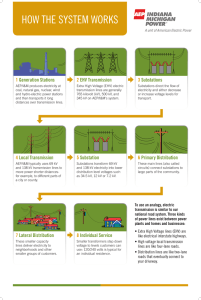

ELEMENTS OF POWER SYSTEMNETWORK AND ITS ECONOMIC OPERATION Engr. Darwin B. Pagcaliwagan, REE, RME Batangas State University, The National Engineering University Electrical and Computer Engineering Department POWER SYSTEM ANALYSIS • The goal of the course is to provide an overview of interconnected power system operation • Modern methods of power system analysis and design • The approach is designed to develop the students thinking processes, enabling them to reach a sound understanding of a broad range of topics related to power system engineering, while motivating their interest in electrical power industry. • The course will equip the students with the basic tools for analysing the operation of a power system in normal as well as emergency conditions. LEARNING OBJECTIVES On completion of this lesson students should be able to: 1. Describe the scope and nature of the course 2. Explain the functions of a Power System 3. Understand the elements of a Power System 4. Describe the components of a Power System and explain their interactions 5. Understand the economic operation of power system. INTRODUCTION Electrical engineers are concerned with every step in the process of generation, transmission, distribution, and utilization of electrical energy. Power plants generate electricity that is delivered to customers through transmission and distribution power lines. High-voltage transmission lines, such as those that hang between tall metal towers, carry electricity over long distances to meet customer needs. Higher voltage electricity is more efficient and less expensive for long-distance electricity transmission. Lower voltage electricity is safer for use in homes and businesses. Transformers at substations increase (step up) or reduce (step down) voltages to adjust to the different stages of the journey from the power plant on long-distance transmission lines to distribution lines that carry electricity to homes and businesses. This module is a brief overview of the development of power system and description of the major components in the power system and its economic operation. POWER SYSTEM The power system of today is a complex interconnected network and can be subdivided into four major parts 1. Generation System 2. Transmission System 3. Distribution System 4. Loads/Consumers • Largest and most complex man made system • Power System provides a vital service to the society. • Electrical power is somewhat like the air we breathe: We think about it only when it is missing. • It should be operated with the goal of achieving: ❑Highest reliability standards ❑Low operation cost ❑Minimum environmental impacts ELECTRIC POWER SYSTEM GENERATION SYSTEM • Generation system is the production of electricity at power stations or generating units where a form of primary energy is converted into electricity. Takes place in power plants. Electricity generation is the process of converting primary energy sources such as coal, natural gas or wind into electrical power. Electricity is produced when a magnet is moved near a wire to create a steady flow of electrons. The flow of electrons is an electrical current or electricity. • We call any device that completes this task a “generator.” Primary energy sources, such as wind or natural gas, power these generators by rotating a turbine that is attached to the shaft of the generator. For example, wind blows and rotates those huge turbines seen in wind farms. The turbines then rotate the shaft of the generator, which causes the magnet to rotate inside the wires and creates electrical energy. This process is the first step in delivering electricity to consumers and is performed by electricity generators at power plants. From power plants, electricity is then transported to homes, schools and businesses through transmission and distribution wires. The generation system consists of geographically dispersed electric generating power plants which are responsible for the production of electricity. Types of Generating Power Plants Conventional Power Plants Electricity is produces by magnetism and mechanical action. Non-Conventional Power Plants Mostly from renewable energy sources. • A power plant may house more than one generating units. Here is a list of some of the Power Plants in the Philippines: Power generation in the Philippines is not considered as a public utility operation, which means interested parties do not need to secure a congressional franchise to operate a power generation company. However, power generation is regulated by the Energy Regulatory Commission (ERC) who must issue a certificate of compliance to interested parties to ensure that the standards set forth in the Electric Power Industry Reform Act of 2001 (EPIRA) are followed. The ERC is also responsible for determining any power abuse or anti-competitive behavior. Here are few examples of how energy sources work to produce electrical energy. The two major sources of energy can be classified under: • Conventional Sources-These sources of energy are also known as non- renewable sources of energy and are available in limited quantity. These primary sources of energy cannot be replenished once used. It can be commercial and non-commercial energy source. Some of the examples are coal, natural gas and petroleum are known as commercial energy since the consumer needs to pay its price to buy them. • Non-Conventional Sources- These non-conventional sources are also known as renewable sources of energy. Examples include solar energy, bioenergy, tidal energy and wind energy. TRANSMISSION SYSTEM (GRID) • The purpose of the electric transmission system is the interconnection of the electric energy producing power plants or generating stations with the loads. Transmission is the “interstate highway” of electricity delivery. It refers to the part of electricity delivery that moves bulk electricity from the generation sites over long distances to substations closer to areas of demand for electricity. Consumers may recognize transmission lines as the larger, taller poles/towers carrying many wires over longer distances. Transmission lines move large amounts of power at a high voltage level – a level that is too much to be delivered directly to a home or business. Transmission lines, transformers, substations and other equipment have voltages of 100 kV (100,000 volts) and above. PHILIPPINE TRANSMISSION SYSTEM • Three transmission grids ❑ Luzon Grid ❑Visayas Grid ❑Mindanao Grid In the Philippines the sending and receiving voltage from the Generation that flow in Transmission line is 350 kV to 500 kV, Sub -Transmission line (NGCP) is 67000 to 69000 V (67kV – 69kV) and common distribution line in three phase system is 13200V, 13800 V to 230000 (13.2 kV, 13.8kV & 230kV), single phase 7620 V, 60 Hz. AC TRANSMISSION LINE AND DC TRANSMISSION LINE • The AC transmission line transmits the alternating current over a long distance. Whereas, the DC transmission line is used for transmitting the DC over the long distance. The AC transmission line uses three conductors for long power transmission. And the DC transmission line uses two conductors for power transmission. AC TRANSMISSION LINE • SHORT TRANSMISSION LINE • MEDIUM TRANSMISSION LINE ➢Pi Model of a Medium Transmission Line ➢T Model of a Medium Transmission Line • LONG TRANSMISSION LINE DISTRIBUTION SYSTEM • Electric power distribution is the final stage in the delivery of electric power; it carries electricity from the transmission system to individual consumers. Distribution substations connect to the transmission system and lower the transmission voltage to medium voltage with the use of transformers. Primary distribution lines carry this medium voltage power to distribution transformers located near the customer's premises. Distribution transformers again lower the voltage to the utilization voltage used by lighting, industrial equipment and household appliances. Often several customers are supplied from one transformer through secondary distribution lines. Commercial and residential customers are connected to the secondary distribution lines through service drops. Customers demanding a much larger amount of power may be connected directly to the primary distribution level or the subtransmission level. ❑ A distribution system is operated by a distribution utility to deliver power from a point in a transmission system, subtransmission system, or power plant to end-users or consumers using its facilities. ❑ A distribution utility is owned by an electric cooperative, a private company, or local government unit that operates, manages and maintains distribution systems. ❑ In the Philippines, the Congress gives a distribution utility an exclusive franchise in operating distribution systems. PRIMARY DISTRIBUTION SYSTEM ❑ Moreover, primary feeders that originally operated as single phase and two phase circuits are all now essentially three-phase circuits; even those originally operated as delta ungrounded circuits are now converted to wye systems, with their neutral common to the secondary neutral conductor and grounded. ❑ Three Basic Types • Radial System • Loop System • Primary Network System RADIAL SYSTEM ❑ It is the simplest and most commonly used. ❑ It comprises several feeders or circuits “radiating” out of the substation or source, each feeder usually serving a given area. ❑ It is a system having a single path over which current may flow for a part or all of the way from the distribution substations or substation to the primary of any distribution transformer. LOOP SYSTEM ➢ Another Means of restricting the duration of interruption employs feeders designed as loops, which essentially provide a two-way primary feed for critical consumers. ➢ Here, should the supply from one direction fail, the entire load of the feeder may be carried from the other end, but sufficient spare capacity must be provided in the feeder. ➢ This Type of system may be operated with o Loop Normally Open o Loop Normally Closed OPEN LOOP SYSTEM ➢ In the open-loop system, the several sections of the feeder are connected together through disconnecting devices, with the loads connected to the several sections, and both ends of the feeder connected to the supply CLOSED LOOP SYSTEM ➢ Where a greater degree of reliability is desired, the feeder may be operated as a closed loop. Here, the disconnecting devices are usually the more expensive circuit breakers PRIMARY NETWORK SYSTEM Although economic studies indicated that under some conditions the primary network may be less expensive and more reliable than some variations of the radial system, relatively few primary network systems have been put into actual operation and only a few still remain in service. This system is formed by tying together primary mains ordinarily found in radial systems to form a mesh or grid. SECONDARY DISTRIBUTION SYSTEM Secondary distribution systems operate at relatively low utilization voltages and, like primary systems, involve considerations of service reliability and voltage regulation. Secondary voltages have changed from nominal 110/220v singlephase values to those now operating at 120/240 V single-phase and 120/208 or 120/240 V for three-phase circuits. Four General Types: 1. Individual Transformer 2. Common Secondary Main 3. Banked Secondaries 4. Secondary Networks INDIVIDUAL TRANSFORMER- SINGLE SERVICE ➢ Individual-Transformer service is applicable to certain loads that are more or less isolated where consumers are far apart and long secondary mains are impractical. ➢ Also used where a particular consumer has an extraordinarily large or unusual load even through situated among a number of ordinary consumers COMMON SECONDARY MAIN ➢ The most common type of secondary system ➢ It takes advantage of diversity between consumers’ loads and demands BANKED SECONDARIES ➢ It is not very commonly used, although such installation exists and are usually limited to overhead system. ➢ May be viewed as a single-feeder low-voltage network, and the secondary may be a long section or grid to which the transformers are connected. SECONDARY NETWORKS ➢ Secondary networks at present provide the highest degree of service reliability and serve areas of high load density, where revenues justify their cost and where this kind of reliability is imperative. ➢ In some instances, a single consumer may be supplied from this type of system by what are known as spot networks, ➢ In general, the secondary network is created by connecting together the secondary mains fed from transformers supplied by two or more primary feeders. CLASSIFICATIONOFPOWERDISTRIBUTIONSYSTEMS According to nature of current 1. DC Distribution system 2. AC Distribution system DC DISTRIBUTION SYSTEM On the basis of scheme of connection: ➢ Unipolar DC distribution system (2-wire DC system) ➢ Bipolar DC distribution system (3-wire DC system) AC DISTRIBUTION SYSTEM On the basis of scheme of connection: ➢ Radial distribution system ➢ Ring main distribution system ➢ Inter-connected distribution system ACCORDING TO TYPE OF CONSTRUCTION 1. Overhead Distribution System 2. Underground Distribution System OVERHEAD DISTRIBUTION LINES UNDERGROUND DISTRIBUTIONS LINES OVERHEAD VS. UNDERGROUND SYSTEM Public Safety OVERHEAD Less safe due to wiring are more exposed to the public. Initial Cost Less expensive because it is easily tapped, rerouted or modified to serve customers Flexibility More Flexible due to poles, wires, transformers can be easily shifted to meet the changes in load conditions Faults Likely because of the flashover of insulators on overhead lines due to lighting. Higher due to cooled through thermal radiation from the air and convection wind. Has relatively efficient cooling mechanisms Messy due to exposed wires that not in use Current carrying capacity and voltage drop Appearance UNDERGROUND Safer because all distribution wiring is placed underground and there are little chances of any hazard More expensive due to high cost of trenching, conduits, cables, manholes and other special equipment. The initial cost of an underground system may be five to ten times than that of overhead system Less flexible due to manholes, duct lines that are permanently placed and installed and the load expansion can only meet by laying new lines Very rare as the cables are laid underground and are generally provided with better insulation Lower due to less inductive reactance because of closer spacing of conductors Better due to all distribution lines are invisible. OVERHEAD VS. UNDERGROUND SYSTEM Fault Location and Repairs More fault, but conductors are visible and easily accessible so that the fault locations and repairs can be easily made Less fault but it is difficult to locate and repair on this system. Useful Life Shorter which has a useful life of 25 years Longer which has a useful life of more than 50 years Maintenance Cost Higher due to common fault and exposed wirings Very low because of less chances of faults and service interruptions from wind, ice, lighting as well as traffic hazards Interference with communication circuits Causes electromagnetic interference with the telephone lines. The power line currents superimposed on speech currents, resulting in the potential of the communication channel being raised to an undesirable level. No such interference LOADS/CONSUMERS TYPES OF ELECTRICAL SYSTEMS DIRECT CURRENT SYSTEMS ➢ Direct current systems usually consist of two or three wires. ➢ Although such distributions systems are no longer employed, except in very special instances, older ones now exist and will continue to exist for some time ➢ Direct current systems are essentially the same as single-phase ac systems of two or three wires; the same discussion for those systems also applies to dc systems. ALTERNATING CURRENT SINGLE-PHASE SYSTEMS TWO-WIRE SYSTEMS ➢ The simplest and oldest circuit consists of two conductors between which a relatively constant voltage is maintained, with the load connected between the two conductors ALTERNATING CURRENT SINGLE-PHASE SYSTEMS THREE-WIRE SYSTEMS ➢ Essentially, the three-wire systems is a combination of two two-wire systems with a single wire serving as the neutral of each of the two-wire systems. ALTERNATING CURRENT SINGLE-PHASE SYSTEMS FOUR-WIRE SYSTEMS ➢ The four-wire system consist of two single-phase two-wire systems in which the voltage in one system is 90 degree out of phase with the voltage in the other system, both usually suppled from the same generator. ALTERNATING CURRENT TWO-PHASE SYSTEMS FIVE-WIRE SYSTEMS ➢ The five-wire system is equivalent to a two-phase four-wire system with the midpoint of both phases brought out and joined in a fifth wire. The voltage is of the same value from any phase wire to the common neutral, or fifth wire. ALTERNATING CURRENT TWO-PHASE SYSTEMS FOUR-WIRE SYSTEMS ➢ The three-phase four-wire system is perhaps the most widely used. It is equivalent to three single-phase two-wire systems supplied form the same generator. ALTERNATING CURRENT THREE-PHASE SYSTEMS THREE-WIRE SYSTEMS ➢ If the load is equally balanced on the three phases of a four-wire system, the neutral carries no current and hence could be removed, making a threewire system. SUBSTATION A substation is a part of an electrical generation, transmission, and distribution system. Substations transform voltage from high to low, or the reverse, or perform any of several other important functions. Between the generating station and consumer, electric power may flow through several substations at different voltage levels. A substation may include transformers to change voltage levels between high transmission voltages and lower distribution voltages, or at the interconnection of two different transmission voltages. The generation, transmission and distribution are the main work of the substation. The substation which generates the power is known as the generation substations. Similarly, the transmission substations transmit the power, and the distribution substations distribute the power to the load. SUBSTATION SYSTEM VOLTAGE CLASSES ➢ Low Voltage (LV): A class of nominal system voltages 1000 volts or less. ➢ Medium Voltage (MV): A class of nominal system voltages greater than 1000 volts and less than 100 kV. ➢ High Voltage (HV): A class of nominal system voltages equal to or greater than 100 kV and equal to or less than 230 kV ➢ Extra-High Voltage (EHV): A class of nominal system voltages greater than 230 kV but less than 1000 kV. ➢ Ultra-High Voltage (UHV): A class of nominal system voltages equal to or greater than 1000 kV. COMPONENTS AND ELEMENTS OF A POWER SYSTEM Single Line Diagram • In single line representation of power system, the components of the system are represented by standard symbols & the transmission lines are represented by straight lines. • “Hence a single line diagram is diagrammatic of power system in which the components are represented by their symbols and the interconnection between them is shown by straight lines”. ELECTRICAL SYMBOLS Elements of a power system Elements of a power system Elements of a power system Power transformers: A transformer is an electrical device that trades voltage for current in a circuit, while not affecting the total electrical power. This means it takes high-voltage electricity with a small current and changes it into low-voltage electricity with a large current, or vice versa. Power transformers are used in generation and transmission network for stepping-up the voltage at generating station and stepping-down the voltage for distribution. Auxiliary transformers supply power to auxiliary equipment's at the substations. Current transformers (CT): The lines in substations carry currents in the order of thousands of amperes. The measuring instruments are designed for low value of currents. Current transformers are connected in lines to supply measuring instruments and protective relays. Potential transformers (PT): The lines in substations operate at high voltages. The measuring instruments are designed for low value of voltages. Potential transformers are connected in lines to supply measuring instruments and protective relays. These transformers make the low voltage instruments suitable for measurement of high voltages. Elements of a power system Circuit breaker (CB): Circuit breakers are used for opening or closing a circuit under normal as well as abnormal (faulty) conditions. Different types of CBs which are generally used are oil circuit breaker, air-blast circuit breaker, and vacuum circuit breaker and SF6 circuit breaker. Isolators or Isolating switches: Isolators are employed in substations to isolate a part of the system for general maintenance. Isolator switches are operated only under no load condition. They are provided on each side of every circuit breaker. Bus-bar: When number of lines operating at the same voltage levels needs to be connected electrically, bus- bars are used. Bus-bars are conductors made of copper or aluminum, with very low impedance and high current carrying capacity. Different types of bus-bar arrangements are single bus bar arrangements, single bus-bar with sectionalization, double bus-bar arrangements, sectionalized double bus-bar arrangement, double main and auxiliary bus-bar arrangement, breaker and a half scheme/1.5 Breaker scheme, and ring bus-bar scheme ECONOMIC OPERATION OF A POWER SYSTEM ECONOMIC OPERATION OF POWER SYSTEM Economic operation is very important for a power system to return a profit on the capital invested. Rates fixed by regulatory bodies and the importance of conservation of fuel place pressure on power companies to achieve maximum possible efficiency. Maximum efficiency minimizes the cost of a kilowatt-hour to the consumer and the cost to the company of delivering that kilowatt-hour in the face of constantly rising prices for fuel, labor, supplies and maintenance. Operational Economics involving power generation and delivery can be subdivided into two parts- one dealing with minimum cost of power production called economic dispatch and the dealing with minimum-loss delivery of the generated power to the loads. OBJECTIVES OF THE ECONOMIC OPERATION OF POWER SYSTEM ➢ ➢ ➢ ➢ Minimize Cost (maximum efficiency) Reliability (Continuity of the supply) Security of Supply Sustainability ACTIONS REQUIRED ➢ Long-term load forecasts ➢ Network development ➢ Short-term load forecasts Power system operation and control For instances: 1. Voltage Regulators (AVR) – Control of Q and V 2. Turbine Speed Governors – Control of P and f 3. Optimization of Power System Operation ➢ Generation Scheduling or Economic Load Dispatch ➢ Minimizing Transmission Losses i. Computers with Optimal power-flow programs are used LOAD CHARACTERISTICS In order to make the best utilization of the power system and available resources, Knowledge on loading conditions and characteristics of the individuals loads are essential. Loads may be characterized in regards to: ➢ ➢ ➢ ➢ Size (Watts to MW) Symmetry (single or three-phase) Load constancy (with respect to time, frequency, voltage) Use cycle (regular or random) Symmetry between three phases can be achieved by intentional distribution of single-phase loads. LOAD CURVES The load on the system varies with time. This variation can be represented graphically and is termed as ‘’Load Curve’’ TYPES OF LOADS A device which taps electrical energy from the electric power system is called a load on the system. The load may be resistive (e.g., electric lamp), inductive (e.g., induction motor), capacitive or some combination of them. The various types of loads on the power system are : Domestic load Domestic load consists of lights, fans, refrigerators, heaters, television, small motors for pumping water etc. Most of the residential load occurs only for some hours during the day (i.e., 24 hours) e.g., lighting load occurs during night time and domestic appliance load occurs for only a few hours. For this reason, the load factor is low (10% to 12%). Commercial load Commercial load consists of lighting for shops, fans and electric appliances used in restaurants etc. This class of load occurs for more hours during the day as compared to the domestic load. The commercial load has seasonal variations due to the extensive use of air conditioners and space heaters. TYPES OF LOADS Industrial load Industrial load consists of load demand by industries. The magnitude of industrial load depends upon the type of industry. Thus small scale industry requires load upto 25 kW, medium scale industry between 25kW and 100 kW and large-scale industry requires load above 500 kW. Industrial loads are generally not weather dependent. Municipal load Municipal load consists of street lighting, power required for water supply and drainage purposes. Street lighting load is practically constant throughout the hours of the night. For water supply, water is pumped to overhead tanks by pumps driven by electric motors. Pumping is carried out during the off-peak period, usually occurring during the night. This helps to improve the load factor of the power system. Irrigation load This type of load is the electric power needed for pumps driven by motors to supply water to fields. Generally this type of load is supplied for 12 hours during night. Traction load This type of load includes tram cars, trolley buses, railways etc. This class of load has wide variation. During the morning hour, it reaches peak value because people have to go to their work place. After morning hours, the load starts decreasing and again rises during evening since the people start coming to their homes. TERMS RELATED TO LOADING CONDITIONS The variation in load introduces some terms that need to be specified these terms are: CONNECTED LOAD It is defined as the “total sum of all loads (ON and OFF) connected to the power system. All the loads may not be switched ON together, but such loads have to be calculated to determine the required power and hence the capacity of the units. For example: If one of the consumers has three lamps of 200 W each, four lamps of 100 W each and a machine consuming 5 kW, then the connected load of the consumer = 3(200) + 4(100) +5000 = 6000 W AVERAGE LOAD As the name implies, it indicates the average value of all the loads occurring on the station for a given time period (such as day/s or month/s or year/s) 𝐴𝑣𝑒𝑟𝑎𝑔𝑒 𝑙𝑜𝑎𝑑 = MAXIMUM DEMAND 𝑁𝑜 𝑜𝑓 𝑢𝑛𝑖𝑡𝑠 𝑘𝑊ℎ 𝑔𝑒𝑛𝑒𝑟𝑎𝑡𝑒𝑑 𝑖𝑛 𝑔𝑖𝑣𝑒𝑛 𝑡𝑖𝑚𝑒 𝑝𝑒𝑟𝑖𝑜𝑑 𝑇ℎ𝑒 𝑡𝑖𝑚𝑒 𝑝𝑒𝑟𝑖𝑜𝑑 It is defined as “the maximum value of load that occurs on the system during a specific time period”. Knowledge of max demand is necessary because the installed capacity of the plant is decided on the basis of max demand since the power station must be capable of supplying the max demand. FACTORS RELATED TO VARIABLE LOADING DEMAND FACTOR It is defined as “the ratio of maximum demand to the connected load of the system.” 𝑀𝑎𝑥𝑖𝑚𝑢𝑚 𝐷𝑒𝑚𝑎𝑛𝑑 𝐶𝑜𝑛𝑛𝑒𝑐𝑡𝑒𝑑 𝐿𝑜𝑎𝑑 Since, all the connected loads are not ON all the time, Maximum Demand < Connected Load. 𝐷𝑒𝑚𝑎𝑛𝑑 𝐹𝑎𝑐𝑡𝑜𝑟 = It is necessary for determination of the required plant equipment capacity. LOAD FACTOR It is defined as “the ratio of average load to the maximum demand in a given time period.” It is the plot of variation of load demand with respect to time. Peak or maximum demand is defined as the maximum load (occurring in the time under consideration). 𝐴𝑣𝑒𝑟𝑎𝑔𝑒 𝐿𝑜𝑎𝑑 𝐿𝑜𝑎𝑑 𝑓𝑎𝑐𝑡𝑜𝑟 = 𝑀𝑎𝑥𝑖𝑚𝑢𝑚 𝐷𝑒𝑚𝑎𝑛𝑑 𝐸𝑛𝑒𝑟𝑔𝑦 𝑐𝑜𝑛𝑠𝑢𝑚𝑒𝑑 𝑑𝑢𝑟𝑖𝑛𝑔 𝑎 𝑝𝑒𝑟𝑖𝑜𝑑 𝑜𝑓 𝑡𝑖𝑚𝑒 𝐿𝑜𝑎𝑑 𝐹𝑎𝑐𝑡𝑜𝑟 = 𝑀𝑎𝑥𝑖𝑚𝑢𝑚 𝐷𝑒𝑚𝑎𝑛𝑑 ∗ 𝑇𝑖𝑚𝑒 𝑢𝑛𝑑𝑒𝑟 𝑐𝑜𝑛𝑠𝑖𝑑𝑒𝑟𝑎𝑡𝑖𝑜𝑛 It can be daily/monthly/yearly load factor according to the time period considered. It is less than unity because Average Load < Maximum Demand. Value of load factor affects the production cost too. It should be as high as possible. If the load factor is high, maximum demand is low and required station capacity (which depends on max demand) is reduced. This reduces cost of production. Load Factor should be as close to 1 as possible. Also, a value of load factor reduces the variable loading problems. This is because a higher value of load factor implies less variation in demands at various times. Due to this, the effects of variable loading are minimized. Hence Load Factor should be as high as possible. HOW TO CALCULATE THE LOAD FACTOR The load factor is derived by dividing the total kilowatt-hours (kWh) consumed in a designated period by the product of the maximum demand in kilowatts (kW) and the number of hours in the period. In the example below the monthly. In the example below, the monthly kWh consumption is 36,000 and the peak demand is 100 kW. There were 30 days in the billing period. 𝐿𝑜𝑎𝑑 𝐹𝑎𝑐𝑡𝑜𝑟 = 36,000 𝑘𝑊𝐻 100 𝑘𝑊 𝑥 30 𝑑𝑎𝑦𝑠 𝑥 24 ℎ𝑟𝑠/𝑑𝑎𝑦 36,000 𝑘𝑊ℎ 𝐿𝑜𝑎𝑑 𝐹𝑎𝑐𝑡𝑜𝑟 = 72,000 𝑘𝑊ℎ 𝐿𝑜𝑎𝑑 𝐹𝑎𝑐𝑡𝑜𝑟 = 50% This load factor indicates the monthly energy consumption of 36,000 kWh used by the customer was 50% of the total energy available (72,000 kWh) for use at the 100 kW level. HOW TO IMPROVE LOAD FACTOR Lowering the facility’s peak demand is the primary step to improving load factor and will reduce the amount paid monthly for electricity. To determine the potential for improving load factor, analyze billing records to identify the seasons during which the peak demand is the greatest. In general, the greatest demand for electricity in the Philippines occurs on hot days in the summer. While this implies that a large electric load is dedicated to space cooling, it is not necessarily true for every facility. It is always best to observe operations at the facility to determine what equipment may be causing the peak demand. Once the contributing equipment loads have been identified, determine what can be done to sequence or schedule events or processes in order to minimize the simultaneous operation of high wattage equipment. PLANT CAPACITY FACTOR It is defined as “the ratio of actual energy produced in a given time period to the total energy that could’ve been produced in the same time period.” 𝑃𝑙𝑎𝑛𝑡 𝐶𝑎𝑝𝑎𝑐𝑖𝑡𝑦 𝐹𝑎𝑐𝑡𝑜𝑟 = 𝐴𝑐𝑡𝑢𝑎𝑙 𝑒𝑛𝑒𝑟𝑔𝑦 𝑝𝑟𝑜𝑑𝑢𝑐𝑒𝑑 (𝑖𝑛 𝑘𝑊ℎ) 𝑀𝑎𝑥𝑖𝑚𝑢𝑚 𝑝𝑜𝑠𝑠𝑖𝑏𝑙𝑒 𝑒𝑛𝑒𝑟𝑔𝑦 𝑡ℎ𝑎𝑡 𝑐𝑜𝑢𝑙𝑑 ′ 𝑣𝑒 𝑏𝑒𝑒𝑛 𝑝𝑟𝑜𝑑𝑢𝑐𝑒𝑑 (𝑏𝑎𝑠𝑒𝑑 𝑜𝑛 𝑖𝑛𝑠𝑡𝑎𝑙𝑙𝑒𝑑 𝑝𝑙𝑎𝑛𝑡 𝑐𝑎𝑝𝑎𝑐𝑖𝑡𝑦) 𝑃𝑙𝑎𝑛𝑡 𝑐𝑎𝑝𝑎𝑐𝑖𝑡𝑦 𝐹𝑎𝑐𝑡𝑜𝑟 = 𝐴𝑣𝑒𝑟𝑎𝑔𝑒 𝐷𝑒𝑚𝑎𝑛𝑑 𝐼𝑛𝑠𝑡𝑎𝑙𝑙𝑒𝑑 𝐶𝑎𝑝𝑎𝑐𝑖𝑡𝑦 If we consider time period to be 1 day then, 𝑃𝑙𝑎𝑛𝑡 𝐶𝑎𝑝𝑎𝑐𝑖𝑡𝑦 𝐹𝑎𝑐𝑡𝑜𝑟 = 𝑇𝑜𝑡𝑎𝑙 𝑘𝑊ℎ 𝑜𝑢𝑡𝑝𝑝𝑢𝑡 𝑜𝑓 1 𝑑𝑎𝑦 𝑃𝑙𝑎𝑛𝑡 𝐶𝑎𝑝𝑎𝑐𝑖𝑡𝑦 ∗ 24 PLANT USE FACTOR It is defined as “the ratio of actual energy produced (in kWh) in a given time period to the product of plant capacity and the number of hours the plant was in operation.’’ 𝑃𝑙𝑎𝑛𝑡 𝑈𝑠𝑒 𝐹𝑎𝑐𝑡𝑜𝑟 𝐴𝑐𝑡𝑢𝑎𝑙 𝑒𝑛𝑒𝑟𝑔𝑦 𝑔𝑒𝑛𝑒𝑟𝑎𝑡𝑒𝑑 (𝑘𝑊ℎ) = [𝑃𝑙𝑎𝑛𝑡 𝑐𝑎𝑝𝑎𝑐𝑖𝑡𝑦 ∗ 𝑇𝑖𝑚𝑒 𝑖𝑛 ℎ𝑜𝑢𝑟𝑠 𝑡ℎ𝑒 𝑝𝑙𝑎𝑛𝑡 ℎ𝑎𝑠 𝑏𝑒𝑒𝑛 𝑖𝑛 𝑜𝑝𝑒𝑟𝑎𝑡𝑖𝑜𝑛] Suppose 100 MW plant produces 50 x 106 kWh energy after being in operation for 2500 hrs. in a year. Then, 50 𝑥 106 𝑃𝑙𝑎𝑛𝑡 𝑈𝑠𝑒 𝐹𝑎𝑐𝑡𝑜𝑟 = [100 𝑥 103 𝑥 2500] Therefor, Plant use factor = 0.2 = 20% DIVERSITY FACTOR A power station supplies a variety of consumers. Each consumer will have an individual maximum demand and such max demands may not occur all at the same time. Diversity Factor is defined as ‘’the ratio of the sum of the individual maximum demands to the total maximum demand on the system. It can be expressed as: 𝐷𝑖𝑣𝑒𝑟𝑠𝑖𝑡𝑦 𝐹𝑎𝑐𝑡𝑜𝑟 = 𝑆𝑢𝑚 𝑜𝑓 𝑖𝑛𝑑𝑖𝑣𝑖𝑑𝑢𝑎𝑙 𝑚𝑎𝑥𝑖𝑚𝑢𝑚 𝑑𝑒𝑚𝑎𝑛𝑑𝑠 𝑀𝑎𝑥𝑖𝑚𝑢𝑚 𝑑𝑒𝑚𝑎𝑛𝑑 𝑜𝑓 𝑡ℎ𝑒 𝑝𝑜𝑤𝑒𝑟 𝑠𝑡𝑎𝑡𝑖𝑜𝑛 Obviously, Diversity Factor is greater than 1. This factor gives us the diversification of the load and is necessary to decide the installation, transmission and distribution capacities of the plants. It should be as high as possible. Higher diversity factor means that maximum demands of different consumers occur at different times, and hence. Interchange and scheduling is easier and operation is optimum. Diversity factors can be defined for loads, substations, feeders, and generating stations. Usually, the maximum demands of the consumers do not occur at the same time. The diversity factor can be equal or greater than 1. If the value of the diversity factor is greater than 1, then it is a good diversity factor, and 1.0 represents a poor diversity factor. A high diversity factor has the effect of reducing the maximum demand. It is obtained by using electrical energy at night load or light load periods. DIVERSITY FACTOR Obviously, Diversity Factor is greater than 1. This factor gives us the diversification of the load and is necessary to decide the installation, transmission and distribution capacities of the plants. It should be as high as possible. Higher diversity factor means that maximum demands of different consumers occur at different times, and hence. Interchange and scheduling is easier and operation is optimum. Diversity factors can be defined for loads, substations, feeders, and generating stations. Usually, the maximum demands of the consumers do not occur at the same time. The diversity factor can be equal or greater than 1. If the value of the diversity factor is greater than 1, then it is a good diversity factor, and 1.0 represents a poor diversity factor. A high diversity factor has the effect of reducing the maximum demand. It is obtained by using electrical energy at night load or light load periods. Another implication of higher diversity factor is that total maximum demand is lower. This reduces the size (capacity) of the required units and also the production cost. In order to increase the diversity factor, following methods have been employed: 1. 2. 3. 4. 5. Scheduling office time with certain time differences (knows as staggering of timing.) Making use of different time zones. Giving incentives to particular consumer to utilize electricity at off-peak hours (such as night time.) Use of daylight savings Using two-part tariff schemes UTILIZATION FACTOR Shows how well the plant is being used. 𝑇ℎ𝑒 𝑡𝑖𝑚𝑒 𝑡ℎ𝑎𝑡 𝑎𝑛 𝑒𝑞𝑢𝑖𝑝𝑚𝑒𝑛𝑡 𝑖𝑠 𝑖𝑛 𝑢𝑠𝑒 𝑈𝑡𝑖𝑙𝑖𝑧𝑎𝑡𝑖𝑜𝑛 𝐹𝑎𝑐𝑡𝑜𝑟 = 𝑇ℎ𝑒 𝑡𝑜𝑡𝑎𝑙 𝑡𝑖𝑚𝑒 𝑡ℎ𝑎𝑡 𝑖𝑡 𝑐𝑜𝑢𝑙𝑑 𝑏𝑒 𝑖𝑛 𝑢𝑠𝑒 A low utilization factor may mean that the plant is used only for standby purpose or that the capacity has been installed well advance of need. A high utilization factor indicates that the plant is probably most efficient in the system. In an isolated system a high utilization factor refers a good design with some reserve capacity allowance. It might be higher than unity which pointing towards that the loads have been carried in excess of the rated capacity of the equipment. RESERVE CAPACITY ➢ To provide best reliability o Failure of one generating unit should not affect the power supply to consumers and / or power quality ➢ This means that additional generating capacity of at least the value of the largest set operating must be available instantaneously. o Known as spinning reserve ➢ Hot Standby o Its output is available in a short time (about 30 minutes) 𝑅𝑒𝑠𝑒𝑟𝑣𝑒 𝐶𝑎𝑝𝑎𝑐𝑖𝑡𝑦 = 𝑃𝑙𝑎𝑛𝑡 𝐶𝑎𝑝𝑎𝑐𝑖𝑡𝑦 − 𝑀𝑎𝑥𝑖𝑚𝑢𝑚 𝐷𝑒𝑚𝑎𝑛𝑑 DEMAND SIDE MANAGEMENT (DSM) ➢ Objective: Encourage the consumer to use less energy during peak hours so load curves lose peak points. ➢ How: Shift demand from peak times i.e. to night time and or weekends ➢ Incentive: Change of tariff or use Smart Metering to advise on best tariff rate and time. OPTIMIZATION METHOD Optimization tools applied in power system areas are becoming increasingly essential to support the complex task of efficiently providing electricity to the grid. • • • Economic Load Dispatch or Generation scheduling Minimizing Transmission Losses Computers with optimal power flow programs are used OPTIMIZATION OF POWER SYSTEM OPERATION To optimize the performance of a power system, a system control strategy is established on a daily, monthly and yearly basis ➢ The result is the preparation of generation schedules, line usage, etc. ➢ Factors to be considered o Fixed cost of supply e.g. interest, fixed salaries and depreciation o Variable cost of supply e.g. fuel o Transmission losses o Transportation of fuel ➢ Obviously, plant rating and stability limits must be observed VARIABLE COST Although fixed element of the generation costs affects the overall cost of production, it is not normally considered when allocating generation to meet demand. The allocation is based entirely on the variable cost. This is obtained by considering fuel costs, generation efficiency, maintenance cost etc. ECONOMIC DISPATCH Economic dispatch is the short-term determination of the optimal output of a number of electricity generation facilities, to meet the system load, at the lowest possible cost, subject to transmission and operational constraints. ECONOMIC DISPATCH Economic dispatch is the short-term determination of the optimal output of a number of electricity generation facilities, to meet the system load, at the lowest possible cost, subject to transmission and operational constraints.