MAS QUANTITATIVE TECHNIQUES PART 1 LECTURE FINAL COPY.doc

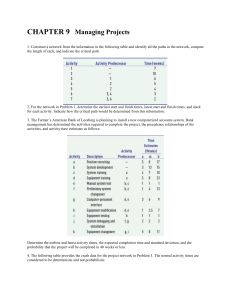

advertisement

PSBA-MANILA ACCOUNTING 14 TOPIC: Quantitative Techniques in Business Prof. C. Gonzaga NETWORK PLANNING TECHNIQUES: PERT-CPM (PROJECT EVALUATION AND REVIEW TECHNIQUECRITICAL PATH METHOD) Network planning techniques involves graphical representation of projects as a sequence of tasks, forming a picture similar to that of a highway (or electrical) network PERT (developed in the late 1950s by the US Defense Department for the purpose of planning the development of the Polaris missile) CPM (developed in the late 1959s) at Remington-Rand and Du Pont for applications in the chemical industry.) Sample Application of Network Planning Techniques Auditing R&D Monthly financial closing Plant construction New product planning Shop loading and sequencing Personnel planning Piping installation Refining systems Market research Computer programming Budget preparation CPM Analysis (Activity-On-Node or AON Diagram) Nodes – represent the activities Arrors (Arcs) – represent the predecences between activities Path- is a sequence of activities connecting the start and finish of the project. Critical Path – the longest path (in terms of total number of days of completion) which connects activities with zero slack time from start to finish. Each activity in the critical path is a critical activity in that it must start and finish on time, otherwise, the completion time of the project will be delayed. Non-critical path activity – an activity which has a slack time, therefore, can be delayed. Slack time – allowable time for delay Formula: SLACK = Late Start (LS) - Early Start (ES) Or Late Finish (LF) – Early Finish (EF) Two (2) Methods in creating a CPM Network (1) Enumeration Method (2) Two-pass method : Forward Pass (ES and EF) ; Backward Pass (LF-LS) PERT Analysis (AOA Network or activity-on-arc diagram) Dummy activity - an activity which requires no time to complete and is inserted simply to maintain the appropriate precedence relationships. Event – the start or finish of an activity Formula: Expected Activity Time Expected Activity Time = optimistic time + (4 * most likely time) + pessimistic time 6 Cost Analysis Cost Control The original goal of network planning is to provide decision-makers with the ability to plan and control the completion of projects by providing them with an understanding of the task times, with the end purpose of controlling costs. Crashing Activities. It is possible that the project completion time as determined by the network planning may be unsatisfactory in that it is too long. In such cases, it may be possible to expedite some or all of the activities. Crashing is reducing the completion time for an activity. Of course crashing usually can be accomplished at some costs – e,g, through the use of overtime, which is more expensive but faster. Crash time – the minimum possible time required to perform the activity This study source was downloaded by 100000864099288 from CourseHero.com on 03-19-2023 20:56:38 GMT -05:00 https://www.coursehero.com/file/26874843/MAS-QUANTITATIVE-TECHNIQUES-PART-1-LECTURE-FINAL-COPYdoc/ 1 Crash cost – the cost of performing the activity in its crash time. Formula: Daily crash cost = Cost increase due to crashing Time decrease due to crashing = Crash cost – Normal cost Normal time – Crash time GATT CHARTS (developed by Henry Gantt) – a representation of the timing of activities on a bar chart. CLASS PROBLEM 1 Charice Construction Company has the following table that describes the steps necessary for designing and building a township playground. Each activity that is part of the project is listed along with its expected length of time to completion and its prerequisite activities. Code Activity Name A Planning B Purchasing C D Excavation Sawing E Placement F Assembly G Infill H Outfill I Decoration Description Time (In days) Find location, determine resource requirements Requisition lumber and sand Dig and grade Saw lumber into appropriate sizes Position lumber in correct locations Nail lumber together Put sand in and under equipment Put dirt around equipment Landscape, paint 20 Immediate Predecessors None 60 Planning 100 30 Planning Purchasing 20 10 Sawing, excavation Placement 20 Assembly 10 Assembly 30 Infill, outfill REQUIRED: 1. Develop a Gantt Chart. What is the completion time (in number of days)? _______ A B C D E F G H I 0 50 days 100 days 150 days 200 days 1. Develop a CPM diagram. What is the project’s completion time (in number of days)? Identify the critical path. Enumerate the critical activities. Determine the slack time of each non-critical activity. Activity Code A B C D E F G H I Early Start Late Start This study source was downloaded by 100000864099288 from CourseHero.com on 03-19-2023 20:56:38 GMT -05:00 https://www.coursehero.com/file/26874843/MAS-QUANTITATIVE-TECHNIQUES-PART-1-LECTURE-FINAL-COPYdoc/ Slack = LS – ES 2 2. Give the following table for the normal and crash times and costs for playground activities, determine the crash cost per day in pesos: Activity Normal Time Normal cost (in Crash time (in Crash Cost (in Crash cost per (in days) thousand days) thousand day (in pesos) pesos) thousand pesos) A 20 300 15 450 B 60 2,100 50 2,140 C 100 4,000 75 4,500 D 30 2,850 20 3,000 E 20 500 F 10 200 G 20 400 H 10 600 I 30 1,350 12,300 CLASS PROBLEM 2 Given the following table of a project: Activity Code Immediate predecessor A None B A C A D B, C E B, D F E G F H G Time (in number of months) 1 6 1 2 2 2 12 4 REQUIRED: 1. Draw a CPM diagram. 2. Determine the project’s completion time. 3. Determine the critical path. 4. Determine the slack time per activity using the two-pass method. CLASS PROBLEM 3 Given a PERT diagram below, answer the following questions: • • • • • 1: Which tasks are on the critical path? 2: What is the slack time for tasks C, D and G? 3: Task C is delayed by one day. What impact would this have on the completion date of the project? Why? 4: Task A will be delayed by 2 days because some equipment has arrived late. If the project manager wants to finish the project on time he will need to shorten the duration of one or more of the tasks. How can he achieve this? 5: The project manager reduces the durations of tasks D and F by one day each. How will this affect the finishing date of the project? CLASS PROBLEM 4 This study source was downloaded by 100000864099288 from CourseHero.com on 03-19-2023 20:56:38 GMT -05:00 https://www.coursehero.com/file/26874843/MAS-QUANTITATIVE-TECHNIQUES-PART-1-LECTURE-FINAL-COPYdoc/ 3 California Building Corporation uses the critical path method to monitor construction jobs. The company is currently 2 weeks behind schedule on Job#181, which is subject to a P10,500 per week completion penalty. Path A-B-C-F-G-H-I has a normal completion time of 20 weeks, and critical path AD-E-F-G-H-I has a normal completion time of 22 weeks. The following activities can be crashed: Activities BC DE EF Cost to Crash 1 week P8,000 10,000 8,800 Cost to Crash 2 weeks P15,000 19,600 19,500 California Building desires to reduce the normal completion time of Job#181 and, at the same time, report the highest possible income for the year. California building should crash: (Multiple choice) a. b. c. d. Activity Activity Activity Activity BC 1 week and activity EF 1 week. DE 1 week and activity EF 1 week. BC 2 weeks. EF 2 weeks. CLASS PROBLEM 5 The network below describes the interrelationships of several activities necessary to complete a project. The arrows represent the activities. The numbers between the arrows indicate the number of months to complete each activity: REQUIRED: 1. How many paths are there in this PERT diagram? 2. What is the critical path in the PERT diagram? 3. What is the shortest time to complete the entire project? 4. What is the slack time (in number of months) for Path A-B-E? 5. What is the slack time for Path A-B-C-D-E end start Activity A-B A-C B-C B-E C-D D-E Time (in months) 4 6 8 12 10 14 CLASS PROBLEM 6 The PERT network diagram and corresponding activity cost chart for a manufacturing project at Networks, Inc. is presented below. The numbers in the diagram are the expected times (in days) to perform each activity in the project. Activity AB AC AD BE CE DE BC BD Expected Time 4.5 days 5.0 5.5 7.0 6.5 7.5 1.0 0.50 Normal Cost P3,000 5,000 4,000 6,000 8,000 6,000 2,500 2,000 Crash Time 3.5 days 4.5 4.0 5.0 5.0 6.5 0.50 0.25 Crash Cost P4,000 5,250 4,750 7,000 9,200 6,750 3,500 2,500 This study source was downloaded by 100000864099288 from CourseHero.com on 03-19-2023 20:56:38 GMT -05:00 https://www.coursehero.com/file/26874843/MAS-QUANTITATIVE-TECHNIQUES-PART-1-LECTURE-FINAL-COPYdoc/ 4 REQUIRED: 1. The critical path is: a. ACE b. ABE c. ADE d. ABCE e. ABDE 2. a. b. c. d. The expected time of the critical path is: 12.0 days 13.0 days 11.5 days 11.0 days 3. In order top keep costs at a minimum and decrease the completion time by 1.5 days, Networks, Inc. should crash activity(ies): a. AD and AB. b. DE. c. AD. d. AB and CE. MULTIPLE CHOICE 4. PERT and the critical path method (CPM) are used for: a. Determining the optimal product mix. b. Determining project costs. c. Project planning and control. d. Determining the number of servers needed in a fast-food restaurant. 5. a. b. c. d. The critical path through a network is the: Shortest path. Longest path. Path with the most nodes. Path with the most slack. 6. When making a cost-time trade-off in PERT analysis, the first activity that should be crashed is the activity: a. With the largest amount of slack. b. With the lowest unit crash cost. c. On the critical path with the maximum possible time reduction. d. On the critical path with the lowest unit crash cost. 7. In PERT, slack is the: a. Number of days an activity can be delayed without forcing a delay for the entire project. b. Uncertainty associated with time estimates. c. Path that has the largest amount of time associated with it. d. Difference between the latest starting time and earliest finishing time. 8. a. b. c. d. The primary difference between PERT and CPM is that: CPM uses probabilities on the activity times and PERT does not. PERT considers activity costs and CPM does not. PERT can assign probabilities to activity times and CPM does not. CPM considers activity costs and PERT does not. This study source was downloaded by 100000864099288 from CourseHero.com on 03-19-2023 20:56:38 GMT -05:00 https://www.coursehero.com/file/26874843/MAS-QUANTITATIVE-TECHNIQUES-PART-1-LECTURE-FINAL-COPYdoc/ 5 9. a. b. c. d. A Gantt chart: Does not necessarily show the critical path through a network. Shows the critical path for a project. Is used for determining an optimal product mix. Shows only the activities along the critical path of a network. 10. Manning Corporation is preparing a proposal for the government to produce a steam generator to be used in nuclear submarines. Manning has three factories that can initiate and complete the generator; however, completion times vary due to different technologies and older equipment within each of the three factories. The decision tool that would best assist Manning in its factory selection is: a. Queuing theory. b. Time series analysis. c. PERT-cost analysis. d. Linear programming. 11. When using PERT, the expected time for an activity when given optimistic time (A), a pessimistic time (B), and a most likely time (M) is calculated by which one of the following formulas? a. (B - A) / 2 b. (A + B) / 2 c. (A + 4M + B) / 6 d. (4ABM) / 6 LEARNING CURVE THEORY This is an application of the Pareto’s Law, which states that “productivity rate marginally increases as employees gain experience in his work.” Normally, efficiency increases by an average of 20% for every doubling of output. Hence, this theory also follows the Pareto’s Law or the “80-20” rule. Two (2) Models Used in the Learning Curve Theory 2. Wright Model (Cumulative Average-Time Learning Model)- it states that each time the cumulative quantity of output doubles, the cumulative (or moving) average time to produce per unit decreases by a certain percentage. The decrease in percentage to produce an additional unit is 20%. This rate changes across industries between 60% and 85%. 3. Crawford Model ( Incremental-unit-time learning Model) – it predicts the time required to produce the last unit and requires getting of each unit’s time to compute cumulative total time and cumulative average time per unit. Learning curves describe the fact that the more experience people have with something, the more efficient tfiey become in doing that task. Higher costs per unit early in production are part of the start-up costs. It is commonly accepted that new products and production processes experience a period of low productivity followed by increased productivity. However, the rate of productivity improvement declines over time until it reaches a level where it remains, until another change in production occurs. Learning curve analysis is used in planning, budgeting and forecasting and also to determine costs when bidding on a contract. Benefits of Learning Curve Analysis Decisions such as the following can be aided by learning curve analysis; t) Make or buy decisions - die analysis of the cost to make will be affected, 2) Life-Cycle costing -- In calculating the cost of a contract, learning curve analysis can ensure that the cost estimates are accurate over the life of the contract, leading to better bidding. 3) Cost-Volume-Profit analysis - in determining a breakeven point. If learning is not considered, the result may be overstatement of the number of units required to break even. 4) Development of standard costs - labor costs should be adjusted regularly in recognition of the fact that learning causes standard costs to change over time. 5) Capital budgeting - costs can be projected more accurately over the life of the capital investment when expected improvements in labor productivity due to learning are included. This study source was downloaded by 100000864099288 from CourseHero.com on 03-19-2023 20:56:38 GMT -05:00 https://www.coursehero.com/file/26874843/MAS-QUANTITATIVE-TECHNIQUES-PART-1-LECTURE-FINAL-COPYdoc/ 6 6) Development ol production plans and labor requirements - production and labor budgets should be adjusted to accommodate learning curves. 7 ) Management control - recognizing that higher costs will occur in theeariy phase of the product life cycle allows more effective evaluation of managers. Limitations of Learning Curve Analysis There are three limitations and problems associated with learning curve analysis; 1) Learning curve analysis is appropriate only for labor-intensive operations involving repetitive tasks where repeated trials improve performance. If the production process is designed to have fast set-Lip times using robotics and computer controls, there is little repetitive labor and thus little opportunity for learning to take place. 2) The learning rate is assumed to be constant. Iri real life, the decline in labor time might not be so constant. It might be that the learning rate would decline at the rate of 70% for the first 75,000 units, followed by 80% for the next 50,000 units and 95% for the next 25,000 units. CLASS PROBLEMS: 1. The Valentine Manufacturing Company assumes a 20% learning rate of workers. A worker initially needs 20 hours to produce the first unit. The average direct labor cost is P30 per direct labor hour. REQUIRED: Analyze the effects of the learning curve theory. a Unit s b Moving average labor hours per unit c = (a x b) Estimated total hrs. to produce the units d Direct labor cost per hour e = (c x d) Total Direct labor cost f = (e/a) Average Direct labor cost/ unit 01 02 04 08 16 32 Learning Curve Rate (based on average DLH per unit) = ___________ Learning Curve Rate (based on average DL cost per unit) = _______________ 2. Given a 90% learning сurve, the following data about productivity may apply: Number of unit 100 200 400 Cumulative average time per unit, minutes 5 4.5 (5 x 90%) 4.05 (4.5 x 90%) REQUIRED : What is the average time per unit required for the second 200 units? _____________ End of Part 1 This study source was downloaded by 100000864099288 from CourseHero.com on 03-19-2023 20:56:38 GMT -05:00 https://www.coursehero.com/file/26874843/MAS-QUANTITATIVE-TECHNIQUES-PART-1-LECTURE-FINAL-COPYdoc/ Powered by TCPDF (www.tcpdf.org) 7