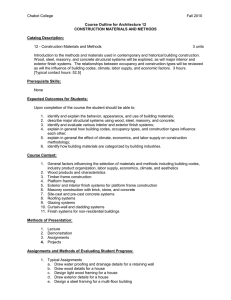

Building Construction Fundamentals: Materials & Methods

advertisement