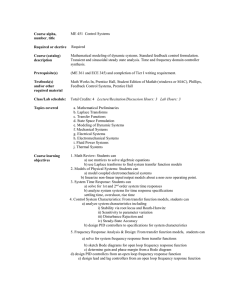

INTRODUCTION TO AUTOMATIC

CHAPTER 1: CONTROL SYSTEM

Control system: Subsystems and processes (or plants) assembled for the purpose of

obtaining a desired output with desired performance.

Input: stimulus

Desired response

Control system

Output: response

Actual response

Examples:

In nature pancreas regulating our blood sugar.

A motor speed controller regulating the speed to the desired amount.

OPEN LOOP AND CLOSED LOOP CONTROL SYSTEMS

Open-loop: the system gives an output based on pre-determined relationship between

the output and input. OR simply is not dependent on the output “no feedback”.

Example: Automatic dish washer

Input

Advantages

• Simple design

• Cheap

Control System

output

Dis-advantages

• Can not eliminate the effect of

disturbances.

• Can not be used for systems requiring

higher accuracy.

OPEN LOOP AND CLOSED LOOP CONTROL SYSTEMS

Closed-loop: the system gives an output based on not only pre-determined relationship

between the output and input but also every time checks whether the output is in

desired range. OR simply is dependent on the output “feedback”. Are self-correcting.

Examples: Walking man (eyes open), tracking systems

Control System

Input

Advantages

• Able to reject disturbances

• More accurate

Dis-advantages

• Complex.

• Expensive.

output

MATHEMATICAL

MODELLING

OF

CHAPTER 2: PHYSICAL SYSTEMS

Mathematical modelling: representation of

Electrical networks

physical systems mathematically which make

Voltage source

=i =

= ∫id

them easy for computation and simulation

Current source i =

purposes.

Mathematical modelling of

Mechanical systems

Translational: F=ma=Bv=kx

Rotational: T=Jα=Bω=kθ

Analogy

F-V

F-I

= ∫ d =

MATHEMATICAL MODELLING OF MECHANICAL

SYSTEMS: TRANSLATIONAL

∑

B

Damper B

k

Spring k

m

=

F-Fb-Fs=ma

Where:

F=ma-Fb-Fs

F-applied force

F=ma+Bv+kx

Fb-force by damper

F=m

Mass m

+kx

Fs-force of spring

a-acceleration

F=m

F

=

Force F

+B

=

+Bv+k ∫ d

d

d

=

d

d

Or

d

=

v- velocity

x- displacement

d

MECHANICAL TRANSLATIONAL

k

k1

B1

x1….

CONT.…

m1

k2

x1….

m1

L1

L2

B12

B

x2…..

m2

F

x2…..

m2

F

MATHEMATICAL MODELLING OF MECHANICAL

SYSTEMS: ROTATIONAL

∑

k

J

= α

T-Tb-Ts= α

T

Where:

T=Jα+Tb+Ts

T-applied torque

F=Jα+Bω+kθ

Tb-torque resistance by damper

B

T=J

+B

+kθ

Ts-torque resistance by spring

α-angular acceleration

ω- angular velocity

=

Or

θ= ∬ α d = ∫ ω d

α=

θ- angular displacement

MECHANICAL ROTATIONAL

CONT.…

k1

J1

B1

J2

k12

ϴ1

T

ϴ2

J2

T

N2

k1

B2

J1

=

=

N1

B1

ELECTRICAL NETWORKS

R

L

i

C

iR

iL

R

L

i

v

v

=

v= i +

+

+

i=

+ ∫id

F-v R-B L-m

F=m

−

+

i=

-B

C

+

+Bv+k ∫ d

F-i

iC

-k

C-m

1

+

1

d +

d

d

ANALOGOUS CIRCUITS Find f-v, f-i and draw circuit

x1….

k

k1

B1

m1

k2

x1….

m1

L1

L2

B12

B

x2…..

m2

F

x2…..

m2

F

ELECTROMECHANICAL SYSTEMS

Ra

JL

La

eb= kbω

N2

Tm=ktia

ia

ea

N1

eb

Tm, θ

TRANSFER FUNCTIONS

Transfer function: a mathematical equation that relates

input of a function to the output [

{ }

].

{ }

1. The equation is derived after converting the function into Laplace domain

2. All initial conditions are zero

3. Works only for linear functions

BASIC LAPLACE TRANSFORM TABLE

Time domain

Laplace domain

u(t) step input

1

tu(t)

1

s2

!

tnu(t)

e-atu(t)

d

( )

f(t)±g(t)

sn+1

1

s+a

( )

s

snF(s)

F(s)±G(s)

FIND TRANSFER FUNCTION

For the mechanical system given above find transfer function

a. Input force to displacement 1 (x1)

b. Input force to displacement 2 (x2)

k1

B1

R

x1….

m1

L

C

k2

i

v

B12

x2…..

m2

Voltage input to the system to voltage at capacitor

F

SIMPLIFYING MULTIPLE SUBSYSTEM

BLOCK DIAGRAM REDUCTION

Forward path

G1(s)

Takeoff point

R(s)

G2(s)

Summing point

C(s)

G3(s)

Feedback path

Block

BLOCK DIAGRAM REDUCTION

Block diagram

R(s)

R(s)

Transfer function

G(s)

C(s)

G1(s)

R(s)

R(s)

±

G2(s)

G(s)

H(s)

±

( )

( )

G(s)

C(s)

G2(s)

G1(s)

CONT.…

G1(s)G2(s)

Series blocks

G1(s)±G2(s)

Parallel blocks

G( )

1 ∓ H s G( )

feedback

C(s)

C(s)

BLOCK DIAGRAM REDUCTION MOVING TAKEOFF POINT

G3

G1

G3/G1

G2

G1

G3

G1

G2

G2

G1G3

G1

G2

BLOCK DIAGRAM REDUCTION MOVING SUMMING POINT

G3/G2

G3

G1

G2

G1

G3

G1

G2

G2G3

G2

G1

G2

BLOCK DIAGRAM REDUCTION examples

H1

G6

R(s)

G1

G2

G3

G5

G4

C(s)

SIGNAL FLOW GRAPH (SFG)

i

1

a

2

b

3

j

c

4

d

5

e

7

f

k

8

g

9

h

10

m

m

• Node: a point where a path start or stop (i.e. 1, 2, 3…)

• Touching loop: loops having common node

• Path gain: value on arrow (i.e. a, b, c…)

• Non-touching loop: loops without common node.

• Loop: start and sink on same node.

• Dummy node: a path with gain equal to 1.

• Self loop:- start and sink on same node without

intermediate nodes

SIGNAL FLOW GRAPH REDUCTION

e

j

f

a

b

k

c

d

a

b

c

d

g

=

k= ef + ab + hg

d= c(ef + ab + hg)

f

k

h

d= kc

e

ℎ( + )

1−

g

h

i

SFG Masons Gain Formula(MGF)

9 =

5

=

∑

Δ

Δ

Pi-gain of the ith forward path

N- total number of forward paths

∆= 1 - ∑ loop gains + ∑ nontouching-loop gains taken two at a time +

∑ nontouching-loop gains taken three at a time –

∑ nontouching-loop gains taken four at a time …

∆i= value of ∆ after eliminating all the loops that touch its forward path.

G9

R(s)

G1

G2

G10

G3

G4

G5

H1

G6

G7

G9

H2

G8

C(s)

BD TO SFG

Convert into SFG and find gain using MGF

H1

G6

R(s)

G1

G2

G3

G5

G4

C(s)

CONTENTS

Feedback and its properties

Stability

Time response

Experimental determination of transfer function

First order system response

Controllers

Second order system response

Physical realization of controllers

Steady state error

Simulation of Mechanical Control Systems

Using SIMULINK

By: Chalachew W.

FEEDBACK AND ITS PROPERTIES

A control system mainly categorized into open and closed loop systems.

Closed loop systems use plant response(output) for determining appropriate control action from

controller. These closed loop systems are also called feedback controllers.

A controller with a feedback may affect properties like

Parameter variation: variation of parameters which are expected (i.e. working domain).

Overall gain: the magnitude in which the input is multiplied.

Disturbance: parameter variation which is unexpected.

Sensitivity: the amount of deviation on a parameter caused by deviation in another parameter.

Stability: response of a system to be in a given band (BIBO).

Time constant: time required the system response to reach 63% of final/desired output.

PARAMETER VARIATION

For a given system with input R(s), output

C(s) and parameter G(s). So transfer

function (i.e. tf=C(s)/R(s)) becomes G(s).

R(s)

G(s)

For closed loop

R(s)

G(s)

C(s)

tf =

G(s)

1 − G s H(s)

tf =

G s + ∆G(s)

1 − [G s +∆G(s)]H(s)

H(s)

C(s)

R(s)

G(s)+∆G(s)

What will be the new tf if G(s) becomes

C(s)

H(s)

G(s)+∆G(s)

tf =

For open loop

( )

∆G(s)

( )

For G(s)>>∆G(s)

tf=G(s)+∆G(s)

R(s)

+

+

G(s)+ ∆G(s)

C(s)

From this we can conclude parameter variation has less effect

on closed loop system than open loop system.

OVERALL GAIN

Open loop

tf=G(s)

Closed loop

Generally closed loop system has smaller

over all gain.

DISTURBANCE

Disturbance on open loop system

Disturbance on a closed system may

occur on

D(s)

R(s)

( )

=

( )

G1(s)

G2(s)

G2(s)

C(s)

a.

b.

c.

Forward path

Output or

Feedback path

To study the effect of disturbance we

remove the input and examine the

response caused by the disturbance

DISTURBANCE ON FORWARD PATH

D(s)

D(s)

R(s)

G1(s)

G2(s)

G2(s)

C(s)

C(s)

G1(s)

H(s)

H(s)

Making the input zero

C(s)

G2(s)

=

(s) 1 − G1(s)G2(s)H(s)

DISTURBANCE ON OUTPUT

D(s)

D(s)

R(s)

G1(s)

C(s)

C(s)

G1(s)

H(s)

H(s)

Making the input zero

C(s)

1

=

(s) 1 − G1(s)H(s)

DISTURBANCE ON FEEDBACK PATH

R(s)

R(s)

G(s)

H1(s)

G(s)

C(s)

H2(s)

H1(s)

H2(s)

D(s)

C(s)

H1(s)G(s)

=

(s) 1 − H1(s)H2(s)G(s)

From these equations we can conclude that closed system less affected by disturbance.

C(s)

SENSITIVITY

How much is the impact of variation in

parameter ‘b’ on parameter ‘a’.

=

⋅

( )

a=

Effect of variation of forward path gain

on overall transfer function on open loop.

a=G(s)

( )

=

=

b=G(s)

=

Effect of variation of forward path gain

on overall transfer function on closed

loop.

⋅ =

( )

( )

⋅

( )

=1x1=1

( )

(

[

)

; b=G(s)

]⋅

( )

[

]

( )

So, closed loop systems are less sensitive than open

loop systems.

STABILITY AND TIME CONSTANT

In general, if properly designed closed loop systems can improve both stability and time

constant.

For stable open loop system making it closed loop may affect the system negatively (i.e.

may become unstable.)

TIME RESPONSE

Transient/natural response,

and die out as time goes. lim

→

Steady state /forced response,

transient response die out.

Total response C(t)=

: response of the system as the input is applied

=0

: response of a system which remain after

+

Order: Order (i.e. highest degree) of differential equations(denominator after cancelling

common factors in the numerator) describing the system.

For system equation represented with numerator and denominator zeros of numerator

is called zeros of the system and zeros of denominator is called poles of the system.

FIRST ORDER SYSTEM RESPONSE

Time constant: time in which the response

reaches 63% of the final value.

Let G(s) first order system with tf G(s)=

and R(s)= (i.e. unit step input)

Output C(s)=R(s)G(s)=

.

The maximum possible value of c(t) is 1

which is the final value and 63% becomes

0.63.

1-e

e

C(s)= .

= +

=>A=1, B=-1;

C(s)= −

c(t)=1-e

=0.63

= 0.37

e

=

- t=-0.994

taking inverse Laplace transform

t≈ 1/

0.37

OPEN VS CLOSED LOOP TIME CONSTANT

R(s)

C(s)

Comparing

& =

k

C(s)=R(s).

C(s)= .

C(s)= −

t=

=

;

;

b=

;

−

=

(

)

;

> 1,

ℎ

.

FIRST ORDER SYSTEM RESPONSE

Rise time ( ): time taken for the system

to reach 10%-90% of the final output.

1-e

=0.9

=

1-e

1-e

.

=

=0.1

=

=

Settling time ( ): time taken the output

to reach and stay ±2% of final output for

the first time.

.

−

=

.

−

.

=

.

=0.98

SECOND ORDER SYSTEM RESPONSE

General second order system

- natural frequency

– damping constant

Find natural frequency and damping constant of

a.

b.

( )

, if

( )

f t = 27 ( ), M = 3, fv =6, K=27

G(s)=s2+4.2s+36

CLASSIFICATION OF 2 ND ORDER SYSTEM USING DAMPING RATIO

=

1−

SECOND-ORDER UNDER DAMPED RESPONSE SPECIFICATIONS

SECOND-ORDER SYSTEM RESPONSE SPECIFICATIONS

UNDERDAMPED

lim

→

STEADY STATE ERROR

e ∞ =lim

→

=

∞ = lim

→

R(s)

=lim 1+G(s)H(s)

→

Steady state error: error of a system as time

approaches to infinity.

Determine order and type of G(s) then find steady state error for

system with

E(s)=R(s)-H(s)C(s)

a.

1

G(s)=s+2, H(s)=0

b.

1

G(s)=s+2, H(s)=1

c.

1

G(s)=s(s+2) , H(s)=1

d.

G(s)=

C(s)=E(s)G(s)

E(s)=R(s)-E(s)G(s)H(s)

E(s)(1+G(s)H(s))=R(s)

R(s)

E(s)=1+G(s)H(s)

1

, H(s)=1

(s+2)

For step, ramp and parabolic input

RELATIONSHIP BETWEEN INPUT, SYSTEM TYPE, STATIC

ERROR CONSTANTS AND STEADY STATE ERRORS

STABILITY OF CONTROL SYSTEM

Stability and transient response of a system affected by location of closed loop poles in

s-plane.

Routh-Hurwitz: tells us number of poles on the right half s-plane.

Root-Locus: shows graphically the movement of poles on s-plane for different

parameter k.

As the parameter changes

If the pole goes to the right the system is becoming unstable.

If the pole goes to the left the system is becoming more stable.

?

ROUTH-HURWITZ STABILITY

CRITERION

How can I know a pole lie on RHP

ROUTH-HURWITZ STABILITY CRITERION

CONT.…

s4

a4

a2

a0

The necessary and sufficient condition the system to be

stable is there SHOULD NOT BE any sign change in

the first column.

s3

a3

a1

0

If there is any sign change

s2

b1

b2

0

s1

c1

0

0

The system is unstable.

The number of sign change shows the number of poles in the

RHP.

s0

d1

0

0

If there is zero

The system is marginally stable.

OPEN VS CLOSED LOOP STABILITY

R(s)

C(s)=

C(s)=

Closed loop

1

1

C(s)

k

C(s)=

Open loop

;

; closed loop

; open loop

- k

- k

For >0; the system is stable

If >0; to be the system stable

k should be less than 1 (i.e. k<1);

ROUTH-HURWITZ STABILITY CRITERION

Check stability of a system given by

1.

G(s)= 2

and H(s)=0.3;

s +4s+2

2.

( )

=

( ) s3

3.

( )

=

( ) s5+3s4+3s3

+6s2+5s+3

4.

( )

=

( ) s5+2s4+3s3

+6s2+5s+3

+5s2+10s+2

CONT.…

SPECIAL CASES OF ROUTH-HURWITZ

1.

Zero in the first column of row

Check stability of the system

a.

Substitute with small number ε: check for sign change for positive

and negative ε.

b.

2.

a.

( )

=

( ) s5+2s4+3s3

+6s2+5s+3

b.

( )

=

( ) s5+7s4+6s3

+42s2+8s+56

Reverse coefficients: reverse coefficients of the polynomial.

Row of zero

Use coefficients of auxiliary polynomial.

Auxiliary polynomial is derivative of the polynomial just above row zero

NB: In these cases the system never become stable but it can be marginally stable.

DESIGN USING ROUTH-HURWITZ

Finding the range of ‘gain’ in which the given system can be

stable.

Find value of k in which the system

a.

G(s)=s(1+0.5s)(1+0.5s) and H(s)=0.2

b.

G(s)=s(1+0.6s)(1+0.4s) and H(s)=0.3

i.

To be stable

ii.

To be marginally stable, how much is its’ frequency of

sustained oscillation

EXPERIMENTAL DETERMINATION OF TRANSFER FUNCTION

Approximated to 1st or 2nd order system

Some parameters need to be collected using

sensors.

1st order system:

G(s)=s+a

Whose step response is

/

/

C(s)=s(s+a) = s - s+a

The collected data plotted with time to

determine the transfer function.

C(t)=a (1-

)

C(ꝏ)=a

If we get the time constant from experiment we can

easily determine the transfer function.

EXPERIMENTAL DETER…

CONT.…

2nd order system:

Percent overshoot and settling time used

for determining denominator or poles

of the transfer function.

NB: In both cases the system should settle to some final

value.

CONTROLLERS

We can alter system dynamics (parameters) to

Commonly used industrial controllers

meet the required responses but sometimes

are:-

this cannot be done because of several

ON-OFF

reasons.

Proportional

Proportional-Derivative (PD)

At this time we need to use controllers.

Proportional-Integral (PI)

Proportional-Integral-Derivative (PID)

CONTROLLERS

CONT.…

Water level controller is used as an example in this topic.

The in flow amount controlled by a servo motor based on the set point. The

out flow is uncontrolled.

The deviation of the water level from set point (desired level) is error signal

which is going to feed the controller.

The controller turns the servo to open and close the tap based on the error

amount.

The angle movement is from 0⁰(fully closed), 45⁰(half open) 90⁰ (fully open).

Assumption: Negative error(0⁰)_Zero error(45⁰)_Positive error(90⁰)

ON-OFF CONTROLLER

This two position works as a switch,

Dead band is introduced to prevent chattering

If the level is below set point, tap is fully open.

effect

If the level is on and above set point, tap is fully

Dead band a range of values below or above set

closed.

Solenoid operated valves and relays are ONOFF type controllers

Even though, these controllers are simple and

economical they are not suitable for complex

systems.

point in which the controller take no action.

PROPORTIONAL

The control action is proportional to the present error.

u=Kp x e

If the error is about negative the tap turns toward 0⁰.

If the error is about positive the tap turns toward 90⁰

Make the system responds faster .

The motion is continuous.

May not eliminate steady state error.

INTEGRAL

The control action is proportional to summation of the past

errors.

u=Ki ∫ e

d

U(s)= E(s)

If the error was more positive, most likely the tap remain

open.

If the error was more negative, most likely the tap remain

closed.

Eliminate steady state error.

DERIVATIVE

The control action is proportional to rate of change of

the error. Dependent on the trend of the error rather

than current condition.

u=Kd

U(s)=sKd x E(s)

If the error rate is positive, the tap should be more open.

If the error is negative, the tap should be more closed.

Derivative controller does not used alone.

Reduce oscillation so reduces settling time

PROPORTIONAL INTEGRAL (PI)

Combination of proportional and integral

controllers.

u = Kp ∗ e(t) + Ki ∫ e

d

So make the response faster without

offset.

There may be oscillation.

PROPORTIONAL DERIVATIVE (PD)

Proportional and derivative controllers

are combined.

u(t)=

∗

+

()

So the system is faster and have less

overshoot.

PROPORTIONAL INTEGRAL DERIVATIVE (PID)

Combines the three controllers and their

advantages.

PID controller is assumed to have faster

response, no steady state error, small

overshoot, less settling time and

oscillation.

u t = Kp ∗ e t + Ki e d +

d ( )

d

PHYSICAL REALIZATION OF INDUSTRIAL CONTROLLERS

USING OPAMP

Proportional

Eo

R2

=−

Ei

R1

Integral

=−

Derivative

=−

(sCR1+1)

PID

=−

(

)(

)

Physically these controllers can be tuned by using variable resistor.

Varying the value of the resistor will alter the gain value.

TUNING PID CONTROLLER ZIEGLER-NICHOLS RULE

METHOD 1

There are two tuning methods in Ziegler-Nichols tuning

rules.

u t = Kp ∗ e t + Ki ∫ e(t) d +

( )

Method 1: Used for a system exhibits s-shaped response for

step input.

Type of Controller

P

Kp

T

L

PI

Ki

Kd

0

0

0.9

T

L

T 0.3

0.9 ∗

L L

1.2

T

L

T 1

1.2 ∗

L 2L

PID

0

0.6

TUNING PID CONTROLLER ZIEGLER-NICHOLS RULE

METHOD 2

First find critical gain (Kcr): Gain at

which the system exhibits sustained

oscillation with Ki and Kd zero.

Critical period (Pcr): Period of the system

at critical gain.

Type of Controller

Kp

Ki

Kd

P

0.5Kcr

0

0

PI

0.45Kcr

PID

Kcr

Pcr

0

3.6

Kcr

Pcr

0.075Kcr*Pcr

1.2

0.6Kcr