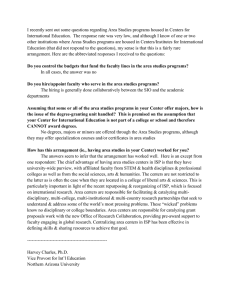

International Journal of Biological Macromolecules 178 (2021) 136–142 Contents lists available at ScienceDirect International Journal of Biological Macromolecules journal homepage: http://www.elsevier.com/locate/ijbiomac Impact of ice structuring protein on myofibrillar protein aggregation behaviour and structural property of quick-frozen patty during frozen storage Fangfei Li a, Xin Du b, Yanming Ren c, Baohua Kong b, Bo Wang b, Xiufang Xia b,⁎, Yihong Bao a,⁎ a b c College of Forestry, Northeast Forestry University, Harbin, Heilongjiang 150040, China College of Food Science, Northeast Agricultural University, Harbin, Heilongjiang 150030, China Heilongjiang Province Agricultural Products and Veterinary Drug Feed Technical Identification Station, Harbin, Heilongjiang 150090, China a r t i c l e i n f o Article history: Received 5 December 2020 Received in revised form 24 January 2021 Accepted 21 February 2021 Available online 23 February 2021 Keywords: Ice structuring protein Quick-frozen pork patties Myofibrillar protein Average particle size Structure unfolding a b s t r a c t The goal of this study was to explore the cryoprotective effect of ice structuring protein (ISP) on the aggregation behaviour and structural changes of myofibrillar protein (MP) from quick-frozen pork patties during frozen storage. Frozen storage causes the formation of large protein aggregates and weakens MP structures. After adding ISP into patties, MP had a more stable aggregation system, which was manifested by a uniform particle size distribution and significantly higher absolute zeta potential (11.71 mV) than the control (9.56 mV) (P < 0.05). Atomic force microscopy results showed that the surface roughness of MP aggregation decreased by 9.78% with ISP after freezing for 180 d. Additionally, compared to patties without ISP, the MP carbonyl content from the ISPtreated patty decreased by 32%, and the free amino content increased by 14.99% during frozen storage. Results from circular dichroism spectroscopy and fluorescence spectroscopy showed that MP secondary and tertiary structure stability in patties improved with ISP. Overall, ISP has the potential to improve MP aggregation and structural stability during frozen storage. © 2021 Elsevier B.V. All rights reserved. 1. Introduction As a type of convenient food, quick-frozen pork patties should be quickly frozen at −30 °C for 30 min and then placed at −18 °C for processing, conservation and sale circulation [1]. These patties are popular with consumers due to their convenient characteristics, satisfactory quality and sensory properties [2]. Frozen storage is one of the most useful methods for food preservation and can effectively prolong the shelf life of meat and meat products by inhibiting microbial spoilage and reducing enzyme activity and biochemical reaction rates [3,4]. However, irreversible changes and quality deteriorations of meat products induced by the formation of ice crystals, recrystallization, oxidative reactions [5] and protein denaturation unavoidably occur during frozen storage [6,7]. Myofibrillar protein (MP), which accounts for approximately 55–65% of meat muscle total protein, is responsible for many physicochemical properties of meat products. Improper MP aggregation and structural degradation are critical factors that reduce protein functionalities, leading to the quality diversification of meat and meat products [8]. For example, the formation of protein aggregates has been known to yield decreasing gel qualities, such as water holding capacity, gel ⁎ Corresponding authors. E-mail addresses: xiaxiufang@neau.edu.cn (X. Xia), baoyihong@163.com (Y. Bao). https://doi.org/10.1016/j.ijbiomac.2021.02.158 0141-8130/© 2021 Elsevier B.V. All rights reserved. strength and microstructure, during frozen storage [9]. Unfolding of the MP structure induced by a high denaturation temperature may cause MP gel to soften and rot, which degrades the final juiciness and organization status of meat products [10]. Also, the destruction of protein structural integrity results in the shrinkage of interfilaments [11], which lead to water moisture and loss of patty after freezing and thawing [4]. Zhang et al. [12] showed that MP oxidative denaturation may lead to a reduction in shrimp texture properties and flavour. Thus, MP properties are critical to improving meat product quality during processing. Emerging techniques, including high-intensity ultrasound [13], electric field-assisted freezing and high-pressure-assisted freezing [14], have been used to inhibit meat quality deterioration by acting on the MP structure. Cryoprotectants, such as alginate oligosaccharides [15], xylooligosaccharides [16], ice structuring protein [17] and plant extract [18], have also been reported to increase functional quality properties when added to food. As a new type of antifreeze agent, ice structuring protein (ISP) is a type of stress-tolerant protein [19] and has been discovered in different organisms, including bony fish [20], insects [21], plants [22], fungi [23] and diatoms [24]. The protective function of ISPs are based on their unique properties, which include ice plane affinity [25], thermal hysteresis [26], ice recrystallization inhibition ( [27] and transient binding of an organism to ice [28]. ISP in frozen food can control the growth morphology and aggregation of ice crystals [29,30], F. Li, X. Du, Y. Ren et al. International Journal of Biological Macromolecules 178 (2021) 136–142 2.6. Surface morphology which can enhance cell integrity and reduce tissue damage [31]. In frozen meat systems, the inhibitory effect of ISP on meat quality deterioration [32] and peroxidation [30] during freezing processes has been demonstrated. Previous studies have also shown that ISP can effectively protect the quality of meat and meat products [33]. To date, information concerning the impact of ISP on MP aggregation behaviour and structural properties in patties during frozen storage has not been reported. The objective of this study was to identify the cryoprotective effect of ISP on the aggregation behaviour and structural changes in MP and to show the mechanism by which ISP maintains the MP characteristics of quick-frozen pork patties during frozen storage. The micromorphology of MP aggregation was measured using atomic force microscopy (AFM). MP (40 mg/mL) was deposited onto glass slides heated at 75 °C for 20 min and then immediately blowdried. Results were acquired using an AFM instrument (Veeco Instruments Inc., USA) in tapping mode. 2.7. MP primary structure 2.7.1. Carbonyl content measurement The carbonyl group was measured using the method described by Li et al. [4] and calculated using the absorption coefficient (22,000 M−1 cm−1). 2. Materials and methods 2.1. Chemical 2.7.2. Free amino content determination MP (0.25 mL, 1 mg/mL) was dissolved in a phosphate buffer (pH 8.2), mixed with 2 mL of TNBS for 60 min, and kept away from light at 50 °C. Absorbance was noted at 340 nm by a spectrophotometer, and the contents of free amino acids were estimated using the L-leucine standard curve. The ice structuring proteins were procured by Nanjing Anfei Bio at a purity above 95%. Piperazine-N,N′-bis-2-ethanesulfonic acid, sodium chloride (NaCl), ortho-phthaldialdehyde, trichloroacetic acid, hydrochloric acid, ethanol, ethyl acetate, guanidine, borax, 2,4dinitrophenylhydrazine, sodium dodecyl sulfate, guanidine hydrochloride, β-mercaptoethanol and L-leucine were purchased from Solabio Corporation (Beijing, China). All chemicals were of analytical grade. 2.8. MP secondary structure The extracted MP (0.2 mg/mL) was characterized on a circular dichroism (CD) instrument (Jasco J-815, Tokyo, Japan) with a scan rate of 100 nm/min and a spectral range from 200 nm to 260 nm. 2.2. Patty preparation Post-rigor pork shoulder and neck were purchased from Jiajiale commercial abattoir (Harbin, Heilongjiang, China). Trimmed of visible connectivity, the meat, ISPs (0% and 0.20%) and 12% ice water were mixed for 5 min. The mixture was made into patties of approximately 100 g each (9 cm diameter and 2 cm thickness) and then kept at −18 °C. A total of 30 patients were divided into 2 groups: the control group (15 samples with 0% ISP) and the ISP group (15 samples with 0.20% ISP). Each group was randomly divided into 5 treatments and frozen for 0, 30, 60, 90 and 180 d. Samples were thawed at 4 °C overnight before analysis. 2.9. MP tertiary structure The MP tertiary structure was measured on a fluorescence spectrophotometer (Hitachi Co., Tokyo, Japan) under an excitation wavelength of 283 nm, a slit width of 5 nm, a scanning wavelength of 300–400 nm and a scan speed of 240 nm/min. 2.10. Statistical analyses Data were analysed using by analysis of variance (ANOVA) with Statistix 8.1 (Analytical Software, St. Paul, MN). The means ± standard deviations were considered significant when P < 0.05. All graphs were generated using SigmaPlot 12.5. 2.3. Myofibrillar protein preparation MP was extracted via the following procedure and stored in a refrigerator (4 °C). Briefly, the minced patty was homogenized 3 times with 4 vol cold-extracted solution (pH 7.0) and then centrifuged at 6500 ×g for 15 min at 4 °C. The obtained pellet was washed 3 times with 4 vol extracting buffer (0.1 M NaCl) and centrifuged at 6500 ×g for 15 min at 4 °C again. The obtained MP extractions were kept at 4 °C. 3. Results and discussion 3.1. Protein aggregation behaviour 3.1.1. Particle size The effects of ISP and frozen storage on myofibrillar protein aggregation was assessed with dynamic light scattering and are shown in Fig. 1A and Table 1. At the start of frozen storage, a relatively uniform and wide particle distribution was observed in the control and ISP groups, which showed that the distribution of fresh samples was uniform and stable. During frozen storage, the first clear trend was an increase in the average particle size of MP from all samples. For the control, d43 and d32 increased by 41.82% and 41.55%, respectively, after freezing for 180 d. The changes in the mean particle diameters were primarily caused by myofibrillar protein unfolding and an increase in protein surface area [9]. Additionally, the disulphide bridges, hydrogen bonds, and hydrophobic interactions between proteins were also strengthened, which promoted the aggregation of MP and increased the average particle size [35]. Compared to the control, the particle size gradually decreased with the addition of ISP. After freezing for 180d, d43 and d32 of the samples with ISP significantly decreased by 4.57% and 4.26% compared to those of the control (P < 0.05). Similarly, d0.1, d0.5 and d0.9 of the samples with ISP significantly decreased by 4.91%, 4.73% and 5.31%, respectively 2.4. Particle size distribution MP particle size was measured with 1.5 mL of MP-dissolving liquid (1 mg/mL) in a Mastersizer 2000 instrument (Malvern, UK). The aggregate degree of the MP was determined by the following statistical parameters: d43-volume-mean diameter; d32-volume-surface-mean diameter; and dV,0.1, dV,0.5, and dV,0.9 represented the size of the particle for which 10%, 50% and 90% of the sample was below this size, respectively. 2.5. Zeta potential The MP zeta potential (0.1 mg/mL) was evaluated using a zeta potential analyser (Zeta Plus, Brookharen, Holtsville, NY, USA), and certain modifications were made based on the method described by Beliciu and Moraru [34]. After the MP concentration was adjusted by double steaming wate, 1 mL of MP was transferred to the measuring tank, and the average measurement was 6. 137 F. Li, X. Du, Y. Ren et al. International Journal of Biological Macromolecules 178 (2021) 136–142 Frozen storage (d) 0 6 0 30 60 90 180 5 -5 Zeta potential 4 3 2 1 0 1 Par (A) 0 m) 90 -15 180 1000 Aa Bb Cb (d) 180 ge a 90 r 60 ol sto 30 -20 ntr 0 Co ozen r (B) F 10 t icl e si 100 ze ( μ 60 30 -10 Ca Da Eb Da Aa Ba Db Control ISP P IS Fig. 1. Effect of ISP on the particle size and Zeta potential of myofibrillar protein of pork patties during frozen storage. a–b indicate significant differences (P < 0.05) with the same frozen storage of different treatments. A–E indicate significant differences (P < 0.05) with the same treatment after different frozen storage. (Fig. 2D) by AFM [41]. As shown in Fig. 2, the bright and dark regions (Fig. 2A and C) occur in convex and concave areas of the MP aggregation surface, respectively. Additionally, the red arrows (Fig. 2B) indicate the highest and the lowest locations on the cross-section of each image [9,42]. The surface morphology of MP aggregation was smooth and homogeneous before frozen storage. The MP aggregation surface had a brighter and concave area, and a larger distance between the highest and lowest points after freezing for 180 d. A significant increase from 23.8 nm to 64.4 nm in the average roughness after 180 d was also observed in the control group (P < 0.05). These observations indicated that the MP in patties underwent substantial molecular changes and gradually formed protein aggregates during frozen storage [43]. The consistent production of these aggregates was due to protein oxidation and denaturation, which were caused by ice crystals growing after freezing [44]. Compared to the control, samples from the ISP group had a smoother and more homogeneous gel morphology and lower Rg after the same storage time. Results showed that the behaviour of protein aggregation was inhibited by adding ISP. Kong et al. [31] found that ISP added to patties could decrease the degree of muscle cell damage by inhibiting recrystallization. Therefore, the adjunction of ISP could maintain protein structure stability to some extent by preventing protein oxidation during frozen storage [27]. (P < 0.05). Results thus showed that ISP added to patties effectively decreased protein aggregation [36]. ISP inhibits the protein aggregation of pork patties during frozen storage, which can be associated with less damage to muscle tissue. ISP can also inhibit recrystallization and prevent irreversible mechanical damage to tissues from ice crystals. Additionally, the protein denaturation induced by freezing can be delayed during frozen storage [27]. 3.1.2. Zeta potential The zeta potential is a critical stability indicator of myofibrillar proteins that can be used to evaluate the driving force for electrostatic interactions between charged biopolymers [37]. As shown in Fig. 1B, control MPs exhibited a relatively low net negative charge (−15.23 mV) because weakly acidic proteins, such as aspartic acid and glutamic acid, form during frozen storage. As frozen storage lengthened, the zeta potential significantly increased to −9.56 mV (P < 0.05), which could be due to partial protein denaturation and aggregate formation [38]. The results are similar to those in Fig. 1A, in which protein aggregation occurred during frozen storage. During storage, patties with ISP had significantly lower MP zeta potentials. Particularly after freezing for 180 d, the MP zeta potential with ISP decreased by 22.48% compared to the control. Results showed that the addition of ISP can inhibit MP aggregation after freezing because the formation of ice crystals was controlled by ISP, thus decreasing protein freezing denaturation and aggregation [39]. The MP particle size with ISP was more uniformly distributed and had a larger electrostatic repulsive force, which could prevent protein aggregation [40]. 3.2. Protein structural property 3.2.1. Carbonyl content Carbonyl content is one of the most important characteristics to evaluate changes in a protein's primary structure. The effect of ISP and frozen storage on the carbonyl groups is shown in Fig. 3A. After being 3.1.3. Surface morphology The surface state of MP aggregation is shown in 2D images (Fig. 2A), cross-sections of images (Fig. 2B), 3D images (Fig. 2C), and Rq values Table 1 Effect of ISP on the particle size of myofibrillar protein of pork patties during frozen storage. Frozen storage (d) Particle size (μm) d32 d43 Control ISP 0 30 60 90 180 0 30 60 90 180 Ea 86.41 ± 0.45 90.47 ± 0.77Da 96.20 ± 0.27Ca 109.28 ± 0.73Ba 122.54 ± 0.85Aa 86.64 ± 1.16Da 89.08 ± 0.66CDa 91.84 ± 1.92Cb 104.95 ± 1.42Bb 116.94 ± 2.03Ab 40.79 46.46 50.74 54.93 57.74 41.48 40.14 46.94 50.88 55.28 dV,0.1 ± ± ± ± ± ± ± ± ± ± Ea 0.89 0.44Da 1.32Ca 0.77Ba 0.19Aa 1.46Da 1.07Db 0.04Cb 1.48Bb 1.04Ab 20.21 22.73 24.34 26.13 27.31 19.91 21.19 23.19 24.26 25.97 dV,0.5 ± ± ± ± ± ± ± ± ± ± Da 0.41 0.54Ca 0.57Ba 0.71Aa 0.05Aa 0.82Ca 0.89Ca 0.60Ba 0.22ABb 0.76Ab 61.27 68.07 72.99 87.92 92.58 63.78 68.75 71.49 76.02 88.20 dV,0.9 ± ± ± ± ± ± ± ± ± ± Da 3.51 0.80Ca 1.00Ba 1.16Aa 0.84Aa 1.47Da 0.94Ca 1.12Ca 0.26Bb 1.28Ab 179.61 186.96 198.90 224.06 254.83 181.22 177.54 183.98 215.89 241.31 ± ± ± ± ± ± ± ± ± ± 1.29Ea 0.13Da 0.96Ca 4.16Ba 3.43Aa 4.16Ca 2.04Cb 4.26Cb 1.17Bb 3.50Ab indicate significant differences (P < 0.05) with the same frozen storage of different treatments. A–E indicate significant differences (P < 0.05) with the same treatment after different frozen storage. a–b 138 F. Li, X. Du, Y. Ren et al. International Journal of Biological Macromolecules 178 (2021) 136–142 Fig. 2. Effect of ISP on the surface roughness of myofibrillar protein (3.0 × 3.0 μm2 scan size) of pork patties during frozen storage. A: The scale displayed on the left ranges from 0 to 200 nm. The straight line on the 2D image represent the incision location of cross-sections. B: The image cross-sections correspond to the section cut by the straight line on the 2D image. a–b indicate significant differences (P < 0.05) with the same frozen storage of different treatments. A–C indicate significant differences (P < 0.05) with the same treatment after different frozen storage. after 30 d of frozen storage. After freezing for 180 d, patties with ISP had lower carbonyl contents than patties without ISP, with a significant difference of 32% (P < 0.05). The large ice crystals formed and destroyed the muscle, which caused MP freezing and oxidative denaturation [4]. With ISP bound, the mechanical damage of muscle was controlled by inhibiting the growth of ice crystals [48]. Therefore, the degree of protein degeneration decreased. frozen for 180 d, there was a significant increase in carbonyl contents in all samples (P < 0.05). Protein oxidation occurs frequently and leads to the formation of carbonyl compounds [45]. During long-term frozen storage, the formation of ice crystals caused damage to the muscle cell ultrastructure, which released free radicals. This process aggravates oxidative changes in proteins and the formation of carbonyl groups [6,46]. Additionally, the NH and NH2 of protein side chains easily undergo oxidative changes and form carbonyl compounds [16]. Cheng, Xu, Xiang, Liu, and Zhu [47] also found that carbonyl accumulation in minced pork slice proteins increased significantly during frozen storage. Although no significant differences were detected at the beginning of frozen storage in all samples (P > 0.05), the control sample showed a sharp rise in carbonyl content compared to samples treated with ISP 3.2.2. Free amino content Changes in the free amino contents of proteins can be used to evaluate alterations in MP primary structure [49]. As shown in Fig. 3B, all samples had significantly decreasing free amino contents after 180 d (P < 0.05). The free amino acid contents of the control group and the 139 Control ISP 3 Aa Ba Ca 2 Ab Ab Bb Da 1 Ea Ca Cb Free amino (nmol/mg protein) International Journal of Biological Macromolecules 178 (2021) 136–142 Carbonyl contents (nmol/mg protein) F. Li, X. Du, Y. Ren et al. Control ISP Aa Aa Bb Ba Ca Da Cb Da Db 80 Eb 60 40 0 0 (A) 100 30 60 90 0 180 Frozen storage (d) (B) 30 60 90 180 Frozen storage (d) Fig. 3. Effect of ISP on the primary structure of myofibrillar protein of pork patties during frozen storage. a–b indicate significant differences (P < 0.05) with the same frozen storage of different treatments. A–E indicate significant differences (P < 0.05) with the same treatment after different frozen storage. recrystallization and changed ice crystal morphology. Thus, cellstructure integrity is maintained, and the degree of protein oxidation decreased [17]. Considering the result regarding carbonyl content, ISP can decrease oxidative damage to patties. ISP group decreased 23.09% and 12.99%, respectively. Proteins are susceptible to attack by reactive oxygen species while frozen [50]. The NH2 groups of amino acid residues could be transformed into carbonyl groups through a deamination process during frozen storage. Additionally, derivatives then reacted with available NH2 groups, thus causing a further decrease in free amino content [51,52]. Results thus responded to changes in carbonyl contents. Compared to the control, the ISP group showed a marginally lower decrease in free amino contents during frozen storage. After the same frozen-storage period, the samples with ISP had higher amino contents than those without ISP. Particularly at 180 d, the difference in amino contents was as high as 14.99%. Mechanical damage to muscle caused by recrystallization leads to protein oxidative denaturation. The higher amino contents in the ISP group indicated that ISP hindered 3.2.3. MP secondary structure The stability of MP secondary structural characteristics can be described by circular dichroism (CD) far-ultraviolet spectra, which comprise α-helices, β-sheets, β-turns and random coils [57]. Fig. 4 shows that the far-ultraviolet wavelengths of all samples exhibit typical negative peaks at 190–250 nm. With longer frozen storage, the secondary structures of all samples showed a similar trend: the percentage of αhelixes and β-turns gradually decreased, while the fraction of β-sheets and random coils significantly increased (P < 0.05). The protein Fig. 4. Effect of ISP on the secondary structure of myofibrillar protein of pork patties during frozen storage. (Control: A and B; ISP: C and D). a–b indicate significant differences (P < 0.05) with the same frozen storage of different treatments. A–C indicate significant differences (P < 0.05) with the same treatment after different frozen storage. 140 F. Li, X. Du, Y. Ren et al. International Journal of Biological Macromolecules 178 (2021) 136–142 0d 30 d 60 d 90 d 180 d 5000 6000 Fluorescence intensity Fluorescence intensity 6000 4000 3000 2000 1000 5000 4000 3000 2000 1000 0 300 (A) 0d 30 d 60 d 90 d 180 d 320 340 360 380 0 400 300 320 (B) Wavelength (nm) 340 360 380 400 420 Wavelength (nm) Fig. 5. Effect of ISP on the tertiary structure of myofibrillar protein of pork patties during frozen storage. (Control: A; ISP: B). protein aggregation, as shown by the MP particle size distribution, zeta potential and AFM. Additionally, the lower carbonyl contents and higher free amino contents of the ISP group showed that MP primary structure degradation was inhibited by ISP. Concurrently, the secondary and tertiary structures of MP from pork patties with ISP tended to stabilize after frozen storage. These results systematically showed the mechanism by which ISP inhibits the frozen denaturation of patties based on the importance of the aggregation behaviour and structure of MP. Therefore, this study provides useful information for the future study of the cryoprotective effect of ISP on meat and meat products. Future research should focus on exploring the molecular interactions between the structure of ISP and MP spatial conformation at the molecular level. oxidation aggravation induced by freezing causes a decrease in the percentage of α-helical conformation [16]. Additionally, freezing destroys hydrogen bonds and disorders the MP structure, which transforms the helix structure to a random structure [40]. Jin et al. [53] showed that the protein structure stability of duck breast muscle decreased due to the hydrophobic interaction of protein during frozen storage. When the storage time was the same, patties with ISP exhibited more stable secondary protein structures, as shown in the significantly fewer changes in the contents of α-helices, β-sheets, β-turns and random coils (P < 0.05). Results thus suggested that ISP decreased the degree of hydrophobic residue exposure and inhibited interaction among amino acid side chains. ISP can modify ice crystal morphology and inhibit recrystallization, minimizing freezing and oxidation damage [31]. Nian et al. [27] also reported the same conclusion that antifreeze proteins could maintain the secondary structural stability of large-mouth bass MP during F-T cycles. Credit author statement Fangfei Li: Methodology, Software, Validation, Formal analysis, Investigation, Writing-Original Draft, Funding acquisition. Xin Du: Investigation, Software. Yanming Ren: Formal analysis. Baohua Kong: Conceptualization, Resources. Bo Wang: Investigation, Formal analysis. Xiufang Xia: Conceptualization, Writing - Original Draft, Supervision, Funding acquisition. Yihong Bao: Conceptualization, Resources. 3.2.4. MP tertiary structure Fluorescence intensity (FI) describes the changes in MP tertiary structure via the reflection of tryptophan (Trp) residues towards the polarity of the microenvironment [54]. Changes in the fluorescence intensity of MP are shown in Fig. 5. All samples exhibited a broad spectrum at 336 nm, and as the frozen storage period increased up to 180 d, FI decreased significantly (P < 0.05). The exposed and denatured indole side chains of Trp residues, which are located in the head and tail regions of myosin, cause the formation of protein aggregation and the weakness of protein conformation affected by freezing [55]. Additionally, MP unfolding and partial changes in protein conformation can lead to the exposure of Trp in amino acids. The decrease in FI of MP was also due to increased steric hindrance, which was caused by the aggregation of MP and the rise in hydrophobic interactions. This result is consistent with a study that showed that the reductions in FI could be due to the exposure and denaturation of Trp residue indole side chains towards the aqueous environment or polarity of the environment [56]. Compared to the control, ISP MP samples exhibited more stable FI after frozen storage. After adding ISP, recrystallization in patties was inhibited, which decreased the damage to protein structure. ISP inhibited myofibrillar protein denaturation and strengthened the hydrogen interactions between protein molecules, which could control the formation and growth of ice crystals during frozen storage [40]. Similar results have been described by Nian et al. [27], who showed that the antifreeze protein could maintain a stable myofibrillar protein tertiary structure after freezing and thawing. Acknowledgements This study was supported by Northeast Forestry University's research funding for talent introduced (grant no. 60201520109) and the National Natural Science Foundation of China (grant no. 31571859 and 31771903). References [1] B. Wang, F.F. Li, N. Pan, B.H. Kong, X.F. Xia, Effect of ice structuring protein on the quality of quick-frozen patties subjected to multiple freeze-thaw cycles, Meat Sci. 172 (2021), 108335. [2] T.W. Zhu, X. Zhang, B. Li, H. Wu, Effect of interesterified blend-based fast-frozen special fat on the physical properties and microstructure of frozen dough, Food Chem. 272 (2019) 76–83. [3] W.W. Cheng, K.M. Sørensen, S.B. Engelsen, D.W. Sun, H.B. Pu, Lipid oxidation degree of pork meat during frozen storage investigated by near-infrared hyperspectral imaging: effect of ice crystal growth and distribution, J. Food Eng. 263 (2019) 311–319. [4] F.F. Li, Q. Zhong, B.H. Kong, B. Wang, N. Pan, X.X. Xia, Deterioration in quality of quick-frozen pork patties induced by changes in protein structure and lipid and protein oxidation during frozen storage, Food Res. Int. 133 (2020), 109142. [5] B.C. Figueirêdo, I.J. Trad, L.R.B. Mariutti, N. Bragagnolo, Effect of annatto powder and sodium erythorbate on lipid oxidation in pork loin during frozen storage, Food Res. Int. 65 (2014) 137–143. [6] C. Leygonie, T.J. Britz, L.C. Hoffman, Impact of freezing and thawing on the quality of meat, Meat Sci. 91 (2) (2012) 93–98. [7] N. Nakazawa, R. Wada, H. Fukushima, R. Tanaka, S. Kono, E. Okazaki, Effect of longterm storage, ultra-low temperature, and freshness on the quality characteristics of frozen tuna meat, Int. J. Refrig. 112 (2020) 270–280. 4. Conclusions The goal of this study was to investigate the protective effect of ISP on the MP aggregation state and structural changes in pork patties during frozen storage. Results show that ISP decreased the degree of 141 F. Li, X. Du, Y. Ren et al. International Journal of Biological Macromolecules 178 (2021) 136–142 [8] B. Chen, J. Guo, Y. Xie, K. Zhou, P.J. Li, B.C. Xu, Modulating the aggregation of myofibrillar protein to alleviate the textural deterioration of protein gels at high temperature: the effect of hydrophobic interactions, Food Chem. 341 (2021), 128274. [9] F.F. Li, B. Wang, B.H. Kong, S. Shi, X.F. Xia, Decreased gelling properties of protein in mirror carp (Cyprinus carpio) are due to protein aggregation and structure deterioration when subjected to freeze-thaw cycles, Food Hydrocoll. 97 (2019), 105223. [10] A.A. Teixeira, Thermal processing for food sterilization and preservation, in: M. Kutz (Ed.), Handbook of Farm, Dairy and Food Machinery Engineering, 3rd ed.Academic Press 2019, pp. 499–523. [11] A. Nawaz, Z.Y. Xiong, H.G. Xiong, S. Irshad, L. Chen, P.K. Wang, ... S.H. Qamar, The impact of hydrophilic emulsifiers on the physico-chemical properties, microstructure, water distribution and in vitro digestibility of proteins in fried snacks based on fish meat, Food &amp; Function 10 (10) (2019) 6927–6935. [12] B. Zhang, C.D. Fang, G.J. Hao, Y.Y. Zhang, Effect of kappa-carrageenan oligosaccharides on myofibrillar protein oxidation in peeled shrimp (Litopenaeus vannamei) during long-term frozen storage, Food Chem. 245 (2018) 254–261. [13] H.T. Liu, H. Zhang, Q. Liu, Q. Chen, B.H. Kong, Solubilization and stable dispersion of myofibrillar proteins in water through the destruction and inhibition of the assembly of filaments using high-intensity ultrasound, Ultrason. Sonochem. 67 (2020), 105160. [14] S.G. Sutariya, V. Sunkesula, Food freezing: emerging techniques for improving quality and process efficiency a comprehensive review, Innovative Food Processing Technologies (2021) 36–63. [15] B. Zhang, J.L. Zhao, S.J. Chen, X.L. Zhang, W.Y. Wei, Influence of trehalose and alginate oligosaccharides on ice crystal growth and recrystallization in whiteleg shrimp (Litopenaeus vannamei) during frozen storage with temperature fluctuations, Int. J. Refrig. 99 (2018) 176–185. [16] N. Walayat, Z.Y. Xiong, H. Xiong, H.M. Moreno, P.K. Wang, M.N. Ahmad, ... P. Wang, Cryoprotective effect of egg white proteins and xylooligosaccharides mixture on oxidative and structural changes in myofibrillar proteins of Culter alburnus during frozen storage, International Journal of Biological Macromolecules 158 (2020) 865–874. [17] H. Xiang, X.H. Yang, L. Ke, Y. Hu, The properties, biotechnologies, and applications of antifreeze proteins, Int. J. Biol. Macromol. 153 (2020) 661–675. [18] A. Damerau, T. Kakko, Y. Tian, S. Tuomasjukka, M. Sandell, A. Hopia, B. Yang, Effect of supercritical CO2 plant extract and berry press cakes on stability and consumer acceptance of frozen Baltic herring (Clupea harengus membras) mince, Food Chem. 332 (2020), 127385. [19] M. Hassas-Roudsari, H.D. Goff, Ice structuring proteins from plants: mechanism of action and food application, Food Res. Int. 46 (1) (2012) 425–443. [20] A.L. Devries, Glycoproteins as biological antifreeze agents in Antarctic fishes, Science 163 (1971) 1152–1155. [21] J.G. Duman, V. Bennett, T. Sformo, R. Hochstrasser, B.M. Barnes, Antifreeze proteins in alaskan insects and spiders, J. Insect Physiol. 50 (4) (2004) 259–266. [22] B. Sharma, D. Sahoo, Renu Deswal, Single-step purification and characterization of antifreeze proteins from leaf and berry of a freeze-tolerant shrub seabuckthorn (Hippophae rhamnoides), J. Sep. Sci. 41 (2018) 3938–3945. [23] J. Cheng, Y. Hanada, A. Miura, S. Tsuda, H. Kondo, Hydrophobic ice-binding sites confer hyperactivity of an antifreeze protein from a snow mold fungus, Biochem. J. 473 (2016) 4011–4026. [24] M.G. Janech, A. Krell, T. Mock, J.S. Knag, J. Raymond, Ice-binding proteins from sea ice diatoms (Bacillariophyceae), J. Phycol. 42 (2010) 410–416. [25] P. Kashyap, S. Kumar, D. Singh, Performance of antifreeze protein HrCHI4 from Hippophae rhamnoides in improving the structure and freshness of green beans upon cryopreservation, Food Chem. 320 (2020) 126559. [26] D.H. Song, M. Kim, E.S. Jin, D.W. Sim, H.S. Won, E.K. Kim, ... J.H. An, Cryoprotective effect of an antifreeze protein purified from Tenebrio molitor larvae on vegetables, Food Hydrocolloids 94 (2019) 585–591. [27] L.Y. Nian, A.L. Cao, L.Y. Cai, Investigation of the antifreeze mechanism and effect on quality characteristics of largemouth bass (Micropterus salmoides) during F-T cycles by hAFP, Food Chem. 325 (2020), 126918. [28] L.L.C. Olijve, K. Meister, A.L. Devries, J.G. Duman, S. Guo, H.J. Bakker, I.K. Voets, Blocking rapid ice crystal growth through nonbasal plane adsorption of antifreeze proteins, Proc. Natl. Acad. Sci. U. S. A. 113 (14) (2016) 3740–3745. [29] P.L. Davies, C.L. Hew, Biochemistry of fish antifreeze proteins, FASEB J. 4 (8) (1990) 2460–2468. [30] S.J. Lee, H.J. Kim, S.H. Cheong, Y.S. Kim, S.E. Kim, J.W. Hwang, ... P.J. Park, Antioxidative effect of recombinant ice-binding protein (rLeIBP) from Arctic yeast Glaciozyma sp. on lipid peroxidation of Korean beef, Process Biochemistry 50 (12) (2015) 2099–2104. [31] C.H.Z. Kong, N. Hamid, Q. Ma, J. Lu, B.G. Wang, V. Sarojini, Antifreeze peptide pretreatment minimizes freeze-thaw damage to cherries: An in-depth investigation, LWT 84 (2017) 441–448. [32] D. Le Tri, C.L. Childers, M.K. Adam, R.N. Ben, K.B. Storey, K.K. Biggar, Characterization of ice recrystallization inhibition activity in the novel freeze-responsive protein Fr10 from freeze-tolerant wood frogs, Rana sylvatica, J. Therm. Biol. 84 (2019) 426–430. [33] X. Du, P. Chang, J.Y. Tian, B.H. Kong, F.D. Sun, X.F. Xia, Effect of ice structuring protein on the quality, thermal stability and oxidation of mirror carp (Cyprinus carpio L.) [34] [35] [36] [37] [38] [39] [40] [41] [42] [43] [44] [45] [46] [47] [48] [49] [50] [51] [52] [53] [54] [55] [56] [57] 142 induced by freeze-thaw cycles, LWT-Food Science and Technology 124 (109140) (2020). C.M. Beliciu, C.I. Moraru, The effect of protein concentration and heat treatment temperature on micellar casein-soy protein mixtures, Food Hydrocoll. 25 (6) (2011) 1448–1460. R.S. Filgueras, P. Gatellier, C. Ferreira, R.C. Zambiazi, Veronique Santé-Lhoutellier, Nutritional value and digestion rate of rhea meat proteins in association with storage and cooking processes, Meat Sci. 89 (1) (2011) 6–12. M. Dong, H.X. Tian, Y.J. Xu, M.Y. Han, X.L. Xu, Effects of pulsed electric fields on the conformation and gelation properties of myofibrillar proteins isolated from pale, soft, exudative (PSE)-like chicken breast meat: a molecular dynamics study, Food Chem. (2021), 128306. D. Mukherjee, S.K. Chang, Y. Zhang, S. Mukherjee, Effects of ultra-high pressure homogenization and hydrocolloids on physicochemical and storage properties of soymilk, J. Food Sci. 82 (10) (2017) 2313–2320. Z.Y. Yu, S.W. Jiang, X.M. Cao, S.T. Jiang, L.J. Pan, Effect of high pressure homogenization (HPH) on the physical properties of taro (Colocasia esculenta (L). Schott) pulp, J. Food Eng. 177 (2016) 1–8. V. Kontogiorgos, H.D. Goff, S. Kasapis, Effect of aging and ice-structuring proteins on the physical properties of frozen flour-water mixtures, Food Hydrocoll. 22 (6) (2008) 1135–1147. Y.Y. Wang, M.T. Rashid, J.K. Yan, H. Ma, Effect of multi-frequency ultrasound thawing on the structure and rheological properties of myofibrillar proteins from small yellow croaker, Ultrason. Sonochem. 70 (2020) 105352. J. Zhao, F. Sun, Y. Li, Q. Liu, B. Kong, Modification of gel properties of soy protein isolate by freeze-thaw cycles are associated with changes of molecular force involved in the gelation, Process Biochem. 52 (2016) 200–208. B. Wang, X. Du, Q. Liu, B.H. Kong, F.F. Li, N. Pan, ... D.J. Zhang, Effect of ultrasound thawing, vacuum thawing, and microwave thawing on gelling properties of protein from porcine longissimus dorsi, Ultrasonics Sonochemistry 64 (2020) 4104860. W. Feng, R. Wang, Z. Chen, T. Wang, Inhibition of aggregation of physically modified rice proteins by isoconcentration of l-Arg and l-Glu, Int. J. Biol. Macromol. 127 (2019) 693–700. S. Posé, A.R. Kirby, J.A. Mercado, V.J. Morris, M.A. Quesada, Structural characterization of cell wall pectin fractions in ripe strawberry fruits using AFM, Carbohydr. Polym. 88 (3) (2012) 882–890. Lund, M. N., & Baron, C. P. (2010). Protein oxidation in foods and food quality. In L. H. Skibsted, J. Risbo, & M. L. Andersen (Eds.), Chemical Deterioration and Physical Instability of Food and Beverages (pp. 33–69). Cambridge: Woodhead Publishing Limited. M. Nikoo, S. Benjakul, X. Xu, Antioxidant and cryoprotective effects of Amur sturgeon skin gelatin hydrolysate in unwashed fish mince, Food Chem. 181 (2015) 295–303. J.R. Cheng, L. Xu, R. Xiang, X.M. Liu, M.J. Zhu, Effects of mulberry polyphenols on oxidation stability of sarcoplasmic and myofibrillar proteins in dried minced pork slices during processing and storage, Meat Sci. 160 (2020), 107973. M. Mangiagalli, S. Brocca, M. Orlando, M. Lotti, The “cold revolution”. Present and future applications of cold-active enzymes and ice-binding proteins, New Biotechnol. 55 (2020) 5–11. E. Sehanobish, M.D. Chacón-Verdú, A. Sanchez-Amat, V.L. Davidson, Roles of active site residues in Lod a, a cysteine tryptophylquinone dependent ε-lysineoxidase, Arch. Biochem. Biophys. 579 (8) (2015) 26–32. G.L. Jia, S. Nirasawa, X.H. Ji, Y.K. Luo, H.J. Liu, Physicochemical changes in myofibrillar proteins extracted from pork tenderloin thawed by a high-voltage electrostatic field, Food Chem. 240 (2018) 910–916. X. Du, H.J. Li, C.H. Dong, Y.M. Ren, N. Pan, B.H. Kong, ... X.F. Xia, Effect of ice structuring protein on the microstructure and myofibrillar protein structure of mirror carp (Cyprinus carpio L.) induced by freeze-thaw processes, LWT-Food Science and Technology xxx (2020) xxx. S.X. Wang, Y.M. Zhang, L. Chen, X.L. Xu, G.H. Zhou, Z.X. Li, X.C. Feng, Dose-dependent effects of rosmarinic acid on formation of oxidatively stressed myofibrillar protein emulsion gel at different NaCl concentrations, Food Chem. 243 (2017) 50–57. S.J. Jin, Q. Pang, R.Q. Liu, H. Yang, F.J. Liu, M. Wang, ... A.S. Shan, Dietary curcumin decreased lipid oxidation and enhanced the myofibrillar protein structure of the duck (Anas Platyrhynchos) breast muscle when subjected to storage, LWT-Food Science and Technology 133 (2020) 109986. W. Zhao, R. Yang, R. Lu, Y. Tang, W. Zhang, Investigation of the mechanisms of pulsed electric fields on inactivation of enzyme: lysozyme, J. Agric. Food Chem. 55 (24) (2007) 9850–9858. M. Takahashi, T. Yamamoto, S. Kato, K. Konno, Species-specific thermal denaturation pattern of fish myosin when heated as myofibrils as studied by myosin subfragment-1 and rod denaturation rates, Fish. Sci. 71 (2) (2005) 405–413. F. Lefevre, B. Fauconneau, J.W. Thompson, T.A. Gill, Thermal denaturation and aggregation properties of Atlantic salmon myofibrils and myosin from white and red muscles, J. Agric. Food Chem. 55 (2007) 4761–4770. B. Wang, B.H. Kong, F.F. Li, Q. Liu, H.W. Zhang, X.F. Xia, Changes in the thermal stability and structure of protein from porcine longissimus dorsi induced by different thawing methods, Food Chemistry 126375 (2020).