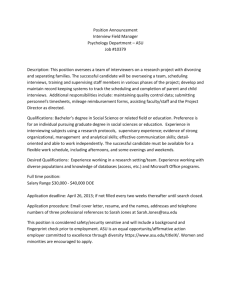

EEE 525: VLSI Design, L-05 Interconnect Vidya Chhabria, vidyachhabria@asu.edu, GWC672 Highlight ▪ ▪ ▪ ▪ Multi-level on-chip interconnects Interconnect parasitics Delay and crosstalk noise Reading: Chapter 3, Chapter 6 EEE525, ASU, V. Chhabria Lecture 05 -2- Highlight ▪ ▪ ▪ ▪ Multi-level on-chip interconnects Interconnect parasitics Delay and crosstalk noise Reading: Chapter 3, Chapter 6 EEE525, ASU, V. Chhabria Lecture 05 -3- Interconnect ▪ Chips are mostly made of wires – In stick diagram, wires set size – Transistors are little under the wires – Many layers of wires ▪ Wires are as important as transistors – Speed – Power – Noise EEE525, ASU, V. Chhabria Lecture 05 -4- Multi-layer Structure ▪ Modern processes use 6-10+ metal layers – M1/2: thin, narrow, high density – Mid layers: thicker and wider (density vs. speed) – Top layers: thickest for VDD/GND, clock, global signaling ▪ Alternating layers run orthogonally Intel 22nm Interconnect EEE525, ASU, V. Chhabria Lecture 05 -5- More and More Important Roles ▪ Wires are as important as transistors – Timing (35% ~ 45% time delay comes from wires) – Power – Noise EEE525, ASU, V. Chhabria Lecture 05 -6- Wire Length Distribution Connection Probability ▪ Local and global wires distributed in a non-uniform way Majority of interconnects are short local wires: Intra cell and intra block wires 0.06 0.04 RC modeling needed Global signals that need better design and planning 0.02 0.2 0.4 0.6 0.8 1.0 Wire length/chip diagonal EEE525, ASU, V. Chhabria Lecture 05 -7- Tracks for Routing ▪ Imaginary lines that serve as guides for routing interconnects. ▪ A wiring route always follows the predefined tracks ▪ Track spacing is typically the minimum allowable DRC spacing between two wires drawn at minimum width EEE525, ASU, V. Chhabria Lecture 04 -8- Highlight ▪ ▪ ▪ ▪ Multi-level on-chip interconnects Interconnect parasitics Delay and crosstalk noise Reading: Chapter 3, Chapter 6 EEE525, ASU, V. Chhabria Lecture 05 -9- Parasitic Parameters ▪ Resistive (R) and Capacitive (C) ▪ Inductive (L): only important in limited cases ▪ Impact on circuit performance – Slow down the signal – Increase power consumption – Reduce reliability EEE525, ASU, V. Chhabria Lecture 05 - 10 - Wire Resistance ▪ R: resistance along the length ▪ ρ(·m): resistivity (Cu 1.7x10-8; Al - 2.7x10-8) ▪ (ρ/t): sheet resistance ▪ Poly gate has resistivity 100x than that of Al ▪ Lower R: – Smaller ρ – Larger w and t – Scale w and t with l EEE525, ASU, V. Chhabria l t R= w l t w Layer Sheet Resistance (/) Poly 3-10 Metal1 0.08 Metal2 0.05 Metal3 0.05 Metal4 0.03 Metal5 0.02 Metal6 0.02 Lecture 05 - 11 - Contact and Via Resistance ▪ Contacts and vias also have 2-20 ▪ Use many contacts for lower R – Many small contacts for current crowding around periphery EEE525, ASU, V. Chhabria Lecture 05 - 12 - Wire Capacitance Ccoupling W t s ▪ ▪ ▪ ▪ C: 2D extraction Neighbor layers are modeled : air – 1; SiO2 – 3.9 Low-k or even airgap h Cground C g = C parallel − plate + C fringe w = 0 + C fringe h EEE525, ASU, V. Chhabria Cc = C parallel − plate + C fringe t = 0 + C fringe s Lecture 05 - 14 - Capacitance in Scaling ▪ R: resistivity goes up because of grain boundaries ▪ C: total C goes down, but Cc/Cg increases as a result of larger t/w; fringe capacitance can also be an issue ▪ RC delay goes up after 22nm [IEDM 2010] EEE525, ASU, V. Chhabria Lecture 05 - 15 - Highlight ▪ ▪ ▪ ▪ Multi-level on-chip interconnects Interconnect parasitics Delay and crosstalk noise Reading: Chapter 3, Chapter 6 EEE525, ASU, V. Chhabria Lecture 05 - 16 - Modeling a RC Network ▪ If Rtotal << Rdriver, then we only need C ▪ If (RC)segment << Tr, then we can use a lumped RC ▪ RC delay should be considered when – tRC >> tgate of the driver – Tr at the line input is Rdriver tgate twire smaller than RC EEE525, ASU, V. Chhabria Lecture 05 - 17 - Elmore Delay Vin Rd r Cd r c r c r c Vout CL ▪ Question: what’s the delay from Vin to each node? ▪ Look at which caps need to be charged through which resistors to get to the node in question T = 0.69 = 0.69 Ci R j i j EEE525, ASU, V. Chhabria Lecture 05 - 18 - Delay of a Distributed RC Line Rd r·(L/N) N segments Vin Cd Vout CL c·(L/N) T = 0.69 = 0.69 Ci R j i j N rL cL = 0.69 (Rd + rL )C L + Rd Cd + i + Rd N N i =1 N ( N + 1) rL cL = 0.69 (Rd + rL )C L + Rd Cd + + Rd (cL ) 2 N N rcL2 = 0.69 (Rd + rL )C L + Rd Cd + + Rd (cL ) 2 EEE525, ASU, V. Chhabria Lecture 05 - 19 - Driving a Long Wire Rd/w, Cdw Identical receiver rL, cL rcL2 Rd Rd (cL) = + rL Cd w + Rd Cd + + 2 w w Rd cL rcL2 = 2 Rd Cd + rLC d w + + w 2 min : rLC d w = Rd cL w c Rd w= r Cd EEE525, ASU, V. Chhabria Lecture 05 - 20 - Crosstalk Noise ▪ Crosstalk can be induced by the adjacent line switching through the coupling capacitance (Cc) ▪ This affects both timing and signal integrity Attacker Cc Victim Cg Cc Noise on a quiet victim VDD C g + Cc EEE525, ASU, V. Chhabria Lecture 05 - 22 - Impact on Timing Attacker V Cc Cg Vdd/2 Victim t Victim Ceff Ceff = Cg + Cc (1 − M ) EEE525, ASU, V. Chhabria − 1 for out - phase switching M = 0 for quiet attacker 1 for in - phase switching Lecture 05 - 23 - Noise Reduction Cc Noise on a quiet victim VDD C g + Cc ▪ Crosstalk gets worse with increasing Cc/Cg ▪ Routing: separate the lines as far as possible ▪ Buffer insertion: break long distance coupling ▪ Design optimization: noiseaware routing and encoding EEE525, ASU, V. Chhabria Lecture 05 - 24 - Summary ▪ Wiring is expensive (gates are cheap) – Cost on delay, energy and area – Routability depends on wiring density, number of layers and design scale ▪ Additional issues on signal integrity – Solutions usually involve the tradeoff between noise reduction and wiring cost EEE525, ASU, V. Chhabria Lecture 05 - 25 -