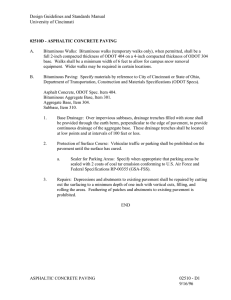

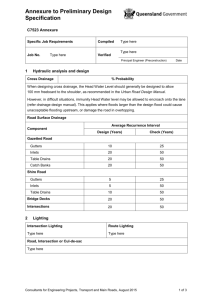

Highway Drainage – prime objective to maintain all parts of the highway in an excellent drainage condition. To prevent slip and congestion accidents Hydrologic and Hydraulic requirements – among the facets must be considered during the early phase pf the design process. Highway Alignment- and its relationship with the drainage system is the foremost concern of the hydraulic engineer • • Horizontal Alignment – where stream crossings will occur and where the traverse and longitudinal encroachments Vertical Alignment – commonly the profile on highway drainage facilities; must be asses in comparing alternate locations; determines the level of upstream flooding 1. Depressed roadways – acts as drainage interceptors; most likely to cut through existing storm drainage 2. Sag Vertical Curves – critical profile areas, serve to trap highway drainage 3. Steepness of the Highway – determines the spacing of inlets in areas of roadway with curbs Three types of Drainage Systems: 1. Surface Drainage 2. Groundwater Drainage 3. Structural Drainage Basic Design Data – planning and design of drainage facilities should always be preceded by accurate field surveys Catchment area – determine the basin boundary from a 1:50,000 mao from NAMRIA • • • • Rainfall Analysis – includes the formation of design hyetographs for hydrological analysis Rational Formula – most widely used methods for estimating peak flows for smaller catchments; Area limits: 5km^2 for urban and 20km^2 for rural. Qp = cIA/3.6 Coefficient of run off “c” – percentage to which the peak run off is reduced due to transitionary storage’ ratio of run off to rainfall Design Storm Frequency – considers estimates of the magnitude of floods based on frequency of occurrence Culvert – convey surface water across or from the highway right-of-way; carry construction and highway traffic, and earth loads. Culvert Location – horizontal and vertical alignment of the culvert with respect to both the stream and highway Deposition – the sediment transport capacity of flow within the culvert is often less than the stream. Closed Conduits – designed for the condition of flowing full Hydrologic Analysis – most important step prior to hydraulic design of a highway drainage structure • Peak Discharges – occur at the peak of the stream’s flood hydrograph • Estimation of Discharge 1. Catchment delineation 2. Design rainfall analysis 3. Choice and use of hydrological analysis techniques Planimeter Triangulation Cross-section mm paper CAD/GIS software • • Reinforced Concrete Pipes – most widely used conduits for carrying water under the roadway Box Culverts – adaptable to uses other than drainage such as underpass for vehicles, pedestrians, or animals Wing walls – where flow currents approach the inlet at an angle Headwalls – stabilize the fill slopes at culvert entrance; prevents undermining and sloughing of the bank into the stream Velocity Limits • • 0.8 m/s – minimum velocity for culverts 5 m/s – max velocity for piped drainage system Minimum Sizing • • 910mm – culverts under local roads 1m – under expressway Cover • 0.6m – of fill over the top of the pipe Shape and Cross Section • • • • • Circular – most commonly used culvert shape is circular; preferred due to available structural options for various fill heights Pipe arch and elliptical shapes – used in lieu of circular pipe where there is limited cover or overfill Box or Rectangular – designed to pass large flood and to fit nearly any site construction Arches – less obstruction to a waterway is a desirable feature and where foundations are adequate for structural support. Multiple Barrels – useful in wide channels where concentration of flow is to be kept to a minimum Outlet Scour Control – to reduce flow velocities prior to discharging to watercourses in order to avoid erosion Rock pad outlets – commonly adopted for culvert outlets. Material for Culverts: • • • • • • Concrete Iron Wood Stainless Steel Plastic Steel Culvert End Structures – are attached to reduce erosion etc Projecting – when the culvert barrel extends beyond the face of the roadway embankment Mitered- is cut to conform with the plane of the embankment slope Pipe End Sections – prefabricated metal or precast concrete sections Headwater – the total flow depth in the stream measured from the culvert inlet invert Tailwater – is the flow depth in the downstream channel measured from the invert at the culvert outlet Two major conditions of Culvert Flow: • • Flow with inlet control Flow with outlet control Highway Storm Drain system – collect, convey, and release storm water runoff. Inlets – enable storm water to be removed from the roadway area • • • • Grate inlets – commonly used inlet structures which are available in a wide variety of shapes and sizes Weir or Curb-opening Inlets – primary opening in the face of the curb. Slotted Drainage inlets – intercept sheet flow, gutter flow with or without curbs, modify existing drainage systems Combination Inlets -combination of all Head loss – energy change in momentum or turbulence in inlets Hydraulic Gradeline – last important feature; aids the designer in determining the acceptability of the proposed system. Manhole – provide access to a storm drain for inspection and maintenance Junction Chambers – used to connect two or more separate storm drains together. Ditches and Gutters Pipe Underdrains – known as French Drains, a trench loosely backfilled with graded stones . Stabilization Trenches – stabilize saturated foundation area. Pavement – portion of the road, place above the subgrade and to provide a running surface for vehicles Rigid – layers of cement concrete. two layers only; Pavement slab & Subbase Course Pavement Process – process of determining the thickness and strength of a pavement laid on a soil foundation Pavement slabs – maybe constructed without reinforcements. Designed as continuous structural elements or jointed structural elements Type of Pavement Sub-base Course – provides a stable working platform of a rigid pavement structure consists of one or more compacted layers of granular or stabilized material placed between the subgrade and the rigid slab • • • Flexible Rigid Unbound, gravel surfaces, unsealed or unpaved roads Flexible Pavements 1. Bituminous surface course 2. Base course 3. Sub-base course – surface of subgrade is the formation level Essential to know the basic limitations: • • • • • Empirical Soil support scale Soil support Value Structural Number Regional Factor Traffic analysis Bituminous Surface Course – surface course of a flexible pavement structure consists of mineral aggregates and bituminous materials Bituminous Prime Coat – a prime coat is an application of low viscosity cutback bituminous asphalt to an absorbent surface Bituminous Tack Coat – a tack coat is a very light application of bituminous asphalt. Usually with water, to bond between surface being paved and overlying course Designing new road pavements: • • • • • Traffic Subgrade support strength Water Pavement material performance Quality of construction Common materials used: • • • Portland Cement Concrete Reinforcing Steel Joint Sealing Materials 1. Liquid Sealants – asphalt, hot-poured rubber, polymers 2. Performed Elastomeric Seals – neoprene seals Development of the Rigid Pavement Design Procedure • • • • Modulus of Subgrade Reaction (K) – equation valid for only one value of modulus of subgrade reaction Westergaard’s Modulus of Subgrade reaction (k) – loads in pounds per square inch Concrete properties Modulus of Elasticity (Ec) of 29 GPa – average value for concrete Base Course – portion of flexible pavement immediately after the surface course; structural portion of the pavement Expansion Joints – prevent the development of damaging compressive stresses due to volume change Sub-base Course – portion of flexible pavement between the subgrade and base Contraction Joints – provide for an orderly arrangement of the cracking that occurs Longitudinal Joints – used to prevent the formation of irregular longitudinal cracks Load transfer Devices Tie Bars – designed to hold the faces of abutting slabs in the firm contact; withstand max. tensile force Pavement structure – layered system designed to distribute concentrated traffic loads to the sub grade Resilient Modulus – measures the stiffness and it is actually an estimate of the Modulus of Elasticity (elastic stiffness) Axle Load – portion of the total vehicle load transmitted to the road though a single axle Load equivalence Factor (LEF) – damaging effect per pass to a pavement by a type of axle to the damage per pass of a standard axle Design Reliability (R) – the probability that a pavement section using the process will perform satisfactory over the traffic and environmental conditions for the design period Serviceability – defined as the ability to serve high-speed, high-volume automobile and truck traffic. Load Transfer Coefficient – factor used in rigid pavement design to account for the ability of a concrete pavement structure to transfer load Jointed Pavements (J) – recommended for a plain jointed pavement or jointed reinforced concrete pavement with some type of load transfer Stabilized Subgrade – improve the performance of plain and reinforced jointed pavements