Production Capacity Planning

advertisement

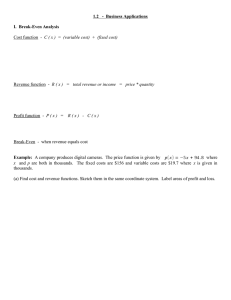

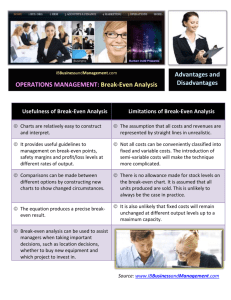

Production Capacity Planning Problem 1: The design capacity for engine repair in our company is 80 trucks/day. The effective capacity is 40 engines/day and the actual output is 36 engines/day. Calculate the utilization and efficiency of the operation. If the efficiency for next month is expected to be 82%, what is the expected output? Problem 2: Given: F fixed cost $1000 V variable cost $2/ unit P selling price $4 / unit Find the break-even point in $ and in units. Problem 3: Develop the break-even chart for Problem 2. Problem 4: Jack’s Grocery is manufacturing a “store brand” item that has a variable cost of $0.75 per unit and a selling price of $1.25 per unit. Fixed costs are $12,000. Current volume is 50,000 units. The Grocery can substantially improve the product quality by adding a new piece of equipment at an additional fixed cost of $5,000. Variable cost would increase to $1.00, but their volume should increase to 70,000 units due to the higher quality product. Should the company buy the new equipment? Problem 5: What are the break-even points ($ and units) for the two processes considered in Problem 4? Problem 6: Develop a break-even chart for Problem 4. Problem 7: Good News! You are going to receive $6,000 in each of the next 5 years for sale of used machinery. A bank is willing to lend you the present value of the money in the meantime at discount of 10% per year. How much cash do you receive now? 1 2