UNIVERSITY OF SCIENCE AND TECHNOLOGY OF HANOI

DEPARTMENT OF AERONAUTICS

FINAL REPORT AUTOMATISM

AUTOMATIC SANITIZER DISPENSER

By Group 4

Nguyễn Hoàng Bách - BI12-041

Nguyễn Duy Hiển - BI12-155

Nguyễn Quang Huy - BI12-199

Phạm Tam Phong – BI12-348

Nguyễn Huy Trường Sinh - BI12-383

Hanoi, December 2022

1

TABLE OF CONTENTS

LIST OF ABBREVIATIONS .........................................................................3

LIST OF TABLES ...........................................................................................4

LIST OF FIGURES .........................................................................................5

SUMMARY/ABSTRACT ...............................................................................6

I. INTRODUCTION ........................................................................................7

II. SYSTEM DESCRIPTION .........................................................................8

III. SYSTEM DESIGN - HARDWARE ........................................................9

IV. SYSTEM DESIGN - SOFTWARE ........................................................18

V. RESULTS...................................................................................................20

VI. CONCLUSION ........................................................................................21

REFERENCES ...............................................................................................22

APPENDICES ................................................................................................23

2

LIST OF ABBREVIATIONS

˚C

Degree Celsius

A

Ampere

AC

Alternating current

DC

Direct current

EEPROM Electrically Erasable Programmable Read-Only

Memory

GND

Ground

Hz

Hertz

ICSB

Liquid-crystal display

LCD

In Circuit Serial Programming

LED

Light-emitting diode

I/O

Input/Output

SMD

Surface-mount device

SRAM

Static random access memory

TTL

Transistor-Transistor Logic

USTH

University of Science and Technology of Hanoi

USB

Universal serial bus

V

Volt

VND

Viet Nam Dong

3

LIST OF TABLES

Table: Component prices ………………….…………………………………………......24

4

LIST OF FIGURES

Figure 3.1 : Arduino UNO R3 board……………………………………........................09

Figure 3.2: UltraSonic HY-SRF05 sensor……………………………….........................10

Figure 3.3: Module Controller Relay 12VDC…………………………….......................13

Figure 3.4: Water pump………………………………………………….........................14

Figure 3.5.1: Battery 1…………………………………………………….......................14

Figure 3.5.2: Battery 2…………………………………………………….......................15

Figure 3.5.3: Battery 3…………………………………………………….......................15

Figure 3.6: Plastic tube.......................................................................................................15

Figure 3.7: One-way valve ................................................................................................16

Figure 3.8: Electrical plastic box.....................................................................................16

Figure 3.9: Wires ...............................................................................................................17

Figure 3.10: Battery base wire ...........................................................................................17

5

SUMMARY/ABSTRACT

This report presents the work of group 4: This device is an automatic sanitizer

dispenser which dispenses a specific amount of sanitizer on to your hand when

placed under the ultrasonic sensor. The Arduino UNO board controls the pump based

on the distance obtained from the ultrasonic sensor. Other components include 9V

and 12V batteries, one Relay control module, a plastic tube, one way valve, a pump,

test board wires, battery base wire, and a USB connector. After some modifications,

our group would like to present a very practical device that can be used in the

pandemic by eliminating the need of touching a public sanitizer bottle. Some

improvements in the future can also be made for a more compact design, longer

battery life, and enhanced user’s overall experience.

4 Keywords: Automatic sanitizer dispenser, ultrasonic sensor, pump, covid

6

I. INTRODUCTION

- In the world today, disease, bacteria and virus are developing very fast, become

more dangerous, hard to cure and have been spread all over the very fast. This could

lead to death for people who infected with them. The best way to prevent it that

people should not contact to each other and wash hands regularly. But when we wash

our hands, we must touch the tab and the bacteria can run from people to people.

Therefore, our product is the solution for it. Just put the hand under water tab, you

can wash your hand automatically.

- The report contains 5 parts: Introduction, System Description, Hardware, Software

and Conclusion.

7

II. SYSTEM DESCRIPTION

- Goal of the device: Put your hand under the tube and the sanitizer automatically

come out.

- Block diagram:

8

III. SYSTEM DESIGN - HARDWARE

3.1. Controller kit

- We use Arduino UNO R3, which use microcontroller of 8bit ATmega328 to

control the system. It’s a controller board based on ATmega328 with 14

digital input/output pins, 6 analog inputs, a 16 MHz crystal oscillator, a USB

connection, a power jack, an ICSP header, and a reset button.

- This brain can handle simple tasks such as controlling flashing LED lights,

processing signals for remote control cars, making a temperature-humidity

measurement station and displaying it on an LCD screen, etc.

Figure 3.1: Arduino UNO R3 board

- Specifications:

Microcontroller

Operating Voltage

Current Consumption

Input Voltage (recommended)

Input Voltage (limits)

Digital I/O Pins

Analog Input Pins

ATmega328

5V DC (only be supplied by the USB)

About 30mA

7 – 12V DC

6 – 20V DC

14

6

9

DC Current per I/O Pin

DC Current for 3.3V Pin

DC Current for 5V Pin

Flash Memory

SRAM

EEPROM

Clock Speed

30mA

50mA

500 mA

32 KB (ATmega328 of which 0.5 KB used

by bootloader

2 KB (ATmega328)

1 KB (ATmega328)

16MHZ

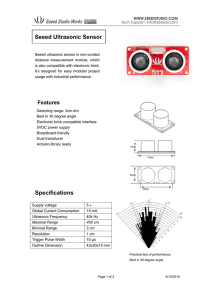

3.2. UltraSonic HY-SRF05 sensor

- UltraSonic ultrasonic sensor HY-SRF05 is used to sense the distance from the

object to the sensor by the ultrasonic waves

- The sensor has fast response time, high accuracy, suitable for object detection

applications. barrier, measuring distance by ultrasonic wave.

Figure 3.2: UltraSonic HY-SRF05 sensor

- Specifications:

COMPONENTS

Operating voltage

Consumption

current

Communication

signal

Signal pins

VALUES

5V

10 – 40 mA

TTL

Echo, Trigger, Out

10

Scan angle

15 degrees

Broadcast

40KHz

frequency

Measured distance 2 – 450 cm

Tolerance

Dimensions

0.3 cm

43mm x 20mm x

17mm

- The ultrasonic sensor SRF05 has 5 pins (Different from the ultrasonic sensor

srf04 has only 4 pins), including:

+ VCC power supply pin: 5V

+ Trigger: The pin activates the ultrasonic wave. In mode 2, the Trigger pin

has both the function of activating the ultrasonic wave and the function of

receiving the signal when the module receives the ultrasonic wave.

+ Echo pin: Used to detect echo sound waves.

+ Out pin: Mode selects pin.

+ GND pin: 0V power supply.

Working principle: 2 modes

- Mode 1: Use Trigger pin to trigger ultrasonic broadcast and Echo pin to receive

feedback signal. In this mode, the Trigger and Echo pins are used

independently of each other. To use this mode, the Out pin is open circuit (not

connected). The pulse diagram of the sensor pins in mode 1 is as follows:

11

- To enable the SRF05 sensor to emit ultrasonic waves, it is necessary to

generate a pulse with a minimum 1 level width of 10 μs on the Trigger pin.

Then the ultrasonic sensor SRF05 will generate 8 pulses to emit ultrasonic

waves. After the ultrasonic wave is emitted, the Echo pin is immediately pulled

high. If the ultrasonic wave encounters an obstacle and reflects to the

ultrasonic sensor, the Echo pin will be brought down to 0. If the measured

pulse width is greater than 30ms, it means there is no obstacle, or the obstacle

is out of range of module permission.

Mode 2: Use 1 Trigger pin to trigger ultrasonic wave and receive feedback

signal. In this mode, only 1 Trigger pin is used simultaneously for 2 functions

of triggering ultrasonic wave and receiving feedback signal. To use this mode,

it is necessary to connect the Out pin to 0V. The pulse pattern of the sensor

pins in mode 2 is as follows.

Similar to mode 1, to enable ultrasonic, it is necessary to generate pulses with

a width of at least 10μs on the Trigger pin, then the ultrasonic sensor will

generate 8 pulses to emit ultrasonic waves. After the ultrasonic wave is

transmitted, the Trigger pin is pulled to level 1, within a period of 100us-25ms,

if there is an echo, the Trigger pin will be brought down to 0. If the measured

pulse width is larger than 30ms, it means that there is no obstruction, or the

obstacle is outside the allowed range of the module.

3.3 Module Controller Relay 12VDC (Actuator)

12

- We use Module Controller Relay 12VDC to receive the signal from Arduino

UNO R3 to control the sanitizer dispenser

- The Module Controller Relay receive the signal from the UltraSonic HYSRF05 sensor to automatically turn on/off the sanitizer dispenser.

Figure 3.3: Module Controller Relay 12VDC

Specifications

- Size: 50mmx25mm

- Voltage used: 12VDC

- Default signal from microcontroller Using Diode 1N4007 SMD anti-reverse

- Using 78L05 voltage regulator IC

- The maximum amperage through the relay contacts with voltage <= 250V

(AC) is 10A.

- The maximum amperage through the relay contacts with voltage <= 30V (AC)

is 15A.

- The maximum amperage through the relay contacts with voltage <= 250V

(AC) is 10A.

3.4. Water pump

13

Figure 3.4. Water pump

- The water pump is made of high quality material, smooth rotation, low noise and

long lifespan. The water pump is widely used for tea machine, water cooling, fish

tank, and other fields. The pump body is sealed to prevent incidental moisture and

dust from entering.

- Specification:

Working voltage: 12V

Working current: 0.5 – 0.7A

Flow: 1.5 – 2 L/min

Maximum suction range: 2m

Life: 2500 hours maximum

Water temperature: 80˚C

Weight: 110g

Size:10x6x3.5cm

3.5. Batteries

- 9V battery (Quantity: 2)

Figure 3.5.1

- 12V battery (Quantity: 1)

14

Figure 3.5.2

- 12V battery (Quantity: 1)

Figure 3.5.3

3.6. Plastic tube

Figure 3.6

3.7. One-way valve

15

Figure 3.7

3.8. Electrical plastic box (83x58x33cm)

Figure 3.8

3.9. Wires

16

Figure 3.9

3.10. Battery base wire

Figure 3.10

17

IV. SYSTEM DESIGN – SOFTWARE

The general idea of the code is that: We calculate the distance between the

user’s hand and the ultrasonic sensor, compare that to our desired value and decide

whether the sanitizer will be pumped or not.

During the coding phase, our group encountered a problem where the sensor

would lag for a second if no ping echo is received. We thought it was the sensor’s

fault but it turned out perfectly fine when we found the NewPing library for Arduino.

First, we include the library:

#include <NewPing.h>;

We have the contructor:

NewPing sonar(3,2,10);

where 3 is the trigger pin, 2 is the echo pin, and 10 is the max distance in cm.

Next we define relay is connected to pin 4:

int relay=4;

Then, we have void setup(), where we put our setup code to run once, and void

loop(), where we put our main code to run repeatedly

In the void setup, we want to get the value from the sensor, we use the

command

Serial.begin(9600);

to turn on the communication between Arduino and the computer through the

USB cable with the value 9600 is the communication speed between the two

After that, we use

pinMode(relay,OUTPUT);

to decide that the relay is the OUTPUT with 100ms delay by the command

delay(100);

18

In the void loop, we use if else argument along with sonar.ping_cm()

command that sends a ping and get the distance in whole centimeters.

if(sonar.ping_cm()!=0)

If the distance is greater than 0, we will turn on relay and wait 0.5ms:

digitalWrite( relay,HIGH);

Serial.println("HIGH");

delay(500);

and turn off off the relay and wait 5s;

digitalWrite(relay, Low);

delay(5000);

On the other hand, if the distance is 0 or too far (which the value returns 0),

we set the relay off

else if(sonar.ping_cm()==0){

digitalWrite(relay,L0W);

Serial.println("LOW");

}

The command above:

Serial.println()

will print out “HIGH” or “LOW” in the serial monitor in a column for better

visualization than in rows

19

V. RESULTS

First, we fill up the tank with water

Second, we connect the wire to run the system. When we put our hand in front of

the sensor, the sensor will transfer the signal back to the Ardunio UNO. It will

control the pump to release the water from the water tank. Then the Module

controller Relay receive the signal from the Ardunio to control the device.

Finally, the water release from the plastic tube

20

VI. CONCLUSION

1. Achievements

- When put the hand under the sensor, the water automatically come out

- Able to wash the hand without touching the product.

2. Limitation

- Must replace the water in the water tank by hand

- The water tank only enables to contains 500ml of water

- Low longevity life

- Low water pressure

- Have to change the battery

3. Future development

- Improve higher capacity for the water tank

- Increase the water pressure

- Increase battery life

21

REFERENCES

https://chotroihn.vn/module-dieu-khien-relay-12vdc-bang-cam-bien-cham

https://hshop.vn/products/cam-bien-sieu-am-srf05

http://arduino.vn/bai-viet/42-arduino-uno-r3-la-gi

https://chotroihn.vn/day-cam-test-board-21cm-day-duc-duc-day-duc-cai-day-caicai-day-noi-7-mau-20cm

https://www.elprocus.com/what-is-arduino-uno-r3-pin-diagram-specification-andapplications/

https://chotroihn.vn/cam-bien-sieu-am-sfr05

https://www.arduino.cc/reference/en/libraries/newping/

22

APPENDICES

APPENDIX 1: CONTRIBUTION OF TEAM MEMBER

1. Nguyễn Hoàng Bách: Buy components, design the product, assembling, coding

Arduino

2. Nguyễn Quang Huy: Buy components, assembling, making PowerPoint

3. Nguyễn Duy Hiển : Buy components, write the report, find the information of

the components, print the report

4. Phạm Tam Phong : Buy components, write the report, find the information of the

components, coding Arduino

5. Nguyễn Huy Trường Sinh : Buy components, assembling

23

APPENDIX 2: BILL OF MATERIALS

Item

Price(VND)

Ultrasonic Sensor Module SRF 05

39,000

Arduino UNO R3

200,000

Module controller relay 12VDC

25,000

Mini Pump RS385

48,000

Plastic tube

5,000

Plastic box

32,000

wire

7,000

Battery 9V

5,900

Battery 12V

9,900

Battery base wire

2,000

TOTAL

373,800

24

APPENDIX 3: SOFTWARE CODE

#include <NewPing.h>;

NewPing sonar(3,2,10);

int relay=4;

void setup() {

Serial.begin(9600);

pinMode(relay,OUTPUT);

delay(100);

}

void loop() {

if(sonar.ping_cm()!=0){

digitalWrite( relay,HIGH);

Serial.println("HIGH");

delay(500);

digitalWrite(relay, Low);

delay(5000);

}

else if(sonar.ping_cm()==0){

digitalWrite(relay,L0W);

Serial.println("LOW");

}

}

25

26