ISSN 1018-5593

European Commission

technical steel research

Properties and service performance

Simplified version of Eurocode 3

for usual buildings

STEEL RESEARCH

European Commission

technical steel research

Properties and service performance

Simplified version of Eurocode 3

for usual buildings

P. Chantrain, J.-B. Schleich

ARBED recherches

BP 141

L-4009 Esch-sur-Alzette

Contract No 7210-SA/513

1 July 1991 to 30 June 1994

Final report

Directorate-General

Science, Research and Development

1997

EUR 16839 EN

LEGAL NOTICE

Neither the European Commission nor any person acting on behalf of the Commission

is responsible for the use which might be made of the following information.

A great deal of additional information on the European Union is available on the Internet.

It can be accessed through the Europa server (http://europa.eu.int)

!

Cataloguing data can be found at the end of this publication.

Luxembourg: Office for Official Publications of the European Communities, 1997

ISBN 92-828-1485-8

© European Communities, 1997

Reproduction is authorised provided the source is acknowledged.

Printed in Luxembourg

[

I

SIMPLIFIED VERSION OF EIIROCODE 3 FOR USUAL BUILDINGS.

ECSC Agreement 7210-SA/513

Summary

The aim of the following E.C.S.C. research is to elaborate a simple but complete document to

design commonly used buildings in steel construction. This document is completely based on

Eurocode 3 and each paragraph is totally conform to Eurocode 3. Only the design formulas

necessary to design braced or non-sway buildings are taken into account in this document.

Tall buildings (skyscrapers) and halls are not treated. The designers and steel constructors

are able to calculate and erect a commonly used steel building with this design handbook.

Therefore also the important load cases from Eurocode 1 will be included in this document.

The working group of the research project was constituted of 10 European engineering

offices. Firstly that working group has carried out different examples of calculation of braced

or non-sway buildings according to Eurocode 3 Part 1.1: check of existing steel structures and

design of new steel buildings. Afterwards thanks to those examples of calculation the needed

design formulas of Eurocode 3 was highlighted and general procedure of design was

determined. The design handbook "Simplified version of Eurocode 3" is based on that

experience.

The link of the working group to the drafting panel of Eurocode 3 was guaranteed by the

Professor Sedlacek of Aachen University.

Liaison has been ensured with both other E.C.S.C. research projects nr SA/312 and nr S A/419

also dealing with Eurocode 3: respectively, "Application software of Eurocode 3: EC3-tools"

(CTICM, France) and "Design handbook for sway buildings" (CSM-Italy).

VERSION SIMPLIFIEE DE L'EUROCODE 3 POUR LES BATIMENTS COURANTS

Agrément CECA 7210-SA/513

Sommaire

Le but de cette recherche est d'élaborer un document simple mais complet pour calculer des

bâtiments courants en construction métallique. Ce document est entièrement basé sur

l'Eurocode 3 et chaque paragraphe est totalement conforme à VEurocode 3. Il n'a été pris en

compte que les formules nécessaires au calcul de bâtiments contreventés et rigides. Les

bâtiments très élancés (gratte-ciel) et les halls industriels n'y sont pas traités. Les bureaux

d'études et constructeurs métalliques devront être capables de calculer et d'ériger un

bâtiment courant en acier avec ce manuel de dimensionnement. Les cas de charges le plus

importants issus de l'Eurocode 1 seront également inclus dans ce document.

Le groupe de travail du projet de recherche était constitué de 10 bureaux d'études européens.

En première partie ce groupe de travail a effectué différents exemples de calculs de bâtiments

contreventés et rigides conformément à l'Eurocode 3 Partie 1.1: vérification de structures en

acier déjà existantes et dimensionnement de nouveaux bâtiments en acier. Grâce à ces

exemples concrets de calcul, les formules de l'Eurocode 3 utiles au dimensionnement ont été

mises en évidence et une procédure générale de dimensionnement a été déterminée. Le

manuel de dimensionnement "Version simplifiée de l'Eurocode 3" se base sur cette

expérience.

La jonction entre le groupe de travail et le groupe de rédaction de l'Eurocode 3 a été faite par

le professeur Sedlacek de l'Université d'Aix-La-Chapelle.

Une collaboration a été assurée avec deux autres projets de recherche CECA N° SA/312 et N°

SA/419 qui concernent aussi l'Eurocode 3: respectivement, "Logiciel d'application de

l'Eurocode 3: EC3-Tools" (CTICM, France) et "Manuel de dimensionnement de bâtiments

souples (à nœuds déplaçables)" (CSM, Italie)

VEREINFACHTE VERSION DES EUROCODE 3 FÜR ÜBLICHE GEBÄUDE.

EGKS Zulassung7210-SA/513

Zusammenfassung

Dieses EGKS Forschungsprojekt hat zum Ziel, ein einfaches aber vollständiges Dokument

für allgemeine (übliche) Stahlbaubemessung auszuarbeiten. Dieses Dokument ist völlig auf

Eurocode 3 basiert und jeder Paragraph paßt genau zu Eurocode 3. Nur die

Bemessungsformeln, die notwendig sind für ausgesteifte oder unverschiebliche Tragwerke ,

werden berücksichtigt. Hochhäuser (Wolkenkratzen) oder Hallen werden nicht behandelt.

Die Ingenieurbüros und Stahlkonstrukteuren haben die Möglichkeit mit diesem DesignHandbuch einen einfachen Stahlbau zu berechnen und zu bauen. Dafür sind die wichtigsten

Lastfälle von Eurocode 1 in diesem Dokument beinhaltet.

Die Arbeitsgruppe des Forschungssprojekt bestand aus 10 europäischen Ingenieurbüros. Die

Arbeitsgruppe hat, im ersten Teil dieses Forschungsvorhabens, verschiedene

Berechnungsbeispiele mit ausgesteiften oder unverschieblichen Tragwerken nach Eurocode

3 Teil 1.1 durchgefühlt : Berechnungs-Nachweis einer existierenden Stahlstruktur und

Dimensionierung eines neuen Stahlbaus. Anschließend an diese konkreten Beispiele, wurden

die benutzten Bemessungsformeln nach Eurocode 3 hervorgehoben und ein allgemeines

Bemessungsverfahren wurde festgelegt. Das Design-Handbuch "Vereinfachte Version des

Eurocode 3" basiert auf dieser Erfahrung.

Die Verbindung zwischen der Arbeitsgruppe und dem technischen Komitee wurde von

Professor Sedlacek der Aachener Universität hergestellt.

Eine Zusammenarbeit bestand mit zwei anderen EGKS Forschungesprojekten N° SA/312

und N° SA/419, die auch Eurocode 3 behandeln : "Application software of Eurocode 3:

EC3-tools" (CTICM, France) und "Design handbook for sway buildings" (CSM-Italy).

Contents

Summary

3

Sommaire

4

Zusammenfassung

5

Contents

7

1. Introduction

9

2. Working group

10

3. Part 1 : Worked examples

3.1. Exercise 1 : Verification of an existing braced or non-sway structure

3.2. Exercise 2: Verification of a non-sway wind bracing in a building

3.3. Exercise 3: Design of a braced or non-sway structure

11

4. Part 2 : Design handbook ·

12

11

12

12

FIGURES (Ito 8 )

APPENDICES

List of symbols

List of tables

List of

flow-charts

(6 pages)

(3 pages)

(1 page)

"Design handbook according to Eurocode 3 for braced or non-sway steel buildings"

(short title : "EC3 for non-sway buildings")

(196 pages)

15

23

29

32

33

1. Introduction

The research was divided into different parts:

- in the first part worked examples of braced or non-sway structures has been carried out by

European engineering offices according to Eurocode 3 and Eurocode 1.

Different contacts have been taken with different engineering offices in Europe and

professional organisations (E.C.C.S. and C.T.I.C.M.). The working group of this research

project has been constituted with 10 engineering offices.

- in the second part the needed formulae for simple design of braced or non-sway structures

have been selected thanks to the exercises about check and design of steel buildings. The

design handbook has been elaborated on the basis of that experience.

The present final report of this research project presents the design handbook called

"Design handbook according to Eurocode 3 for braced or non-sway steel buildings"

(short title : "EC3for non-sway buildings").

2. Working group

The research project was fully managed and carried out by ProfilARBED-Research (RPS

Department), with the active support of the following working group which is particularly

thanked for the fruitful collaboration :

- the following 10 engineering offices which were involved to perform 3 worked examples :

Reference

Number

Engineering office

City

Country

2

Adem

Mons

Belgium

3

Bureau Delta

Liège

Belgium

4

Varendonck Groep / Steelrrack

Gent

Belgium

6

Ramboll & Hanneman

Copenhagen

Denmark

7

Bureau Veritas

Courbevoie

France

9

Socotec

Saint-Quentin-Yvelines

France

10

Sofresid

Montreuil

France

13

Danieli Ingegneria

Livorno

Italy

14

Schroeder & Associés

Luxembourg

Luxemburg

16

D3BN

Nieuwegein

The Netherlands

- Professor Sedlacek and assistant from Aachen University (Germany) which guaranteed the

link of this working group to the drafting panel of Eurocode 3 and Eurocode 1,

- some other engineering offices which participated to the meetings of the full working group :

Reference

number

City

Country

5

Engineering

office

Verdeyen & Moenart

Associate Partner

Bruxelles

Belgium

12

18

Ingenieur gruppe Bauen

Ove Arup & Partners

Karlsruhe

London

19

ECCS-TCll

Kiel

Germany

United

Kingdom

Germany

10

-some members of CTICM (France) and SIDERCAD (Italy) involved in complementary

research projects about simplified approaches of Eurocode 3 (respectively, "Application

software of Eurocode 3 : EC3-tools" and "Design handbook for sway buildings") :

. which participated to the meetings of the full working group,

. and with which a general flow-chart (FC1) about elastic global analysis of steel frame

according to EC3 has been established.

3. Part 1 : Worked examples

In order to find the needed formulae and to familiarise the engineering offices to the

Eurocodes, it has been decided to perform 3 different exercises (check and design of a steel

structure),

- exercise 1: verification of an existing braced or non-sway steel structure,

- exercise 2: verification of a non-sway steel wind bracing in a building,

- exercise 3: design of a braced or non-sway steel structure,

Different drawings issued from the exercises of the offices are enclosed in the technical report

n° 4 (TR4) showing the type of the calculated buildings and some details :

- office building with bracing system (engineering offices n° 2, 9 and 16),

(Annex 1 of TR4); - car park (engineering office n° 3), (Annex 2 of TR4);

- residential building with bracing system (engineering office n° 7), (Annex 3 of TR4);

- office building with bracing system (engineering office n° 10), (Annex 4 of TR4);

- industrial building with catalytic reactors (engineering office n° 13), (Annex 5 of TR4);

- office building with concrete core (engineering office n° 14), (Annex 6 of TR4);

- office building with concrete core (engineering office n° 4), (Annex 7 of TR4);

- office building with bracing system (engineering office n° 6), (Annex 8 of TR4).

3.1. Exercise 1 : Verification of an existing braced or non-sway structure

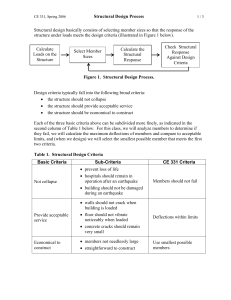

The flow-chart of figure 1 shows the procedure followed for the verification of an existing

building with the Eurocodes 1 and 3. This first exercise aimed to find the needed formulae

given by the Eurocodes in order to check the safety of the different limit states.

This exercise was not an iterative processes, but was only a verification procedure of an

existing braced or non-sway building.

The flow-chart of figure 1 is divided into 3 subjects:

a. The "Keywords" representing the different steps of a check procedure.

1. conceptional type of structure.

2. occupancies.

3. shape.

4 structural concept.

5 action effects.

6. design and verification.

b. The "Requirements and References" of each step of the verification.

The references are Eurocode 1, Eurocode 3 and the product standards

EN 10025 and EN 10113.

c. The "Object" describing each step of the verification.

11

3.2. Exercise 2: Verification of a non-sway wind bracing in a building

The non-sway wind bracing consisted of a latticed steel structure. The flow-chart of figure 2

gives the procedure of the verification of this wind bracing. This exercise was also not an

iterative process.

The description of the present flow-chart (figure 2) is the same than in the first example

presented in the chapter 3.1 (figure 1).

3.3. Exercise 3: Design of a braced or non-sway structure

After the two first exercises, the engineering offices were familiarised with the Eurocodes 1

and 3. They were able to perform a complete design of a structure by using an iterative

procedure. The aim of this exercise was to analyse the way to find a good solution.

This exercise allowed us to follow step by step the calculation of a structure in practice. The

practical design handbook about the simplified version of the Eurocode 3 follows an

improved way than the one defined in the initial design procedure. The figure 3 shows the

different data for the design and the type of chosen optimisation. The Figure 4 gives the type

of building to be designed.

4. Part 2 : Design handbook

A list of the needed formulae taken from the Eurocode 3 has been established following the

initial procedure defined for the exercises (see figures 5 to 8).

This initial design procedure nearly corresponds to the sequence of the chapters of Eurocode

3. It had to be adapted to common practice.

The solved exercises E3 (design of a building) and the experience of each engineering office

allowed to determine a more suitable design procedure which constitutes the frame of the

design handbook.

About that practical design procedure reference may be made to the enclosed design

handbook which is called "Design handbook according to Eurocode 3 for braced or nonsway steel buildings" (short title : "EC3for non-sway buildings") :

- table of contents

- general flow-chart FC1 about elastic global analysis of steel frames according to

Eurocode 3 (see chapter I of the design handbook); this flow-chart FC1 constitutes the

link with the 2 other researches about simplified approaches of EC3 : from CTICM and

SIDERCAD (see chapter 2 of the present report),

- flow-chart FC3.1 and FC3.2 about general procedures to study structures submitted to

actions (see chapter ΠΊ of the design handbook), with load cases which are respectively

defined :

. by relevant combinations of characteristic values of load arrangements, (g, q, s, w,

...), in general cases,

. or, by relevant combinations of characteristic values for the effects of actions (N,

V, Μ; δ, f,...), in case of first order elastic global analysis.

- flow-chart FC4 about elastic global analysis of braced or non-sway steel frames

according to Eurocode 3 (see chapter IV of the design handbook),

- flow-chart FC 12 about elastic global analysis of bracing system according to Eurocode 3

(see chapter ΧΠ of the design handbook)

12

In general, for the design of buildings we need to :

- define the analysis model of frames (assumptions of plane frames, bracing systems,

connections, members,...)

- characterise the load arrangements and load cases,

- carry out the elastic global analysis of frames in order to determine the effects of actions :

. deformations (δ), vibrations (f) for Serviceability Limit States (SLS) and,

. internal forces and moments (N, V, M) for Ultimate Limit States (ULS).

- check the members at SLS (vertical and horizontal displacements, eigenfrequencies) and

at ULS (resistance of cross-sections, stability of members and stability of webs) for :

. members in tens on (braces,...)

. members in compression (columns,...)

. members in bending (beams,...)

. members with combined axial load force and bending moment (beam-columns,...)

- check the local effects of transverse forces on webs at ULS (resistance and stability of

webs),

- check the connections at SLS and at ULS.

Especially for members to be checked at ULS specific tables are given in the concerned

chapters of the handbook, with list of checks according to different types of loading (separate

or combined internal forces and moments : N, V, M).

The design handbook which is enclosed to this final report of the research project, intends to

be a design aid in supplement to the complete document Eurocode 3 - Part 1.1 in order to

facilitate the use of Eurocode 3 for the design of such steel structures which are usual in

common practice : braced or non-sway steel structures.

Although the present design handbook has been carefully established and intends to be selfsufficient it does not substitute in any case for the complete document Eurocode 3 - Part 1.1,

which should be consulted in conjunction with the NAD, in case of doubt or need for

clarification.

All references to Eurocode 3 - Part 1.1 which appear systematically, are made in [...].

Any other text, tables or figures not quoted from Eurocode 3 are considered to satisfy the

rules specified in Eurocode 3 - Part 1.1.

The lists of all symbols, tables and flow-charts included in the "Design Handbook" are

enclosed to the present appendices.

13

1. conceptional rype of structure

different braced non sway structures <, 20 storeys

: Classification

non­sway: Vsd / VCT <, 0.1

braced: φ h £ 0.2 φ ^

I

2. occupancies

types of occupancy

­ ware house

­ office building

­ industrial hall

*

3.shape

shape of the building

(

Basis of design. Imposed

loads on floor and roofs

^

■cEC 1: Wind loads, Snow loads

Τ

4. structural concept

structural model

Geometric dimensions

Non­structural elements

Load bearing structure

Joints

Profiles

3

}

EC 3: Non­sway

Product standards:

EN 10025, EN 10113

EC 3 ­> b /1 classification

Floor structure

Material properties

5. action effects

determination of the action effects

(global and local)

EC 1: Load cases

EC 3: Load combinations

elastic or plastic model

SLS

ULS

I

6. dimensioning and verification

SLS limits

ULS limits

Frame stability

deformations

vibrations

Static equilibrium

Resistance of cross section

EC 3: Imperfections

EC 3: Modelling depending on

b /1 classification

1 s t order analysis

V_

• tension

• comprei»ion

• bending moment

- bending montent vid »hear

· bending momtia and axial force

- bending moment, sbear and axial force

- abear

· transverse farces c a webs

- ine ar boe kl mg

Resistance of members (stability)

• compression members : bocfcling

- lateral torsional buckling of beams

- bending and axial ami ion

• bending and axial compresaseli

Legend

Keywords

Γ

I

Requirement & References

)

C

Object

Connection

I

- joints

• base of colorons

Exercise 1. Verification of an existing braced non­sway structure

Figure 1

15

I

1. conceptiqnal type of structure

non­sway wind bracing in a building

(latticed structure )

EC 3: Classification

non­sway :VSd / VCT <, 0.1

1 s t order theory

. Τ .„

2. occupancies

part of an office building

EC 1: Basis of design, vertical loading

m

Horizontal loading

3. shape

­ position in the building

­ locations from load introduction and con­

nections from floors, roofs, claddings etc.

J

4. structural concept

structural model

Geometric dimensions

Non­structural elements

Joints

Profiles

Vertical f orces from gravity loads,

imposed loads, snow and wind loads

Horizontal forces from wind,

imperfections

EC 3: Non­sway

Product standards:

EN 10025, EN 10113

EC 3 ­> b / 1 classification

Material properties

J

5. action effects

EC 1: Load cases

EC 3: Load combinations

determination of the action effects

(global and local)

EC 3: Imperfections

EC 3: Modelling depending on

b / 1 classification

elastic or plastic model

SLS

ULS

1 s t order analysis

6. dirnehsioning and verification

SLS limits

ULS limits

deformations

Frame stability

vibrations

Static equilibrium

Resistance of cross section

- tension

- compression

• bending moment

- shear

- bending moment and shear

- bending moment and axial force

- bending moment, shear and axial force

- transverse forces on webs

■ shear buckling

Resistance of members (stability)

- compression members : buckling

- lateral torsional budding of beams

- bending and axial tension

- bending and axial compress ion

Legend

Keywords

WÊÉBÊÊ

Requirement & References

C

Object

Connection

-joints

• baae of columns

Exercise 2.Verification of a non­sway wind bracing in a building

Figure 2

16

1. conceptional type of structure

Braced non sway structure (defined)

I

2. occupancies

types of occupancy (defined)

- office building

3. shape

shape of the building (defined)

1

J

4. structural concept

structural model

Geometric dimensions (defined)

Non-structural elements (not defined)

Load bearing structure (not defined)

Type of joints (defined)

Profiles ( not defined)

7. optimisation of the weight

Floor structure (not defined)

Material properties (not defined)

Profiles:

- max 3 different profiles

for the columns

Type of joints:

- hinged or rigid

connections

Steel: FeE 235

or FeE 355

or FeE 460 grades

I

5. action effects

determination of the action effects

(global and local)

elastic or plastic model

SLS

t

ULS

6. dimensioning and

SLS limits

deformations

vibrations

t

verification

ULS limits

Frame stability

Static equilibrium

Resistance of cross section

and axial force

abear and axial force

■ compression

- sbear bedding

Resistance of members (stability)

- cflfupyraHin membera ι bockung

- lateral torsional bedding of beams

• ^"Hiraj and axial tension

* bending and axial compresiion

Connection

•joints

- base of columns

Exercise 3.Design of a braced non-sway structure

Figure 3

17

plane view

lift

Χ

front view

Ν

ζ

!

II

ce

I

CA

C

Reference

number

2

6

7

9

10

13

Engineering office

n°

X Y storeys Joints

n=

(m) (m)

Adem

1 30 10

5

Rigid

Rambøll, Hannemann & Højlund

2 30 10

15

Rigid

Veritas

3 50 14

10

Hinged

Socotec

4 50 14

15

Hinged

Sofresid

5 50 18

20

Rigid

Danieli

6 50 18

15

Hinged

Exercise 3 : Type of building to be designed

Figure 4

18

Eurocode 3 Formulae References

···· · i

Λ. C« · ■ ·

1. Conceptional type of structure.

1.1. non-sway

­> Chapter 5.2.5.2

1.2. braced

­> Chapter 5.2.5.3

1.3

storeys

2. Occupancies.

2.1. Type of building, (category,...)

2.2. Imposed loads on floors and roof (p and P) ­> Chapter EC 1, part 2.4: Imposed load

3, Shape,

3.1. Wind loads fw) ­> Chapter EC1 Part 2.7: Wind loads.

3.2. Snow loads (s) ­> Chapter EC1 Part 2.5: Snow loads.

4. Structural concept.

4.1. Structural model.

4.2. Geometric dimensions.

4.3. Non structural elements.

4.4. Load bearing structure.

4.5. Joints.

4.6. Profiles.

4.7. Floor structure.

4.8. Material properties.

5. Action effects.

5.1. Load cases. ­> EC1.

­ permanent loads: g and G

­ variable loads: q and Q:

­ imposed loads: ρ and Ρ (presentparagraph 2.2.)

- wind loads: w (presentparagraph 3.1.)

- snow loads: s (presentparagraph 32.)

5.2. Load combinations. ­> EC3.

SLS:

-> Chapter 2.3.4 clause (5), formulae (2.17) and (2.18)

ULS:

­> Chapter 2.3.3.1 clause (5), formulae (2.11) and (2.12)

5.3. Imperfections. -> EC3.

Frame :

­> Chapter 5.2.4.3

clause (1) formula (5.2)

Bracing system: ­> Chapter 5.2.4.4

clause (1) formulae (5.3) and (5.4)

[Members :

­> Chapter 5.2.4.2.

clause (4) formula (5.1)7

5.4. Elastic or plastic model -> EC3: Chapter 5.3: classification of cross­sections (b/t ratios).

Flange:

­> table 5.3.1 (sheet 3)

Web:

­> table 5.3.1 (sheet 1)

­> Chapter 5.4.6

clause (7) shear buckling

=> (presentparagraph 72.9 )

Section:

­> Chapter 5.3.4 for elastic global analysis

­> Chapter 5.3.3 for plastic global analysis

Figure 5

19

Eurocode 3 Formulae References

6. Verification SLS. -> Chapter 4

6.1. Global analysis. -> beams, portal f rames,structural frames Calculation for

- > bracing system

δ vertical

and δ horizontal

6.2. Deformations.

6.3. Vibrations.

-> Chapter 4.2.2 clause (1) δ vertical table 4.1, figure 4.1

clause (4) δ horizontal

-> Chapter 4.3. (ECCSpublication n°65: table4.4;... ;

7. Verification ULS.

7.1. Global analysis.

= > internal forces: Μ, Ν and V

- Elastic analysis -> Chapter 5.2.1.3

- Plastic analysis -> Chapter 5.2.1.4

- 1st or 2nd order analysis (present paragraph 1.1 )

7.2. Resistance of cross-sections. -> Chapter 5.4

7.2.1. tension.

-> Chapter 5.4.3 clause (1) formula (5.13)

7.2.2. compression.^ Chapter 5.4.4 clause (1) formula (5.16)

7.2.3. bending moment.-> Chapter 5.4.5

-> Chapter 5.4.5.1

clause (1) formula (5.17)

clause (2) formula (5.18)

f Ύ

-> Chapter 5.4.5.3

clause(l) formula(5.19) => A v n e t > -2- ,­iÖ­

U

' Mo

0.9

(remark: y m factors should be ignored)

7.2.4. shear.

­> Chapter 5.4.6 clause (1) formula (5.20)

clause (2): Ayz

Avy: ECCS publication n°65: table 5.14

clause (8) formula (5.21)

clause (9)

7.2.5. bending and shear.

-> Chapter 5.4.7 clause (2)

clause (3) a), b) formula (5.22)

for cross­sections with unequal flanges:

M S d <L M V j R d = Mf>Rd + (Mp 1>Rd ­ Mf >Rd )1 ­

VSd ­ 1

'pl,Rd

^Mc,Rd

7.2.6. bending and axial force.

Class 1 and 2 cross-sections:

-> Chapter 5.4.8.1

clause (3)

clause (4) formulae (5.25) and (5.26)

clause (11) formula (5.35)

Class 3 cross-sections:

-> Chapter 5.4.8.2

clause (1) formula (5.37)

7.2.7. bending, shear and axial force.

-> Chapter 5.4,9

clause (2)

clause (3)

­> biaxial bending: (ECCS publication η °65: tables 5.15 and 5.16)

Figure 6

20

Eurocode 3 Formulae References

7.2.8. transverse forces on webs.

-> Chapter 5.4.10

clause (3) -> clause (1) formula (5.41)

clause (2) formula (5.42) figure 5.4.3

or

-> clause (4) formula (5.43)

clause (5) formula (5.44)

-> Chapter 5.7.1

clause (3) figure 5.7.1 (a)

clause (4) figure 5.7.1 (b)

clause (5)

-> Chapter 5.7.2

clause (3) figure 5.7.2

-> Chapter 5.7.3 Crushing clause (1) formulae (5.71) and (5.72)

ƒ clause (4) formula (5.74) J

-> Chapter 5.7.4 Crippling clause (1) formula (5.77)

clause (2) formula (5.78)

-> Chapter 5.7.5 Buckling clause (1) formula (5.79)

clause (3) figure 5.7.3

7.2.9. shear buckling. -> Chapter 5.6.1 clause (1) limit condition (present paragraph 5.4 )

7.2.10 flange-induced buckling.

-> Chapter 5.7.7

ECCS publication n °65: table 520

7.3. Resistance of members. (->for 1 st order analysis)

7.3.1. compression members: buckling.

-for 1 st order elastic analysis:

-> Chapter 5.5.1.1

clause (1) formula (5.45)

-> Chapter 5.5.1.2

clause (1) formula (5.46) with table 5.5.1, or table 5.5.2

-> Chapter 5.5.1.4

clause (1) table 5.5.3

clause (3) formula (5.47)

-> Chapter 5.5.1.5

clause (2) Annex E

- for 2 "d order elastic analysis:

-> Chapter 5.2.6.2

clause (2)

7.3.2. lateral-torsional buckling of beams.

-> Chapter 5.5.2

clause (1) formula (5.48)

clause (2) formula (5.49)

clause (3)

clause (5)

clause (6) Annex F

clause (7) limit condition

clause (8)

7.3.3. bending and axial tension.

-> Chapter 5.5.3

7.3.4. bending and axial compression.

-> Chapter 5.5.4 -without lateral-torsional buckling:

clause (1) formula (5.51) class 1 and 2 cross-sections

clause (3) formula (5.53) class 3 cross-sections

- with lateral-torsional buckling:

clause (2) formula (5.52) class 1 and 2 cross-sections

clause (4) formula (5.54) class 3 cross-sections

clause (7) figure 5.5.3

7.4. Resistance of connections.

7.4.1. boltedjoints. -> Chapter 6.5

7.4.1.1. Positioning of holes.

-> Chapter 6.5.1 figures 6.5.1 to 6.5.4

(ECCSpublication n°65: table 62 )

7.4.1.2. Design shear rupture resistance.

-> Chapter 6.5.2.2

clause (2) formula (6.1)

clause (3) figure 6.5.5

Figure 7

21

Eurocode 3 Formulae References

7.4.1.3. Angles.

-> Chapter 6.5.2.3

clause (2) formulae (6.2) to (6.4)

clause (3) figure 6.5.6

7.4.1.4. Categories of bolted connections.

-> Chapter 6.5.3 and table 6.5.2

7.4.1.5. Distribution offorces between fasteners.

-> Chapter 6.5.4

figure

6.5.7

7.4.1.6. Design resistance of bolts.

-> Chapter 6.5.5

clause (2) table 6.5.3

clause (3)

clause (4) formula (6.5)

clause (5) formula (6.6)

clause (9)

clause (10)

(ECCSpublication n°65: tables 6.6, 6.7and6.8)

7.4.1.7. High strength bolts in slip-resistant connections

-> Chapter 6.5.8

-> Chapter 6.5.9

Annex J

-> Chapter 6.5.10

clause (1) formula (6.11) and figure 6.5.10

[-> Chapter 6.5.11

clause (2) formula (6.12)7

[-> Chapter 6.5.12

clause (1) formula (6.13)7

-> Chapter 6.5.13.

tables 6.5.6 and 6.5.7, figure 6.5.12

[7.4.2 Joints with rivets.

-> Chapter 6.5.67

-> Chapter 6.6

7.4.3 Welded connections.

clause (3)7

[-> Chapter 6.6.3

clause (1)

-> Chapter 6.6.4

clause (4)

clause (7)

-> Chapter 6.6.5.1

clause (2)

-> Chapter 6.6.5.2

clause (2)

-> Chapter 6.6.5.3

clause (1) Annex M

clause (3) formula (6.14)

clause (4) formula (6.15)

clause (5)

-> Chapter 6.6.8

clause (2) formula (6.16)

clause (3)

[-> Chapter 6.6.9

clause (1)7

[

clause (3) formula (6.18)7

-> Chapter 6.6.10

clause (2)

clause (3)

7.4.4 Beam-to-column connections. -> Chapter 6.9 and Annex J

7.4.5. Column bases.

-> Chapter 6.11 and Annex L

7.5. Frame stability.

-> Chapter 5.2.6.1

clause (1)

clause (3)

clause (4)

7.6. Static equilibrium.

-> Chapter 2.3.2.4

clauses (1) to (12)

Figure 8

22

1. List of symbols in the "Design Handbook"

1.

List of symbols (1/6)

Latin symbols

a

a

a<i

ay

aup

ao

a i , &2

A

ci )

eo,d

designation of a buckling curve

throat thickness of filllet weld

geometrical data of the effects of actions

geometrical data for the resistance

design throat thickness for submerged arc welding

designation of a buckling curve

distance between fastener holes and edge

accidental action; area of building loaded by external pressure of wind;

area of gross cross-section

effective area of class 4 cross-section

effective area of class 4 cross-section subject to uniform compression

(single N x .sd)

effective area of class 4 cross-section subject to uniaxial bending

(single My.sd or single M z .sd)

net area of cross-section

reference area for C f (wind force)

tensile stress area of bolt

shear area of cross-section

effective shear area for resistance to block shear

shear area of cross-section according to yy axis

shear area óf cross-section according to zz axis

designation of a buckling curve; flange width; building width

effective breadth

design punching shear resistance of the bolt head and the nut

designation of a buckling curve; out stand distance

altitude factor for reference wind velocity

dynamic factor for wind force

direction factor for reference wind velocity

exposure coefficient for wind pressure and wind force

wind force coefficient

external pressure coefficient for wind pressure

roughness coefficient for determination of c e

topography coefficient for determination of c e

temporary (seasonal) factor for reference wind velocity

nominal value related to the design effect of actions

factors for determination of F v jyc

factors for determination of MC T

designation of a buckling curve; web depth

bolt diameter

mean diameter of inscribed and circumscribed circles of bolt head or nut

hole diameter

shift of relevant centroidal axis of the class 4 effective cross-section subject to

uniform compression (single N x .sd)

shift of the y centroidal axis of the class 4 effective cross-section subject to

uniform compression

shift of the ζ centroidal axis of the class 4 effective cross-section subject to

uniform compression

shift of relevant centroidal axis of the class 4 effective cross-section subject to

uniaxial bending (single My.Sd or single Mz.Sd)

equivalent initial bow imperfection

design value of equivalent initial bow imperfection

ei, e2

E

ECCS

ECSC

distance between hole fastener and edge

modulus of elasticity or Young Modulus; effect of actions at SLS

European Convention for Constructional Steelwork

European Community of Steel and Coal

Aeff

Atff.N

Aeff.M

Anet

A re f

Ag

Av

Av.net

A v .y

A v .z

b

beff

Bp.Rd

c

CALT

ca

DIR

ce

Cf

Cpe

cr

ct

C

CTEM

Cd

C i , C2

C1.C2.C3

d

d

d,,,

do

βΝ

eNy

βΝζ

eM

23

EC 1

EC 3

EC 8

Ed

Ek

fd

fe

fmin

fu

fub

f,

¿b

fyb

fyw

F, Fi, F2

FC

FbUd

FbJUc

Fd

Ffr

Fh.sd

Fk

Fp.Rd

Fsd

Fsk

FsHd

Fs.Rd.ser

Fs.Rk

Ft.Rd

Ft .Rk

Ft.sd

FvRd

FvRk

Fv.sd

Fv.sd.ser

Fw

Fw.Rk

Fw.sd

g

G

Gd

Gk

h

ho

H

i

I

Ieff

It

Iw

Iz

k

k

kur

k<y

kw

ky, kz

List of symbols (2/6)

Eurocode 1

(/l/)

Eurocode 3

(/2/)

Eurocode 8

(/3/)

design value of the effect of action

characteristic value of effects of actions at SLS

design natural frequency

natural frequency

recommended limit of natural frequency

ultimate tensile strength

nominal value of ultimate tensile strength for bolt

yield strength

basic yield strength of the flat steel material before cold forming

nominal value of yield strength for bolt

yield strength of the web

action (load, transverse force, imposed deformations,...)

flow-chart

design bearing resistance per bolt

characteristic value of bearing resistance per bolt

design value of action

friction force

force on bolt calculted from Msd and/or Fbjtd

characteristic value of action

design punching shear resistance per bolt

design transverse force applied on web through the flange

characteristic value of transverse force

design slip resistance per bolt at the ultimate limit state

design slip resistance per bolt at the serviceability limit state

caracteristic slip-resistance per bolt and per friction interface

design tension resistance per bolt

characteristic value of tension resistance per bolt

design tensile force per bolt for the ultimate limit state

design shear resistance per bolt

characteristic value of shear resistance per bolt and per shear plane

design shear force per bolt for the ultimate limit state

design shear force per bolt for the serviceability limit state

resultant wind force

characteristic value of resistance force of fillet weld

design force of fillet weld

distributed permanent action; dead load

permanent action

design permanent action

characteristic value of permanent action

overall depth of cross-section; storey height; building height

overall height of structure

total horizontal load

radius of gyration about relevant axis using the properties of gross cross-section

second moment of area A

second moment of effective area Aeff (class 4 cross-section)

torsional constant

warping constant

second moment of area about zz axis

subscript meaning characteristic (unfactored) value

effective length factor

factor for lateral-torsional buckling with N-M interaction

buckling factor for outstand flanges

effective length factor for warping end condition

factors for N-M interaction

24

ί

L

Lb

LTB

Ly

m

max

min

M

M b .Rd

MCT

M

cRd

M€

Mf.Rd

MN.Rd

MN.VJld

MN.V.yJRd

MN.V.z.Rd

MN.y.Rd

MN.z.Rd

Mpf

Mp£Rd

Mp/iw.Rd

Mp£y.Rd

MptzJRd

MRd

Msd

Mv.Rd

Mw.sd

My

My.Sd

Mz

Mz.sd

η

rie

nr

n8

Ν

NAD

NbÄd

Nb.yJld

NbiJld

Ν compression

Ner

NcRd

Nxsd

NpCRd

List of symbols (3/6)

roughness factor of the terrain

portion of a member

effective length for out­of­plane bending

system length; span length; weld length

buckling length of member

lateral­torsional buckling

distance between extreme fastener holes

mass per unit length

maximum

minimum

bending moment

design resistance moment for lateral­torsional buckling

elastic critical moment for lateral­torsional buckling

design resistance moment of the cross­section

torsional moment

elastic moment capacity

design plastic resistance moment of the cross­section consisting of the flanges

only

reduced design plastic resistance moment allowing for axial force Ν

reduced design plastic resistance moment allowing for axial force Ν and by

shear

force V

reduced design plastic resistance moment about yy axis allowing for axial force

Ν and shear force V

reduced design plastic resistance moment about zz axis allowing for axial force

Ν and shear force V

reduced design plastic resistance moment about yy axis allowing for axial

force Ν

reduced design plastic resistance moment about zz axis axial force Ν

plastic moment capacity

design plastic resistance moment of the cross­section

design plastic resistance moment of the web

design plastic resistance moment of the cross­section about yy axis

design plastic resistance moment of the cross­section about zz axis

design bending moment resistance of the member

design bending moment applied to the member

design plastic resistance moment reduced by shear force

design value of moment applied to the web

bending moment about yy axis

design bending moment about yy axis applied to the member

bending moment about zz axis

design bending moment about zz axis applied to the member

number of fastener holes on the block shear failure path

number of columns in plane

number of members to be restrained by the bracing system

number of storeys

normal force; axial load

National Application Document

design buckling resistance of the member

design buckling resistance of the member according to yy axis

design buckling resistance of the member according to zz axis

normal force in compression

elastic critical axial force

design compression resistance of the cross­section

design value of tensile force applied perpendicular to the fillet weld

design plastic resistance of the gross cross­section

25

NRd

Nsd

NLRd

rN tension

Nu.Rd

N x .sd

Pl»P2

Ρ

q

qk

qref

Q

Qd

Qk

Vkmax

r

R

Ra,Rd

Rb,Rd

Rd

Rk

Ry,Rd

S

S

Sd

Sk

Ss

S

Sd

Sk

SLS

t

tf

tp

tp

tw

U

ULS

v

Vref

Vref.O

V

VbaJld

Ver

V//Sd

Vj.sd

Vp£Rd

VpiyJld

Vp£ z Jld

vRd

Vsd

Vy

Vy.Sd

vz

VZ.Sd

w

List of symbols (4/6)

design resistance for tension or compression member

design value of tensile force or compressive force

design tension resistance of the cross-section

normal force in tension

design ultimate resistance of the net cross-section at holes for fasteners

design internal axial force applied to member according to xx axis

distances between bolt holes

Point load

imposed variable distributed load

characteristic value of imposed variable distributed load

reference mean wind pressure

imposed variable point load

design variable action

characteristic value of imposed variable point load

variable action which causes the largest effect

radius of root fillet

rolled sections

design crippling resistance of the web

design buckling resistance of the web

design resistance of the member subject to internal forces or moment

characteristic value of Rd

design crushing resistance of the web

snow load

thickness of fillet weld

design snow load

characteristic value of the snow load on the ground

length of stiff bearing

effects of actions at ULS

design value of an internal force or moment applied to the member

characteristic value of effects of actions at ULS

Serviceability Limit states

design thickness, nominal thickness of element, material thickness

flange thickness

thickness of the plate under the bolt head or the nut

thickness of a plate welded to an unstiffened flange

web thickness

major axis

Ultimate Limit States

minor axis

reference wind velocity

basic value of the reference wind velocity

shear force; total vertical load

design shear buckling resistance

elastic critical value of the total vertical load

design value of shear force applied parallel to the fillet weld

design value of shear force applied perpendicular to the fillet weld

design shear plastic resistance of cross-section

design shear plastic resistance of cross-section according to yy axis (// to web)

design shear plastic resistance of cross-section according to zz axis (_L to flange)

design shear resistance of the member

design shear force applied to the member; design value of the total vertical load

shear forces applied parallel to yy axis

design shear force applied to the member parallel to yy axis

shear force parallel to zz axis

design internal shear forces applied to the member parallel to zz axis

wind pressure on a surface

26

List of symbols (5/6)

design wind load

wind pressure on external surface

welded sections

elastic section modulus of effective class 4 cross­section

elastic section modulus of effective class 4 cross­section according to yy axis

elastic section modulus of effective class 4 cross­section according to zz axis

elastic section modulus of class 3 cross­section

elastic section modulus of class 3 cross­section according to yy axis

elastic section modulus of class 3 cross­section according to zz axis

plastic section modulus of class 1 or 2 cross­section

plastic section modulus of class 1 or 2 cross­section according to yy axis

plastic section modulus of class 1 or 2 cross­section according to zz axis

axis along the member

characteristic value of the material properties

principal axis of cross section (parallel to flanges, in general)

principal axis of cross section (parallel to the web, in general)

reference height for evaluation of c e

Wd

we

W

Weff

Weff.y

Weff.z

Wef

We£y

We£z

Wpi

WpÉy

Wp£Z

x, xx

Xk

y, yy

z, zz

Ze

2u

Oreek symbols

α

α

α

aa

PA

βM

ßMl/r

ßMy

βκίζ

βw

ßw

YF

YG

YM

YMb

7Ms.ser

TMW

YMO

coefficient of frequency of the basis mode vibration

coefficient of linear thermal expansion

factor to determine the position of the neutral axis

coefficient of critical amplification or coefficient of remoteness of critical state

of the frame

non­dimensional coefficient for buckling

equivalent uniform moment factor for flexural buckling

equivalent uniform moment factor for lateral­torsional buckling

equivalent uniform moment factor for flexural buckling about yy axis

equivalent uniform moment factor for flexural buckling about zz axis

non-dimensional coefficient for lateral-torsional buckling

correlation factor (for a fillet weld)

partial safety factor for force or for action

partial safety factor for permanent action

partial safety factor for the resistance at ULS

ΎΜΙ

YM2

YQ

δ

Ob

5d

6dv

partial safety factor for the resistance of bolted connections

partial safety factor for the slip resistance of preloaded bolts

partial safety factor for the resistance of welded connections

partial safety factor for resistance at ULS of class 1,2 or 3 cross-sections

(plasticity or yielding)

partial safety factor for resistance of class 4 cross-sections

(local buckling resistance)

partial safety factor for the resistance of member to buckling

partial safety factor for the resistance of net section at bolt holes

partial safety factor for variable action

relative horizontal displacement of top and bottom of a storey

horizontal displacement of the braced frame

design deflection

design vertical deflection of floors, b e a m s , . . .

¿¿d

OHmax

δς

design horizontal deflection of frames

recommended limit of horizontal deflection

in plane deflection of the bracing system due to q plus any external loads

YMI

27

δς

δ\,

Ôvd

°Vmax

δο

δι

θ2

Δ

θ

λ

λι

λ

λβο.ν

λβΚ.y

λβιϊ.ζ

XLT

λρ

λν

λy

λζ

μ

Hi

μι,τ

μγ

μζ

ρ

ρ

py

pz

σ

List of symbols (6/6)

deflection due to variable load (q)

horizontal displacement of the unbraced frame

design vertical deflection of floors, beams,...

recommended limit of vertical deflection

pre­camber (hogging) of the beam in the unloaded state (state 0)

svariation of the deflection of the beam due to permanent loads (G) immediatly

after loading (state 1)

variation of the deflection of the beam due to the variable loading (Q) (state 2)

displacement

235

(with fy in N/mm2)

J

rotation

slenderness of the member for the relevant buckling mode

Euler slenderness for buckling

non­dimensional slenderness ratio of the member for buckling

effective non­dimensional slenderness of the member for buckling about w axis

effective non­dimensional slenderness of the member for buckling about yy axis

effective non-dimensional slenderness of the member for buckling about zz axis

non-dimensional slenderness ratio of the member for lateral-torsional buckling

plate slenderness ratio for class 4 effective cross-sections

non-dimensional slenderness of the member for buckling about vv axis

non dimensional slenderness ratio of the member for buckling about yy axis

non dimensional slenderness ratio of the member for buckling about zz axis

factor for FsjRk depending on surface class

snow load shape coefficient

factor for N-M interaction with lateral-torsional buckling

factor for N-M interaction

factor for N-M interaction

density

reduction factor due to shear force Vsa

reduction factor due to shear force Vy.sd

reduction factor due to shear force Vz.sd

normal stress

Gq

numerical values for the stabilizing forces of a bracing system

GxEd, <*xm.Ed»

design values of normal stresses for web check with Von Mises criteria

^z£d

τ

υ

φ

χ

%Ul

Xmin

Xy

Xz

shear stresss

Poisson's ratio

initial sway imperfection of the frame

reduction factor for the relevant buckling mode

reduction factor for lateral-torsional buckling

minimum of %y and χ ζ

reduction factor for the relevant buckling mode about yy axis

reduction factor for the relevant buckling mode about zz axis

28

2. List of tables in the "Design Handbook"

O.c

Table 0.1

I

Table 1.1

Table 1.2

Table 1.3

Table 1.4

Table 1.5

Table 1.6

Table 1.7

Table 1.8

Π

Table Π.1

Table Π.2

Table Π.3

Table Π.4

Table Π.5

Table Π.6

Table Π.7

Table Π.8

ΙΠ

Table ΠΙ.1

Table ΠΙ.2

Table ΠΙ.3

Table ΠΙ.4

Table ΠΙ.5

Table ΠΙ.6

Table ΠΙ.7

Table ΙΠ.8

Table ΙΠ.9

IV

Table IV. 1

Table IV.2

Table IV.3

Table IV.4

Table IV.5

Table IV.6

Table V.l

Table V.2

Table V.3

List of tables (1/3)

Pages of the Handbook

SYMBOLS AND NOTATIONS

Dimensions and axes of rolled steel sections

INTRODUCTION

Summary of design requirements

Partial safety factor γΜ for the resistance

Definition of framing for horizontal loads

Checks at Serviceability Limit States

Member submitted to internal forces, moments and transverse forces

Planes within internal forces, moments (Nsd> V$d, Msd) and transverses

forces Fsd are acting

Internal forces, moments and transverse forces to be checked at ULS for

different types of loading

List of references to chapters of the design handbook related to all check

formulas at ULS

STRUCTURAL CONCEPT OF THE BUILDING

Typical types of joints

Modelling of joints

Comparison table of different steel grades designation

Nominal values of yield strength f« and ultimate tensile strength fu for

structural steels to EN 10025 and EN 10113

Maximum thickness for statically loaded structural elements

Maximum thickness for statically loaded structural elements

Nominal values of yield strength fyb and ultimate

tensile strength fub for bolts

Material coefficient

LOAD ARRANGEMENTS AND LOAD CASES

Load arrangements (Ffc) for building design according to EC1

Imposed load (qk, Qk) on floors in buildings

Pressures on surfaces

Exposure coefficient c e as a function of height ζ above ground

External pressure Cpe for buildings depending on the size of

the effected area A

Reference height ZQ depending on h and b

Combinations of actions for serviceability limit states

Combinations of actions for ultimate limit states

Examples for the application of the combinations rules in Table III.8.

All actions (g, q, P, s, w) are considered to originate from different sources

DESIGN OF BRACED OR NON-SWAY FRAME

Modelling of frame for analysis

Modelling of connections

Global imperfections of the frame

Values for the initial sway imperfections φ

Specific actions for braced or non-sway frames

Recommended limits for horizontal deflections

CLASSIFICATION OF CROSS-SECTIONS

Definition of the classification of cross-section

Determinant dimensions of cross-sections for classification

Classification of cross-section : limiting width-to thickness ratios for

class 1 & class 2 I cross-sections submitted to different types of loading

29

46

51

52

63

64

65

66

67

68

70

71

72

73

74

75

75

76

80

81

82

83

83

84

85

86

86

88

87

97

98

99

100

105

112

113

Table V.4

Table V.5

Table V.6

Table V.7

Table V.8

Table V.9

Table V.10

VI

Table VI. 1

Table VI.2

Table VI.3

Table VI.4

vn

Table Vn.l

Table Vfl.2

Table Vfl.3

Table VH.4

Table Vfl.5

Table VH.6

vm

Table Vm.l

Table vm.2

Table Vni.3

Table Vm.4

Table vm.5

Table vm.6

Table vm.7

Table Vffl.8

Table

Vin.9

Table Vm. 10

Table Vm. 11

Table Vm. 12

Table VIfl.13

Table Vm. 14

EX

Table DC. 1

Table DC.2

Table K . 3

List of tables (2/3)

Pages of the Handbook

Classification of cross­section : limiting width­to thickness ratios for

114

class 3 I cross­sections submitted to different types of loading

Buckling factor k<y for outs tan d flanges

115

Classification of cross­section : limiting width­to­thickness ratios for

internal flange elements submitted to different types of loading

116

Classification of cross­section : limiting width­to­thickness ratios for

angles tubular sections submitted to different types of loading

117

Effective cross­sectional data for symmetrical profiles

(class 4 cross­sections)

118

Limiting values of axial load Nsd for web classification of I cross­sections

subject to axial load Nsd and to bending according to major axis My.sd

119

120

Examples of shift of centroidal axis of effective cross­section

MEMBERS IN TENSION (Ntension)

List of checks to be performed at ULS for the member in tension (Ntension) 124

125

Gross and net cross­sections

126

Reduction factors ß2 and ß3

127

Connection of angles

MEMBERS IN COMPRESSION (NCOmpression)

List of checks to be performed at ULS for the member

in compression (NCOmp.)

Imperfection factor α

Value of Euler slenderness λι

Selection of buckling curve for a cross­section

Buckling length of column : LD

Reduction factors χ = ί(λ)

MEMBERS IN BENDING (V ; M ;( V,M))

List of checks to be performed at ULS for the member in bending according

to the applied internal forces and/or moments(V ; M ;( V,M))

Recommended limiting values for vertical deflections

Vertical deflections to be considered

Recommended limiting values for floor vibrations

Shear area A v for cross-sections

Determination of Av.net for block shear resistance

Limiting width-to-thickness ratio related to the shear buckling in web

Simple post-critical shear strength xDa

Buckling factor for shear k t

Reduction factor %LT = f (λυτ) for lateral-torsional buckling

Effective length factors : k, kw

Numerical values for Ci and definition of ψ

Reduced design plastic resistance moment My Rd allowing for shear force

Interaction of shear buckling resistance and moment resistance

with the simple post-critical method

MEMBERS WITH COMBINED AXIAL FORCE AND

BENDING MOMENT ((N, M) ;(N, V, M))

List of checks to be performed at ULS for the member submitted to

combined axial force and bending moment (Ν, M)

Principle of interaction formulas between axial force Nsd

and bending moment Msd

Reduced design plastic resistance moment MN.Rd allowing for axial load

for Class 1 or 2 cross-sections

30

131

134

134

135

136

137

143

147

147

148

150

151

151

152

152

156

156

157

159

160

164

170

171

Table K.4

Table DÍ.5

Table DC.6

Table DC.7

Table Di. 8

Table DÍ.9

Table X.l

Table X.2

Table X.3

Table X.4

Table X.5

Table X.6

Table X.7

Table X.8

Table X.9

XI

Table XI. 1

Table XI.2

Table XI.3

Table XI.4

Table XI.5

Table XI.6

Table XI.7

Table XI.8

Table XI.9

Table XI. 10

Table XI. 11

Table XI. 12

Table XL 13

Table XL 14

Table XL 15

Table XL 16

XII

Table ΧΠ.1

Table ΧΠ.2

Table ΧΠ.3

Table ΧΠ.4

Table D.l

List of tables (3/3)

Pages of the Handb '

Interaction formulas for the (N,M) stability check of members

of Class 1 or 2

175

Interaction formulas for the (NM) stability check of members of Class 3 176

General interaction formulas for the (N,M) stability check of

members of Class 4

177

Supplementary interaction formulas for the (N,M) stability check

of members of Class 4

178

Reduced design resistance Ny.Rd allowing for shear force

179

Reduced design plastic resistance moment MN.VJM allowing for axial load

and shear force for Class 1 or 2 cross­sections

181

TRANSVERSE FORCES ON WEBS (F ; (F,N,V,M))

Failure modes due to load introduction

187

Stresses in web panel due to bending moment, axial force

and transverse force

188

Yield criteria to be satisfied by the web

189

Load introduction

190

Length of stiff bearing, s s

190

Interaction formula of crippling resistance and moment resistance

191

Effective breadth beff for web buckling resistance

192

Compression flange buckling in plane of the web

1*93

Maximum width­to­thickness ratio d/tw

193

CONNECTIONS

Designation of distances between bolts

196

Linear distribution of loads between fasteners

196

Possible plastic distribution of loads between fasteners. Any realistic

combination could be used, e.g.

197

Prying forces

197

Categories of bolted connections

198

Bearing resistance per bolt for recommended detailing

for t = 10 mm in [kN]

199

Shear resistance per bolt and shear plane in [kN]

200

200

Long joints

201

Tension resistance per bolt in [kN]

201

Interaction formula of shear resistance and tension resistance of bolts

Characteristic sup resistance per bolt and friction interface for 8.8 and 10.

bolts, where the holes in all the plies have standard nominal clearances

202

Common types of welded joints

203

204

Throat thickness

204

Action effects in fillet welds

205

Resistance of a fillet weld

206

Effective breadth of an unstiffened tee joint

DESIGN OF BRACING SYSTEM

Load arrangements of the bracing system

216

Bracing system imperfections

218

Values for the equivalent stabilizing force Zq

218

Bracing system imperfections (examples)

219

APPENDK D

List of references to Eurocode 3 Part 1.1 related

to all check formulas at ULS

221

31

3. List offlow-chartsin the "Design Handbook"

©

Chapter Pages

Elastic global analysis of steel frames according to Eurocode 3

General

Details

Comments (6 pages)

I

I

14

15

16 to 21

[FC 3.1] Load arrangements & load cases for general global analysis of

m

38

ni

39

(FCM)Elastic global analysis of braced or non­sway steel frames

according to EC 3

General

Details

Comments (4 pages)

IV

IV

IV

50

51

52 to 55

ÍFC 5. lì Classification of I cross­section

V

62

(FC 5.2J Calculation of effective cross­section properties of Class 4

rv

63

VI

82

VI

83

vn

90

vm

102

ΧΠ

ΧΠ

ΧΠ

168

169

170 to 175

the structure

[FC 3.2J Load arrangements & load cases for first order elastic global

analysis of the structure

cross­section

(FC6.Ì)

(FC 6.11 Members in tension (Ntension)

(FC6.2)

(FC7)

Angles connected by one leg and submitted to tension

Members in compression (Ncompression)

(FC 8Î Design of I members in uniaxial bending (Vz;My;(Vz,My)) or

(Vy;Mz;(VyJvIz);

ÍFC 12ÌElastic global analysis of bracing system according to

Eurocode 3

General

Details

Comments (6 pages)

32

Design handbook according

to Eurocode 3 for

braced or non-sway steel buildings

Short title: EC 3 for non-sway buildings

Profil ARBED-Recherches

Chantrain Ph.

Conan Y.

Mauer Th.

TABLE OF CONTENTS

0

PRELIMINARIES

0.a

O.u.l

0.a.2

0.a.3

O.a.4

0.a.5

O.b

Foreword

Generalities

Objective of this design handbook

Warning

How to read this design handbook

Acknowledgements

References

41

41

41

41

41

42

42

43

O.c

Symbols and notations

O.c.l

Symbols

O.c.2

Convention for member axes

0.C.3

Dimensions and axes of rolled steel sections

0.C.4

Notations in flow-charts

O.d

Definitions and units

O.d.1

Definition of special terms

0.d.2

Units

44

44

44

44

45

47

47

' 47

INTRODUCTION

La

Basis of design

I.a.1

Fundamental requirements

I.a.2

Definitions

I.a.2.1

Limit states

I.a.2.2

Actions

I.a.2.3

Material properties

I.a.3

Design requirements

I.a.3.1

General

I.a.3.2

Serviceability Limit States

I.a.3.3

Ultimate Limit States

Lb

General flow-charts about elastic global analysis

I.b.l

Flow-chart FC LElastic global analysis of steel frames according to EC 3

Lb. 1.1

Flow-chart FC 1: general

I.b.1.2

Flow-chart FC 1: details

I. b. 1.3

Comments on flow-chart FC 1

Le

Content of the design handbook

I.c.1

Scope of the handbook

I.C.2

Definition of the braced frames and non-sway frames

I.C.3

Summary of the table of contents

I.C.4

Checks at Serviceability Limit States

I.C.5

Checks of members at Ultimate Limit States

35

f

._

.R

7°

~™

49

49

50

50

50

50

53

53

53

53

56

61

61

62

64

64

65

TABLE OF CONTENTS

Π

STRUCTURAL CONCEPT OF THE BUILDING

69

n.a

Structural model

69

n.b

Geometric dimensions

69

n.c

Non structural elements

69

n.d

Load bearing structure

69

n.e

Joints ? 0

n.f

Profiles

'Jl

U.g

Floor structure

7­

U.h

Material properties

72

n.h. 1

Nominal values for hot rolled steel

7~

n.h.2

Fracture toughness

n.h.3

Connecting devices

\?

75

n.h.3.1

Bolts

U.h.3.2

Welding consumables

76

n.h.4

Design values of material coefficients

76

m

IV

LOAD ARRANGEMENTS AND LOAD CASES

77

ULa

Generalities

ni.b

Load arrangements

m.b.l

Permanent loads (g and G)

m.b.2

Variable loads (q, Q, w and s)

III.b.2.1

Imposed loads on floors and roof (q and Q)

m.b.2.2

Wind loads (we,i, F w )

m.b.2.2.1 Wind pressure (we¿)

m.b.2.2.2 Wind force (Fw)

m.b.2.3

Snow loads (s)

ULc

Load cases

m.c.l

Load cases for serviceability limit states

m.c.2

Load cases for ultimate limit states

77

80

80

80

80

81

81

84

84

85

85

86

DESIGN OF BRACED OR NON­SWAY FRAME

87

rV.a

Generalities

IV.a.l

Analysis models for frames

IV.a.2

Flow­chart FC 4:Elastic global analysis of braced or non­sway steel frames

according to Eurocode 3

IV.a.2.1

Flow­chart FC 4 general

rV.a.2.2

How­chart FC 4 details

rv.a.2.3

Comments on flow­chart FC 4

rv.b

Static equilibrium

rv.c

Load arrangements and load cases

IV.c.l

Generalities

IV.C.2

Frame imperfections

rV.d

Frame stability

rv.e

First order elastic global analysis

rV.e.l

Methods of analysis

IV.e.2

Effects of deformations

IV.e.3

Elastic global analysis

rv.f

Verifications at SLS

rv.f.l

Deflections of frames

rv.g

Verifications at ULS

rv.g.l

Classification of the frame

rv.g. 1.1

Hypothesis for braced frame

rv.g. 1.2

Hypothesis for non­sway frame

rv.g.2

ULS checks

87

87

36

89

89

89

92

96

96

96

96

97

98

98

98

99

99

100

10

°

*00

*00

100

100

TABLE OF CONTENTS

V

VI

VII

CLASSIFICATION OF CROSS-SECTIONS

ΙΟΙ

V.a

Generalities

V.b

Definition of the cross-sections classification

V.c

Criteria of the cross-sections classification

V.c. 1

Classification of compression elements of cross-sections

V.C.2

Classification of cross-sections

V.c.3

Properties of class 4 effective cross-sections

V.d

Procedures of cross-sections classification for different loadings

V.d. 1

Classification of cross-sections in compression

V.d.2

Classification of cross-section in bending

V.d. 3

Classification of cross-sections in combined (N,M)

101

104

106

106

106

106

109

109

109

110

M E M B E R S IN TENSION (Ntension)

Vl.a

Generalities

VLb

General verifications at ULS

Vl.b. 1

Resistance of gross cross-section to Ntension

VI.b.2

Resistance of net cross-section to Ntension

VLc

Particular verifications at ULS for angles connected by one leg

VI.c. 1

Connection with a single row of bolts

VI.C.2

Connection by welding

M E M B E R S IN COMPRESSION (NCOnipression)

Vn.a Generalities

VILb Classification of cross-sections

VII.c General verifications at ULS

Vn.c.l

Resistance of cross-section to Ncompression

VII.C.2 Stability of member to Ncompression

Vn.c.2.1 Resistance to flexural buckling

Vn.c.2.2 Resistance to torsionnal buckting and to flexural-torsional buckling

VILd Particular verifications at ULS for class 4 monosymmetrical cross-section

VILd. 1 Resistance of cross-section to Ncompression

VII.d.2 Stability of member to Ncompression

VILe Particular verifications at ULS for angle connected by one leg

VILe. 1 Connection with a single row of bolts

Vn.e. 1.1 Resistance of cross-section to NCOmpression

Vn.e. 1.2 Stability of member to Ncompression

VII.e.2 Connection by welding

Vn.e.2.1 Resistance of cross-section to Ncompression

Vn.e.2.2 Stability of member to NCOmpression

VIII MEMBERS IN BENDING (V ; M ; (V, M))

VHLa Generalities

VHLb Verifications at SLS

Vm.b.l Deflections

Vin.b.2 Dynamic effects - vibrations

VIII.c Classification of cross-section

VIILd Verifications at ULS to shear force Vsd

Vin.d. 1 Resistance of cross-section to Vsd

VIII.d.2 Stability of web to Vz.sd

Vin.e Verifications at ULS to bending moment Msd

Vin.e. 1 Resistance of cross-section to Msd

Vm.e.2 Stability of member to My.sd

Vin.f Verifications at ULS to biaxial bending moment (My.sd> Mz.sd)

Vin.f. 1 Resistance of cross-section to (My.sd, Mz.sd)

Vm.f.2 Stability of member to (My.sd, Mz.sd)

37

121

121

124

124

125

126

126

· 128

129

129

132

J 33

^

133

137

J38

^ °

^8

139

139

^9

139

139

139

139

140

140

145

145

147

147

148

148

150

152

152

I53

156

156

157

TABLE OF CONTENTS

LX

X

XI

Vm.g Verifications at ULS to combined (Vsd, Msd)

Vrn.g.1 Resistance of cross-section to (Vsd. Msd)

Vin.g. 1.1 Shear force Vsd and uniaxial bending Msd

Vin.g. 1.2 Shear force Vsd and biaxial bending moment Msd

Vm.g.2 Stability of web to (Vz.Sd,My.Sd)

MEMBERS WITH COMBINED AXIAL FORCE AND

BENDING MOMENT ((N, M) ; (N, V; M))

157

157

157

158

159

161

Di.a

Generalities

K.b

Verifications at SLS

LX.b.l

Deflections

LX.b.2

Vibrations

DC.c

Classification of cross-section

DCd

Verifications at ULS to (N,M)

LX.d. 1

Resistance of cross-section to (Nsd, Msd)

LX.d. 1.1

Uniaxial bending of class 1 or 2 cross-sections

LX.d. 1.2

Biaxial bending of class 1 or 2 cross-sections

LX.d. 1.3

Bending of class 3 cross-sections

LX.d. 1.4

Bending of class 4 cross-sections

LX.d.2 Stability of member to (Nsd,Msd)

K.d.2.1

Stability of member to (Ntension» My.sd)

LX.d.2.2

Stability of member to (Ncompression* Msd)

DC.e

Verifications at ULS for (N$d ,Vsd)

LX.e.l

Resistance of cross-section to (Nsd.Vsd)

JX.f

Verifications at ULS to (Nsd ,Vsd,Msd)

LX.f.l

Resistance of cross-section to (Nsd>Vsd>Msd)

LX.f. 1.1

Uniaxial bending of class 1 or 2 cross-section

LX.f. 1.2

Biaxial bending of class 1 or 2 cross-section

LX.f. 1.3

Bending of class 3 cross-section

LX.f. 1.4

Bending of class 4 cross-section

LX.f.2 Stability of web to (Nx.Sd, Vz.Sd, My.Sd)

161

167

167

167

167

167

1 ^7

167

170

170

171

171

171

172

X.a

Generalities

X.b

Classification of cross-section

X.c

Resistance of webs to (F,N,V,M)

X.C.1

Yield criterion to (F,N,V,M)

X.c.2

Crushing resistance to F

X.d

Stability of webs to (F ; (F, M))

X.d.l

Crippling resistance to (F;(F, M))

X.d. 1.1

Crippling resistance to F

X.d. 1.2

Crippling resistance to (F,M)

X.d.2

Buckling resistance to F

X.e

Stability of webs to compression flange buckling

184

185

I8 5

185

187

188

188

188

188

189

190

TRANSVERSE FORCES ON WEBS (F ; (F, N, V, M))

CONNECTIONS

XLa

Generalities

XI.b

Bolted connections

XLb. 1

Positioning of holes

XI.b.2

Distribution of forces between bolts

XI.b.3

Prying forces

XI.b.4

Categories of bolted connections

XI.b.5

Design ULS resistance of bolts

XI.b.5.1

Bearing resistance

XI.b.5.2

Shear resistance

XI.b.5.2.1 General case

38

176

I77

177

^7^

178

180

180

181

182

184

191

191

191

191

191

193

193

194

194

196

196

TABLE OF CONTENTS

XI.b.5.2.2 Long joints

XI.b.5.3

Tension resistance

XI.b.5.4

Punching shear resistance

XI.b.5.5

Shear and tension interaction

XI.b.6

ULS resistance of element with bolt holes

XI.b.6.1

Net section ULS resistance

XI.b.6.2

ULS resistance of angle with a single row of bolt

XI.b.6.3

Block shear ULS resistance

XI.b.7

High strength bolts in slip-resistant connections at SLS

XI.c

Welded connections

XI.c. 1

Type of weld

XI.C.2

Fillet weld

XI.C.3

Design resistance of fillet weld

XI.C.3.1

Throat thickness

XI.c.3.2

Design resistance

XI.C.4

Design resistance of butt weld

XI.c. 5

Joints to unstiffened flanges

Xl.d

Pin connections

XI.e

Beam-to-column connections

Xl.f

Design of column bases

196

197

197

197

198

198

198

198

198

199

199

199

200

200

201

201

202

202

202

202

XII DESIGN OF BRACING SYSTEM

203

203

203

203

203

206

212

212

212

213

216

216

216

216

216

216

216

APPENDIX A :

List of symbols

217

APPENDIX Β

List of tables

List of flow-charts

223

List of references to Eurocode 3 Part 1.1 related to

all check formulas at ULS

227

XILa Generalities

XILa. 1 Flow-chart FC 12:Elastic global analysis of bracing system according to EC 3

XILa. 1.1 Flow-chart FC 12: general

XD.a.1.2 Flow-chart FC 12: details

XILa. 1.3 Comments on flow-chart FC 12