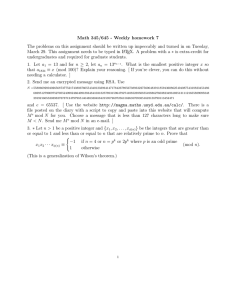

Rochester Institute of Technology

RIT Scholar Works

Theses

8-1-1994

Comparing the ability of subjective quality factor and information

theory to predict image quality

Shyi-Shyang Li

Follow this and additional works at: https://scholarworks.rit.edu/theses

Recommended Citation

Li, Shyi-Shyang, "Comparing the ability of subjective quality factor and information theory to predict image

quality" (1994). Thesis. Rochester Institute of Technology. Accessed from

This Thesis is brought to you for free and open access by RIT Scholar Works. It has been accepted for inclusion in

Theses by an authorized administrator of RIT Scholar Works. For more information, please contact

ritscholarworks@rit.edu.

Comparing the ability of Subj ective Quality Factor and Information

Theory to predict Image quality.

By

Shyi - Shyang Li

B.S. Chinese Culture University

( 1982)

A thesis submitted in partial fulfillment

of the requirements for the degree of

Master of Science in the

Center for Imaging Science in the

College of Imaging Arts and Sciences of the

Rochester Institute of Technology

August, 1994

Signature of Author: _S~h_y_i-S_h_y_a_n_g_L_i

Accepted by:

Dana G. Marsh

_

>

~

Coordinator, M.S. Degree P gram

/

~ Ifff

.

COLLEGE OF IMAGING ARTS AND SCIENCES

ROCHESTER INSTITUTE OF TECHNOLOGY

ROCHESTER, NEW YORK

CERTIFICATE OF APPROVAL

M.S. DEGREE TIIESIS

The M.S. Degree Thesis of Shyi-Shyang Li

has been examined and approved

by the thesis committee as satisfactory

for the thesis requirement for the

Master of Science Degree

Dr. E. M. Granger Thesis Advisor

Dr. Dana G. Marsh

Mr. Joseph Altman

r

~/97'jI

Date

THESIS RELEASE PERMISSION FORM

ROCHESTER INSTITUTE OF TECHNOLOGY

COLLEGE OF IMAGING ARTS and SCIENCES

Comparing the ability of Subjective Quality Factor and Information

Theory to predict Image quality.

I, Shyi - Shyang (Robert) Li., hereby grant permission to the Wallace

Memorial Library of the Rochester Institute of Technology to reproduce

my thesis in whole to in part. Any reproduction will not be for commercial

use or profit.

Signature:

Date:

_=--

_----l....

_

_

ill

"

Comparing the ability of Subjective Quality Factor and

to predict Image

Information

Quality."

By

Shyi-Shyang Li

Submitted to the Center for

in

partial

fulfillment

for the Master

of

Imaging Science

of the requirements

Science Degree

Rochester Institute

of

at the

Technology

Theory

ABSTRACT

The

Information

methods of

the

is to

purpose of this project

Theory

This study

to predict image quality

exposing film. One

other allows

compare the

the flux to

exposure

ability

as a

of

the

function

holds the total

Subjective

of

film

Quality

speed

Factor

and

for two different

number of photons constant and

vary.

will:

1 Determine the relationship between

.

when

the resulting images are reproduced at the

2. Compare the resulting granularity

with

film

grain size and

the normal exposure method

and

image quality for

of the constant

flux

condition

the shutter speed as a function of

speed.

3. Compare the ability

accurately

predict

of

Subject

Quality Factor and

resulting image

quality.

flux

same size.

image quality

of varying

constant

Information

Theory to

ACKNOWLEDGMENTS

This

paper would not

have been

possible without the support of a

number

of people.

First,

to

insight

periods.

Dr. Edward M. Granger

and

guidance

Dr. Granger

Special thanks

served as

A

are

Thanks for

special

word

Thoughout the

on

principal advisor.

my thesis

I

must also thank

committee member as well as

Dana G. Marsh for the continuing

through the highs and lows that went with this

extended

being

of

long

the

ongoing technical

through the difficult

support.

support and encouragement

project.

the

provided

that allowed me to proceed

Mr. Joseph Altman for serving

providing technical

who

to Dr.

understanding.

thanks

is

owed

to

my

loving

period of this project she stood

wife,

steadfastly

Liang-Jen.

by

me.

The

many hours and days she willingly gave for me to complete this project.

Her unwavering patience made this struggle an enjoyable journey and I

will

forever be indebted.

Finally, I like

to

present

this

work

to

my parent, they

provided

and emotional support made the completion of this work possible.

VI

financial

TABLE OF CONTENTS

CERTIFICATE OF APPROVAL

ii

COPYRIGHT RELEASE

iii

ABSTRACT

v

TABLE OF CONTENTS

vii

LIST OF FIGURES

ix

LIST OF TABLES

x

I. Introduction

1 1

-

.

1

Granularity and Image Quality

l-2.Subjective

1

Quality Factor (SQF)

1-3. Information

4

Theory (I. T.)

7

1-3-1 General Information

1-3-2 Photographic Applications

1-3-3 Photographic Applications

7

:

Discrete Signals

8

Continuous Signals

11

15

n. Methods

2-1 Photograph

2-2

15

preparation

determining exposure condition

2-1-1

Setting up

2-1-2

Developing film

Evaluating image

and

and photographic paper

quality

2-2-1 Instructions to

33

2-2-2 Results from evaluating image quality

Calculating MTF

2-4

Determining granularity

29

32

of photographs

observers

2-3

15

of photograph

34

36

of photographs

38

Vll

TABLE OF CONTENTS (CONT.)

2-5

Calculating

of photographs

39

2-6

Calculating Information Capacity of photographs

40

SQF

III. Results

3-1 MTF

3-2

41

Granularity analysis

3-3 SQF

V

46

47

of photographs

3-4 Information

IV

41

of photographs

Capacity of Photographs

49

Discussion

51

4-1

Comparing the

4-2

Comparing the results

results

base

on

on

SQF

and

T-MAX-400

References

Information

and

Theory

51

TRI-X 400 films

54

56

VI. Appendices

58

Vlll

LIST OF FIGURES

FIGURE 1

Subjective

FIGURE 2

A typical

FIGURE 3

MTF

of T-MAX

1 00 film

w/

25

mm

lens

38

FIGURE 4

MTF

of T-MAX

1 00 film

w/

25

mm

lens

42

FIGURE 5

MTF

of T-MAX

400 film

w/

25

mm

lens

42

FIGURE 6

MTF

of T-MAX

3200 film

FIGURE 7

MTF

of TRI-X

400 film

w/

25

mm

lens

43

FIGURE 8

MTF

of TRI-X

400 film

w/

55

mm

lens

44

FIGURE 9

MTF

of T-MAX

400 film

FIGURE 10

MTF

of T-MAX

3200 film

FIGURE 11

SQF

FIGURE 12

Information

Theory and

FIGURE 13

Comparison

of

2

Quality Loss Vs Granularity

visual system

5

MTF

w/

w/

25

50

w/

mm

mm

135

lens

43

lens

mm

44

lens

45

48

results

SQF ranking

Granularity by using I.

IX

prediction

T.

and

SQF

51

53

LIST OF TABLES

TABLE 1

List

TABLE 2

Information

TABLE 3

Conditions

TABLE 4

Statistic data for

"Grey

TABLE 5

Statistic data for

"Egg"

35

TABLE 6

Statistic data for

"Flower"

36

TABLE 7

Granularity results

46

TABLE 8

Calculated

47

TABLE 9

SQF

TABLE 10

Results

TABLE 1 1

Information

TABLE 12

Results

TABLE 13

Summary

of

data

10

capacities of four

used

for this

films

project

Card"

14

30

35

Granularity results

47

results

of prediction

by using

SQF

Theory results

of prediction

by using Information Theory

of the results

48

49

50

52

I.

1

.

INTRODUCTION

Granularity and Image Quality

When

an emulsion

is uniformly illuminated

fluctuations due to the

This is known

unpredictable

negative.

as

random

distribution

photographic

of great

defined

and

determines the

density

and

statistical characteristic of

distribution

distribution

scanning,

of

with a

the

aperture

It is

that

in

blackening

each

a

of

in the microdensitometer, the

emulsion, and the type

image quality

will

be degraded

in image quality

study \Lisson,\ 983], the loss

variance of the noise

of emulsion

depends

and

(rms granularity),

It is

expressed

measured

in

the

of

sets a

)

is

limit

are

a well

negative,

is

on

[fT/.se/-,1986]

found to be linear

by

measured

a

have been

function

of

of

the

.

increases. In

density units and

the size

distribution

density

as the grain noise

was

small,

a measure of the random

image,

The granularity

a

exposed

the photosensitive material that

density.

emulsion.

area

fluctuation

uniformly

is

density

density fluctuations

density

Granularity

in the

small

science, because it

imaging

distribution in

photographic grain

a uniform

used

photographic

obvious

grain

in the

is to introduce

effect

root mean square

microdensitometer, areas

developed to

developed

by

silver particles

the grains in the developed photosensitive material.

exposed and

circular

the

(

the negative shows

Although the individual

photographic noise-level.

created

The

importance in

mean magnitude

developed,

developed

photographic

to the quality of photographic images.

unpredictable, their

of

granularity.

uncertainty into the

This uncertainty is

and then

a recent

with respect

shown

to the

in Figure(l).

Figure 1 Subjective

Quality Loss vs. Granularity

^r

o

z

->

m

O

_i

2-

3

a

m

>

3

tn

o

RMS

In this project,

optical system.

constant

for

means

samples will

be

be

pupil

from

printed

a given area on

the original object.

speed, the lens focal length

Since the final

and

prints made

the

to

obtain equal print size.

will pass

As

image

through

a

a result of this

size

increase in

from different films

to the same size, the system MTF and

magnification required

flux in the

exposed under constant photon

that in a given amount of time, N photons

to the film speed.

speeds will

by the

film

a constant shutter

proportion

different

scaled

This

diameter lens

restriction

direct

some of the

Granularity

granularity

with

will

be

The

following

diagram

provides

information

about

the relationship

of

the

object

lens to

the different size images that result due to film speed.

25

mm

lens

F#:4

Slow speed film

50

mm

lens

F*:8

135

mm

lens

F#:22

Fast

speed

film

As

shown

in the

the

image

generated.

diagram,

the same size print

as

with

The

the constant flux condition, the faster the

negative must

Quality Factor (

A

difference in image quality

SQF

phenomenon of just noticeable

change

in the

judging

weight and

Granger

to make the

slower

film

generate

)

loudness

[Granger, 1972]

can

difference

has been

stimulus

to a logarithmic spatial

be

(JND) being

for many

observed

follow

of sounds

by changing

obtained

what

is known

by 7-10%.

This

to a constant percentage

related

neural

SQF

processes.

as

Tasks

Weber's Law.

such

as

This led

to hypothesize that image quality might in some way be related

frequency

(OTF). If so, image quality

spatial

magnified

the bigger

the fast film.

2. Subjective

perceptible

be

film,

weighting

of

the

system

Optical Transfer Function

might correlate with the area under the system

OTF

on a

log

frequency scale.

The Subjective

Quality

result of a search

directly measured

for

in

Factor

(

SQF

an objective

)

was

figure

developed

by

Granger

of merit which could

and

be easily

Cupery,

as

the

calculated and

practice and which would correlate with subjective rank regardless of

Modulation Transfer Function

(MTF) form.

A

number of experiments were performed

to

test the quality factor for a wide variety of MTF shapes. The results of the experimental

program were

was

0.988

that SQF

was able

correlated with

the

to predict

measured

data

image quality

within normal reader error and

[Z,/55o,1983]

.

The quality

of a visual

visual system

typical

has

an

visual system

image is

MTF

related to the scale of the

which peaks

MTF is

in the

shown plotted

Figure 2. Atypical

Spatial

postulating

stimulate

Based

on

system

this

effect

which

MTF( including

scaled

includes the

the retina. A

2.

MTF

100.0

Cycles/Degree

nature

for the eye, the limits

of

integration to

have been defined.

these observations, a

MTF has been

-

the retina. The human

cycles/mm at

10.0

Frequency

arbitrary bandpass

an

10-20

on

log frequency in Figure

visual system

1.0

0.1

By

Vs

region of

image

eye.

lenses

to the

one-dimensional

and

films)

retina of

SQF

was

between the limits

the observer

by

defined

of

as the

10-40

integral

of

the

cycles/mm when

the

the magnification of the system,

40

SQF

=

k\\T(f)\d(\ogf)

(1)

10

r(f) is the Optical Transfer Function.

/ is the

\/k is

spatial

a

normalizing

integration to

There is

no

Because

real

by equating the above

=1.

images involve

system.

weighting information

by describing

constant obtained

to limit the considerations to

reason

factored into the

MTF

frequency.

a

That

over all

the

two-dimensional

system

is,

MTF,

the impression

directions. The SQF

MTF in

one-dimensional

a

two dimensional MTF must be

quality is

of

MTF descriptions.

value can

polar coordinates and

obtained

by

for

a general

performing the

following

be

obtained

integration:

402*

SQF

=

kj\\r(f, ep{loS f)W

(2)

10 0

Where:

/ is the

spatial

frequency in

cycles

/

mm

along

of line structure.

it is the

appropriate

normalizing

constant.

402*

A

=

JJ<5(log/)<a?

10 0

(3)

equally

a given azimuth

9

The

above

the limits

It is

formula

of the

is

not

magnification.

when

Image Sharpness Scale

characteristic

assessment

allows a simple calculation of the

the

of

(ISS) [Granger, 1972]

system

and

of

subjective

intrinsic to the image itself but only

Therefore, it is important

calculating the SQF

3 Information

SQF

quality

of a print which

within

a

quality

range.

quality

evaluation, that

image

to the

lies

as viewed at a specified

that the proper system magnification be specified

of a system.

Theory

3-1 General Information

The theorems

the

within

general

Shannon in 1948. These theorems

communication

communication

channels

system,

field

were

of

information theory

developed

largely

but they may be readily

such

are

within

based

by

the context of electrical

to

adapted

on research

any

other

as the optical transmission or photographic

type

of

recording

of

information.

It is

estimated

per year and

that the total

that this

amount of printed

figure doubles

information

about each

decade. In

future large-scale information-handling problems, the

approach as provided

by information theory is

alone

need

self-evident.

is in

1016

excess of

view of

for

a

bits

these present and

fundamental

analytical

In

is

photographic applications the photographic process

it is important to

and

achieve the

incoming

structure of

the

how to best

present the signal to

be desirable to

in the

photographic

system

noise.

is

When

a

specified

photographically

the

known,

well

are

This

determined

rate.

question

element.

type

the

of

and

signal

(for example,

highest information

M

=

N

close

result, it may

frequencies

spatial

and

spectrum of

relationship between

binary form)

storage per unit

may

log2

KG2

M

+

Altman

in the image using

[Z,ev7,1958]

.

(4)

1

is to be

(5)

stored

area, simplified models

prove adequate.

:

-^r

2

in

on a unit storage cell

in the form

=

a

Discrete Signal

according to Levi

C

As

one of

[Da int y&Shaw,l 974].

DQE

for the influence

written

statistical

becomes

the system MTF and the Wiener

based

of noise

The

medium

highest information capacity

demonstrates the very

approach

application :

by

gave a method of analysis

be

the

the photographic recording

photographic process as a storage medium

unit area can

and

element which yield the

recording

with

highest information recording

fairly

information capacity, recording rate,

3-2 Photographic

the recording

the Wiener spectrum of incoming signals to the

These frequencies

rate.

the

match

signal

used as

and

of

Zweig

a simple model

The information capacity

per

where: c

is

a constant.

C is the information capacity

M is the

The

for

parameter

number of cells

R is the

density range (D^

A is the

cell size.

R may be

a specified separation

written as equation

A~'

be

assumed to

criterion,

constant

only A

K,

for

levels

are

of equation

for

capacity.

a series of Kodak

(5)

can

be

be

as

(6):

(6)

films

A

I

cA2

(6)

+1

that C increases as A

information

we conclude

This

[^]log2

=

reveals

maximum

necessary, so

information

a given photographic process and so

remains as a variable and equation

(

small as possible

D^J

-

=

C

Investigation

levels

number of recording

N is the

N

of the channel

conclusion

is

confirmed

which are summarized

However,

capacity.

that, in principle,

decreases,

binary

by the

in Table I.

at

so

A

should

least two recording

recording

will give optimum

results of Altman and

Zweig

for

TABLE I

Spread

Available

function

levels

Bit capacity for an image

of

0 x 10

area

diameter

fjm

logf

M

Kodak Fine Grain

M-level

Binary Experimei

8

3

0.33

0.11

12.5

6

2.6

1.6

0.64

1.1

15

4

2

0.88

0.44

1.1

3

1.6

0.33

0.21

15

3

1.6

0.7

0.44

0.5

27

2

1

0.14

0.14

0.05

1

2

1

160

160

160

Altaian

and

Cine Positive

Recordak Fine

Grain Type 5454

Recordak Fine

Grain Type 7456

Kodak

plus-X

Kodak Pan-X

lodak Royal-X Pan

Kodak High

Resolution Type

649

An

analysis

of

binary

and

[Altman& Zweig,\ 963] concludes

rather

in M

than

gives

binary recording is not

only

a

multilevel

that the gain in

substantial.

cell size or spread

function

10

information capacity

It follows from

logarithmic increase in capacity,

important factor. The

by

recording

and

equation

therefore

having a

by using

Zweig

multilevel

(4) that an increase

small cell size

storage area

is the

most

of\fjmx\/jm,

as

opposed to

100/imx

100/xw,

messages and codes are

coding

be

For

advantage over

increase in capacity

104

Where

of

binary

commonplace, recording levels higher than two may involve

difficulties,

complications and

well separated.

would give an

especially in

view of

the fact that the levels have to

these reasons multilevel recording may

all

offer

little

practical

binary.

3-3 Photographic Application: Continuous Signal

It is important to know that the

continuous approach will not

they may

allows

or

the information capacity to

apparent.

For

photographic

an

same as

types of information

turn the close relationship

for

be the

using

applications

of the

signal, this

be

input. The

expressed as a

in

scientific

spatial

must

photography

frequency

approach

continuous channel with average mean-square

photographic

process

fog density

is

more

and

photographic process and

great

nearly

Dmax. A

function

the wide

a peak-limited

variation of

operating limits.

11

and

practice

concern

frequency,

systems,

is that

and

including

highest information

as the result

Gaussian

channel,

with

noise.

in

its operating

over

the

rate

for the

In fact the

due to the non-linearity

imaging properties

a

DQE then become

and

is usually taken

arises

its

rate

they

using

of this approach

of spatial

achieve the

limitation

difficulty

benefit

where overall

be designed to

when

discrete approach, but in

between information transfer

recording element,

incoming

between

for information capacity

turn out to be quite close. The results are different because

different questions,

it

results obtained

region

of

the range

the

of its

According

to

Dainty [Da int y& Shaw, 197 4]

continuous channel with an average

C

If the

B,

=

P

Af log2

+

C

If we

use

noise

WN(f)

the

1/2

=

limitation is

:

N

(7)

N

signal and noise power are

each of width

"power"

the result for the information capacity of a

f,

then the

approximately

constant over two adjacent regions

capacity for the total band

|A/(log2(l+

power spectrum of

P/N)

+log,(l +

the signal,

width approximates

%J)

WN (/) for

P

and

A

and

to :

(8)

the power spectrum of the

for N, then

f

flog2

Since

de

signal and noise are

two dimensional functions of space, for photographic

77

Since the

assumed

(

statistical properties of

to be

isotropic,

(9)

wN{f\

V

Ws(u,v)

the

and since

dudv

photographic

for

optimum

12

process,

coding the

images

(10)

including

image noise, may be

signal will also

have the

nature

isotropic

of an

spatial

pattern, it is

noise

frequency,

w2

w,

where

convenient to work

u2

v2

+

=

,

in terms

(H)

wdw

If we

assume that a natural scene

C

r

x

=

since

Equation

(11)

Ws(w)

constant over a

as

an attempt

to

constrained

theorem

for

2/,..\A

( 1+ MTF2(w)

\>

d>v

limited

calculate

between

the

(12)

w

evaluating the information capacity

of

input/output,

restrict

it to

maximum

fog density

ratio

in terms

exposure/density

Dmax, Jones

of

the

of power spectra will

range.

To

keep

equation

is

peak-limited.

13

the photographic process

[./owes, 1961]

then made various ad

photographic process

of

small signals condition.

information capacity

and

a power-limited channel and

for the fact that the

to 1/w then

MTF2(w)

Due to non-linearity the S/N

(1 1) "exact", it is necessary to

In

a power spectrum proportional

illustrates the dilemma

photographic process.

only be

\og2

has

the one-dimensional

leading to

WN{w\

V

o

of

By

hoc

usi

used

Shannon's

corrections to account

for the

of

information

respective

interest,

are summarized

Table II. Information

estimated

Film

capacities.

His results, along

with other comparative values

in Table II.

capacities of four

films,

and various comparative

values,

as

by Jones.

Information

Area for 1

Information

capacity

bit

rate

Comparative

Exposure

for

one

bit

Film

time for Hi-Fi

area

equiv.

system

one

to

TV

frame

bits

2

fjm2

cm

bits erg

(xia-)

'

photons

K")

(x,0-)

sec cm

2

em2/

/frame

R.oyal-X

0.449

200

26.5

8.18

3.01

2.98

Tri-X

0.845

118.4

7.35

29.4

5.1

1.76

Plus-X

1.86

53.8

6.45

33.6

11.2

0.8

Pan-X

2.85

35.0

7.45

29.2

17.2

0.52

Although

manufacturers of

image quality is

given.

film

provide a speed

While the

speed

insufficient

ordinary photographer, it is

the

We have defined Information

capacity

of a

film to

Theory

receive and store

each

rating is usually

when

greatest possible amount of information

rating for

choosing

has to be

a

14

usually

satisfactory

film for

recorded

and we will use

information.

a

film,

no

rating

guide

of

for the

scientific purposes where

by the film.

this powerful tool to obtain the

n

The

experimental

2. 1 Photograph

2.1.1

setup

and

Four films

were used

T-MAX 3200

all

and

four films. It

following steps:

in the study, they

Kodak T-MAX

"older"

an

are:

medium

be

would

grain,

and

interesting to

T-MAX 3200 has the largest

know how they

we

professional

films

product of Eastman

actually take

combination and also

illustrate the

variables

IM

grain of

perform under normal

flux.

are newer

Kodak

a picture of the

the

shutter speed.

needing to be

15

so

and

it is

TRI-X 400 is

interesting to find if

products.

object,

The

we must select

the lens and film

following equations

controlled

(13)

LS

products,

Company,

is any difference between these two

Before

100, T-MAX 400,

T-MAX

TRI-X 400. T-MAX 100 has the finest grain, T-MAX 400

exposure and constant

(F-y

the

determining exposure time.

TRI-X 400 have

there

on

preparation:

Setting up

and

is based

process

METHODS

in the

experiment.

are used

to

t : shutter speed

L

luminance in

S

film

:

cm2

cdls/

speed

F#

: numerical aperture

F#=f

where

I D

(14)

f : lens focal length

D

When the

:

lens diameter

shutter speed and

relationship

can

be

the total flux are constant, the

following

established:

4ASA

If we let

and

a

order

same,

>

when

ASA=100,

ASA=3200.

a proper range of focal

25 mm,

f,

=4 when

F#=22;

have

In

F*

focal length

Also,

>

According to

D

of 48 mm when

to have constant

it follows that F#=8;

must

be

constant

length. When F#=4

flux,

the

while new shutter speeds

h

then

t3

F#=8,

and

t2

we use a

and a

shutter speed

are set

(i.

e.

lens

(f,)

ASA=400

D=6 mm) in

focal length

setting

for

when

of focal

of

132

needs to

order

length

whenF#=22.

be the

normal exposure and

tr

the

above

discussion,

the

following

determined:

16

to

exposure conditions can

be

(1) For T-MAX100 film:

(a)

A lens

of 25 mm

focal length

F#

and

of 4 was used

to take a picture of each

object.

(2) For T-MAX 400

(a)

A lens

of

50

film:

F#

focal length

mm

of

and

8

was used

to take a picture of each

object.

(b)

A lens

of 25 mm

object.

This step

F#

focal length

and

produced the same

of 4 was used

image size, in

to take picture

order

of each

to study the effect

of different magnification on each print.

(3) For TRI-X 400 film:

F#

mm

focal length

and

(b) A lens

of 25 mm

focal length

and

object.

This step

(a)

A lens

of

50

of

8

was used

to take a picture of each

object.

produced

F*

the same

of 4 was used

image size, in

to take

order

a picture of each

to study the effect

of different magnification on each print.

(4) For T-MAX 3200 film:

(a) A lens

of

135

mm

focal length

F#

and

of 22 was used

to take a picture of

each object.

(b)

A lens

object.

of 25 mm

focal length

This step

produced

F*

and

of 4 was used

the same image size, in

to take a picture of each

order

to study the effect

of different magnification on each print.

To

summarize

the

above statement

the

following combinations

our project:

17

have been

used

for

(1). Conditions to

produce constant

flux (fixed

F#

Focal Length

amount of photons):

Shutter

speed

T-MAX 100

25

mm

4

1/30

sec

T-MAX 400

50

mm

8

1/30

sec

TRI-X 400

50

mm

8

1/30

sec

135

mm

22

1/30

sec

T-MAX 3200

(2). Conditions to

give normal exposure:

F#

Focal Length

T-MAX 400

25

TRI-X 400

25

T-MAX 3200

(3). The

25

mm

mm

"busy"

Photographs

Shutter

speed

4

1/250

4

1/250

sec

1/1000

se

4

mm

orders of the pictures

gray card,

(r,)

(/,)

sec

taken for the scenes are : gray card,

scene.

attached:

18

"simple"

scene,

V

Ima<?e from T-MAX 100 film / 25

Image from T-MAX 400 film / 25

19

mm

mm

lens

lens

20

Image from TRI-X 400 film / 25

mm

lens

Image from T-MAX 3200 film / 25

mm

lens

Image from T-MAX 400 film / 50

Image from TRI-X 400 film / 50

21

mm

mm

lens

lens

22

Image from T-MAX 3200 film / 135

mm

lens

Image from T-MAX 100 film / 25

mm

lens

Image from T-MAX 400 film / 25

Image from TRI-X 400 film / 25

23

mm

mm

lens

lens

Image from T-MAX 3200 film / 25

Image from T-MAX 400 film / 50

24

mm

mm

lens

lens

25

Image from TRI-X 400 film / 50

mm

lens

Image from T-MAX 3200 film / 135

mm

lens

Image from T-MAX 100 film / 25

Image from T-MAX 400 film / 25

26

mm

mm

lens

lens

27

Image from TRI-X 400 film / 25

mm

lens

Image from T-MAX 3200 film / 25

mm

lens

Image from T-MAX 400 film / 50

Image from TRI-X 400 film / 50

28

mm

mm

lens

lens

Image from T-MAX 3200 film / 135

2.1.2

Developing film and

(1)

All films

were

photographic paper.

developed

Film Processor V-5N for

(2)

at the

RI.T. campus, using the Kodak Versamat

developing the films.

(a)

Process

speed

for T-MAX 100

was

2.2 ft /

(b)

Process

speed

for T-MAX 400

was

2.75 ft /

(c)

Process

speed

for TRI-X 400

(d) Process

speed

for T-MAX 3200

The

was

1.5 ft/

was

min.

min.

min.

2.2 ft /

min.

following conditions were used to project images from negative to

photographic paper:

29

mm

lens

Table ILL Conditions

(1) When 25

mm

#,& H2:

Films

lens

371/2"

used

for this

project

was used:

&

Objects

53/4"

Filter

Exposure Time

X

Magnification

T-MAX 100

Gray

T-MAX 100

Card

3.5

27

sec

631.9

Egg

4.0

44

sec

760.8

T-MAX 100

Flower

4.0

48

sec

860.4

T-MAX 400

Gray Card

4.0

38

sec

608.8

T-MAX 400

Egg

4.5

27

sec

597.3

T-MAX 400

Flower

4.5

27

sec

632.2

TRI-X 400

Gray Card

3.5

28

sec

601.4

TRI-X 400

Egg

4.0

46

sec

784.0

TRI-X 400

Flower

4.0

46

sec

632.2

T-MAX 3200

Gray

T-MAX 3200

Egg

4.0

31

sec

784.0

T-MAX 3200

Flower

4.0

33

sec

632.2

Card

37

4.0

30

sec

711.5

(2) When 50 mm lens was used:

//,& H2:

Films

371/2"

&

Objects

53/4"

Filter

Exposure Time

X

Magnification

T-MAX 400

Gray Card

T-MAX 400

Egg

T-MAX 400

4.0

11.5

sec

190.4

4.0

10.0

sec

196.0

Flower

4.0

10.0

sec

215.1

TRI-X 400

Gray Card

3.5

9.0

TRI-X 400

Egg

3.5

7.5

TRI-X 400

Flower

3.5

(3) When

135

mm

H,& H2:

lens

196.0

sec

7.0

215.1

sec

was used:

371/2"

53/4"

&

Exposure Time

Filter

Objects

Films

190.4

sec

x

Magnification

T-MAX 3200

Gray Card

T-MAX 3200

Egg

T-MAX 3200

Flower

(3). All

photographic paper was

7.7

sec

21.1

4.0

6.3

sec

21.5

4.5

7.1

sec

21.4

4.5

developed

at

the R.I.T.

Kreonite B/W Process

(4). All

negatives were printed

to the

same

image

31

size.

campus

by using a

2-2

Evaluating image quality of photographs

The

successive categories method was used

The underlying

stated

(1)

The

assumptions of the

by Togerson (1958)

law

in this

project

for

statistical analysis.

of successive categorical

[Togerson,\95S]

judgments have been

:

psychological continuum of the subject can

be divided into

a specified number

of order categories or steps.

(2) Owing to various

necessarily

and

always

sundry

located

also projects a normal

factors,

a given

category

boundary is not

at a particular point on the continuum.

distribution

of positions on

different category boundaries may have different

the continuum.

mean

locations

Rather, it

Again,

and

different

dispersions.

(3)

The

subject

whenever

judges

a given stimulus to

be below

a given

category

boundary

the value of the stimulus on the continuum is less than that of the

category boundary.

There

are

many forms

techniques and

data

of category

scaling

reduction algorithms

and a wide

about the

participated

image quality

in this

photograph on a

project.

7-point

scaling

was used

of twenty-one photographs.

They were asked to

scale.

The instructions

32

of experimental

that have been used in category scaling. A

common experimental method of category

data

variety

in this

project to gather

Thirty-three

rate the overall

observers

image quality

and results were as

follows:

of each

2-2-1 Instrustions to

observers

INSTRUCTIONS TO OBSERVERS

You

will

be

the image quality

Please do

Do

of the

not

photograph,

dirt,

and

1

intervals

any

physical

rating for the

defects in the

should not exceed

express your opinion

unusable and

using

you

to

make a

judgment

on

print.

represents excellent

of image quality.

The

image

quality.

categories used

(2) Very Good

Good

(4) Acceptable

(5) Unsatisfactory

(6) Poor

(7) Unusable

33

photograph.

12 inches.

a scale of number

(1) Excellent

(3)

like

not consider composition.

The viewing distance

equal

and give a

would

directly touch the photographs.

Ignore scratches,

Please

We

shown a number of photographs.

from 1 to 7

where

Numbers between 1

in these

7

and

experiment are:

7

represents

represent

You may

not use

from 1 to

7;

fractions

no other

or

decimals;

integers may be

you must use

An image quality

three months.

professional

were

assessment

The

presented

of the photograph

is

randomly chosen, among them

and

ordinary

observers.

The

were:

photographs

to each observer for evaluation. The randomness

is important. This

performed

process allowed control of accuracy of

to generate

mean value

(2) Thirty three viewers were asked to make

(m)

viewers a statistic

and standard

a judgment on

deviation

photograph and a

means

(3) Data:

The

gray

card:

rating

and

excellent,

"7"

was given

(S)

the image quality of

"

the

be

of photographs

the rating data. After collecting all the data from the

analysis

should

by the observers was performed in a period of

observer were

people, students,

randomly

The integers

used.

2-2-2 Results from evaluating the image quality

(1)

integers.

to the photograph. A rating of 1

"

means unusable.

Appendix 1

abbreviations are as

Egg:

G,

T-MAX100 / 25

TRI-X 400 / 25

follow:

mm:

mm:

T-MAX 3200 / 135

T-MAX 400 / 25

1,

TRI-X 400 / 50

4,

mm:

Flower: F

E,

7

34

mm:

mm:

5,

2,

T-MAX 3200 / 25

T-MAX 400 / 50

mm:

mm:

3,

6,

(4)

A

(5)

The

statistical analysis was performed

original results were

represented

identified

as

by

1

to evaluate the data.

transferred to a

and original

7 is

new scale where

represented

by 0.

These

the

original

1 is

new numbers are

"Ranking"

Ranking (R)

=

116.666-16.666

x

mean

(m)

(15)

Table TV Statistic data for

"Grey

Card"

Gl

G2

G3

G4

G5

G6

G7

3.55

4.15

5.30

4.52

3.0

2.30

1.79

Ranking (R)

0.575

0.475

0.283

0.413

0.666

0.783

0.868

Standard Deviation

0.99

1.08

1.34

1.13

0.85

0.90

0.73

Mean

(m)

w

Table V Statistic data for

Mean

(m)

Standard Deviation

(S)

"

Egg

"

El

E2

E3

E4

E5

E6

E7

3.97

4.73

5.36

4.97

3.36

2.42

1.88

1.03

1.11

1.20

1.11

1.07

0.99

1.01

35

Table VI Statistic data for

Mean(m)

Standard Deviation

2-3

(S)

Calculating MTF

Many

F2

F3

F4

F5

F6

3.52

4.52

5.39

4.97

3.18

3.21

1.91

0.93

1.13

1.13

1.19

1.03

1.01

0.71

The quality

The human

response at

of

eye

MTF is

cycles per

used

one-dimensional

in the

includes the

of

logarithmic

log

spatial

obtained

image is

by

changing the

quality

In

rank.

proven quite successful

function

rank can

fact,

that a perceptible

scale of

related to the scale of the

a modulation transfer

These

noticed

(MTF)

be

Quality

frequency

frequency

weighting

(SQF)

of

correlates with

the

tells

computed

computations

scale.

36

that

the retina.

broad

if the

use

rank

peak

"true"

only the

for

two-

that the one-dimensional treatment

us

under

visual properties

that image quality

system optical

the area

on

with

in predicting quality

successes suggest

Factor

the point spread

image

two-dimensional

weighting function to describe the

Specifically, image quality

on a

be

calculation of

Subjective

spatial

has

structure.

proper

the image.

can

degree (cpd). Image quality

MTF have

dimensional image

image quality definition have

of a visual

visual system

6

F7

of photographs

difference in image quality

function.

"

Flower

Fl

in the field

studies

"

the

transfer

system

is

related to

function (OTF).

OTF

when

displayed

A Crosfield Magnascan 636

All

card photographs.

The data

MTFs'

4*)

=

drum

photographs were

were then read

calculation.

reflection

in

Photoshop

scanner was used

carefully

4-5 to

scan seven of

aligned and scanned at

generate raw

of each print were calculated

to

pixels

data for granularity

according to the

^

18

following

the gray

/

and

mm.

MTF

equations:

d6)

(17)

md07F(f)=]i(x)ea'*'&

oo

MTF{f)

A

routine was written

calculations are shown

The MTF

curve

combination

is

as

=

\OTF(f\

in Mathcad 4.0

(18)

and used to

do the

calculation.

The

program and

in Appendix-3.

for the

print

generated

from T-MAX 100 film

following:

37

and

25

mm

lens

Figure 3 MTF

of final print

by using T-Max

1.5

100 film

w/25 mm

lens

2.5

2

Frequency (lines/mm)

2-4

Determining granularity

Photoshop 4-5

obtained

with a

The digital data

used

in the

low

obtain

filter

pass

and

were scaled as an

equation

granularity data to

^New

to

was used

below. The

"New"

log

one set of data was

the granularity

data,

the

data was

second set

integers between 0

and

255. A

mean of

128

filter.

was

following equation was used to transform original

granularity data:

Noise(p)

White

obtained without a

+

log2

,

38

(19)

No^y-hlfpl

V

where white

A linear relationship

pixels

=

was

255

developed between Information Theory

predict the subjects averaged response

was

relationship

response

2-5

for

Calculating

objective

for

developed between SQF

A

each set of prints.

and

oD to

predict

and

aD to

second

linear

the subjects averaged

each set of prints.

SQF

A Subjective

(20)

vofpixels

of photographs.

Quality Factor (SQF) was developed

figure

of merit which could

be easily

as the result of a search

calculated and

the eye

merit

function

image

appearance

averaged response

granularity.

was

for

developed between SQF

each set of prints.

form.

linearly when the actions of

including the magnification of the image are taken into

A linear relationship

and

aD to

Image quality is

consideration.

predict the subjects

related

to both MTF and

They act independently as when increase in granularity then we expect

loss in image quality

quality

predicts

an

directly measured in

practice and which would correlate with subjective rank regardless of MTF

The SQF

for

and also when a

loss

as well.

39

of MTF we can expect a

loss

of image

a

/

A

Q.

=

SQF

routine was written

2-6

aaD

(21)

in Mathcad 4.0

calculations are shown on

by using

-

and used

to calculated SQF. Programs and

Appendix-4. An image quality

assessment was performed

SQF.

Calculating Information Capacity.

Information capacity

of an emulation

depends

(MTF) and the granularity of the emulsion.

obtained

and

first,

<jd to

I.Q.=

A

the modulation transfer function

In this study MTF

of each system was

then a linear relationship was developed between Information

predict

the subjects averaged response for

Theory

each set of prints.

a0+b0(lC)

routine was written

Capacity. Programs

was also used

granularity

on

in Mathcad 4.0

to calculate Information

and calculations are shown on

to predict image quality

into

and used

Appendix-5. Information

Theory

by calculating information capacity and taking

consideration.

40

m. Results

3-

1 MTF

All

(1)

of the

final

prints was calculated:

of the seven

gray

card photographs were scanned and

Crosfield Magnascan 636

and a

scanning

(2). MTF's

4x)

=

of

18

reflection

pixels

/

drum

scanner.

An

digitized

edge

trace

by using

was

performed,

mm was used.

of each print were calculated

according to the

following equations:

*x)

dx.

otfw)=

J(xy2^ac

n=l

MTF{f)

A

=

\OTF{fl

routine was written

are as

in Mathcad 4.0

and used

follows:

41

to do the

calculation.

The MTF's

Figure 4 MTF

of final print

by using T-MAX

2

1.5

100 film

w/

25mm lens

2.5

Frequency (lines/mm)

Figure 5 MTF

of final print

by using T-MAX 400 film w/25

2

1.5

Frequency (lines/mm)

42

"

mm

lens

Figure 6 MTF

of final print

by using T-MAX 3200 film w/25

2

1.5

mm

lens

2.5

Frequency (lines/mm)

Figure 7 MTF

of final print

by using

TRI-X 400 film

2

1.5

Frequency (lines/mm)

43

2-5

w/25 mm

lens

Figure 8 MTF

of final print

by using TRI-X 400

film w/ 50

mm

lens

mm

lens

Frequency (lines/mm)

Figure 9 MTF

of final print

by using

T-MAX 400 film

2

1.5

Frequency (lines/mm)

44

2.5

w/

50

Figure 10 T-MAX 3200 film

w/

135

mm

lens

0.98

0.96

0.94

-

0.92

-

0.9

0.88

-

15

2

2.5

Frequency (lines/mm)

3-2

Granularity analysis

Photoshop

4-5

was used

to obtain the granularity data from the final prints.

this measurement contain a systems level

and scanner used

measurement.

second set of

data

integers between 0

and

and

an

for

the

readings

from

One

of

MTF, including MTF

set of data was obtained

was obtained without a

255

Photoshop 4-5

and mean of

128

with and without

45

of

film,

with a

filter. The digital data

was used

the low

for

pass

calculation.

filter

are:

Therefore

paper, lens

low

pass

filter

were scaled as

Granularity

Table VII

Granularity results

T-MAX 100

T-MAX 400

T-MAX 3200

TRI-X 400

TRI-X 400

T-MAX 400

T-MAX 3200

25

25

25

25

50

50 mm

135

mm

mm

mm

mm

mm

mm

Print

Granularity W/ filter

5 1

9.3

10.3

8.0

4.6

5.4

5.1

Print

Granularity w/o

9 4

9.7

19.1

15.3

8.7

9.6

14.6

By using

.

.

equation:

New

'log^M)+,g2

White

V

we

have

new

granularity data

as:

Table VHI Calculated

Granularity results

T-MAX 100

T-MAX 400

T-MAX 3200

TRI-X 400

TRI-X 400

T-MAX 400

T-MAX 3200

25

25

25

25

50 mm

50 mm

135

mm

mm

mm

mm

Print

Granularity W/ filter

0.0183

0.0322

0.0353

0.028

0.017

0.0196

Granularity w/o

0.0325

0.0334

0.0486

0.0507

0.0303

0.0331

print

46

mm

0.0187

0.0621

3-3 SQF

of photographs

Image quality

was

determined

by using the correlation of SQF &

aDF

subject

data for

each photograph.

(1). A

routine was written

in Mathcad 4.0 to

calculate

Table TX SQF

The

results

T-MAX 100

T-MAX 400

T-MAX 3200

TRI-X 400

TRI-X 400

T-MAX 400

T-MAX 3200

25

25

25

25

50 mm

50

135

mm

0.57

SQF

(2)

the SQF.

mm

0.51

mm

mm

0.54

0.48

following equation was used to take granularity into

2

{l\Pr^on){N)-aSQF{N)-ba0{N))

=i

a=l andb=-3.6

then

R(prediction)

=

SQF-3.6G

47

=0

0.77

mm

0.79

consideration:

mm

0.97

Table X Results

(prediction)

R,

'(measured)

of prediction

by using

SQF

T-MAX 100

T-MAX 400

T-MAX 3200

TRI-X 400

TRI-X 400

T-MAX 400

T-MAX 3200

25

25

25

25

50

50 mm

135

mm

mm

mm

mm

mm

0.51

0.40

0.36

0.44

0.71

0.72

0.91

0.57

0.51

0.48

0.54

0.77

0.79

0.97

Fig

11 SQF

results

1

0.9

0.8

0.7

0.6

O 0.5

0.4

-

0.3

0.2

--

0.1

--

0

4

Films

3-4 Information

Capacity of photographs

Image quality

mm

was obtain

by using Information Theory for each print:

48

A

(1)

in Mathcad 4.0 to

routine was written

granularity taken into

calculate

The

consideration.

results are as

Table XI Information

I.C.

(2)

with

the

follows:

Theory results

T-MAX 100

T-MAX 400

T-MAX 3200

TRI-X 400

TRI-X 400

T-MAX 400

T-MAX 3200

25

25

25

25

50

50 1

135

63.2

63.5

mm

30.9

The

information capacity

mm

30.0

following

mm

24.8

equation was used

mm

31.1

mm

47.1

r

to take granularity into consideration:

%^M=00884+00119*IC

Table XII Results

R{prediction)

of prediction

by using Information Theory

T-MAX 100

T-MAX 400

T-MAX 3200

TRI-X 400

TRI-X 400

T-MAX 400

T-MAX 3200

25

25

25

25

50 mm

50 mm

135

mm

mm

mm

mm

0.46

0.44

0.38

0.46

0.65

0.84

0.84

0.57

0.51

0.48

0.54

0.77

0.79

0.97

D

(measured)

mm

49

TV DISCUSSION

4-1 Comparison

Judging the

of results

results

can produce

very

predicting image

using SQF

from Figure

and

(12)

reasonable results.

Information Theory.

we can

But

say both SQF

overall

the SQF

and

Information

does

a

Theory

better job

of

quality.

Figure 12 I.T.

and

SQF ranking

prediction

.

.

/

I.T.

s

SQF

_

il.

/

0.3

0.5

0.4

Ranking

-

06

Measured

50

The

prediction of the

Is Image

Quality

image quality Vs

a

granularity

(crD) :

?

,

-J

measured

ASA

(a) When constant flux is used for exposure, the fast film has better image

It is because the

fast films

are

gain

usually

(b) Under normal

in MTF

more

grain

effects; also, because the

better.

sensitized

exposure

than offsets the

quality.

the slower film

Table XIII

has better image

Summary of the

quality.

results:

T-MAX 100

T-MAX 400

T-MAX 3200

TRI-X 400

TRI-X 400

T-MAX 400

T-MAX 3200

25

25

25

25

50

50 mm

135

mm

mm

mm

mm

mm

r

SQF

0.57

0.51

0.48

0.54

0.77

0.79

0.97

Information Cap.

10.16

9.98

10.55

9.8

15.21

21.73

27.72

Granularity w/ fil.

5.1

9.3

10.3

8.0

4.6

5.4

5.1

Granularity w/o

9.4

9.7

19.1

15.3

8.7

9.6

14.6

0.51

0.40

0.36

0.44

0.71

0.72

0.91

0.46

0.44

0.38

0.46

0.65

0.84

0.84

^(prediction/

SQF)

^(prediction/ 1.

T.)

Note:

(1)

Constant flux

condition:

G5: TRI-X 400 film / 50

mm

G6: T-MAX 400 film / 50

lens

mm

lens

51

(2) Normal

exposure condition:

G2: T-MAX 400 film / 25

G4: TRI-X 400 film / 25

mm

mm

Figure 13 Comparison

lens

lens

of

granularity by using I. T.

and

SQF

0.05

.&

0.04

C

O

0.03

4

Films

Photoshop

4-5

was used

to obtain the granularity data from the final prints.

level

measurement contain a systems

scanner used

for

the second set

measurement.

of

integers between 0

compare

reach

the

data

and

One

MTF, including MTF

set of

data

was obtained

was obtained without a

255

and a mean of

the granularity on each

following

of

by

using SQF

52

with a

for the

was used

conclusions :

film,

and

paper, lens and

low

filter. The digital data

128

photograph

of

Therefore this

pass

were

and

scaled as

When

we

Theory,

we

calculation.

Information

filter

(a) When

SQF is

Under

for

used

prediction:

flux the granularity in the

constant

normal exposure

aD

varies

in

print shows no

to the

proportion

big changes,

but

under

granularity.

(b) When Information Theory is used for prediction:

From Figure

(13), it is

obvious

that it is very difficult to

predict

granularity

by using

Information Theory.

(c) The reason that

low

pass

SQF

filter to

film granularity is because SQF

can predict

simulate

the human

visual system and

(d) From this project we learn that when a fixed

size are used

it is better to

conditions, a

slower

4-2 Results

Compared

on

be

a

better

and a

fixed

print

under normal

words,

TRI-X 400 films

and

TRI-X

400,

T-MAX 400 film is

we used

other

flux

Theory does not.

choice.

400,

with

and

would

T-MAX

Company. In this study

quality,

film

Information

amount of photon

fast film. In the

use a

uses a

both SQF

and

a newer product

Information

from Eastman Kodak

Theory to

predict

image

films.

to study the differences between these two

(a) Under constant flux condition:

The scanning

was

done from the final

measurement contain

and scanner used

for

a systems

measurement.

by using the data in table XIII,

or without a

level

filter for

prints

of

in this

project.

MTF, including MTF

According to

the

when under constant

measurement

Therefore this

results

flux it is

of

film,

paper, lens

from this

clear

project and

that

the granularity of T-MAX 400 film

53

either with

is

smaller

than TRI-X 400

compared to

film. In the

other

words, the T-MAX 400 film is

a

finer film

when

TRI-X 400 film.

(b) Under normal exposure condition:

By using the

without

using

compared to

granularity

in the

used

same

a

Table XIII,

filter it is

of

result of granularity

T-MAX 400 film has finer grain,

8.0 Vs 9.3 for T-MAX 400. It is

system or

can make a

fixed

obvious that the

exposure, the

TRI-X 400 film. When the filter is used, TRI-X 400 film has

the truncation of data

photographic paper used

(c) We

under normal

is

possible that this

during the

scanning

is

caused

process.

when

a

by the filter

Possibly the

a cause.

brief conclusion for this

amount of photons were used

in

a

project as:

When the

system, it is better to

54

print size

use a

is fixed

fast film.

and a

V REFERENCES

James A.

Master

Wisner,

Film

Thesis, R.I.T.,

Granularity and the Effect on

Subjective Image Quality,

1986

Lisson, G, Digital Image Modeling of Film Granularity

Pictorial

Quality,

Granger,

E. M.

with

J.C.

Master

Thesis, R.I.T.,

and

Merit Function

Subjective Image Judgments, Photogr. Sci. Eng. 16

Jones, R. C.

Information capacity

Levi, L. On the

photographic recordings.

Altman, J. H.

and

dynamic

J. Opt. Soc. Amer.

Zweig, H. J. Effect

content of photographic recordings.

(SQF),

,221

Subjective

,

of spread

,

9

California,

information

,(1958

function

on

Photogr. Sci. Eng. 7

55

)

1974.

films. J. OPSoc.Amer.,51.1159.

range and

48

which correlates

(1972

10 Academic Press Inc.

of photographic

effect of granularity on

on

1983

&, Cupery, K. N. An Optical

Dainty, & R. Shaw. Image Science

Effect

,

(1961)

content of

)

the

storage of information

173, (1963 ).

W.S.

Togerson, "Theory

and

Method

of

Scaling"

John

Wily

and

Sons,

New

York,

1958.

G. P

M. J.

Clayton,

Photogr. Sci. Eng.

(1982)

M. C.

Corey,

Davidson,

and

K. N. Cupery. Scene Dependence

J. Opt. Soc. Am.

58,

1300 (1968).

56

of Image

Quality

VI APPENDICES

APPENDIX

The followings

1

-

are subjective ratings of 21 photographs

from 33 different

viewers.

Data:

The

Gray Card:

abbreviations are as

G

follow:

Egg:E

Flower: F

T-MAX100/25mm: 1

T-MAX 400 / 25

TRI-X 400 / 25

TRI-X 400 / 50

mm:

T-MAX 3200 / 135

4

mm:

mm:

mm:

5

2

T-MAX 3200 / 25

T-MAX 400 / 50

mm:

mm:

3

6

7

Gl G2 G3 G4 G5 G6 G7 El E2 E3 E4 E5 E6 E7 Fl F2 F3 F4 F5 F6 F7

Viewer #1

234422234543223455331

Viewer #2

344432243342324444342

Viewer #3

23

Viewer #4

345343234543313454332

Viewer#5

34534

1143542222444332

Viewer #6

34433

1134553122344231

Viewer #7

333411155554214555231

Viewer #8

2232

Viewer #9

23

3432344443334444342

12

763

2

122332112342

146752313

57

121

677421

Viewer #10

467642

155775214775

332

Viewer #11

2

234322223

342

Viewer #12

466644356565323

776673

Viewer #13

4

677

Viewer #14

54763

1257643125

576321

Viewer #15

45

763

2

145363213

576421

Viewer #16

44

5

422235542324

656433

Viewer #17

3

4643

3

255654324456332

Viewer #18

5

6

4

256665545

Viewer #19

44653

Viewer #20

5

Viewer #21

437422145762212363243

Viewer #22

6

Viewer #23

455432246754214567221

Viewer #24

345521124552124454342

Viewer #25

3

Viewer #26

345533234543223454342

Viewer #27

456642

144654223565421

Viewer #28

456443

145655114565432

Viewer #29

445

Viewer #30

555432353443224455332

Viewer #31

3

Viewer #32

336532225662222344223

Viewer #33

446533245654323455332

2

4

2

7

5

2

6

4

4

3

4

2

3

366775324

7

5

44

44423

4

6

53

5

2

666

533

443

1146764314565241

66644256665535

6

334

3

2

366674435

244554333

135553223

344654225

58

565442

577443

354322

344232

566

542

APPENDIX

The

following Line

Spread Function data was

2

obtained

by using Photoshop 2-5.

(a)T-MAX100/25mm:

Pixel #

Edge Reflectance

Line Spread Function

1

231

2

230

1

3

228

2

4

226

2

5

221

5

6

213

8

7

200

13

8

184

16

9

162

22

10

144

18

11

130

14

12

124

6

13

119

5

14

117

2

15

114

3

16

111

3

17

109

2

59

(b)

T-MAX 400 /25

Pixel #

1

2

mm:

Edge Reflectance

Line

Sp

227

226

1

3

226

0

4

223

3

5

220

3

6

215

5

7

209

6

8

200

9

9

187

13

10

172

15

11

154

18

12

137

17

13

128

9

14

121

7

15

116

5

16

113

3

17

111

2

18

108

3

19

107

1

20

104

3

60

(c) T-MAX 3200 /25

Pixel #

mm:

Edge Reflectance

Line

Sp

1

225

2

224

1

3

223

1

4

221

2

5

218

3

6

213

5

7

206

6

8

196

10

9

180

16

10

159

21

11

137

22

12

121

16

13

110

11

14

103

7

15

98

5

16

96

2

17

92

4

18

88

4

19

85

3

20

82

3

21

81

1

61

(d)

TRI-X 400 /25

Pixel #

mm:

Edge Reflectance

Line Spi

1

225

2

221

4

3

218

3

4

215

3

5

207

8

6

194

13

7

178

16

8

158

20

9

139

19

10

129

10

11

119

10

12

116

3

13

109

7

14

104

5

15

100

4

16

99

1

62

(e)

TRI-X 400 / 50

Pixel #

mm

Edge Reflectance

Line Spi

1

223

2

222

1

3

220

2

4

218

2

5

212

6

6

194

18

7

162

32

8

129

33

9

109

20

10

101

8

11

97

4

12

95

2

13

93

2

14

91

2

63

(f) T-MAX 400 /50

Pixel #

mm:

Edge Reflectance

1

229

2

227

3

Line

Sp

2

225

2

4

215

10

5

186

29

6

141

45

7

119

22

8

112

7

9

104

8

10

97

7

11

97

0

12

96

1

13

94