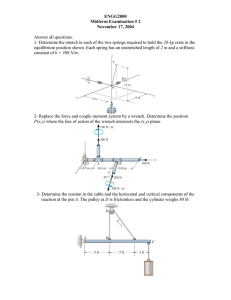

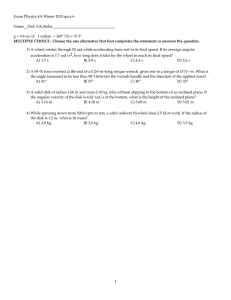

MECHANICAL FABRICATION 1 HANDS-ON SKILLS FOR MODULE 2: WRENCHES ITEMS NEEDED FOR HANDS-ON SKILLS Amatrol Supplied 1 950-MPF1 Mechanical Fabrication 1 Learning System School Supplied Safety glasses FIRST EDITION, MODULE 2, REV. D Amatrol, AMNET, CIMSOFT, MCL, MINI-CIM, IST, ITC, VEST, and Technovate are trademarks or registered trademarks of Amatrol, Inc. All other brand and product names are trademarks or registered trademarks of their respective companies. Copyright © 2019, 2015 by AMATROL, INC. All rights Reserved. No part of this publication may be reproduced, translated, or transmitted in any form or by any means, electronic, optical, mechanical, or magnetic, including but not limited to photographing, photocopying, recording or any information storage and retrieval system, without written permission of the copyright owner. Amatrol, Inc., 2400 Centennial Blvd., Jeffersonville, IN 47130 USA, Ph 812-288-8285, FAX 812-283-1584 www.amatrol.com L19004-XA02UEN-E1 REV. D WRENCHES Copyright © 2019 Amatrol, Inc. SKILL 1 INSPECT AND INSTALL A THREADED FASTENER PROCEDURE OVERVIEW In this skill, you will select and inspect threaded fasteners. They will then be used to assemble several parts. 1. Perform the following safety checkout. Make sure that you are able to answer yes to each item before proceeding. YES/NO SAFETY CHECKOUT Wear safety glasses Wear tight fitting clothes Ties, watches, rings, and other jewelry are removed Long hair is tied up or put in a cap or under a shirt Wearing heavy duty shoes Wear short sleeves or long sleeves are rolled up Floor is dry 2. Review the following image of the Clamp Plate, Notched disk, and Fastening Disk assembly. Understanding that the final assembly will help you during the assembly process. CLAMP PLATE FASTENING DISK NOTCH DISK Figure 1-1. Clamp Plate, Notched Disk, and Fastening Disk Assemblies L19004-XA02UEN-E1-S01, REV. D WRENCHES Copyright © 2019 Amatrol, Inc. S01-1 SKILL 1 INSPECT AND INSTALL A THREADED FASTENER 3. Gather the parts to be assembled in the quantities shown. Quantity Part Number 4 M8×30HHCS Part Name 8 M8FW M8 Flat Washer 4 M8LW M8 Lock Washer 4 M8HX M8 Hex Nut 1 M12×30HHCS 1 M12FW 1 M12LW M12 Lock Washer 1 15903 Clamp Plate 1 15905 Notched Disk M8×30mm Hex Hd Cap Screw M12×30mm Hex Hd Cap Screw M12 Flat Washer 4. Inspect the fasteners for damage or debris. Visually check the fasteners for damage. If the threads are damaged or there is debris in the threads, do not use the fastener. Get a new one and give the damaged one to the instructor. 5. Perform the following substeps to assemble the Clamp Plate to the workplate. A. Place an M8 flat washer over one of the M8 30mm hex head cap screws. M8 X 30 MM HEX HEAD CAP SCREW M8 FLAT WASHER Figure 1-2. M8 Flat Washer on the M8 x 30mm Hex Head Cap Screws L19004-XA02UEN-E1-S01, REV. D WRENCHES Copyright © 2019 Amatrol, Inc. S01-2 SKILL 1 INSPECT AND INSTALL A THREADED FASTENER B. Place the Clamp Plate over the holes in the workplate, as shown in figure 1-3. CLAMP PLATE WORK PLATE Figure 1-3. Place Clamp over Mounting Holes on Workplace C. From the underside of the workplate, insert the M8 30mm hex head cap screw with the washer through the clearance hole in the workplate and the Clamp Plate, as shown in figure 1-4, and hold it. CLAMP PLATE Figure 1-4. M8 HEX HEAD CAP SCREW Cap Screw through Clamp Plate Fastening Hole L19004-XA02UEN-E1-S01, REV. D WRENCHES Copyright © 2019 Amatrol, Inc. S01-3 SKILL 1 INSPECT AND INSTALL A THREADED FASTENER D. Place an M8 flat washer over the M8 30mm hex head cap screw threads showing through the hole in the Clamp Plate, as shown in figure 1-5. CLAMP PLATE M8 HEX HEAD CAP SCREW M8 FLAT WASHER Figure 1-5. Top View of the Fastener Threads with the Flat Washer Installed E. Place an M8 lock washer on the M8 30mm hex head cap screw, as shown in figure 1-6. CLAMP PLATE M8 HEX HEAD CAP SCREW LOCK WASHER M8 FLAT WASHER Figure 1-6. Add a Lock Washer to the Fastener Stack-Up L19004-XA02UEN-E1-S01, REV. D WRENCHES Copyright © 2019 Amatrol, Inc. S01-4 SKILL 1 INSPECT AND INSTALL A THREADED FASTENER F. Hand start an M8 hex nut on the M8 30mm hex head cap screw by aligning the threads and turning the fastener clockwise, as shown in figure 1-7. CLAMP PLATE M8 HEX NUT LOCK WASHER FLAT WASHER Figure 1-7. Add the M8 Hex Nut to the Fastener Stack-Up G. Hand tighten the nut on the hex head cap screw until the nut contacts the lock washer, as shown in figure 1-8. Once contact is made with the lock washer, hand tightening will become difficult. The fastener is now installed and ready for the finish tightening process. Figure 1-8. Complete Fastener Stack-Up Hand Tightened H. Repeat substeps C through G for the second hole in the Clamp Plate. That completes the hand assembly of the Clamp Plate to the workplate. Next you will assemble the Notched Disk to the workplate. L19004-XA02UEN-E1-S01, REV. D WRENCHES Copyright © 2019 Amatrol, Inc. S01-5 SKILL 1 INSPECT AND INSTALL A THREADED FASTENER 6. Perform the following substeps to assemble the Notched Disk to the workplate, as shown in figure 1-9. Figure 1-9. Completed Hand Tightened Notched Disk A. Place the Notched Disk over the holes in the workplate, as shown in figure 1-10. CLAMP PLATE NOTCHED DISK HOLES IN WORKPLATE Figure 1-10. Notched Disk Location L19004-XA02UEN-E1-S01, REV. D WRENCHES Copyright © 2019 Amatrol, Inc. S01-6 SKILL 1 INSPECT AND INSTALL A THREADED FASTENER B. Place an M8 flat washer on the M8 30mm hex head cap screw, as shown in figure 1-11. M8 X 30 MM HEX HEAD CAP SCREW M8 FLAT WASHER Figure 1-11. Fastener and Flat Washer C. From the underside of the workplate, insert the M8 30mm hex head cap screw with the washer through the clearance hole in the workplate and the Notched Disk, as shown in figure 1-12. and hold it. NOTCHED DISK M8 X 30 HEX CAP SCREW Figure 1-12. Notched Disk and Fastener L19004-XA02UEN-E1-S01, REV. D WRENCHES Copyright © 2019 Amatrol, Inc. S01-7 SKILL 1 INSPECT AND INSTALL A THREADED FASTENER D. Place a flat washer, lock washer, and a nut on the hex head cap screw and hand tighten, as shown in figure 1-13. M8 HEX NUT LOCK WASHER FLAT WASHER Figure 1-13. Fastener Stack-Up E. Repeat substeps B through D for the second slot in the Notched Disk, as shown in figure 1-14. HAND TIGHT Figure 1-14. Notched Disk and Fasteners That completes the hand assembly of the Notched Disk to the workplate. Next you will assemble the Fastening Disk to the Notched Disk. L19004-XA02UEN-E1-S01, REV. D WRENCHES Copyright © 2019 Amatrol, Inc. S01-8 SKILL 1 INSPECT AND INSTALL A THREADED FASTENER 7. Perform the following substeps to assemble the Fastening Disk to the Notched Disk. A. Place the Fastening Disk on top of the Notched Disk with the M12 clearance hole lined up with the threaded hole in the center of the Notched Disk, as shown in figure 1-15. FASTENING DISK M12 CLEARANCE HOLE Figure 1-15. Clearance Hole of the Fastening Disk Aligned with the Threaded Hole in Notched Disk B. Place an M12 split ring lock washer and an M12 flat washer on the M12 X 30mm hex head cap screw, as shown in figure 1-16. The cap screw will not be used with a nut, but instead will be screwed into the threaded hole in the Notched Disk to secure the Fastening Disk. M12 SPLIT RING LOCK WASHER M12 FLAT WASHER M12 X 30 MM HEX HEAD CAP SCREW Figure 1-16. M8 Flat Washer on the M8 30mm Hex Head Cap Screws L19004-XA02UEN-E1-S01, REV. D WRENCHES Copyright © 2019 Amatrol, Inc. S01-9 SKILL 1 INSPECT AND INSTALL A THREADED FASTENER C. Insert the M12 hex head cap screw with flat and lock washer into the hole in the center of the fastening disk. Align the threads and hand tighten the cap screw into the threaded hole of the Notched Disk, as shown in figure 1-17. Figure 1-17. Hand Tightened Stack-Up for Securing the Fastening Disk to the Notched Disk D. Tighten the cap screw until the screw head bearing surface contacts the split ring lock washer and it becomes difficult to turn. This completes the hand tightening portion of the assembly process. The fastener is now installed and ready for the finish tightening process. Figure 1-18. Hand Tightened Stack-Up for Securing the Fastening Block to the Notched Disk NOTE If time permits, keep the assembly intact for use in the next skill. If there is not enough time, disassemble the assembly and return the parts to the proper storage bins. L19004-XA02UEN-E1-S01, REV. D WRENCHES Copyright © 2019 Amatrol, Inc. S01-10 SKILL 2 USE A FIXED WRENCH TO TIGHTEN A THREADED FASTENER PROCEDURE OVERVIEW In this skill, you will be tightening several fasteners, using the box, open, and offset wrenches. 1. Perform the following safety checkout. Make sure that you are able to answer yes to each item before proceeding. YES/NO SAFETY CHECKOUT Wear safety glasses Wear tight fitting clothes Ties, watches, rings, and other jewelry are removed Long hair is tied up or put in a cap or under a shirt Wearing heavy duty shoes Wear short sleeves or long sleeves are rolled up Floor is dry 2. Review the following image of the Clamp Plate, Notched Disk, and Fastening Disk assembly, as shown in figure 2-1. Understanding that the final assembly will help you during the assembly process. FASTENING DISK NOTCHED DISK CLAMP PLATE Figure 2-1. Clamp Plate, Notched Disk, and Fastening Disk Assembly L19004-XA02UEN-E1-S02, REV. D WRENCHES Copyright © 2019 Amatrol, Inc. S02-1 SKILL 2 USE A FIXED WRENCH TO TIGHTEN A THREADED FASTENER 3. If you are continuing from the previous skill, and the assembly is still in place, as shown in figure 2-2, proceed on to step 4. If the assemblies are not in place, assemble the Clamp Plate, Notch Disk, and Fastening Disk with hand tightening only. When complete, your assemblies should appear as shown in figure 2-2. M12 LOOSELY ASSEMBLED M8 LOOSELY ASSEMBLED Figure 2-2. M8 LOOSELY ASSEMBLED Assemblies from Skill 1 4. Perform the following substeps to tighten the Clamp Plate to the workplate. A. Obtain the 13-mm offset and one of the 13-mm combination wrenches from the shadow board. The offset wrench will be used to clear the obstruction on the Clamp Plate that makes the fasteners difficult to tighten with other types of fixed wrenches. 13MM 12 POINT OFFSET WRENCH 13MM COMBINATION WRENCHES Figure 2-3. The 13-mm Offset and the 13-mm Combination Wrench L19004-XA02UEN-E1-S02, REV. D WRENCHES Copyright © 2019 Amatrol, Inc. S02-2 SKILL 2 USE A FIXED WRENCH TO TIGHTEN A THREADED FASTENER B. Place the box end of the 13-mm combination wrench on the head of one of the M8 30mm hex head cap screws holding the Clamp Plate to the workplate from the underside of the workplate. This is the backup wrench. COMBINATION WRENCH Figure 2-4. The 13mm Box End Wrench Holding the M8 30mm Hex Head Cap Screw C. Place the 13-mm end of the offset wrench on the M8 nut on the end of the same cap screw on the topside of the workplate. This application is a good example of the need for an offset wrench because the lip of the clamp plate would prevent the movement of other types of fixed wrenches. OFFSET WRENCH LIP Figure 2-5. Offset Wrench in Use L19004-XA02UEN-E1-S02, REV. D WRENCHES Copyright © 2019 Amatrol, Inc. S02-3 SKILL 2 USE A FIXED WRENCH TO TIGHTEN A THREADED FASTENER D. Tighten the fastener by grasping the offset wrench handle furthest away from the fastener. Turn the offset wrench clockwise toward your body while applying a counter holding force to the backup wrench. Continue tightening until the split ring lock washer is fully compressed. TIGHTEN CLOCKWISE Figure 2-6. Tightened Clamp Plate Fastener NOTE If you reach the end of your arm travel or you encounter an obstruction, reposition the offset wrench by lifting it off the nut and return it to the starting position. Figure 2-7. Repositioning Wrench E. Repeat substeps B through D for the remaining Clamp Plate fastener. F. Remove the wrenches from the fastener. This completes the tightening of the Clamp Plate to workplace. L19004-XA02UEN-E1-S02, REV. D WRENCHES Copyright © 2019 Amatrol, Inc. S02-4 SKILL 2 USE A FIXED WRENCH TO TIGHTEN A THREADED FASTENER 5. Perform the following substeps to tighten the Notched Disk to the workplate. A. Obtain an additional 13-mm combination wrench from the shadow board. B. Place the boxed end of one of the 13-mm combination wrenches on the head of one of the M8 30mm hex head cap screws holding the Notched Disk to the workplate from the underside of the workplate. This is the backup wrench. UNDERSIDE M8 HEX CAP SCREW Figure 2-8. Backup Wrench on M8 Hex Cap Screw C. On the topside of the workplate, place the 13-mm open end of the second combination wrench on the M8 nut of the same cap screw on the Notched Disk. This is a good example of an application that needs the design of the open wrench. 13 MM OPEN END OF COMBINATION WRENCH Figure 2-9. Tightening Wrench L19004-XA02UEN-E1-S02, REV. D WRENCHES Copyright © 2019 Amatrol, Inc. S02-5 SKILL 2 USE A FIXED WRENCH TO TIGHTEN A THREADED FASTENER D. Tighten the fastener by grasping the top combination wrench handle furthest away from the fastener. Turn the top combination wrench clockwise toward your body while applying a counter holding force to the back up wrench. Continue tightening until the split ring lock washer is fully compressed, as shown in figure 2-10. Figure 2-10. Fastener Tightened NOTE You may have to reposition the open end wrench. You can flip the wrench to fit on the fastener at a different angle for better access. *SEE NOTE *SEE NOTE Figure 2-11. Flipping the Wrench for Access to the Wrench Flats in Tight Areas (*Fastening Disk Removed for Clarity Only) E. Repeat substeps B through D for the remaining fastener. F. Remove the wrenches from the fastener. This completes the tightening of the Notched Disk to the workplate. 6. Disassemble the Clamp Plate assembly and return the parts to their proper storage areas. 7. If there is sufficient time remaining, leave the Notched Disk and Fastening Disk assembly in place and proceed to the next objective and skill. If not, disassemble the Notched Disk and Fastening Disk assembly and return the parts to their proper storage areas. 8. Return the wrenches to their locations on the shadow board. L19004-XA02UEN-E1-S02, REV. D WRENCHES Copyright © 2019 Amatrol, Inc. S02-6 SKILL 3 USE AN ADJUSTABLE WRENCH TO TIGHTEN A THREADED FASTENER PROCEDURE OVERVIEW In this skill, you will tighten the fastener you loosely assembled in the previous skill. You will properly fit and adjust the jaws of an adjustable wrench. 1. Perform the following safety checkout. Make sure that you are able to answer yes to each item before proceeding. YES/NO SAFETY CHECKOUT Wear safety glasses Wear tight fitting clothes Ties, watches, rings, and other jewelry are removed Long hair is tied up or put in a cap or under a shirt Wearing heavy duty shoes Wear short sleeves or long sleeves are rolled up Floor is dry 2. Review the following image of the Notched Disk and Fastening Block assembly, figure 3-1. Understanding that the final assembly will help you during the assembly process. Figure 3-1. Notched Disk and Fastening Block Assembly L19004-XA02UEN-E1-S03, REV. D WRENCHES Copyright © 2019 Amatrol, Inc. S03-1 SKILL 3 USE AN ADJUSTABLE WRENCH TO TIGHTEN A THREADED FASTENER 3. If you are continuing from the previous skill, proceed directly to step 4. If not, set up the Notch Disk and Fastening Disk as shown in figure 3-2. If you are unsure of the assembly procedures, review the previous skills. M12 HEX HEAD CAP SCREW LOOSE M8 HEX HEAD CAP SCREWS TIGHT Figure 3-2. Assembly 4. Obtain one adjustable wrench from the shadow board. ADJUSTABLE WRENCHES Figure 3-3. Adjustable Wrenches L19004-XA02UEN-E1-S03, REV. D WRENCHES Copyright © 2019 Amatrol, Inc. S03-2 SKILL 3 USE AN ADJUSTABLE WRENCH TO TIGHTEN A THREADED FASTENER 5. Turn the worm gear to adjust the wrench opening greater than the width of the head of the M12 30mm hex head cap screw. WORM Figure 3-4. Adjustable Wrench Open 6. Place the adjustable wrench on the M12 hex head bolt head with the adjustable jaw toward the direction of pull, as shown in figure 3-5. FIXED JAW AGAINST WRENCH FLAT GAP Figure 3-5. Open Adjustable Wrench L19004-XA02UEN-E1-S03, REV. D WRENCHES Copyright © 2019 Amatrol, Inc. S03-3 SKILL 3 USE AN ADJUSTABLE WRENCH TO TIGHTEN A THREADED FASTENER 7. Turn the worm gear to adjust the wrench until its jaws securely grip the wrench flats of the bolt head. TIGHT Figure 3-6. Close Adjustable Wrench 8. Firmly grasp the adjustable wrench handle furthest away from the fastener. 9. Turn the adjustable wrench clockwise toward your body. Continue tightening until the split ring lock washer is fully compressed, as shown in figure 3-7. LOCK WASHER COMPRESSED Figure 3-7. Fastener Tightened L19004-XA02UEN-E1-S03, REV. D WRENCHES Copyright © 2019 Amatrol, Inc. S03-4 SKILL 3 USE AN ADJUSTABLE WRENCH TO TIGHTEN A THREADED FASTENER NOTE You may have to reposition the adjustable wrench. You can flip the wrench to fit on the fastener at a different angle for better access. Remember to retighten the adjustable wrench after each repositioning. Figure 3-8. Flipping Wrench for Access 10. Remove the wrenches from the fastener. This completes the tightening of the Fastener Disk to the Notched Disk. 11. Disassemble the assembly and return the parts to their proper storage areas. 12. Return the wrenches to their locations on the shadow board. L19004-XA02UEN-E1-S03, REV. D WRENCHES Copyright © 2019 Amatrol, Inc. S03-5 SKILL 4 USE AN ALLEN WRENCH TO TIGHTEN A THREADED FASTENER PROCEDURE OVERVIEW In this skill, you will be assembling and tightening several fasteners using the two Allen wrench types you have just learned about. 1. Perform the following safety checkout. Make sure that you are able to answer yes to each item before proceeding. YES/NO SAFETY CHECKOUT Wear safety glasses Wear tight fitting clothes Ties, watches, rings, and other jewelry are removed Long hair is tied up or put in a cap or under a shirt Wearing heavy duty shoes Wear short sleeves or long sleeves are rolled up Floor is dry 2. Review the following image of the Pneumatic Block, as shown in figure 4-1. Understanding that the final assembly will help you during the assembly process. Figure 4-1. Pneumatic Block Assembly 3. Gather the parts in the quantities shown to be assembled. Quantity Part Number Part Name 2 M8×35SHCS M8×35mm socket hd cap screw 2 M8×55SHCS M8×55mm socket hd cap screw 4 M8HX M8 hex nut 4 M8LW M8 lock washer 4 M8FW M8 flat washer L19004-XA02UEN-E1-S04, REV. D WRENCHES Copyright © 2019 Amatrol, Inc. S04-1 SKILL 4 USE AN ALLEN WRENCH TO TIGHTEN A THREADED FASTENER 4. Inspect the fasteners for damage. Also check for dirt or debris. If there is damage, do not use the fastener. Get a new one and give the damaged one to the instructor. DAMAGED THREAD Figure 4-2. Inspect the Fasteners 5. Obtain the 6mm L-Allen wrench, the 6mm T-Allen wrench, and the 13mm combination wrench from the shadow board. 13MM COMBINATION WRENCHES 6MM L-ALLEN WRENCH 6MM R-ALLEN WRENCH Figure 4-3. Skill 4 Tools L19004-XA02UEN-E1-S04, REV. D WRENCHES Copyright © 2019 Amatrol, Inc. S04-2 SKILL 4 USE AN ALLEN WRENCH TO TIGHTEN A THREADED FASTENER 6. Perform the following substeps to assemble the Pneumatic Block to the workplate. A. Place the Pneumatic Block over the holes in the workplate, as shown in figure 4-4. The pipe fitting hole in the block should be on the right side. SHALLOW COUNTERBORE HOLES DEEP COUNTERBORED HOLES Figure 4-4. PIPE FITTING HOLE Pneumatic Block Location on Work Place B. Place the two M8 X 55mm socket head cap screws in the shallow counterbored holes in the Pneumatic Block, as shown in figure 4-5. M8 X 55 MM SHALLOW COUNTERBORED HOLES Figure 4-5. Two M8 X 55mm Socket Head Cap Screws in the Shallow Holes in the Pneumatic Block L19004-XA02UEN-E1-S04, REV. D WRENCHES Copyright © 2019 Amatrol, Inc. S04-3 SKILL 4 USE AN ALLEN WRENCH TO TIGHTEN A THREADED FASTENER C. Place the two M8 X 35mm socket head cap screws in the deep counterbored holes in the Pneumatic Block, as shown in figure 4-6. M8 X 35 MM DEEP COUNTERBORED HOLES Figure 4-6. Two M8 X 35mm Socket Head Cap Screws in the Deep Counterbored Holes in the Pneumatic Block D. From the underside of the workplate, place an M8 flat washer, an M8 lock washer, and an M8 nut on all of the socket head cap screws and hand tighten, as shown in figure 4-7. FLAT WASHER LOCK WASHER HEX NUT Figure 4-7. Flat Washers, Lock Washers, and Nuts Securing the Pneumatic Block (Underside View) L19004-XA02UEN-E1-S04, REV. D WRENCHES Copyright © 2019 Amatrol, Inc. S04-4 SKILL 4 USE AN ALLEN WRENCH TO TIGHTEN A THREADED FASTENER E. Place the short end of the 6mm L-Allen wrench in one of the M8 X 55mm socket head cap screws. 6-MM L-ALLEN M8 X 55 SOCKET HEAD CAP SCREW Figure 4-8. Using the L-Allen Wrench F. From the underside of the workplate, place the boxed end of the 13-mm combination wrench on the M8 nut on the same fastener as a backup wrench. 13-MM WRENCH Figure 4-9. Backup Wrench on M8 Hex Nut L19004-XA02UEN-E1-S04, REV. D WRENCHES Copyright © 2019 Amatrol, Inc. S04-5 SKILL 4 USE AN ALLEN WRENCH TO TIGHTEN A THREADED FASTENER G. Tighten the fastener by turning the 6-mm L-Allen wrench clockwise toward your body, while holding the nut with the backup wrench. Continue to tighten until the split ring lock washer on the fastener is fully compress. NOTE While it is preferable to hold a fastener head and turn the nut during the tightening process, in this example the Allen wrenches are being turned to demonstrate the different Allen wrench uses. Figure 4-10. Using the L-Allen Wrench NOTE You may have to reposition the wrench to avoid obstacles. H. Remove the wrench when the fastener is tightened snugly. I. Repeat the tightening steps for the M8 X 55mm socket head cap screw in the other shallow counterbored hole. L19004-XA02UEN-E1-S04, REV. D WRENCHES Copyright © 2019 Amatrol, Inc. S04-6 SKILL 4 USE AN ALLEN WRENCH TO TIGHTEN A THREADED FASTENER J. Insert the short end of the 6-mm L-Allen wrench into one of the M8 X 35mm socket head cap screws. While the short end of the L-Allen wrench will reach the screw head there is no room for your hand to turn the wrench, as shown in figure 4-11. K. Remove the L-Allen wrench and insert the 6-mm T-Allen wrench into the screw head. NO HAND CLEARANCE Figure 4-11. L-Allen Wrench in Too Deep L. From the underside of the workplate, place the boxed end of the 13-mm combination wrench on the M8 nut on the same fastener as a backup wrench. M. Tighten the fastener by turning the 6-mm T-Allen wrench clockwise while holding the nut with the backup wrench. Continue to tighten until the split ring lock washer on the fastener is fully compressed. 6-MM T-HANDLE WRENCH Figure 4-12. Using the T-Allen Wrench N. Repeat substeps K through M for the remaining socket head cap screws. O. Remove the wrench when complete. That completes the tightening of the Pneumatic Block. 7. Disassemble and return the parts and tools to their proper storage. L19004-XA02UEN-E1-S04, REV. D WRENCHES Copyright © 2019 Amatrol, Inc. S04-7 SKILL 5 USE A RATCHET WRENCH TO TIGHTEN A THREADED FASTENER PROCEDURE OVERVIEW In this skill, you will assemble and tighten several fasteners using a ratchet wrench and a socket like you have just learned about. 1. Perform the following safety checkout. Make sure that you are able to answer yes to each item before proceeding. YES/NO SAFETY CHECKOUT Wear safety glasses Wear tight fitting clothes Ties, watches, rings, and other jewelry are removed Long hair is tied up or put in a cap or under a shirt Wearing heavy duty shoes Wear short sleeves or long sleeves are rolled up Floor is dry 2. Review the following image of the Fastening Disk, as shown in figure 5-1. Understanding that the final assembly will help you during the assembly process. Figure 5-1. Fastening Disk L19004-XA02UEN-E1-S05, REV. D WRENCHES Copyright © 2019 Amatrol, Inc. S05-1 SKILL 5 USE A RATCHET WRENCH TO TIGHTEN A THREADED FASTENER 3. Gather the parts to be assembled in the quantities shown. Quantity Part Number Part Name 4 M10 X 40HHCS M10×40mm hex hd cap screw 4 M10HX M10 hex nut 4 M10LW M10 lock washer 8 M10FW M10 flat washer 1 15905 Fastening Disk 4. Obtain the 17mm 3/8-inch drive Socket Wrench, the 3/8-inch Ratchet Wrench, and the 17-mm combination wrench from the shadow board. 17-MM COMBINATION WRENCH 3/8-INCH RATCHET WRENCH 17-MM DEEP SOCKET Figure 5-2. Wrenches 5. Inspect the fasteners for damage. Also, check for dirt or debris. If the threads are damaged or there is debris in the threads, do not use the fastener, get a new one and give the damaged one to the instructor. L19004-XA02UEN-E1-S05, REV. D WRENCHES Copyright © 2019 Amatrol, Inc. S05-2 SKILL 5 USE A RATCHET WRENCH TO TIGHTEN A THREADED FASTENER 6. Perform the following substeps to assemble the Fastening Disk to the workplate. A. Place four M10 flat washers on the four M10 X 40mm hex head cap screws B. Place the Fastening Disk so that its holes are aligned with the holes in the workplate, as shown in figure 5-3. HOLES ALIGNED WITH WORKPLATE HOLES Figure 5-3. Fastening Disk Location on the Workplate C. From the underside of the workplate, place a M10 X 40mm hex head cap screw with washer in the clearance hole in the workplate through the hole in the Fastening Disk, as shown in figure 5-4. Hold it in position. M10 HEX HEAD CAP SCREW Figure 5-4. View of the Fastening Disk L19004-XA02UEN-E1-S05, REV. D WRENCHES Copyright © 2019 Amatrol, Inc. S05-3 SKILL 5 USE A RATCHET WRENCH TO TIGHTEN A THREADED FASTENER D. Place an M10 flat washer, an M10 lock washer, and an M10 nut on the hex head cap screws and hand tighten, as shown in figure 5-5. M10 HEX NUT M10 LOCK WASHER M10 FLAT WASHER Figure 5-5. Fastening Disk Fastener E. Repeat substeps B through D for the remaining holes in the Fastening Disk, as shown in figure 5-6. HAND TIGHT Figure 5-6. Fastening Disk Fasteners L19004-XA02UEN-E1-S05, REV. D WRENCHES Copyright © 2019 Amatrol, Inc. S05-4 SKILL 5 USE A RATCHET WRENCH TO TIGHTEN A THREADED FASTENER F. Place the 17-mm 3/8-inch drive deep socket on the 3/8-inch drive of the Ratchet Wrench. 3/8-INCH RATCHET WRENCH 17-MM DEEP SOCKET Figure 5-7. Wrench NOTE Remember, some ratchet wrenches have release buttons that must be pushed to install or remove the socket. This is to prevent accidental disconnection of the ratchet wrench and socket. If the wrench you are using has this feature, push the button to engage and disengage the socket. G. Place the 17-mm 3/8-inch drive socket on one of the M10 hex nuts. 17-MM SOCKET Figure 5-8. Ratchet Correctly Placed on the Fasteners of the Fastening Disk L19004-XA02UEN-E1-S05, REV. D WRENCHES Copyright © 2019 Amatrol, Inc. S05-5 SKILL 5 USE A RATCHET WRENCH TO TIGHTEN A THREADED FASTENER H. Place the boxed end of the 17-mm combination wrench on the M10 hex head cap screw from the underside of the workplate. TIGHTENING WRENCH BACKUP 17-MM COMBINATION WRENCH Figure 5-9. Backup Wrench I. Tighten the fasteners by pulling the ratchet wrench clockwise toward your body in a smooth motion while holding the fastener head with the backup wrench. When you reach the end of your arm’s travel, rotate the handle in the reverse direction to reposition it to the start position. Continue this until the split ring lock washer on that fastener stack-up is fully compressed. PULL Figure 5-10. Tighten the Fasteners NOTE You may have to reverse or “ratchet” the wrench several times to avoid obstacles or in a confined area. L19004-XA02UEN-E1-S05, REV. D WRENCHES Copyright © 2019 Amatrol, Inc. S05-6 SKILL 5 USE A RATCHET WRENCH TO TIGHTEN A THREADED FASTENER J. Remove the wrench when the fasteners are tightened. K. Repeat substeps F through J for the remaining fasteners following the bolt tightening sequence shown in figure 5-11. Figure 5-11. Tightening Sequence L. Remove the wrenches. This completes the tightening of the Fastener Disk to the Notched Disk. 7. Disassemble and return the parts and tools to their proper storage. L19004-XA02UEN-E1-S05, REV. D WRENCHES Copyright © 2019 Amatrol, Inc. S05-7