Job Sheet

REFRTGERATION COMPOTVE TTS (PART l0

AND ENTHALPY DIAGRAM

OBJECTIVE

In this job, you will learn how to observe the system temperatures and pressures

over lime at various points of the system, using the Trend Recorder of the LVHVAC

software. You willthen use an enthalpytable to determine the values required to plot

the refrigeration cycle ofthe system. You will then observe the refrigeration cycle of

the system and measure the coefficient of performance, using a Pressure/Enthalpy

diagram.

EQUIPMENT REQUIRED

Lab-Volt Refrigeration Training System, Model 3431

PROCEDURE

Observing the System Temperatures and Pressures Over Time

!

of the Refrigeration Training System, make sure the

main POWER switch is set to OFF (O).

1. On the control panel

Connect the Refrigeration Training System to the computer used to run the

LVHVAC software, via a USB cable. Turn on the computer and then run the

LVHVAC software.

!

2.

Activate the Trend Recorder of the LVHVAC softlvare: in the menu bar of

this software, select the Iools menu, and then select the Trend Recorder

option. This will bring up the Trend Recorder, as Figure 4-1 '1 shows (without

the signals displayed in this figure, since the recorder has not been started

vet):

-

Locate the section General of the Settings panel in the right section of

the Trend Recorder. Set the Sca/e (min) field of this section to 30. This

sets the displaytime (range ofobservation ofthe variables)ofthe Trend

Recorder to 30 minutes.

REFRIGERATTON COMPOTVEMS PART I0

AND ENTHALPY DIAGRAM

Locate the section Data of lhe Settings panel in the right section of the

Trend Recorder. Select the following variables only (deselect the other

variables if they are selected):

.

.

.

.

.

Pressure 1;

Pressure 2;

Temperature 3;

Temperature 7;

Compressor Current.

ln the menu bar of the Trend Recorder, select Acquisition, and then

Start to start the display of the selected variables.

FL VH Acqj'$o

> ll r g€

H.lp

psrg

.F

TN

l$

e,o-

NO

130

8,0

-

210

u0

?,0

-

A

POIUER

fo- a-l

la- E-l

FEl/)

UrP

E

NORTAL HEAT

LOAD

C0rient

Tim (min)

Cursor Po5ition

lg,

m

6,0 -

t.x)

70

5,0

ta

50

d0-

m

n

3'0

ctur

-

"'

2,0-

d)

l0

n

.10

1,0

0

.I}

o,o'

_

-I

i /"y'n

J

V1,/---------------.-

--1r--t-B

]

46,!8

l*

(min) f---

Descrhtion VaIrc Unit

Pr6.sc I

107,5 pJiS

Pr6we 2

I 8, 56 prll

--

3

I

lflpr.turc 2

Presrue

Tompa.hJo

pstg

-

l

Tof,psahrr.3 30,:4

i

Tcmpaafurc 4

CURRENT

Tempryatui8

I

__4

-.--.-=-----------lZ

33

Time

(nir)

5

oF

oF

ot:

oF

Iemp*Eture 6

? {1,?5 eF

Curfft

2,3 A

\t

vdtag€

- w

Elfectiva Feor

Tempdoturc

a

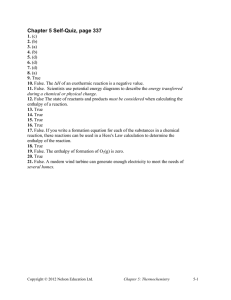

Figure 4-'t'1. Trend Recorder of the LVHVAC software displaying the selected variables as a

function of time.

tr 3. On the Refrigeration

Training System, make the following settings:

Note: Do not tum on the Refrigeration Training Sysfem for now.

COMPRESSORSwitch

...

OFF(O)

EVAPORATOR-FANSPEEDcontrolknob. ... HtcH

CONDENSER-FAN SPEEDcontrolknob. ..... Hatf of H|GH

HEAT LOAD switch

. OFF (O)

Thermostatsetpoint

.....5"C(41.F)

Manually-operated valves

V1 . . .

. . . . . Open (handleturnedfullycounterclockwise)

V2...

V3...

....Closed(handleturnedfullyclockwise)

....Closed(handleturnedfullyclockwise)

REFRTGERATTON COMPONENTS

PART t0

AND ENTHALPY DIAGRAM

tr4.

!5.

Turn on the Refrigeration Training System, then turn on the compressor. Let

the system run for about 20 minutes.

On the Trend Recorder, examine the signal of Temperature 3 (temperature

at the evaporator outlet), and fill in the following sentences.

lmmediately after power up, the temperature sensed by the thermal bulb of

the TEV at the evaporator outlet is

(higher/lower) than the

thermostat setpoint of 5"C (41'F). This causes the opening of the

thermostatic expansion valve (TEV) to be maximum to allow the full

refrigerant flow to enter the evaporator. As a result, Temperature 3

(increases/decreases).

As the evaporator cools down, the TEV opening is reduced to decrease the

flow of refrigerant entering the evaporator, causing Temperature 3 to

(increase/decrease). As more refrigerant is allowed into the

evaporator, the superheat sensed by the TEV sensing bulb

(increases/decreases). This causes the TEV opening to

(increase/decrease), causing the superheat to increase. This phenomena

can repeat, cyclically or not, untilthermal equilibrium is reached.

n 6. (Refer to the recorded signals). While Temperature 3 varies, does

Temperature 7 (temperature in the cooling chamber) slowly decrease in a

steady way until it becomes close to the thermostat setpoint of 5'C (41 'F),

causing the compressor to stop?

nYes

trNo

n 7. (Refer to the

recorded signals). When

Temperatures 3 and 7 both start to

the

compressor stops,

(increase/decrease) in a

a certain amount, the

steady way. Once Temperature 7 has risen by

compressor restarts to begin a new cycle.

tr 8. Leave the Trend Recorder open for the rest of the exercise,

but minimize

this window. You should now see the Refrigeration Diagram of the

LVHVAC software.

Determining Refrigerant Enthalpy at Different Pressures and Temperatures

tr 9. Figure 4-12 shows an example of the temperatures

and pressures that can

be read at the various test points of the Refrigeration Diagram, under the

current operating cond itions.

RE F RI G ERAT I O N TRAI N I NG S YSTEM

REFRTGERATION COMPONEVTS

AND ENTHALPY DIAGRAM

?ART t0

Using the temperatures and pressures indicated in Figure 4-12, fill in

Table 4-1-once complete, this table contains all the data required to plot

the refrigeration cycle of the system.

-

ln the first (leftmost) column, record the gauge pressures indicated at

PS1 and PS2 of Figure 4-12. Conved these pressures into absolute

pressures and record your results in the second column.

ln the third column, record the temperatures indicated at T1 through T5

of Figure 4-'12.

ln the fourth and fifth columns, record the enthalpy corresponding lo

each recorded temperature (T1 through T5), according to the enthalpy

table for the R134-a in Appendix D of this manual.

GAUGE

PRESSURE

ABSOLUTE

TEMPERATURE

PRESSURE

('c/'F)

(barg/psig)

(ba. abs./psia)

HP side

(PS1):

HP side:

ENTHALPY (kJ/kg or Btu/lbm)

Ltouto

T1:

T4:

T5:

LP side

(PS2):

LP side:

T2.

T3;

* To be completed later

Table 4-1. Pressu.e, temperature, and enthalpy data required to plot the refrigeration cycle.

VAPOR

REFRTGERATTON COMPOTVENTS

PART il)

AND ENTHALPY DIAGRAM

@

0.9 barg

H

ail

-1..7 0C

14 psig 28.7

0F

\,

{,t_r

_-z

-

@oC

12.3

e3"F

,

PI

I

46.4

J.

i

ta

"F

;

,

.-I

@

0.9 barg

14 Dsiq

^

(r)

GI

rg

6.8

ba

o""'n

eil

37.A

99.3

aC

0F

-il

21.3 .C

70.0 "F

o@o

r23V 2.3A

185 W

"c

-L2s,6

78.0'F

Figure 4.12. Example ofthe temperatures and pressures that can be read atthe various test points

ot the system.

n 10. According

to the data recorded in Table 4-'1, the temperature of the highpressure liquid refrigerant is at a minimum at test point

(T1lT4lT5). At that point, the enthalpy of the refrigerant is

(minimum/maximum), the refrigerant being

(superheated/subcooled) when it reaches the inlet of the expansion device.

\

REFRIGERATTON COM?OTVE VTS

AND ENTHALPY DIAGRAM

?ART t0

Conversely, the temperature of the low-pressure vapor refrigerant is

maximum at test point

(T2lT3). At that point, the enthalpy of

the refrigerant is

(minimum/maximum), the refrigerant being

(superheated/subcooled) at the evaporator outlet.

Observing the Refrigeration Cycte and Measuring the Coefficient of

Performance

n

11.

ln the LVHVAC software, locate the

Refrigeration Training System panel

to the right of the Refrigeration Diagram. The System lnformation section

of this panelallows you to enterthe current settings of the system. Enterthe

current temperature controller setpoint, and the settings of the fan speeds

and heat load.

Now locate the Temperature Test Points section of the Refrigeration

Training System panel, as Figure 4-13 shows. This section indicates the

current temperature, absolute pressure, and enthalpy at test points Tl

through T5 of the Refrigeration Diagram. This data is continuously

refreshed.

$qq 6e g ooooo s

e.rng-mua'-l

R.,*Fffi

Trhg Srtm

E

",'j'l

ill

r* s L "rrr=,

f nronrmot

tritpd rE

t#..effi04..

-pea G-e)

Try&@robr

*rd.({)

GD

[o

'il

Sg.Gd

=t

rp,rl

f- sr..d

lr

I

E

il

r2

t:,

Ir

15

B

.b

2J l.(

o@o

r2l!

llA

r

lsii!

r ('.)

:':t

l. :

: -:

iir.

rr.a

P (b.r)

tj:

tt!

a)

H(tl/tq) l

: ii

al.

::-

s$'lEd(t)

(mpr6tloR*h

uR.IriC.renffet(lJ/tq)

ldcd wnk dcrytu

GJ/kq)

dfl R*. o, RcliiFd (tg./r)

(lw)

R.fdF*bo tryt,

aarfi(EilortEr'm(e

RdcdHREiGtu*rh.Cdd;ns(H)

v& Floi R*. ot th. fryE.or

(m!/mh)

Vol, dot r*! olRdri$ * thc [ve. O(lGt (mr,/dn)

RGfrIg. trRt torr ry wd d th. lU, rt!

(l!rtg)

:irr

I ffmp.

;{:: ! resr

li:l J eonns

7,.

4.23

lS.$

s.Zr0.61r

s r:

S.:39

tlzji

?.gffi

:.sU

s2.67

t-__--.

@

27.2 "C

Figure 4-13. Sysfem lnformation and Temperature Test Poinfs sections of the Refrigeration

Training System panel.

REFRTGERATTON COMPONE VTS

qART il)

AND ENTHALPY DIAGRAM

tr

12. While the compressor is running, make the following observations in the

Temperature

lest Polnfs section of the Refrigeration Training System

panel.

.

.

tr13

The pressures at T1, T4, and T5 are equal. They correspond to the

absolute pressure on the HP side of the system.

The pressures at T2 and T3 are approximately equal. They correspond

to the absolute pressure on the LP side of the system.

ln the menu bar of the LVHVAC software, select the lools menu, and then

click on Options..., which will bring up the Opfions dialog box. Make sure the

Display the Cycle /cons check box is selected, and then click OK to close

the Opfions dialog box.

!

14. Activate the Pressure/Enthalpy Diagram of the LVHVAC software. To do

this, click on this window's tab, as Figure 4-14 shows.

The Pressure/Enthalpy Diagram shows the refrigeration cycle of the

system, plotted by using the temperatures and absolute pressures at T'1

through T5 of the system (as displayed in the Temperature Iesf Pornfs

section of the Refrigeration Training System panel).

The display of the refrigeration cycle is continuously refreshed to reflect any

changes that may occur in the measured temperatures and pressures.

R E F RI G

ERAT I O N

T

RAI N I NG

S

YSIEM

REFRIGERATTON COM?O,wE VTS

AND ENTHALPY DIAGRAM

qART r0

TAB TO CUCK

r.*6rr|,ipru.9-l

Pressure/Enthalpy Diagram -

R-1 34a

R.ffgpr*

TrD.

l*Rry.

Cryto&.

R-!3t

To,

s.tD.f* G*g)

Tc.iF&rc Co.tola

s.tD.ht ('f)

l-s

Evry&i

tr sF.d

I'D

Cqdcrs

Fn so..d

llqt

10.0

TI

G

t2

T3

b

o

l'@-_l

Load

l*--

Pc

HP€IDE

f4

LP€IDE

T5

-l

I ("C)

2i,i3

-11 84

-5.11

60,1{

12,19

P (bar)

a.0:

l.8t

1,89

8,0?

Lm

H

(kJ,/ks)

2x1.Ba

237.88

395.57

426,11

42!.16

sup€rhc.t('{)

Compr6ri0 Ratlo

0,60::J

Ratc ofHedt

109,90

Refrige.ntion Er.(t

Reifttion.t thc ffidenrer (klv)

Yol. Flo* R.t. ofth. Compre!.s (mr/'riln)

VoL Hoe nate o[ Refrb, at thd Evap. &*lct (m,/ntn)

Rcfrig. trh(t tor. by wrk of thc EsF D.vke (k],/kq)

lm t25

lro

t?5 N n5 lu

I

I

I

n5 3(I, w

EIflmlpy ftJ/kg)

350

rr5 l(I} eJ 1fi

I

I

05

I

I

I

HEAT OF

COHPRESS!ON

FI

Figure 4-14. Pressure/Enthalpy Diagram with normal heat load when the TEV is used.

!

15. Allow the compressor to stop, then wait until it restarts to begin a new cycle.

3 minutes later, print the Pressure/Enthalpy Diagram and Refrigeration

Training System panel.

REF RI G ERATI O N T RAI N I NG S YS TE'T'

6,J

4.Il

(kJ,/kg)

td.C wdk of Cnlprcr.lon (kllkg)

flo, Rate of Rehi{rd.ot (IO/t)

R.frigeratio, C.paity (krv)

(@lncic.* ofPdfo]m.ne

il.t

157.69

3

L

1

i

94 97

5.(159

3 0102

3.0 102

52,93

REFRTGERATTON COMPOTENrS PART il)

AND ENTHALPY DIAGRAM

n

16. Determine the net refrigeration effect (N.E.R.) graphically on your printed

diagram. To do so, draw vertical lines downward from points

I

and

@

until

they cross the enthalpy (horizontal) axis, as shown in Figure 4-14. The

difference on the enthalpy axis where the lines cross this axis is equal to

the N.R.E. Record your result below.

Compare your result to the value displayed in the field Net Refrigeration

Effect of the System Pertormance section on your printed Refrigeration

Training System panel. Are these values approximately equal?

EYes

tr

trNo

17. Determine the heat of compression graphically on your printed diagram.

To do so, draw vertical lines downward from points 0 and @ untilthey cross

the enthalpy (horizontal) axis, as shown in Figure 4-14. The difference on

the enthalpy axis where the lines cross this axis is equal to the heat of

compression. Record your result below.

Compare your result to the value displayed in the field ldeal Work of

Compression

of the Sysfem Performance section on your printed

Refrigeration Training System panel. Are these values approximately

equal?

E Yes

tr

trNo

18. Based on the N.E.R. and heat of compression obtained in the previous

steps, calculate the coefficient of performance of the system. Record your

result.

Coefficient of performance

Net refrigeration effect,*r/ks

=

Heat of compression

REF RI G ERATIO N TRAI N I NG

or Bru/tbm)

(kJ/ks or Bru/tbm)

S YS

TEM

R E F RtG ERATT O N COM POTVENTS

qART

t t)

AND ENTHALPY DIAGRAM

Compare your result

Peiormance

to the value displayed in the field Coefficient of

Performance section on your printed

of the System

Refrigeration Training System panel. Are these values approximately

equal?

!Yes

tr

nNo

19. Turn off the trainer and clos6the LVHVAC software.

Date:

lnstructor's approval: