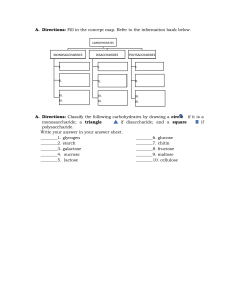

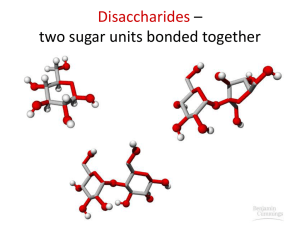

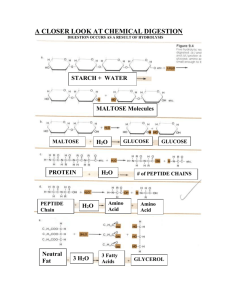

CONSTRUCTION OF MALTOSE CALIBRATION CURVE And THE DETERMINATION OF KM AND VMAX VALUES OF α-AMYLASE FOR STARCH BALOYI P 201906566 BIOCHEMISTRY 3 (MBIA031) 18 april 2023 TUESDAY GROUP Introduction Maltose is a disaccharide made up of two subunits of glucose monomers(figure1). It is also called malt sugar. It is present in germinating grain, in a smaller amount in corn syrup, and is a product of the partial hydrolysis of starch. Maltose is considered an important constituent in making fermented barley which is used to brew beer. Furthermore, maltose is a reducing sugar that could be used as a standard for estimating reducing sugar in unknown samples. Constructing a standard curve for maltose helps us to estimate the concentration of reducing sugars present in an unknown sample and for determining the activity of amylase enzyme in forthcoming experiments (Mohamed et al., 2009). (figure1) α –D-glucopyranosyl, (1-4) D-glucopyranose Maltose is a reducing sugar figure2 (those carbohydrates which have a free aldehyde or keto group can reduce Fehling's and Benedict's reagents are called reducing sugars). Maltose can be used as a standard for estimating reducing sugar in unknown samples. Constructing a standard curve/graph for maltose helps us to estimate the concentration of reducing sugars present in an unknown sample and for determining the activity of amylase enzyme in forthcoming experiments. The standard curve for maltose is usually constructed using 3, 5-Dinitro salicylic acid (DNS) as the reagent. Maltose reduces the pale, yellow-coloured alkaline 3,5-Dinitro salicylic acid (DNS) to the orange-red coloured 3 amino,5 nitro salicylic acid (Jain, 2020) (Figure2) The intensity of the colour is proportional to the concentration of maltose present in the solution. This intensity change in colour is measured using a colorimeter as the absorbance at 540nm wavelength. Wavelength is set to 540 nm because it is the region where another orangered colour absorbs (Auras et al.,2004). A series of solutions containing varying concentrations of maltose is prepared in test tubes and a known quantity of DNS is added to each. The dinitro salicylate (DNS) method detects the reducing sugars liberated by the action of hydrolase enzymes on carbohydrates, under specific pH and temperatures (Bailey et al., 1992). These test tubes are then heated in a water bath for a few minutes and their optical densities are measured using a colorimeter. A graph is then plotted with the amount of maltose on the X-axis and the observed optical density on the Y-axis. The plot thus obtained is called a standard maltose curve. Standard curves are graphs of light absorbance versus solution concentration that can be used to determine the solute concentration in unknown samples (Morris, 2015). Enzymes are biological catalysts (a substance that helps a chemical reaction to occur). The presence of an enzyme lowers the activation energy threshold for a chemical reaction to occur. This reduces the kinetic energy required for the reaction to take place and so the rate of reaction increases (Arsalan, Younus, 2018). The enzyme being studied in this experiment is amylase, an enzyme that cleaves complex sugars (polysaccharides) into simple sugars (disaccharides). Amylase catalyzes the hydrolysis (splitting) of α-1,4 glycosidic linkages in polysaccharides (like starch) which breaks the large molecules into smaller molecules of sugar like maltose. Maltose is a reducing sugar that consists of two molecules of glucose bonded together (Lim, Pullicin, 2019). In this reaction, starch is the substrate, and the product is maltose (Figure 3). Figure 3: Hydrolysis of starch into maltose by amylase Alpha-amylase is produced by organisms from all three domains of life and serves to break down starch, producing simple sugars. In humans, alpha-amylase is a component of saliva produced by the salivary glands and of pancreatic secretions produced by the pancreas to measure enzymatic activity, a colorimetric assay is used to measure the amount of substrate remaining or the amount of product produced through an enzyme-catalyzed reaction (Lim, Pullicin, 2019). In the reaction catalyzed by amylase, the product, maltose, can be measured utilizing a colorimetric assay. Colorimetric assays utilize a reagent that changes color in the presence of a compound of interest. The reagent that will be utilized is 3,5-dinitro salicylic acid (DNS) which changes color in the presence of maltose (the product) from yellow to red/orange. The DNS assay utilizes an oxidation-reduction reaction that occurs between a reducing sugar (like maltose) and DNS. The reducing sugar forms free aldehyde or ketone groups, enabling the molecule to reduce the DNS reagent (Figure 4). In this oxidation-reduction process, maltose is oxidized into maltonic acid and DNS is reduced to ANSA (3-amino-5-nitrosalicylic acid). Figure 4: Reduction of DNS (yellow) by maltose into ANSA (red/orange) DNS is yellow in color. As maltose is produced through the hydrolysis of starch by amylase, DNS is reduced by the maltose, forming ANSA which is orange/red in color. The reduction of DNS will be catalyzed by heat in a boiling water bath. More maltose produced results in a darker orange/red color. Buffer is also defined as the solution of reserve acidity or alkalinity which resists change of pH upon the addition of a small amount of acid or alkali. Many chemical reactions are carried out at a constant pH. In nature, there are many systems that use buffering for pH regulation. To measure the amount of a colored product, a spectrophotometer will be utilized. The spectrophotometer allows for the quantitative measurement of light transmitted through a sample. This transmittance can then determine the amount of light absorbed (absorbance) by that sample. Figure 6 shows a single-wavelength spectrophotometer, the wavelength is set to a particular frequency of light (in this case 540nm) and the light is then passed through the sample. Enzyme kinetics is the study of enzyme reaction rates and the conditions which affect them. Kinetic measurement of enzymatically catalyzed reactions is among the most powerful techniques for elucidating the catalytic mechanisms of enzymes. In enzyme-catalyzed reactions, the enzyme (E) forms a complex with the substrate (S) forming an enzyme-substrate complex (ES), later the complex breaks down to liberate the enzyme and release the product (P). This can be represented as are the rates of respective reactions. Based on this they derived an equation, Where vo=Initial rate of reaction, Vmax = max velocity of the reaction, Km= Michaelis Menten constant, [S]= concentration of the substrate (Silverman,2002). Line weaver Burk in 1934 modified the above equation as By plot tin 1/v vs. 1/[S] a straight line is obtained from which Km & Vmax value is calculated. Km & Vmax values are essential for selecting a suitable substrate for a given enzyme and vice versa. AIM • To construct a standard Maltose Curve. • To find the enzyme activity of beta-amylase from a starch OBJECTIVES • • • To determine the effect of temperature on the production of maltose To determine the effect of the concentration of maltose on the intensity of the colour. To determine the effect of Km and Vmax values on the concentration of a substrate MATERIALS AND APPARATUS • Test tubes • Weighing balance • Water bath -Merck • Spectrophotometer - Spectramax • Maltose - Sigma • Distilled water • DNS - Sigmaaldrick • Sodium hydroxide - Rochelle chemicals • Sodium potassium - Riedel-de haen • Test tube rank • Magnetic stirrer - FMH instruments • Beaker - glassco • Spatula • Measuring cylinder • Pipette • Micro pipette - Gilson • Centrifuge - Remi • Mass reader - Scientech • 96 well plate - Greiner cellstar • PH meter - Bante • 196 starch solution- Rochelle chemical • Phosohate buffer • Alpha amylase • Sodium dinydrogen orthophosphate - AralaR • Potasslum sodium tarsrate tastahwara - Riedai-de neen • Filter paper • Magnetic stirrer-scientech • Stopwatch- IRhone 11 • 1% starch solution in phosphate buff METHODOLOGY Firstly, DNS was made by adding 0.8 g of sodium hydroxide in 10 ml of distilled water into a conical flask, 0.5g of DNS reagent was also added to this mixture. On the other side 50 g sodium tartrate was dissolved into 25 ml of distilled water eventually mixing the two to make 50 ml of volume, if the volume didn't add to 50 ml, distilled water could be added to achieve the desired volume of 50 ml volume. Subsequently, the substrate was formed by mixing 1% starch solution and 0.5 g of starch dissolved into 50 ml phosphate buffer. The a-amylase was also formed by adding 10 g of a-amylase into 10 ml of distilled water and then once dissolved 20 ml of distilled water was added. Aliquots of the phosphate buffer, starch solution, and enzyme solution according to the given table were pipetted out. The tubes were incubated at room temperature for 5 minutes, then 1ml DNS reagent was added. Furthermore, the tubes were incubated in boiling water for 10 minutes.Cool the tubes and add 5ml distilled water. The absorbance was read at 540 nm. Moreover, the maltose calibration curve was utilized to determine the amount of maltose released from starch in each tube (based on the absorbance value). The enzyme activity was calculated using the formula activity= Amount of maltose liberated Molecular weight of maltose incubation time. In addition, the volume used for incubation was 2ml and time was 5 minutes incubation before the addition of DNS reagent. Results were to be presented in a table format and the construction of the Lineweaver-Burk plot and was needed to determine the values of KM and Vmax values. RESULTS Table 1: Table of results of concentration of maltose and Absorbance Tube Vol of Maltose (ml) Vol of dist.H 2 O (ml) 0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 2.0 1.8 1.6 1.4 1.2 1.0 0.8 0.6 1 2 3 4 5 6 7 8 Vol of DNS (ml) 1 1 1 1 1 1 1 1 Vol of Concentration Dist.H 2 O of maltose (ml) (mg/ml) 10 10 10 10 10 10 10 10 0 0.02 0.03 0.05 0.06 0.08 0.09 0.11 0,12 0,1 y = 0,0493x - 0,0187 R² = 0,8262 Absorbance 0,08 0,06 0,04 0,02 0 0 0,5 1 1,5 2 2,5 -0,02 -0,04 Concentration of maltose Figure 1: Maltose calibration curve before incubation 0,12 y = 0,1148x - 0,0119 R² = 0,8762 Absorbance 0,1 0,08 0,06 0,04 0,02 0 -0,02 0 0,2 0,4 0,6 0,8 Concentration of Maltose Figure 2: Maltose calibration curve after incubation 1 1,2 OD at 540nm Before incubation 0.084 0.450 1.032 1.516 1.845 1.968 0.585 2.266 OD at 540nm after incubation 0.090 0.221 0.447 0.629 0.826 0.735 0.741 0.971 Figure 3: picture for color change after incubation Calculations Calculate mass of NaOH: CV = n 𝑚 CV = 𝑀 2 𝑚𝑜𝑙 ( 𝐿 × 0.01 𝐿 1 𝑚 ) = 40 𝑔 / 𝑚𝑜𝑙 𝑚 2 mol (0.01) = 40 𝑔 / 𝑚𝑜𝑙 m = 0.8 g of NaOH 𝑚 C1 = 𝑣 C1 = 50 𝑚𝑔 50 𝑚𝑙 C1 = 1 mg/ml Therefore, C1 is going to be constant. V2 = 0 ml + 2.0 ml +1 ml + 10 ml = 13 ml C1 V 1 = C2 V 2 (1 mg/ml) (0 ml) = C 2 (13 ml) C2 = 0 mg/ml V2 = 0.2 ml +1.8 ml + 1 ml + 10 ml = 13 ml C1 V 1 = C2 V 2 (1 mg/ml) (0.2 ml) = C 2 (13 ml) C2 = 0.02 mg/ml Table 2: Table of results for absorbance, activity and concentration Tube Vol Vol of no of enzyme buffer (ml) (ml) Vol of substrate in (ml) 1 2 3 4 5 6 7 8 9 10 11 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0 1.5 1.4 1.3 1.2 1.1 1.0 0.9 0.8 0.7 0.6 0.5 0.5 0.5 0.5 0.5 0.5 0.5 0.5 0.5 0.5 0.5 0.5 Abs Concentration at 540 of maltose nm (mg/ml) released for graph 1 0.111 2.6376 0.147 3.3678 0.160 3.6247 0.178 3.9830 0.177 3.9696 0.183 0.2444 0.192 4.2738 0.166 3.7532 0.152 3.4625 0.150 3.4151 0.149 3.4084 Concentration of maltose (mg/ml) released for graph 2 1.0735 1.3870 1.4974 1.6513 1.6455 1.6977 1.7761 1.5526 1.4277 1.4074 1.4045 Activity Activity (gmol/min) (gmol/min) For graph 1 For graph 2 Concentration of substrate (mg/ml) 2.92 x10-3 3.74 x 10-3 4.02 x 10-3 4.42 x 10-3 4.41 x 10-3 2.71 x 10--4 4.74 x 10-3 4.17 x 10-3 3.84 x 10-3 3.79 x 10-3 3.78 x 10-3 0 0.125 0.25 0.375 0.5 0.625 0.75 0.875 1 1.125 1.25 1.19 x 10-3 1.54 x 10-3 1.66 x 10-3 1.83 x 10-3 1.83 x 10-3 1.88 x 10-3 1.97 x 10-3 1.72 x10-3 1.58 x 10-3 1.56 x 10-3 1.56 x 10-3 y = 114,41x + 0,1 R² = 0,0011 4000 3500 3000 1/V0 2500 2000 1500 1000 500 0 -2 -500 0 2 4 6 8 10 800 1000 1/[S] Figure 4: Lineweaver- Burk plot of 1/[S] and 1/V 0 9 8 7 1/V0 6 5 4 3 y = 0,0027x + 0,4 R² = 0,0435 2 1 0 -200 0 200 400 600 1/[S] Figure 5: lineweaver-Burk plot of 1/[S] and 1/V 0 [12] Figure 6 : picture of after incubation Calculations Y = 114.41x + 0.1 1 𝐾𝑚 1 1 = . + 𝑉 𝑉𝑚𝑎𝑥 [𝑆] 𝑉𝑚𝑎𝑥 1 𝑉𝑚𝑎𝑥 = 0.1 Vmax = 10 gmol/min 𝐾𝑚 𝑉𝑚𝑎𝑥 = 𝐾𝑚 10 = 0.1 Km = 1 mM Y = 0,0027x + 0.4 1 𝐾𝑚 1 1 = . + 𝑉 𝑉𝑚𝑎𝑥 [𝑆] 𝑉𝑚𝑎𝑥 1 𝑉𝑚𝑎𝑥 = 0.4 Vmax = 2.5 gmol/min 𝐾𝑚 𝑉𝑚𝑎𝑥 = 𝐾𝑚 2.5 = 0.4 Km = 1 mM [13] Calculation for maltose released for graph 1: Test tube 1 Y = 0.0493x -0.0187 0.1113 = 0.0493x – 0.0187 X = 2.6376 Test tube 2 Y = 0.0493x – 0.0187 0.1473 = 0.0493x – 0.0187 X = 3.3678 Calculations for maltose released for graph 2: Test tube 1 Y = 0.1148x -0.0119 0.1113 = 0.1148x -0.0119 X = 1.0735 Test tube 2 Y = 0.1148x – 0.0119 0.1473 = 0.1148x – 0.0119 X = 1.3870 Calculation for enzyme activity: For graph 1 𝑎𝑚𝑜𝑢𝑛𝑡 𝑜𝑓 𝑚𝑎𝑙𝑡𝑜𝑠𝑒 𝑙𝑖𝑏𝑒𝑟𝑎𝑡𝑒𝑑 ×𝑣𝑜𝑙𝑢𝑚𝑒 Activity = 𝑚𝑜𝑙𝑒𝑐𝑢𝑙𝑎𝑟 𝑤𝑒𝑖𝑔ℎ𝑡 𝑜𝑓 𝑚𝑎𝑙𝑡𝑜𝑠𝑒 × 𝑖𝑛𝑐𝑢𝑏𝑎𝑡𝑖𝑜𝑛 𝑡𝑖𝑚𝑒 = 𝑔 ×2 𝑚𝑙 𝑚𝑜𝑙 𝑔 360 .31 ×5 𝑚𝑖𝑛𝑠 𝑚𝑜𝑙 2.6376 = 2.92 x 10 -3 gmol/min 𝑎𝑚𝑜𝑢𝑛𝑡 𝑜𝑓 𝑚𝑎𝑙𝑡𝑜𝑠𝑒 𝑙𝑖𝑏𝑒𝑟𝑎𝑡𝑒𝑑 ×𝑣𝑜𝑙𝑢𝑚𝑒 Activity = 𝑚𝑜𝑙𝑒𝑐𝑢𝑙𝑎𝑟 𝑤𝑒𝑖𝑔ℎ𝑡 𝑜𝑓 𝑚𝑎𝑙𝑡𝑜𝑠𝑒 × 𝑖𝑛𝑐𝑢𝑏𝑎𝑡𝑖𝑜𝑛 𝑡𝑖𝑚𝑒 = 𝑔 ×2 𝑚𝑙 𝑚𝑜𝑙 𝑔 360 .31 ×5 𝑚𝑖𝑛𝑠 𝑚𝑜𝑙 3.3678 = 3.47 x 10-3 gmol/min For graph 2 𝑎𝑚𝑜𝑢𝑛𝑡 𝑜𝑓 𝑚𝑎𝑙𝑡𝑜𝑠𝑒 𝑙𝑖𝑏𝑒𝑟𝑎𝑡𝑒𝑑 ×𝑣𝑜𝑙𝑢𝑚𝑒 Activity = 𝑚𝑜𝑙𝑒𝑐𝑢𝑙𝑎𝑟 𝑤𝑒𝑖𝑔ℎ𝑡 𝑜𝑓 𝑚𝑎𝑙𝑡𝑜𝑠𝑒 × 𝑖𝑛𝑐𝑢𝑏𝑎𝑡𝑖𝑜𝑛 𝑡𝑖𝑚𝑒 = 𝑔 ×2 𝑚𝑙 𝑚𝑜𝑙 𝑔 360 .31 ×5 𝑚𝑖𝑛𝑠 𝑚𝑜𝑙 1.0735 [14] = 1.19 x 10-3 gmol/min 𝑎𝑚𝑜𝑢𝑛𝑡 𝑜𝑓 𝑚𝑎𝑙𝑡𝑜𝑠𝑒 𝑙𝑖𝑏𝑒𝑟𝑎𝑡𝑒𝑑 ×𝑣𝑜𝑙𝑢𝑚𝑒 Activity = 𝑚𝑜𝑙𝑒𝑐𝑢𝑙𝑎𝑟 𝑤𝑒𝑖𝑔ℎ𝑡 𝑜𝑓 𝑚𝑎𝑙𝑡𝑜𝑠𝑒 × 𝑖𝑛𝑐𝑢𝑏𝑎𝑡𝑖𝑜𝑛 𝑡𝑖𝑚𝑒 = 𝑔 ×2 𝑚𝑙 𝑚𝑜𝑙 𝑔 360.31 ×5 𝑚𝑖𝑛𝑠 𝑚𝑜𝑙 21.3870 = 1.54 x 10-3 gmol/min Calculation of substrate: 𝑚 C1 = 𝑣 500 𝑚𝑔 C1 = 50 𝑚𝑙 C1 = 10 mg/ml V2 = 1.5 ml + 0.5 ml + 0 ml + 1ml + 5 ml V2 = 8 ml C1 V 1 = C2 V 2 (10 mg/ml) (0 ml) = C 2 (8 ml) C 2 = 0 mg/ml V2 = 1.4 ml + 0.5 ml + 0.1 ml + 1 ml + 5 ml V2 = 8 ml C1 V 1 = C2 V 2 (10 mg/ml) (0.1 ml) = C 2 (8 ml) C2 = 0.125 mg/ml [15] DISCUSSION The results obtained in this experiment, clearly showed that the intensity of the color depends upon the concentration of maltose. This intensity change in color is measured using a colorimeter as the absorbance at 540nm wavelength. Wavelength is set to 540 nm because it is the region where the orange-red color absorbs. In Figure 1 where we have the standard curve of maltose using 5ml of distilled water, the graph showed the linear relationship between optical density and the concentration of maltose. The density increased as the concentration of maltose was increasing, and this showed the direct proportion. The points that are not in phase according to the graph, are caused by human error in the lab or the accuracy of the measurements. Figure 2 indicates the maltose standard curve using 10 ml of distilled water. The two graphs are not the same in a way that points in Figure 2 and mostly in phase than points in Figure 1. This change is caused by adding different volumes of distilled water. The addition of distilled water caused the dilution of the concentration of maltose that was in the test tube. After incubation of the test tubes, the 11 test tubes had different colors in terms of their intensity. They ranged from a lighter orange color to a darker orange-red color. The intensity of the color increased from test tube one to test tube eleven. This is because of the volume of the maltose before incubation. The volume of maltose was increasing from test tube one to test tube eleven. While on the other hand, the dilution with distilled water was decreasing from test tube one to test tube eleven. The values of the absorbances measured in Table 1, were decreased as the initial volume of the substrate was increased while the volume of the buffer was decreased. The calculated values of the amount of maltose released were increasing relative to the absorbance values. These values were calculated using the equation from the two standard curves of maltose. The values showed a linear relationship with the measure absorbance. This means that the absorbance was increasing with an increase in the concentration of maltose. The concentration of the substrate was calculated using the c1v1 = c2v2 formula where c2 was the concentration of the substrate. This allowed us to determine the enzyme activity in the test tubes and showed the fluctuation of the values relative to the absorbance. [16] CONCLUSION The maltose calibration curve demonstrated how the presence of maltose affects the colour’s intensity. This was demonstrated by measuring absorbance and examining the colour of the solutions in several test tubes. It was also demonstrated using the straight-line rising function from the standard curve. [17] REFERENCE Aehle W & Misset O, 1999, Enzymes for industrial applications In- Biotechnology, 2nd ed. HJ Rehm & G Reed (eds), Wiley-VCH, Germany, pp 189–216. Agger T, Spohr AB & Nielsen J, 2001, α-Amylase production in high cell density submerged cultivation of Aspergillus oryzae and A. nidulans, Applied Microbiology & Biotechnology, 55, 81–84. Aghajari N, Feller G, Gerday C & Haser R, 1998, Crystal structures of the psychrophilic αamylase from Altermonas haloplanktis in its native form and complexes with an inhibitor, Protein Science, 7, 564–572. Arsalan, A. and Younus, H., 2018. Enzymes and nanoparticles: Modulation of enzymatic activity via nanoparticles. International journal of biological macromolecules, 118, pp.18331847. Auras, R., Harte, B. and Selke, S., 2004. An overview of polylactides as packaging materials. Macromolecular bioscience, 4(9), pp.835-864 Baig MA, Pazlarova J & Votruba J, 1984, Kinetics of α-amylase production in a batch and fedbatch culture of Bacillus subtilis, Folia Microbiologia, 29, 359–364. Bahar, B., Miskon, M.F., Bakar, N.A., Shukor, A.Z. and Ali, F., 2009. Australian Journal of Basic and Applied Sciences. vol, 8, pp.168-182 Bailey, M.J., Biely, P. and Poutanen, K., 1992. Interlaboratory testing of methods for assay of xylanase activity. Journal of biotechnology, 23(3), pp.257-270 Demtröder, W. and Demtröder, W., 2003. Nonlinear spectroscopy (pp. 439-498). Springer Berlin Heidelberg. Gupta, R., Gigras, P., Mohapatra, H., Goswami, V.K. and Chauhan, B., 2003. Microbial αamylases: a biotechnological perspective. Process biochemistry, 38(11), pp.1599-1616. Jain, A., Jain, R., Jain, S., Jain, A., Jain, R. and Jain, S., 2020. Quantitative analysis of reducing sugars by 3, 5-dinitrosalicylic acid (DNSA method). Basic Techniques in Biochemistry, Microbiology and Molecular Biology: Principles and Techniques, pp.181-183. Lim, J. and Pullicin, A.J., 2019. Oral carbohydrate sensing: Beyond sweet taste. Physiology & behavior, 202, pp.14-25. McCleary, B.V. and McGeough, P., 2015. A comparison of polysaccharide substrates and reducing sugar methods for the measurement of endo-1, 4-β-xylanase. Applied biochemistry and biotechnology, 177(5), pp.1152-1163. Mohamed, S.A., Al-Malki, A.L. and Kumosani, T.A., 2009. Partial purification and characterization of five α-amylases from a wheat local variety (Balady) during germination. Aust J Basic Appl Sci, 3, pp.1740-8. Morris, R., 2015. Spectrophotometry. Current Techniques, 11(1), pp.2-1. Protocols Essential Laboratory Silverman, R.B., 2002. Organic chemistry of enzyme-catalyzed reactions. Academic press. [18] [19]