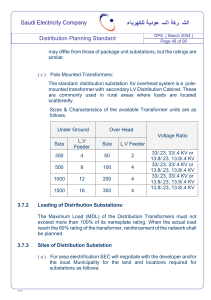

TM2.62.850 AVANGRID TECHNICAL MANUAL Revision 5 Date : 2-2020 Technical Manual A SINGLE PHASE SUBMERSIBLE TRANSFORMERS Approved By AVANGRID Manager – Electric Network Standards Digitally signed by Michael Zaffina DN: cn=Michael Zaffina, o=AVANGRID, ou=Electric Network Standards, email=mike.zaffina@uinet.com, c=US Date: 2020.02.10 13:17:10 -05'00' Date: 02-10-2020 February 5, 2020 Single Phase SubmersibleTransformers TM 2.62.850 INDEX Page No. 1.0 GENERAL ...................................................................................................................... 4 1.1 PURPOSE AND SCOPE ................................................................................................ 4 1.2 REFERENCE STANDARDS .......................................................................................... 4 2.0 RATINGS........................................................................................................................ 5 3.0 CHARACTERISTICS ..................................................................................................... 6 3.1 CONSTRUCTION ........................................................................................................... 6 3.2 PROTECTION ................................................................................................................ 7 3.3 GROUNDING ................................................................................................................. 7 3.4 PRIMARY CONNECTIONS ............................................................................................ 7 3.5 SECONDARY CONNECTIONS...................................................................................... 7 3.6 TAPS................................................................................................................................7 3.7 OIL SPECIFICATIONS ................................................................................................... 8 4.0 MATERIAL DESCRIPTIONS.......................................................................................... 8 5.0 NAMEPLATE AND MARKINGS .................................................................................... 9 5.1 NAMEPLATE .................................................................................................................. 9 5.2 TERMINAL MARKINGS ................................................................................................. 9 5.3 TEMPORARY BAR CODE LABELS ............................................................................... 9 5.4 WARNING LABELS, DANGER SIGNS, AND DECALS.................................................. 9 6.0 PACKAGING ................................................................................................................ 10 7.0 WARRANTY ................................................................................................................. 10 8.0 TESTING ...................................................................................................................... 10 8.1 QUALIFICATION/DESIGN TESTS .............................................................................. 10 8.2 PRODUCTION TESTING ............................................................................................. 10 9.0 DOCUMENTATION ...................................................................................................... 10 11.0 RIGHT TO REVIEW...................................................................................................... 11 APPENDEX A – DRAWING REQUIREMENTS ....................................................................... 12 Page 2 of 18 February 5, 2020 Single Phase SubmersibleTransformers TM 2.62.850 REVISION HISTORY Revision Date Description Author 1 10/5/2011 Initial Changeover to Iberdrola USA Format BCB 2 10/3/2014 Changed TM spec number to TM2.62.850 HBD 3 5/7/2015 Added Protection Section (Section 5) MID # Appendix added. (Section 11). HBD 4 12/20/2018 5 2/5/2020 Combined requirements of RG&E, NYSEG, CMP, UI, made document consistant with the other transformer TM documents. Added 12,470 volt transformers, corrected typos Page 3 of 18 RSV, KM RSV February 5, 2020 Single Phase SubmersibleTransformers 1.0 TM 2.62.850 GENERAL The transformer shall meet all applicable requirements of IEEE C57.12.23– most recent version, except as otherwise specified herein. All characteristics, definitions, terminology, voltage designations and tests shall be in accordance with the most recent versions of the Institute of Electrical and Electronics Engineers (IEEE) standards. 1.1 PURPOSE AND SCOPE This technical manual specifies the technical and functional requirements for Single Phase Submersible Transformers for the Avangrid Networks operating companies (CMP, NYSEG, RG&E, UI). Radial and Loop-feed transformers are covered. 1.2 REFERENCE STANDARDS This specification references the latest revisions of the following industry standards: Industry Standard IEEE C57.12.23 IEEE C57.12.00 IEEE C57.12.32 IEEE C57.12.35 IEEE C57.12.70 IEEE C57.12.80 IEEE C57.106 IEEE C57.154 IEEE C57.12.90 10 CFR Part 431, Subpart K ASTM D3487 Description IEEE Standard for Submersible Single phase Transformers, 167kVA and Smaller: High Voltage, 25000 Volts and Below; Low Voltage, 600 Volts and Below Standard for General Requirements for LiquidImmersed Distribution, Power, and Regulating Transformers Standard for Submersible Equipment-Enclosure Integrity Standard Bar Coding for Distribution Transformers and Step Voltage Regulators Standard for Standard Terminal Markings and Connections for Distribution and Power Transformers Standard Terminology for Power and Distribution Transformers Guide for Acceptance and Maintenance of Insulating Mineral Oil in Electrical Equipment Standard for Design, Testing, and Application of LiquidImmersed Distribution, Power, and Regulating Transformers Using High-Temperature Insulating Systems and Operating at Elevated Temperatures Standard Test Code for Liquid-Immersed Distribution, Power, and Regulating Transformers Energy Efficiency Program for Certain Commercial and Industrial Equipment - Distribution Transformers Standard Specification for Mineral Insulating Oil Used in Electrical Apparatus Page 4 February 5, 2020 Single Phase SubmersibleTransformers TM 2.62.850 2.0 RATINGS 2.1 Kilovolt–ampere (kVA) rating shall be based on a 55 ºC average winding temperature rise and a 70 ºC hot–spot temperature rise. The temperature rise of the insulating oil shall not exceed 55 ºC when measured near the top of the tank. The transformer shall have a 65 ºC temperature rise insulation system. 2.2 Cooling class - ONAN. 2.3 This TM pertains to Single Phase Submersible Transformers with the following kVA ratings and listed primary and secondary voltages: kVA Sizes 25 37.5 50 100 167 250 500 Primary Voltages 4160GRDY/2400 4160 GrdY/2400 X 13800 GrdY/7970 12470 GrdY/7200 2.4 Frequency – 60 Hz. 2.5 BIL Ratings Secondary Voltages 120/240 120 277 2.5.1 Primary Windings – 13,800 volts - 95 kV BIL 2.5.2 Primary Windings – 12,470 volts - 95 kV BIL 2.5.3 Primary Windings – 4,160 volts - 60 kV BIL 2.5.4 Secondary Windings – 30 kV BIL 2.6 Impedance shall not be lower than 1.8%. The tolerance on the impedance shall be as specified in IEEE C57.12.00, clause 9.2. Page 5 February 5, 2020 Single Phase SubmersibleTransformers 3.0 CHARACTERISTICS 3.1 CONSTRUCTION TM 2.62.850 3.1.1 Lifting lugs, to provide a balanced and level lift, shall be provided. 3.1.2 Transformer tank to be of completely welded tank construction. 3.1.3 Finless transformer designs are preferred. 3.1.4 The transformer tank and base bars shall be constructed of 12 gauge (preferred) 316L series stainless steel. 3.1.5 Provisions shall be taken to reduce cathodic corrosion between the 316L stainless steel tank and other dissimilar metal that makes up the rest of the transformer. 3.1.6 Base bars shall provide 1.5 inches of clearance from the floor for jacking and shall not extend more than 1.5 inches beyond the tank. 3.1.7 Overall diameter for transformers with top mounted secondary terminals shall not exceed 28 inches, including all attachments, fins, and appurtenances. 3.1.8 Overall diameter for transformers with side mounted secondary terminals shall not exceed 36 inches, not including all attachments, fins, and appurtenances. 3.1.9 The maximum height for transformers with side mounted secondary terminals shall be 48 inches, including all attachments and appurtenances. 3.1.10 The maximum height for the secondary terminals for side mounted secondaries shall be 40 inches from grade to the centerline of the terminals. 3.1.11 The maximum height for transformers with top mounted secondary terminals shall be 64 inches, including all attachments, fins, and appurtenances. 3.1.12 Qualitrol pressure–relief device #202–014 shall be installed in the cover in Segment 2 or 4. 3.1.13 For transformers with two parking stands, the parking stands located on the cover in segment 3 shall have a minimum of 6 inches separation between the center lines of the high voltage bushing wells and the parking stands. 3.1.14 The transformer shall be manufactured to meet the efficiency requirements specified in the Department of Energy (DOE) Final Rule for Energy Conservation Program for Commercial Equipment: Distribution Transformers Energy Conservation Standards – 10 CFR Part 431 and summarized in Table 431.196(b). Page 6 February 5, 2020 Single Phase SubmersibleTransformers 3.2 PROTECTION TM 2.62.850 3.2.1 High voltage, under-oil (preferred), current limiting (C.L.) fuse shall be provided. 3.3 GROUNDING 3.3.1 Grounding provisions shall be in accordance with IEEE C57.12.23. 3.3.2 High voltage grounding provision shall be located on the tank cover near each high voltage bushing well. 3.3.3 Four transformer tank ground connectors (Burndy Cat No. EQC632C or equivalent) shall be on the transformer side wall or top for easy access. 3.4 PRIMARY CONNECTIONS 3.4.1 200 ampere bushing wells shall be provided. 3.4.2 Bushing wells shall have a 125 kV. BIL rating. 3.4.3 Bushing wells shall have removable studs. 3.4.4 Each bushing well shall have a suitable moisture proof shipping cover. 3.4.5 Parking stand bracket(s) of 12 gauge 316L stainless steel shall be mounted adjacent to the high voltage bushing(s). The brackets shall be mounted so that accessory bushings and portable feedthru bushings may be installed and removed using an eight (8) foot long hotsticks without disturbing other connections. Loop feed transformers shall have two parking stand brackets. 3.5 SECONDARY CONNECTIONS 3.5.1 Secondary terminations shall be either top mounted insulated cables or NEMA spade terminals or side mounted NEMA spade terminals, as described in Table 1. below. 3.5.2 The top mounted secondary cable leads shall extend a minimum of 16 inches above the top of the cover or 16 inches above the top end of the connectors used to attach the secondary leads, whichever is higher. 3.5.3 The leads or NEMA Spades shall be positioned as indicated in Figure 1 and Figure 2 of IEEE C57.12.23. 3.5.4 Secondary leads or NEMA Spades are not to be grounded inside the tank. 3.6 TAPS 3.6.1 When required, 2-2½% above and 2-2½% below rated. See Table 1 Below. Page 7 February 5, 2020 Single Phase SubmersibleTransformers 3.7 TM 2.62.850 OIL SPECIFICATIONS 3.7.1 The transformer shall be filled with transformer mineral oil, electrical grade, meeting the requirements of ASTM D3487 Type II, and applicable sections of IEEE C57.106. 3.7.2 Maximum acceptable PCB concentration is 1 PPM PCB. 4.0 MATERIAL DESCRIPTIONS The following transformers are included in this Technical Manual. Table 1. AVANGRID Single Phase Submersible Transformers MID Number D447251E D447374E D447501E D447757E D447013E D447331E D867252E D867452E D867552E 9708320 kVA Primary Voltage 25 37.5 50 75 100 167 50 100 167 50 9708340 100 9708360 167 9708150 9708160 9708400 250 500 100 9708410 9708420 9708170 167 250 500 4160GRDY/2400 4160GRDY/2400 4160GRDY/2400 4160GRDY/2400 4160GRDY/2400 4160GRDY/2400 12470 GrdY/7200 12470 GrdY/7200 12470 GrdY/7200 4160 GrdY/2400 X 13800 GrdY/7970 4160 GrdY/2400 X 13800 GrdY/7970 4160 GrdY/2400 X 13800 GrdY/7970 13800 GrdY/7970 13800 GrdY/7970 4160 GrdY/2400 X 13800 GrdY/7970 13800 GrdY/7970 13800 GrdY/7970 13800 GrdY/7970 Secondary Voltage 120/240 120/240 120/240 120/240 120/240 120/240 120/240 120/240 120/240 120/240 Radial or Loop Radial Radial Radial Radial Radial Radial Loop Loop Loop Loop Taps Configuration No No No No No No Yes Yes Yes No Top - 2/0AWG Cu Cables Top - 4/0AWG Cu Cables Top - 4/0AWG Cu Cables Top - 500 kcmil Cu Cables Top - 500 kcmil Cu Cables Top - 6-Hole NEMA Spades Top - 4-Hole NEMA Spades Top - 4-Hole NEMA Spades Top - 6-Hole NEMA Spades Side - 4-Hole NEMA Spades 120/240 Loop No Side - 4-Hole NEMA Spades 120/240 Loop No Side - 6-Hole NEMA Spades 120 120 277 Loop Loop Loop No No No Side - 6-Hole NEMA Spades Side - 6-Hole NEMA Spades Side - 4-Hole NEMA Spades 277 277 277 Loop Loop Loop No No No Side - 4-Hole NEMA Spades Side - 6-Hole NEMA Spades Side - 6-Hole NEMA Spades Page 8 February 5, 2020 Single Phase SubmersibleTransformers 5.0 NAMEPLATE AND MARKINGS 5.1 TM 2.62.850 NAMEPLATE 5.1.1 The nameplate shall be constructed of 300 series stainless steel and all printing on the nameplate shall be UV stabilized 5.1.2 Nameplate shall be fastened to the cover using threaded nuts and studs. 5.1.3 The nameplate shall include all information specified in C57.12.23 and C57.12.00, Namplate “A”. 5.1.4 Additionaly, the namplate shall include the following information: Number of gallons of oil Internal circuit diagram Total weight of transformer, in pounds AVANGRID Material ID Barcode of Manufacturer and Serial Number 5.2 TERMINAL MARKINGS 5.2.1 All terminal connections are to be marked in accordance with IEEE C57.12.70. 5.2.2 All markings shall be clearly legible, weather-proof and UV-stabilized. 5.3 TEMPORARY BAR CODE LABELS 5.3.1 Transformers shall have temporary bar code labels meeting the requirements of IEEE C57.12.35. UI transformers shall have an additional temporary bar code label containing the UI MID. The temporary bar code labels shall be located on the side, near the top of the tank. 5.4 WARNING LABELS, DANGER SIGNS, AND DECALS 5.4.1 Warning labels, Danger Signs, and Decals shall be included Page 9 February 5, 2020 Single Phase SubmersibleTransformers 6.0 PACKAGING TM 2.62.850 6.1 Transformers are to be placed on wooden pallets and strapped down. One transformer per pallet. 6.2 Transformers are to be shipped on a flatbed truck with either removable siderails or without siderails. 7.0 WARRANTY 7.0.1 The manufacturer shall agree to repair or replace at their own expense, and to the satisfaction of the purchaser, any part of the equipment which is found to be defective, due to faulty design, workmanship or material for a minimum period of eighteen months after shipment or one year after energization, whichever occurs first. 7.0.2 If the manufacturer elects to return the equipment to their shop for repair, the manufacturer will bear the cost of transportation in both directions and shall be responsible for loss and damage to the equipment during shipment and while in their possession. 8.0 TESTING 8.1 QUALIFICATION/DESIGN TESTS 8.1.1 All tests identified in IEEE C57.12.23 shall be performed in accordance with the noted guidelines, C57.12.00, C57.12.90, and as modified by instructions given in C57.12.23. 8.1.2 A digital copy of all test results shall be made available upon request. 8.2 PRODUCTION TESTING 8.2.1 All routine tests identified in IEEE C57.12.23 shall be performed. Routine tests shall be performed on all transformers delivered to AVANGRID. 8.2.2 AVANGRID reserves the right to be present and witness routine and sample tests. Copies of Production test reports shall be furnished,if requested,for all tests performed. The supplier shall furnish all labor and materials for all tests, including testing facilities, power, instrumentation, and replacement of damaged parts. 9.0 DOCUMENTATION 9.1 ROUTINE TEST DATA - A certified test report, as described in IEEE C57.12.00 shall be provided with all transformers delivered to AVANGRID. The certified test report shall be electronically transmitted to the Manager – Distribution Standards and, in addition, include outline drawings with dimensions and weights. Page 10 February 5, 2020 Single Phase SubmersibleTransformers TM 2.62.850 9.2 Approval drawings are required for all transformers. Drawings shall include a sample nameplate within the same file. Drawings shall be submitted to and approved by AVANGRID Distribution Standards before manufacture. 9.3 Approval drawing filenames shall begin with the TM specification number followed by the AVANGRID MID and the name of the manufacturer. Example “TM2.62.850 D447251 Manufacturer”. Additional information may be included in the filename after the name of the manufacturer. 9.4 Approval drawings shall be in accordance with APPENDIX A of this document. 9.5 For any material or design changes, the Manufacturer shall notify AVANGRID and provide approval drawings to AVANGRID Distribution Standards before manufacture. 10.0 SUPPLIER QUALIFICATION 10.1 The Supplier must have a minimum 10 consecutive years proven track record of manufacturing distribution single phase submersible type transformers for North American Utilities. 10.2 AVANGRID reserves the right to audit the Supplier’s manufacturing facility. Supplier may be disqualified based on the results of the audit, or poor equipment performance. 11.0 RIGHT TO REVIEW AVANGRID reserves the right to review any changes to the principal components in a transformer following approval. Further, AVANGRID reserves the right to be kept informed of any such change to allow a review of any changes that may raise concerns. Failure to notify AVANGRID of any significant changes in transformer design and/or change in manufacturing location may result in vendor disqualification. Page 11 February 5, 2020 Single Phase SubmersibleTransformers TM 2.62.850 APPENDEX A – DRAWING REQUIREMENTS 1. Approval and Production Drawings shall include the following information: Manufacturer Name Customer Name (“AVANGRID”) Drawing Revision Date TM Specification (“TM2.62.850”) Revision Number of TM Specification and/or Revision Date AVANGRID MID kVA Rating Frequency Rating Primary Voltage Rating(s) Secondary Voltage Rating(s) Total Weight with Oil (Pounds) Quantity of Oil (Gallons) All Dimensions (Inches) 2. Drawing must visually show, number, callout, and list the following components: Primary Bushings Secondary Bushings Lifting Hooks Nameplate (specify material) Dual Voltage Switch (if applicable) Tap Changer Handle (if applicable) Tank Ground Provisions Temporary Barcode Label All manufacturer labels 3. Drawing shall include an example nameplate in accordance to Section 5.1 of this document. Page 12 February 5, 2020