

[1] H. Hõimoja, M. Vasiladiotis, S. Grioni, M. Capezzali, A. Rufer, H.B. Püttgen,

Toward ultrafast charging of electric vehicles, Tech. rep., 2012.

[2] M. Hosseinzadehtaher, D. Tiwari, N. Kouchakipour, A. Momeni, M. Lelic, Z.

Wu, Grid resilience assessment during extreme fast charging of electric vehicles via developed power hardware-in-the-loop, in: 2022 IEEE Transportation

Electrification Conference & Expo, ITEC, IEEE, 2022, pp. 929–934.

[3] L. Wang, Z. Qin, T. Slangen, P. Bauer, T. van Wijk, Grid impact of electric vehicle

fast charging stations: Trends, standards, issues and mitigation measures-an

overview, IEEE Open J. Power Electron. 2 (2021) 56–74.

[4] N. Deb, R. Singh, R.R. Brooks, K. Bai, A review of extremely fast charging stations

for electric vehicles, Energies 14 (22) (2021) 7566.

[5] S. Chang, Y. Niu, T. Jia, Coordinate scheduling of electric vehicles in charging

stations supported by microgrids, Electr. Power Syst. Res. 199 (2021) 107418.

[6] N. Chen, C.W. Tan, T.Q. Quek, Electric vehicle charging in smart grid: Optimality

and valley-filling algorithms, IEEE J. Sel. Top. Sign. Proces. 8 (6) (2014)

1073–1083.

10