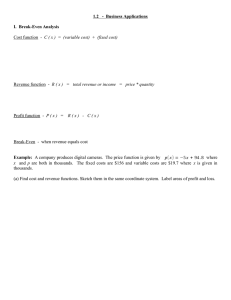

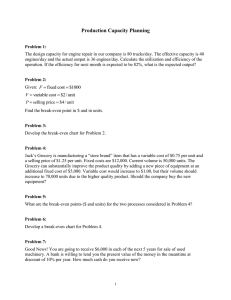

Operations and supply management Operations and supply management Chapter 7 Question 1 solution. a. Throughput time (time to convert raw materials into product) In the process of manufacturing that is generally referred to as the work center for example job shops which are involved in manufacturing a particular commodity or a group of similar commodities or jobs. During this period the commodity produced commonly takes few changes over time and therefore increased throughput time while in the work center. The final products are not produced in this phase but particular processes are undergone with very little time needed before arriving at the assembly line stage. Throughput time once the commodity arrives in this stage the assembly line phase increases due to the combination of the various ingredients to produce the final commodity. b. Capital/labor intensity The first stage of manufacturing process requires very minimal labor diversity hence little intervention is done hence a particular job is performed however manual labor is all that is needed in this stage. Due to the low specialization and few processes the capital is less and not labor intensive the assembly phase is labor intensive and capital intensive as the capital needed for machine installation and purchasing the machines is high. In addition specialization increases the cost by need of more labor. c. Bottle necks The performance is normally within the particular specified task indicated for the bottlenecks hence the bottleneck points are few in the process of manufacturing that is limited. But the limitation in the assembly phase is caused by the process or method of production of the finished product Question 2 solution What is the break-even point? FC = (P - VC) * Break-even =$300,000 = ($23.00 - $8.00) * Break-even Break-even = 20,000 books 1 Operations and supply management Facility layout problem a. b. 130 seconds to produce first unit; But actually the bottleneck is E which takes 40 seconds Hence speed is (8 * 3600) / 40 = 720 2 Operations and supply management Chapter 9 Service problems 1. The service package 2. How service systems differ from manufacturing systems. Service systems have i) Higher degree of customer contact ii) More labor involvement. ii) A higher degree of input variability. iv) Service systems have poorer wages than manufacturing systems. v) Maintaining quality in service systems is difficult. vi) Less inventory is used in service systems compared to manufacturing systems. 3