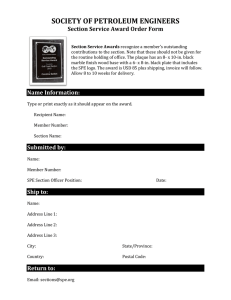

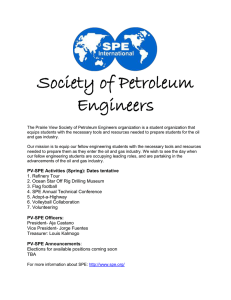

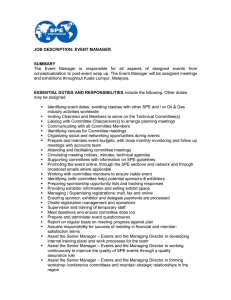

www.advenergymat.de Conformational Regulation of Dielectric Poly(Vinylidene Fluoride)-Based Solid-State Electrolytes for Efficient Lithium Salt Dissociation and Lithium-Ion Transportation Yan-Fei Huang,* Jian-Ping Zeng, Shuang-Feng Li, Chen Dai, Jun-Feng Liu, Chen Liu,* and Yan-Bing He* conductivities (≈10−3 S cm−1 at room Restricted by the poor ability of polymers to dissociate lithium salts and transtemperature).[1,2] Solid-state electrolytes (SSEs) are developed to replace flammable port ions, solid-state polymer electrolytes (SPEs) show extremely low ionic and unstable LEs to improve the safety conductivities (≈10−7–10−5 S cm−1) and transference number of lithium ions and stability of lithium metal batteries (tLi+ ≈0.2–0.4) at 25 °C. Here, a novel polymer matrix of SPEs that simultane(LMBs).[3–6] Among all SSEs, solid-state ously promotes lithium salt dissociation and ion transportation based on a high polymer electrolytes (SPEs) have attracted dielectric poly(vinylidene fluoride-trifluoroethylene-chlorotrifluoroethylene) (TerP) extensive attention in recent years due to their desirable flexibility, low density, and an all-trans conformational poly(vinylidene fluoride-trifluoroethylene) (CoP), facile processability, and good interfacial CH is developed. The high dielectric constant increases the polarity of 2CF2 contact with electrodes.[7–9] However, most + polar groups; then, brings a strong electronegative end that dissociates Li from SPEs suffer from low ionic conductivities lithium salts. The all-trans conformation assures all fluorine atoms locate on one (≈10−7 to 10−5 S cm−1) and low lithium ions side of the chain, constructing ion hopping highways. As a result, the TerP/CoP (Li+) transference numbers (tLi+, usually −4 −1 (TC) SPE exhibits a high ionic conductivity (2.37 × 10 S cm ) and a quite large ≈0.2–0.4) at room temperature.[10–13] This is mainly because lithium salts cannot be tLi+ of 0.61 at 25 °C. The Li/TC SPE/Li symmetric cells cycle stably for more than efficiently dissociated by a polymer matrix half a year (>4500 h) and the LiNi0.8Co0.1Mn0.1O2/TC SPE/Li cell cycles steadily with a low εr (usually less than 10) and for 1000 and 600 cycles at 1 C and 2 C at 25 °C, respectively. This work paves Li+ is hardly transported through polymer a new way to prepare high-performance SPEs by simultaneously modulating chains with disordered hopping sites, dielectric constants and conformation of polymers. which consequently result in unsatisfactory cycling stability of LMBs. To improve the ion conduction ability, 1. Introduction the most commonly used method is introducing ceramic fillers such as Li6.5La3Zr1.5Ta0.5O12 and Al2O3 into SPEs to build ion conducting pathways or reduce the crystallinity of SPEs.[14–17] Liquid electrolytes (LEs) usually contain cyclic carbonates with high dielectric constants (εr > 30) to dissociate lithium salts Nonetheless, inorganic fillers are easy to agglomerate and have high mass densities,[18,19] which results in inhomogeneous and linear carbonates to facilitate ions transport for high ionic Li+ flux distribution and would reduce the energy density of batteries.[20] It would be highly desirable, yet remains a great Y.-F. Huang, J.-P. Zeng, S.-F. Li, C. Dai, J.-F. Liu, C. Liu challenge, to construct an all-polymeric SPE that offers a high College of Materials Science and Engineering Shenzhen Key Laboratory of Polymer Science and Technology ion conduction ability. To achieve this goal, first, the polymer Guangdong Research Center for Interfacial Engineering of Functional Materials matrix should have a high ability to dissociate lithium salts, Shenzhen University just like cyclic carbonates in LEs. The dissociation of lithium Shenzhen 518055, P. R. China salts in SPEs occurs by the coordination interactions between E-mail: yanfeihuang@szu.edu.cn; liuchen@szu.edu.cn the Li+ and the polar functional groups in polymer chains.[21–24] Y.-F. Huang State Key Laboratory of Polymer Materials Engineering Increasing the εr intensifies the charge separation in polar Sichuan University groups and then promotes Li salts dissociation.[22,24,25] ThereChengdu 610065, P. R. China fore, a high dielectric polymer is needed as the matrix of Y.-B. He SPEs.[26] However, even for poly(vinylidene fluoride) (PVDF) Shenzhen Gein Graphene Center that shows a relatively higher εr (≈10) than the other polymer Institute of Materials Research matrix such as poly(ethylene oxide) (PEO) (εr < 5) and Tsinghua Shenzhen International Graduate School Tsinghua University poly(methyl methacrylate) (PMMA) (εr < 4),[27–32] its ability to Shenzhen 518055, P. R. China dissociate lithium salts is still far from expectations for high E-mail: he.yanbing@sz.tsinghua.edu.cn ionic conductivities. To improve the εr of PVDF, some dielectric The ORCID identification number(s) for the author(s) of this article fillers such as BaTiO3 and TiO2 can be incorporated;[33–36] howcan be found under https://doi.org/10.1002/aenm.202203888. ever, their inert nature for ion conduction may reduce the ion transport efficiency. Recently, a new family of PVDF that shows DOI: 10.1002/aenm.202203888 Adv. Energy Mater. 2023, 2203888 2203888 (1 of 8) © 2023 Wiley-VCH GmbH 16146840, 0, Downloaded from https://onlinelibrary.wiley.com/doi/10.1002/aenm.202203888 by Shenzhen University, Wiley Online Library on [06/03/2023]. See the Terms and Conditions (https://onlinelibrary.wiley.com/terms-and-conditions) on Wiley Online Library for rules of use; OA articles are governed by the applicable Creative Commons License Research Article Figure 1. Schematic diagram of Li slat dissociation and ion transportation facilitated by the polymer matrix of SPE with different dielectric constants and conformations. a unique relaxor ferroelectric (RFE) behavior is found to show a high εr (≈30–70).[26,37–39] Therefore, these RFE PVDF would show high abilities to dissociate Li salt into free ions. In addition to Li salt dissociation, the ability of PVDF to transport Li+ is also important for achieving high ionic conductivities and tLi+. As is well known, the residual N, N-dimethylformamide (DMF) would solvate with Li+ to form [Li(DMF)x]+, which could be transported by the PVDF through interactions of [Li(DMF)x]+ with PVDF chains.[5,40,41] Such interaction is through coordination and uncoordination of [Li(DMF)x]+ with electronegative atoms, that is, the F atoms. In this context, the spatial arrangement of F atoms on molecular chains (i.e., the conformation) would influence the hopping pathways of [Li(DMF)x]+, then may have a significant effect on ion transport efficiency. For RFE PVDF such as poly(vinylidene fluoride trifluoroethylene chlorotrifluoroethylene) [P(VDF-TrFE-CTFE)] terpolymer (TerP) or PVDF prepared by conventional solution casting, the conformation is mainly trans–gauche–trans–gauche (TGTG’) and T3GT3G’ in which F atoms distribute on both sides of the carbon chain (Figure 1a,b).[8,27,28,42,43] When ions hop from one F site to another, the transmission path would be twisted and disordered (Figure 1a,b), which is undesired for [Li(DMF)x]+ transport. Unlike TGTG’ and T3GT3G’, all-trans (TTTT) conformation assures all F atoms locate on one side of the carbon chain,[8] which brings a great potential to construct connected electronegative channels as hopping highways for [Li(DMF)x]+ (Figure 1c). Unfortunately, due to the limitation of processing methods, abundant TTTT conformation has never been achieved in both PVDF and RFE PVDF SPEs as far as we know. In this work, a P(VDF-TrFE) random copolymer (CoP) is innovatively introduced into a RFE TerP to disturb the crystallization of TerP, then induce a conformational change from Adv. Energy Mater. 2023, 2203888 mixed TGTG’ and T3GT3G’ conformations into TTTT conformation. With well-aligned F atoms, the TTTT conformation of coupled TerP/CoP (TC) provides ion hopping highways to motivate ion transportation (Figure 1c). Meanwhile, the increased real part of relative permittivity (εr′) of TC from ≈10 for PVDF to ≈33 helps to promote the dissociation of lithium salts. As a result, TC SPE shows an increased ionic conductivity (2.37 × 10−4 S cm−1) as well as a significantly high tLi+ of 0.61 (vs 0.29 for PVDF SPE and 0.36 for TerP SPE) at 25 °C. Furthermore, the high-voltage LiNi0.8Co0.1Mn0.1O2 (NCM811)/TC SPE/Li cell cycles stably for 1000 and 600 cycles at 1 and 2 C, respectively, at 25 °C. The Li/TC SPE/Li symmetric cell shows a uniform stripping and plating performance for more than half a year (>4500 h) at 25 °C. This work proposes a new strategy to prepare high-performance SPEs by manipulating the dielectric constant and conformation of polymers. The prepared SPE shows great potential to applicate as high-energy-density and safe solid-state LMBs. 2. Results and Discussion The polymer and SPE films are prepared by solution casting following an optimized procedure as reported in our previous work.[26] First, the TerP and CoP are coupled in different weight ratios and when it is 5:5, the TC matrix shows a relatively high εr′ (≈30, Figure S1, Supporting Information), a low glass transition temperature (Tg, Figure S2, Supporting Information), and the highest ionic conductivity of TC SPE (Figure S3, Supporting Information). Therefore, 5:5 is the optimized weight ratio and will be employed hereinafter. From Fourier transform infrared spectrometer (FTIR), TerP shows mixed TGTG′, T3GT3G′, and TTTT conformations (Figure 2a, blue curve), and PVDF 2203888 (2 of 8) © 2023 Wiley-VCH GmbH 16146840, 0, Downloaded from https://onlinelibrary.wiley.com/doi/10.1002/aenm.202203888 by Shenzhen University, Wiley Online Library on [06/03/2023]. See the Terms and Conditions (https://onlinelibrary.wiley.com/terms-and-conditions) on Wiley Online Library for rules of use; OA articles are governed by the applicable Creative Commons License www.advenergymat.de www.advancedsciencenews.com www.advenergymat.de Figure 2. a) FTIR, b) XRD, and c) εr′ as a function of temperature at different frequencies for TC, TerP, CoP, and PVDF films. The SEM images of d,f) TC SPE and e,g) PVDF SPE. The insets of Figure 2d,e are optical images of TC SPE and PVDF SPE membranes, respectively. h) TGA and i) FTIR of TC, TerP, and PVDF SPE. shows mixed TGTG′ and T3GT3G′ conformations (Figure 2a, green curve). After introducing CoP with pure TTTT conformation (Figure 2a, yellow curve) into TerP, TC shows pure TTTT conformation with typical peaks at 1285, 842, 505, 472, and 426 cm−1 (Figure 2a, red curve).[27,44–46] This could be further confirmed by Raman results (Figure S4, Supporting Information) where only the TTTT conformation is observed at typical peaks at 841, 1443, and 2974 cm−1.[47–49] From X-ray diffraction (XRD) measurement, PVDF show reflections of (020), (110), (200), and (002) planes, proving the mixed TGTG′ and T3GT3G′ conformations (Figure 2b). As for the TC film, the (110/200) crystal plane for RFE phase and (110), (120), and (201) for ferroelectric (FE) phase are observed at the reflections at 12.8, 14.2, 24.7, and 28.5 nm−1, respectively.[8,26] The RFE phase brings TC with a high εr′ of ≈33 (Figure 2c) compared to ≈10 for PVDF at 10 Hz and 25 °C.[43] The FE phase that could be further proved by differential calorimetric scanning (DSC, Figure S5, Supporting Information) assures a TTTT conformation for TC at room temperature.[50] The high εr′ and TTTT conformation Adv. Energy Mater. 2023, 2203888 may endow TC with simultaneously high abilities to dissociate lithium salts and facilitate ions transport. Then, a high ionic conductivity and tLi+ can be anticipated for TC SPE. Scanning electron microscopy (SEM) is employed to observe the morphologies of TC SPEs. It is shown that granules of TC (Figure 2d) and TerP (Figure S6a, Supporting Information) are more connected than PVDF SPE (Figure 2e), which is responsible for the more transparent morphology (insets of Figure 2d,e) and thinner thickness for TC (Figure 2f) and TerP SPEs (Figure S6b, Supporting Information) than PVDF SPE (Figure 2g). The varied morphology between TC and PVDF SPE is due to the different crystallization driving forces of these two films (Figure S7, Supporting Information). The denser morphology brings a more continuous path for ion transport and a better ductility for TC and TerP SPE than PVDF SPE (Figure S8, Supporting Information), which may contribute to better interfacial compatibility between SPEs with rigid electrodes. Thermo gravimetric analysis (TGA) is performed to detect the residues of DMF in SPEs. The minor weight loss before 55 °C (region I) 2203888 (3 of 8) © 2023 Wiley-VCH GmbH 16146840, 0, Downloaded from https://onlinelibrary.wiley.com/doi/10.1002/aenm.202203888 by Shenzhen University, Wiley Online Library on [06/03/2023]. See the Terms and Conditions (https://onlinelibrary.wiley.com/terms-and-conditions) on Wiley Online Library for rules of use; OA articles are governed by the applicable Creative Commons License www.advancedsciencenews.com Figure 3. a) Ionic conductivities of TC, TerP, and PVDF SPEs at varied temperatures. b) Chronoamperometry profiles of Li/TC SPE/Li symmetrical cells under a polarization voltage of 10 mV. The insets show EIS curves before and after the polarization. c) tLi+ of TC, TerP, and PVDF SPEs at 25 °C. Raman peaks of d) TC SPE, e) TerP SPE, and f) PVDF SPE around 741 cm−1. g) Long cycling performance of Li/TC SPE/Li, Li/TerP SPE/Li, and Li/PVDF SPE/ Li symmetrical cells at 25 °C under a current density of 0.05 mA cm−2. h) Long cycling performance of Li/TC SPE/Li symmetrical cell at 25 °C under a current density of 0.1 mA cm−2. in Figure 2h comes from the evaporation of the trapped moisture, and the weight loss between 55 °C and 200 °C is ascribed to the residual DMF.[5,51] From Figure 2h, PVDF, TerP, and TC SPEs show comparable amounts (12.8%) of residual DMF, which are bounded with Li+ to form [Li(DMF)x]+ as evidenced by FTIR results (Figure 2i), indicating there exist no free DMF molecules.[5,40] The ionic conductivity was calculated by electrochemical impedance spectroscopy (EIS) measurement (Figure S9, Supporting Information). From Figure 3a, ionic conductivities are much higher for TC SPE in comparison to PVDF SPE at varied temperatures. Especially, TC SPE shows a high ionic conductivity of 2.37 × 10−4 S cm−1 at 25 °C, which is 2.4 times as much as PVDF SPE (9.70 × 10−5 S cm−1), and much higher than other reported all-polymeric SPEs without any inorganic fillers (≈10−7 to 10−5 S cm−1).[5,15,52–55] Moreover, the activation energy Ea decreases from 0.33 eV for PVDF SPE to 0.27 eV for TC SPE, Adv. Energy Mater. 2023, 2203888 indicating a lower migration barrier for Li+ in TC SPE. As the crystallinity (Figure S10, Supporting Information) and DMF residue (Figure 2h) of TC SPE are comparable to PVDF SPE, and the segmental motion is more difficult for TC than PVDF (Tg,TC = −24.0 °C, Tg,PVDF = −35.2 °C, Figure S11, Supporting Information), the much higher ionic conductivities and lower activation energy of TC SPE than PVDF SPE must be attributed to the high εr′ and abundant TTTT conformation of TC that facilitate the Li salts dissociation and ions transportation, respectively. Noting that with an even higher εr′ of TerP (≈45, Figure 2c) than TC, TerP SPE with minor TTTT conformation (Figure 2a) displays a lower ionic conductivity and a higher Ea (0.29 eV) than TC SPE (Figure 3a). This indicates the important role of abundant TTTT conformation in constructing highways for efficient ion transportation in the TC SPE. As is well known, the ionic conductivity is contributed by both Li+ and anions, and for LMBs, only the current carried 2203888 (4 of 8) © 2023 Wiley-VCH GmbH 16146840, 0, Downloaded from https://onlinelibrary.wiley.com/doi/10.1002/aenm.202203888 by Shenzhen University, Wiley Online Library on [06/03/2023]. See the Terms and Conditions (https://onlinelibrary.wiley.com/terms-and-conditions) on Wiley Online Library for rules of use; OA articles are governed by the applicable Creative Commons License www.advenergymat.de www.advancedsciencenews.com www.advenergymat.de by Li+ matters;[2] so here, the tLi+ that quantifies the proportion of current from Li+ movement is measured according to a method reported in literature.[56,57] From the chronoamperometry profiles (Figure 3b), the tLi+ of TC SPE is calculated as 0.61 (Figure 3c), which is not only remarkably higher than PVDF SPE (0.29) and TerP SPE (0.36, Figure S12, Supporting Information) but also superior to other reported SPEs (usually ≈0.2–0.4).[5,10,11,26,58] The high tLi+ of TC SPE is highly related to the mechanism of TC to transport Li+. To be specific, the [Li(DMF)x]+ first coordinates with the electronegative F atoms from TC chains, and as the molecular chain segments move, uncoordination occurs and [Li(DMF)x]+ detaches from the original coordination site and hops to the next F site. The TTTT conformation with connected electronegative channels of TC shortens the hopping pathway; then, a high movement of Li+ as well as a high tLi+, can be obtained. The fast Li+ movement can be further proved by the 350 times higher diffusion coefficients of Li+ (DLi+) for TC SPE than PVDF SPE (Figure S13, Supporting Information). With such a high tLi+ and DLi+, the overwhelming movement and accumulation of anions near electrodes and the resultant concentration polarization can be greatly hindered,[11,59–61] which benefits the cycling performance of TC SPE when assembled in LMBs. Raman test is further performed to examine the Li+ coordination state with FSI anions in TC SPE. The peak around 741 cm−1 can be fitted into three peaks as shown in Figure 3d–f, where C1 and C2 correspond to cisoid and transoid conformers from free FSI anions, respectively, and Ccoord comes from the Li+ coordinated FSI anions.[5,62–64] The total amount of C1 and C2 is calculated as 85.3% for TC SPE (Figure 3d), much higher than 75.5% for TerP SPE (Figure 3e) and 69.0% for PVDF SPE (Figure 3f ), indicating more amount of movable Li+ exists in TC SPE. These above results support our speculation that the high εr′ can facilitate the dissociation of lithium salts and the TTTT conformation helps to construct ion transport highways. Benefiting from the high ionic conductivity and tLi+, the Li/ TC SPE/Li symmetric cell shows a quite stable cycling performance for more than 4500 h (>half a year) with a small polarization voltage of only 22 mV at 25 °C under a current density of 0.05 mA cm−2 (Figure 3g). In clear contrast, Li/TerP SPE/ Li and Li/PVDF SPE/Li symmetric cells display short circuits only after 1300 and 500 h, with polarization voltage of 29 and 52 mV, respectively. At the current density of 0.1 mA cm−2, the Li/TC SPE/Li symmetric cell still displays a stable cycling performance for 1500 h (Figure 3h). Further increasing the current density to 0.2 and 0.3 mA cm−2, Li/TC SPE/Li symmetric cell still shows better stability than the Li/PVDF SPE/ Li symmetric cell (Figure S14a,b, Supporting Information) although they have comparable critical current densities (≈0.6 mA cm−2; Figure S14c, Supporting Information). These results demonstrate that the TC SPE has a superior ability to suppress the Li dendrite growth. This will be proved later by SEM observation. The electrochemical stability window (ESW) is measured by linear sweep voltammetry (LSV), and it is 4.5 V for TC SPE (Figure 4a) and TerP SPE (Figure S15a, Supporting Information), and 4.7 V for PVDF SPE (Figure S15b, Supporting Information). The higher ESW of PVDF SPE than TC SPE may Adv. Energy Mater. 2023, 2203888 be related to the higher nonbonding orbital energy of F than Cl, which gives PVDF a lower valence band minimum then a higher oxidation potential to widen the ESW.[65] However, although the ESW of TC SPE is slightly lower than PVDF SPE, it is high enough to match well with high voltage NCM811 cathodes. To prove this, the rate performance of NCM811/TC SPE/Li batteries is detected. As shown in Figure 4b; Figure S16, Supporting Information, the NCM811/TC SPE/Li cell shows a specific capacity of 160.4, 143.2, 132.9, and 111.3 mAh g−1 at 0.5, 1.5, 2.5, and 5 C, respectively. When the rate goes back to 0.5 C, the specific capacity returns to 160.0 mAh g−1 and retains ≈98% after 100 cycles (Figure 4c). This suggests a good compatibility between TC SPE and NCM811 cathodes. Increasing the rate to 1 C, the NCM811/TC SPE/Li cell presents a rather stable cycling performance with capacity retention of 97.8% and 65.1% after 500 and 1000 cycles at 25 °C, respectively (Figure 4d,e). In clear contrast, the NCM811/PVDF SPE/Li cell exhibits a dramatical capacity decay (Figure 4d; Figure S17a, Supporting Information), and the NCM811/TerP SPE/Li cell only cycles steadily for the initial 50 cycles then short circuits after 120 cycles at 1 C and 25 °C (Figure 4d; Figure S17b, Supporting Information). The much better cycling performance of NCM811/TC SPE/Li cells than NCM811/PVDF SPE/Li cells is attributed to the remarkably better stability of TC SPE against Li anodes (Figure 3g), the much higher tLi+ (Figure 3c) that could reduce the concentration polarization near NCM811 cathodes, the better compatibility between TC SPE and NCM811 (Figure S18, Supporting Information), and the more stable interfacial impedance of NCM811/TC SPE/ Li cells during cycling (Figure S19, Supporting Information). Further increasing the rate to 2 C, a quite high rate for SPE, the NCM811/TC SPE/Li cell still shows good cycling performance with capacity retention of 82.6% after 600 cycles at 25 °C (Figure 4f,g). These above results demonstrate that the promoted Li salts dissociation by high εr′ and the highly efficient ion transport provided by TTTT conformation endows the TC SPE with high electrochemical properties, especially the high tLi+, good cycling stability of both Li//Li and NCM811//Li batteries in comparison to other reported SPEs (Table S1, Supporting Information). To verify the superior ability of TC SPE to inhibit lithium dendrite growth, the cycled Li surfaces are observed by SEM. From Figure 5a, the Li surface from cycled NCM811/TC SPE/ Li cell is dense, uniform, and smooth, while for NCM811/PVDF SPE/Li cell, the cycled Li shows a coarse and roughened appearance (Figure 5b). This reveals that TC SPE has a much stronger ability than PVDF to impede the growth of lithium dendrites. It is probably because there are more amount of free ions with high mobility in TC SPE, which brings a more continuous and uniform Li deposition then gets rid of lithium dendrite growth.[66] Furthermore, owing to the much better ductility of TC SPE than PVDF SPE (Figure S8, Supporting Information), TC SPE shows a very tight interface with NCM811 cathodes (Figure 5c,e,f), in clear contrast to the loose contact between PVDF SPE and NCM811 (Figure 5d). Such a good interfacial compatibility between TC SPE and NCM811 reduces the interface impedance (Figure S13, Supporting Information) and favors ions transport, consequently bringing a quite long lifespan for high-voltage LMBs (Figure 4d). 2203888 (5 of 8) © 2023 Wiley-VCH GmbH 16146840, 0, Downloaded from https://onlinelibrary.wiley.com/doi/10.1002/aenm.202203888 by Shenzhen University, Wiley Online Library on [06/03/2023]. See the Terms and Conditions (https://onlinelibrary.wiley.com/terms-and-conditions) on Wiley Online Library for rules of use; OA articles are governed by the applicable Creative Commons License www.advancedsciencenews.com Figure 4. a) The LSV curve of TC SPE. b) Rate capacities of the NCM811/TC SPE/Li cell. c) Long-term cycling performance of NCM811/TC SPE/Li cells at 0.5 C and 25 °C after the rate cycling in (b). Long-term cycling performance of d) NCM811/TC SPE/Li, NCM811/TerP SPE/Li, and NCM811/PVDF SPE/Li cells at 1 C and 25 °C and f) NCM811/TC SPE/Li cell at 2 C and 25 °C. Charge–discharge voltage profiles of NCM811/TC SPE/Li cells e) at 1 C and 25 °C from (d), and g) at 2 C and 25 °C from (f). 3. Conclusion We developed a novel polymer matrix of SPE with simultaneously high abilities to dissociate Li salts and transport ions through coupling a high dielectric P(VDF-TrFE-CTFE) with an all-trans conformational P(VDF-TrFE). The dielectric constant of the coupled matrix, TC, increased from ≈10 for PVDF to ≈33, which intensified the charge separation in polar functional groups and brought a highly electronegative end that absorbed Li+ to realize high-efficient Li salts dissociation. The TTTT conformation made all electronegative F atoms locate on one side of the carbon chain, which provided ion transport highways for rapid hopping motion of [Li(DMF)x]+. As a result, TC SPE showed a high ionic conductivity of 2.37 × 10−4 S cm−1 at 25 °C and a quite high tLi+ of 0.61 (vs 0.2–0.4 for other SPEs). With more amount of free Li+ with desirable mobility, Li stripping and plating are more uniform. Adv. Energy Mater. 2023, 2203888 Therefore, the Li/TC SPE/Li symmetric cell shows a stable cycling for more than half a year (>4500 h) at 25 °C, in clear contrast to Li/PVDF SPE/Li symmetric cell that is short circuit only after 500 h. Furthermore, TC SPE exhibits a denser morphology and better ductility than PVDF SPE, which contributes to a continuous path for ions transport, a better affinity with electrodes, and a lower interfacial impedance of LMBs. In consequence, the high-voltage NCM811/TC SPE/ Li cell performs stably for 1000 and 600 cycles at 1 and 2 C at 25 °C, respectively. In particular, the capacity retention of NCM811/TC SPE/Li cell is 97.8% after 500 cycles at 1 C, which is significantly higher than 16.7% for NCM811/PVDF SPE/Li cells after 200 cycles at 1 C. This work, for the first time, demonstrates that the dielectric and conformational modulation can enable polymers to show high abilities to dissociate Li salts and transport ions. The prepared TC SPE shows great application potential as high-energy-density LMBs. 2203888 (6 of 8) © 2023 Wiley-VCH GmbH 16146840, 0, Downloaded from https://onlinelibrary.wiley.com/doi/10.1002/aenm.202203888 by Shenzhen University, Wiley Online Library on [06/03/2023]. See the Terms and Conditions (https://onlinelibrary.wiley.com/terms-and-conditions) on Wiley Online Library for rules of use; OA articles are governed by the applicable Creative Commons License www.advenergymat.de www.advancedsciencenews.com www.advenergymat.de using a VMP3 multichannel electrochemical station. The Li/SPEs/Li symmetric cells were assembled to explore the Li plating/stripping performance on a battery test system (LAND CT2001A) at 25 °C. The NCM811/SPEs/Li cells were cycled at 25 °C with a voltage range from 2.8 to 4.3 V. Supporting Information Supporting Information is available from the Wiley Online Library or from the author. Acknowledgements Figure 5. SEM images of the cycled Li surface from a) NCM811/TC SPE/ Li and b) NCM811/PVDF SPE/Li. The cross-section of the c) NCM811/TC SPE interface and d) NCM811/PVDF SPE interface after cycling. e,f) The energy dispersive spectroscopy (EDS) maps of (c). 4. Experimental Section Conflict of Interest Preparation of SPEs: P(VDF-TrFE-CTFE) 65.4/26.2/8.8 mol% (TerP, Mw = 5.8 × 105 g mol−1, Arkema), P(VDF-TrFE) 80/20 mol% (CoP, Mw = 4.5 × 105 g mol−1, Arkema), and LiFSI (Canrd, China) were dissolved in DMF at a weight ratio of 1:1:2 under magnetically stirring for 8 h at 25 °C. Then, the polymer solution was transferred into a glass dish and dried at 55 °C to obtain the TC SPE. The preparation of PVDF SPE and TerP SPE followed a similar procedure with a polymer to LiFSI weight ratio of 1:1. To make sure the amount of residue DMF was similar, different preparation time ranging from 19 to 50 h was used to prepare TC, TerP, and PVDF SPEs. Characterizations: FTIR measurement was conducted using a Nicole 6700 FTIR spectrometer (Thermo Fisher Scientific, USA) in an attenuated total reflection (ATR) mode. XRD curves were collected using a Rigaku Smartlab with Cu-Kα radiation. The equation q = (4π sinθ)/λ was used to calculate the scattering vector q, where θ and λ are the half-scattering angle and the wavelength (1.5418 Å), respectively. BDS (Novocontrol Concept 40) was performed under an applied voltage of 1.0 Vrms (i.e., room-mean-square voltage), and before test, the polymer films were evaporated with Au electrodes on both sides. SEM (Hitachi SU-70, Japan) was conducted under an operation voltage of 5 kV. TGA curves were collected by a TGA 55 analyzer (TA Instrument, USA) from room temperature to 800 °C under a N2 atmosphere, and the ramping rate was 10 °C min−1. Raman test was conducted on a RENISHAW invia Raman microscope (UK). Assembling of Cells and Electrochemical Measurements: NCM811, super P, PVDF, and LiFSI were dissolved into N-methyl-2-pyrrolidone (NMP) with weight ratio of 8:1:1:1 to obtain a slurry. After casting the slurry on an Al foil and drying at 80 °C for 8 h, the NCM811 cathode was prepared with mass loading of ≈1 mg cm−2. The CR2032 solid-state cells were assembled in an Ar-filled glove box. The ionic conductivities of SPEs were calculated from the EIS data obtained from a VMP3 multichannel electrochemical station (Bio-Logic Science Instruments, France) with frequency from 7 MHz to 1 Hz and a 10 mV AC oscillation voltage. The tLi+ was obtained from the chronoamperometry profiles under a polarization voltage of 10 mV and EIS data before and after the polarization. LSV was examined by assembling Li/SPEs/stainless steel (SS) cells from 0 to 6 V versus Li/Li+ at a scanning rate of 1 mV s−1 Adv. Energy Mater. 2023, 2203888 Y.-F.H. acknowledges the financial support from the National Natural Science Foundation of China (52103037), the Natural Science Foundation of Guangdong Province (2023A1515030247; 2021A1515011976), Shenzhen Science and Technology Research and Development Fund (JCYJ20220531102013031; 20200807113743001), and the Opening Project of State Key Laboratory of Polymer Materials Engineering (Sichuan University) (Grant No. sklpme2022-4-07). Y.-B.H. acknowledges the financial support from the Shenzhen All-Solid-State Lithium Battery Electrolyte Engineering Research Center (XMHT20200203006) and the Shenzhen Technical Plan Project (RCJC20200714114436091). The authors declare no conflict of interest. Data Availability Statement The data that support the findings of this study are available from the corresponding author upon reasonable request. Keywords all-trans conformation, dielectric constant, ionic conductivity, lithium ions, solid-state polymer electrolytes Received: November 15, 2022 Revised: January 29, 2023 Published online: [1] K. Xu, Chem. Rev. 2014, 114, 11503. [2] K. Xu, Chem. Rev. 2004, 104, 4303. [3] K. Shi, Z. Wan, L. Yang, Y. Zhang, Y. Huang, S. Su, H. Xia, K. Jiang, L. Shen, Y. Hu, S. Zhang, J. Yu, F. Ren, Y.-B. He, F. Kang, Angew. Chem., Int. Ed. 2020, 59, 11784. [4] L. Chen, Y.-F. Huang, J. Ma, H. Ling, F. Kang, Y.-B. He, Energy Fuels 2020, 34, 13456. [5] K. Yang, L. Chen, J. Ma, C. Lai, Y. Huang, J. Mi, J. Biao, D. Zhang, P. Shi, H. Xia, G. Zhong, F. Kang, Y.-B. He, Angew. Chem., Int. Ed. 2021, 60, 24668. [6] Z. Wan, K. Shi, Y. Huang, L. Yang, Q. Yun, L. Chen, F. Ren, F. Kang, Y.-B. He, J. Power Sources 2021, 505, 230062. [7] P. Shi, J. Ma, Y. Huang, W. Fu, S. Li, S. Wang, D. Zhang, Y.-B. He, F. Kang, J. Mater. Chem. A 2021, 9, 14344. 2203888 (7 of 8) © 2023 Wiley-VCH GmbH 16146840, 0, Downloaded from https://onlinelibrary.wiley.com/doi/10.1002/aenm.202203888 by Shenzhen University, Wiley Online Library on [06/03/2023]. See the Terms and Conditions (https://onlinelibrary.wiley.com/terms-and-conditions) on Wiley Online Library for rules of use; OA articles are governed by the applicable Creative Commons License www.advancedsciencenews.com [8] J. Zeng, J. Liu, H.-D. Huang, S.-C. Shi, B. Kang, C. Dai, L. Zhang, Z. Yan, F. J. Stadler, Y. He, Y. Huang, J. Mater. Chem. A 2022, 10, 18061. [9] H. Huo, Y. Chen, R. Li, N. Zhao, J. Luo, J. G. Pereira da Silva, R. Mücke, P. Kaghazchi, X. Guo, X. Sun, Energy Environ. Sci. 2020, 13, 127. [10] C. Yang, Q. Wu, W. Xie, X. Zhang, A. Brozena, J. Zheng, M. N. Garaga, B. H. Ko, Y. Mao, S. He, Y. Gao, P. Wang, M. Tyagi, F. Jiao, R. Briber, P. Albertus, C. Wang, S. Greenbaum, Y.-Y. Hu, A. Isogai, M. Winter, K. Xu, Y. Qi, L. Hu, Nature 2021, 598, 590. [11] K. M. Diederichsen, E. J. McShane, B. D. McCloskey, ACS Energy Lett. 2017, 2, 2563. [12] P. Zhai, Z. Yang, Y. Wei, X. Guo, Y. Gong, Adv. Energy Mater. 2022, 12, 2200967. [13] H. Huo, Y. Chen, J. Luo, X. Yang, X. Guo, X. Sun, Adv. Energy Mater. 2019, 9, 1804004. [14] D. Lei, Y.-B. He, H. Huang, Y. Yuan, G. Zhong, Q. Zhao, X. Hao, D. Zhang, C. Lai, S. Zhang, J. Ma, Y. Wei, Q. Yu, W. Lv, Y. Yu, B. Li, Q.-H. Yang, Y. Yang, J. Lu, F. Kang, Nat. Commun. 2019, 10, 4244. [15] X. Zhang, T. Liu, S. Zhang, X. Huang, B. Xu, Y. Lin, B. Xu, L. Li, C.-W. Nan, Y. Shen, J. Amer. Chem. Soc. 2017, 139, 13779. [16] J. Bae, Y. Li, J. Zhang, X. Zhou, F. Zhao, Y. Shi, J. B. Goodenough, G. Yu, Angew. Chem., Int. Ed. 2018, 57, 2096. [17] H. Ling, L. Shen, Y. Huang, J. Ma, L. Chen, X. Hao, L. Zhao, F. Kang, Y.-B. He, ACS Appl. Mater. Interfaces 2020, 12, 56995. [18] A. C. Balazs, T. Emrick, T. P. Russell, Science 2006, 314, 1107. [19] Y.-F. Huang, J.-Z. Xu, D. Zhou, L. Xu, B. Zhao, Z.-M. Li, Compos. Sci. Technol. 2017, 151, 234. [20] S. Li, J. Huang, Y. Cui, S. Liu, Z. Chen, W. Huang, C. Li, R. Liu, R. Fu, D. Wu, Nat. Nanotechnol. 2022, 17, 613. [21] J. H. Kim, M.-S. Kang, Y. J. Kim, J. Won, N.-G. Park, Y. S. Kang, Chem. Commun. 2004, 1662. [22] K. S. Ngai, S. Ramesh, K. Ramesh, J. C. Juan, Ionics 2016, 22, 1259. [23] E. E. Ushakova, A. V. Sergeev, A. Morzhukhin, F. S. Napolskiy, O. Kristavchuk, A. V. Chertovich, L. V. Yashina, D. M. Itkis, RSC Adv. 2020, 10, 16118. [24] P. Hu, J. Chai, Y. Duan, Z. Liu, G. Cui, L. Chen, J. Mater. Chem. A 2016, 4, 10070. [25] K. C. Kao, in Dielectric Phenomena in Solids: With Emphasis on Physical Concepts of Electronic Processes, (Ed: K. C. Kao), Academic Press, San Diego, CA 2004, Ch. 4. [26] Y.-F. Huang, T. Gu, G. Rui, P. Shi, W. Fu, L. Chen, X. Liu, J. Zeng, B. Kang, Z. Yan, F. J. Stadler, L. Zhu, F. Kang, Y.-B. He, Energy Environ. Sci. 2021, 14, 6021. [27] Y. Huang, G. Rui, Q. Li, E. Allahyarov, R. Li, M. Fukuto, G.-J. Zhong, J.-Z. Xu, Z.-M. Li, P. L. Taylor, L. Zhu, Nat. Commun. 2021, 12, 675. [28] Y. Huang, J.-Z. Xu, T. Soulestin, F. D. Dos Santos, R. Li, M. Fukuto, J. Lei, G.-J. Zhong, Z.-M. Li, Y. Li, L. Zhu, Macromolecules 2018, 51, 5460. [29] M. Kumar, S. S. Sekhon, Eur. Polym. J. 2002, 38, 1297. [30] S. Gross, D. Camozzo, V. Di Noto, L. Armelao, E. Tondello, Eur. Polym. J. 2007, 43, 673. [31] C. M. Costa, M. M. Silva, S. Lanceros-Méndez, RSC Adv. 2013, 3, 11404. [32] S. J. Liu, L. Zhou, J. Han, K. H. Wen, S. D. Guan, C. J. Xue, Z. Zhang, B. Xu, Y. H. Lin, Y. Shen, L. L. Li, C. W. Nan, Adv. Energy Mater. 2022, 12, 2200660. [33] G. Zhang, D. Brannum, D. Dong, L. Tang, E. Allahyarov, S. Tang, K. Kodweis, J.-K. Lee, L. Zhu, Chem. Mater. 2016, 28, 4646. [34] H. X. Tang, Y. R. Lin, H. A. Sodano, Adv. Energy Mater. 2013, 3, 451. Adv. Energy Mater. 2023, 2203888 [35] Y. Jiang, X. Zhang, Z. Shen, X. Li, J. Yan, B.-W. Li, C.-W. Nan, Adv. Funct. Mater. 2020, 30, 1906112. [36] D. Ai, H. Li, Y. Zhou, L. L. Ren, Z. B. Han, B. Yao, W. Zhou, L. Zhao, J. M. Xu, Q. Wang, Adv. Energy Mater. 2020, 10, 1903881. [37] L. Zhu, J. Phys. Chem. Lett. 2014, 5, 3677. [38] M. R. Gadinski, Q. Li, G. Zhang, X. Zhang, Q. Wang, Macromolecules 2015, 48, 2731. [39] Y. Li, T. Soulestin, V. Ladmiral, B. Ameduri, T. Lannuzel, F. Domingues Dos Santos, Z.-M. Li, G.-J. Zhong, L. Zhu, Macromolecules 2017, 50, 7646. [40] X. Zhang, J. Han, X. Niu, C. Xin, C. Xue, S. Wang, Y. Shen, L. Zhang, L. Li, C.-W. Nan, Batter Supercaps 2020, 3, 876. [41] L. Chen, T. Gu, J. Ma, K. Yang, P. Shi, J. Biao, J. Mi, M. Liu, W. Lv, Y.-B. He, Nano Energy 2022, 100, 107470. [42] G. Rui, Y. Huang, X. Chen, R. Li, D. Wang, T. Miyoshi, L. Zhu, J. Mater. Chem. C 2021, 9, 894. [43] L. Yang, B. A. Tyburski, F. D. Dos Santos, M. K. Endoh, T. Koga, D. Huang, Y. Wang, L. Zhu, Macromolecules 2014, 47, 8119. [44] W. Li, S. Guo, Y. Tang, X. Zhao, J. Appl. Polym. Sci. 2004, 91, 2903. [45] H. A. C. Gil, R. M. Faria, Y. Kawano, Polym. Degrad. Stab. 1998, 61, 265. [46] M. Kobayashi, K. Tashiro, H. Tadokoro, Macromolecules 1975, 8, 158. [47] F. Orudzhev, S. Ramazanov, D. Sobola, P. Kaspar, T. Trčka, K. Částková, J. Kastyl, I. Zvereva, C. Wang, D. Selimov, R. Gulakhmedov, M. Abdurakhmanov, A. Shuaibov, M. Kadiev, Nano Energy 2021, 90, 106586. [48] A. Arrigoni, L. Brambilla, C. Bertarelli, G. Serra, M. Tommasini, C. Castiglioni, RSC Adv. 2020, 10, 37779. [49] M. Veitmann, D. Chapron, S. Bizet, S. Devisme, J. Guilment, I. Royaud, M. Poncot, P. Bourson, Polym. Test. 2015, 48, 120. [50] L. Yang, X. Li, E. Allahyarov, P. L. Taylor, Q. M. Zhang, L. Zhu, Polymer 2013, 54, 1709. [51] W. Liu, C. Yi, L. Li, S. Liu, Q. Gui, D. Ba, Y. Li, D. Peng, J. Liu, Angew. Chem., Int. Ed. 2021, 60, 12931. [52] X. Zhang, S. Wang, C. Xue, C. Xin, Y. Lin, Y. Shen, L. Li, C. W. Nan, Adv. Mater. 2019, 31, 1806082. [53] Y. Li, W. Zhang, Q. Dou, K. W. Wong, K. M. Ng, J. Mater. Chem. A 2019, 7, 3391. [54] Y. Sun, X. Zhan, J. Hu, Y. Wang, S. Gao, Y. Shen, Y. T. Cheng, ACS Appl. Mater. Interfaces 2019, 11, 12467. [55] Z. Bi, S. Mu, N. Zhao, W. Sun, W. Huang, X. Guo, Energy Storage Mater. 2021, 35, 512. [56] J. Evans, C. A. Vincent, P. G. Bruce, Polymer 1987, 28, 2324. [57] D. Kumar, S. A. Hashmi, J. Power Sources 2010, 195, 5101. [58] Z. Xue, D. He, X. Xie, J. Mater. Chem. A 2015, 3, 19218. [59] K. Timachova, H. Watanabe, N. P. Balsara, Macromolecules 2015, 48, 7882. [60] J. L. Schaefer, D. A. Yanga, L. A. Archer, Chem. Mater. 2013, 25, 834. [61] L. Chen, W. Li, L.-Z. Fan, C.-W. Nan, Q. Zhang, Adv. Funct. Mater. 2019, 29, 1901047. [62] G. Yang, C. Chanthad, H. Oh, I. A. Ayhan, Q. Wang, J. Mater. Chem. A 2017, 5, 18012. [63] V. Amoli, J. S. Kim, E. Jee, Y. S. Chung, S. Y. Kim, J. Koo, H. Choi, Y. Kim, D. H. Kim, Nat. Commun. 2019, 10, 4019. [64] D. Kim, X. Liu, B. Yu, S. Mateti, L. A. O’Dell, Q. Rong, Y. Chen, Adv. Funct. Mater. 2020, 30, 1910813. [65] L. Chen, S. Venkatram, C. Kim, R. Batra, A. Chandrasekaran, R. Ramprasad, Chem. Mater. 2019, 31, 4598. [66] C.-Z. Zhao, X.-Q. Zhang, X.-B. Cheng, R. Zhang, R. Xu, P.-Y. Chen, H.-J. Peng, J.-Q. Huang, Q. Zhang, Proc. Natl. Acad. Sci U. S. A. 2017, 114, 11069. 2203888 (8 of 8) © 2023 Wiley-VCH GmbH 16146840, 0, Downloaded from https://onlinelibrary.wiley.com/doi/10.1002/aenm.202203888 by Shenzhen University, Wiley Online Library on [06/03/2023]. See the Terms and Conditions (https://onlinelibrary.wiley.com/terms-and-conditions) on Wiley Online Library for rules of use; OA articles are governed by the applicable Creative Commons License www.advenergymat.de www.advancedsciencenews.com