IMEX USER GUIDE

THREE-PHASE, BLACK-OIL

RESERVOIR SIMULATOR

VERSION 2015

15.IM.M3

This publication and the application described in it are furnished under license

exclusively to the licensee, for internal use only, and are subject to a confidentiality

agreement. They may be used only in accordance with the terms and conditions of

that agreement.

All rights reserved. No part of this publication may be reproduced or transmitted in any

form or by any means, electronic, mechanical, or otherwise, including photocopying,

recording, or by any information storage/retrieval system, to any party other than the

licensee, without the written permission of Computer Modelling Group.

The information in this publication is believed to be accurate in all respects.

However, Computer Modelling Group makes no warranty as to accuracy or

suitability, and does not assume responsibility for any consequences resulting from

the use thereof. The information contained herein is subject to change without notice.

Copyright 2015 Computer Modelling Group Ltd.

All rights reserved.

The license management portion of this program is based on:

Reprise License Manager (RLM)

Copyright 2006-2015, Reprise Software, Inc.

All rights reserved.

IMEX uses Intel(R) Compilers.

IMEX, CMG, and Computer Modelling Group are registered trademarks of

Computer Modelling Group Ltd. All other trademarks are the property of their

respective owners.

Computer Modelling Group Ltd.

200, 1824 Crowchild Trail N.W.

Calgary, Alberta Canada T2M 3Y7

Tel: (403) 531-1300

Fax: (403) 289-8502

E-mail: cmgl@cmgl.ca

Preface

IMEX is CMG's new generation adaptive implicit-explicit black-oil simulator which

includes features such as local grid refinement, comprehensive well management,

pseudo-miscible option, volatile oil option, polymer flooding, horizontal wells, dual

porosity/permeability, flexible grids, and many more. IMEX was developed to simulate

primary depletion, coning, water, gas, solvent, and polymer injection in single and double

porosity reservoirs.

This User Guide provides a step-by-step procedure for preparation of an input data

set for this program. A tutorial section is provided as well as a set of appendices

describing the underlying theory. Use of this User Guide requires a basic knowledge

of reservoir engineering and some exposure to reservoir simulation.

Every attempt has been made in the preparation of this User Guide to provide the

user with all the necessary details. If questions arise, please contact:

Computer Modelling Group Ltd.

200, 1824 Crowchild Trail N.W.

Calgary, Canada

T2M 3Y7

Telephone: (403) 531-1300 Fax: (403) 289-8502 E-mail: cmgl@cmgl.ca

Confidentiality: All components of CMG technology including software and related

documentation are protected by copyright, trademark and secrecy. CMG technology

can be used only as permitted by your license from CMG. By the license, you have

agreed to keep all CMG technology confidential and not disclose it to any third party.

All rights reserved. No part of this publication may be reproduced or transmitted in any

form or by any means, electronic, mechanical, or otherwise, including photocopying,

recording, or by any information storage/retrieval system, to any party other than the

licensee, without the written permission of Computer Modelling Group.

Corrections/Errors: CMG ENDEAVORS TO PRODUCE TECHNOLOGY OF THE

HIGHEST QUALITY; NEVERTHELESS ERRORS OR DEFICIENCIES IN SUCH

TECHNOLOGY ARE INEVITABLE. IF YOU FIND AN ERROR OR DEFICIENCY, YOU

ARE REQUESTED TO PROVIDE DETAILS OF IT AND ILLUSTRATIVE DATA SET(S)

TO CMG SUFFICIENT TO PERMIT CMG TO REPRODUCE THE ERROR OR

DEFICIENCY. CMG SHALL ENDEAVOR TO REMEDY A DEFICIENCY IN A TIMELY

MANNER AND SHALL PERIODICALLY REPORT TO YOU AS TO THE STEPS BEING

TAKEN TO REMEDY THE DEFICIENCY. THE RESPONSE TIME FOR A DEFICIENCY

MUST BE PRIORITIZED FOR THEIR GENERAL APPLICATION TO CMG MEMBERS

AND WHETHER THEY FORM PART OF A CMG PROGRAM. CMG DOES NOT

WARRANT THAT DEFICIENCIES WILL BE REMEDIED.

Limited Liability: CMG does not warrant the accuracy or usefulness of the technology

and software - Refer to your license.

Contents

Introduction

1

Important Changes between IMEX 2015.10 and IMEX 2014.10................................. 1

Important Changes between IMEX 2014.10 and IMEX 2013.10................................. 4

Important Changes between IMEX 2013.10 and IMEX 2012.10................................. 7

Important Changes between IMEX 2012.10 and IMEX 2011.10............................... 10

Important Changes between IMEX 2011.10 and IMEX 2010.10............................... 14

Important Changes between IMEX 2010.10 and IMEX 2009.10............................... 19

Important Changes between IMEX 2009.10 and IMEX 2008.10............................... 22

Important Changes Between IMEX 2008.10 and IMEX 2007.10 .............................. 24

Important Changes Between IMEX 2007.10 and IMEX 2006.10 .............................. 26

Important Changes Between IMEX 2006.10 and IMEX 2005.10 .............................. 30

Important Changes Between IMEX 2005.10 and IMEX 2004.10 .............................. 35

Important Changes Between IMEX 2004.10 and IMEX 2003.10 .............................. 37

Important Changes Between IMEX 2003.10 and IMEX 2002.10 .............................. 39

Important Changes Between IMEX 2002.10 and IMEX 2001.10 .............................. 42

Important Changes Between IMEX 2001.10 and IMEX 2000.10 .............................. 46

Important Changes Between IMEX 2000.10 and IMEX 1999.10 .............................. 49

Important Changes Between IMEX 1999.10 and IMEX 98.05 .................................. 54

Important Changes Between IMEX 98.05 and IMEX 98.00 ...................................... 57

Important Changes Between IMEX 98.00 and IMEX 97.00 ...................................... 58

Important Changes Between IMEX 97.00 and IMEX 96.00 ...................................... 63

Important Changes Between IMEX 96.00 and IMEX 95.00 ...................................... 68

Important Changes Between IMEX 95.00 and IMEX 94.00 ...................................... 72

Important Changes Between IMEX 93.00 and 92.00 ................................................. 76

Introduction to IMEX ................................................................................................. 80

Tutorial

85

Introduction................................................................................................................. 85

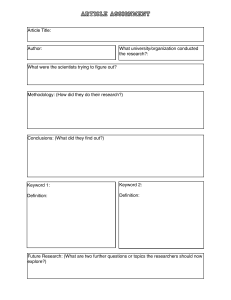

Data Groups in the Keyword Input System ................................................................ 86

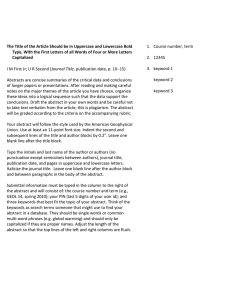

How to Document Your Data Set ............................................................................... 87

How to Do a Restart.................................................................................................... 88

Controlling Contents of the Output File ..................................................................... 90

Controlling Contents of the Graphics File (SR2)........................................................ 91

Describing Your Grid System..................................................................................... 92

IMEX User Guide

Contents • i

Describing Refined Grid ............................................................................................ 94

Using Dual Porosity/Dual Permeability ..................................................................... 95

Input of Null Blocks ................................................................................................... 99

Using the Aquifer Option (see Appendix G) ............................................................ 101

Using the Pseudo-Miscible Option........................................................................... 103

Using the Rock Compaction/Dilation Model Option ............................................... 104

Using the Polymer Option ........................................................................................ 112

Problems with Small Timesteps or Long Execution Times ..................................... 113

Using the API Tracking Option................................................................................ 116

Problems with Solver Convergence ......................................................................... 117

Simulating a Gas-Water or Gas Reservoir ............................................................... 118

Simulating a Gas-Water with Condensate Reservoir ............................................... 119

Simulating a Tilted Water-Oil/Water-Gas Contact .................................................. 121

Horizontal Wells....................................................................................................... 125

Vertical Equilibrium Calculation ............................................................................. 126

Defining Multiple PVT Regions/Initialization Regions ........................................... 130

Defining Wells ......................................................................................................... 135

Defining the Well Type ............................................................................................ 136

How to Shut In a Well and Reopen It....................................................................... 137

Voidage Replacement............................................................................................... 139

Using the Wellbore Model ....................................................................................... 140

Operating and Monitoring Constraints ..................................................................... 142

Definition of Well Indices within IMEX.................................................................. 144

Input of Well Indices ................................................................................................ 146

Stopping a Simulation Run....................................................................................... 148

Using Wildcards in Well Lists ................................................................................. 149

Guidelines for Setting Up Well Data........................................................................ 150

Recurrent Data from Other Sections ........................................................................ 153

Subsidence Output.................................................................................................... 155

Parallel IMEX........................................................................................................... 157

Using the Seawater Injection Option........................................................................ 159

Using the Scale Buildup Option ............................................................................... 160

Simulating a Volatile Oil Reservoir ......................................................................... 162

Using the Subdomain-Dual Permeability-Reinfiltration Model ............................... 163

Modelling Non Darcy Flow in Hydraulic Fractures Accurately Using a Grid

Based Approach .................................................................................................. 165

Using the Fracture Clean-up Model ......................................................................... 171

Using the Oil Wet Option......................................................................................... 175

Special Keywords for Advanced Users (SHIFT) ..................................................... 182

Modelling Non Darcy Flow in Fractured Shale Gas Reservoirs .............................. 183

The WATER_FIX Keyword .................................................................................... 196

Introducing a Hydraulic Fracture in Recurrent Data ................................................ 197

Relative Permeability and Capillary Pressure Hysteresis in Oil-Water Systems ..... 198

Two and Three Point Scaling of Relative Permeability Values ............................... 205

ii • Contents

IMEX User Guide

Keyword Data Entry System

209

Introduction to Keyword System .............................................................................. 209

Comments (Optional) ............................................................................................... 215

Blank Lines (Optional) ............................................................................................. 216

Scan Mode for Checking Errors ............................................................................... 217

Include Files (Optional) ............................................................................................ 218

Controlling Data File Listing (Optional) .................................................................. 219

Controlling Data File Listing Using NOLISTLIM (Optional) ................................ 220

Changing the Comment Indicator (Optional) ........................................................... 221

Changing the Keywords by Using Translate Rules (Optional)................................. 222

Input of Grid Property Arrays ................................................................................... 223

Entering Matrix Grid Properties ............................................................................... 225

Entering Fracture Grid Properties ............................................................................. 226

Entering Refined Grid Properties.............................................................................. 227

Assign Data to Block Groups ................................................................................... 228

J and K Direction Data from I Direction .................................................................. 230

Constant Value Arrays .............................................................................................. 231

Array Input in IJK Notation ...................................................................................... 232

Array Input of Values that Vary in the I Direction ................................................... 234

Array Input of Values that Vary in the J Direction ................................................... 235

Array Input of Values that Vary in the K Direction ................................................. 236

Values that Vary for Most or All Grid Blocks .......................................................... 237

Assign Property to Fracture Zone (Conditional)....................................................... 238

Modifying Array Data (Conditional) ........................................................................ 240

Interpolating Table Data (Optional).......................................................................... 243

Input/Output Control

245

Command Line Input/Output Control ....................................................................... 245

Values Stored in Binary Form .................................................................................. 249

ASCII Characters ...................................................................................................... 251

Input/Output File Names (Optional) ......................................................................... 252

Important Notes (Run Time Dimensioning) ............................................................. 256

Problem Type Where IMEX Fails to Allocate Adequate/ Appropriate Storage ......... 257

Run Time Dimensioning (Optional) ......................................................................... 258

Background (Run Time Dimensioning).................................................................... 263

Advantages of Run Time Dimensioned IMEX ......................................................... 264

Project Main Title (Optional).................................................................................... 265

Project Second Title (Optional) ................................................................................ 266

Project Third Title (Optional) ................................................................................... 267

Case Identification (Optional)................................................................................... 268

Check Only (Optional).............................................................................................. 269

Trap UNIX Signal 2 Interrupt (Optional) ................................................................. 270

ASCII Form of SR2 (Optional)................................................................................. 272

IMEX User Guide

Contents • iii

Precision of SR2 (Optional) ..................................................................................... 273

Controlling Data File Listing Using NOLISTLIM (Optional) ................................. 274

Input Data Units (Optional) ...................................................................................... 275

Output Data Units (Optional) ................................................................................... 278

Data Range Checking (Optional) .................................................................................. 279

Maximum Number of Error Messages (Optional) ................................................... 280

Restart Timestep (Optional) ..................................................................................... 281

Separate or Combined Restart/Graphics (Optional) ................................................. 283

Restart Record Writing Frequency (Optional) ......................................................... 284

Output Printing Frequency (Optional)...................................................................... 286

Items in Output Print File (Optional) ....................................................................... 289

Simulation Results File Writing Frequency (Optional)............................................ 297

Items in Simulation Results File (Optional) ............................................................. 299

Items in Diary File (Optional) .................................................................................. 306

Production Split Output (Optional) .......................................................................... 308

Debug Output (Optional).......................................................................................... 309

Reservoir Description

313

Fundamental Grid Definition (Required) ................................................................. 313

K Direction Index (Optional) ................................................................................... 320

Block Dimensions for the I Direction (Conditional) ................................................ 322

Block Dimensions for the J Direction (Conditional) ................................................ 324

Block Dimensions for the K Direction (Conditional) .............................................. 326

Depth to the Centre of a Grid Block (Conditional) .................................................. 328

Depth to the Tops of Grid Blocks (Conditional) ...................................................... 330

Depths to Centre of Pay (Conditional).......................................................................... 332

Depths to Top of Block (Conditional) ...................................................................... 334

Grid Tilt Angles (Conditional) ................................................................................. 336

Corner Point Depths for Corner Point Grids (Conditional)...................................... 338

Lateral Corner Point Locations for Corner Point Grids (Conditional) ..................... 340

Line-Based Corner Point Locations for Corner Point Grids (Conditional) .............. 342

Complete Corner Point Locations for Corner Point Grids (Conditional) ................. 344

Corner-point Node Locations (Conditional) ............................................................ 347

Convert Corner Point Grid to Node Based Grid (Conditional) ................................ 352

Block Groups (Optional) .......................................................................................... 353

Local Refined Grid (Optional) ................................................................................. 355

Planar Fracture Template ......................................................................................... 367

Dual Porosity (Optional) .......................................................................................... 371

Dual Permeability (Optional) ................................................................................... 372

Dual Porosity Subdomain Method (Optional) .......................................................... 373

Assigning Fractional Volumes to Subdomain blocks (Optional) ............................. 375

Subdomain to Subdomain Flow Transmissibility Multipliers (Optional) ................ 377

Dual Porosity MINC Method (Optional) ................................................................. 379

iv • Contents

IMEX User Guide

Shape Factor Calculation (Conditional).................................................................... 380

Matrix-Fracture Transfer Calculation (Conditional)................................................. 382

Allowing Addition Matrix-Fracture Connections (Optional) ................................... 384

Fracture Spacing (Conditional) ................................................................................. 385

Null Block Indicator (Optional) ................................................................................ 386

Porosity (Required) ................................................................................................... 388

Rock Compressibility (Required) ............................................................................. 389

Pore Volume Modifiers (Optional) ........................................................................... 391

Block Geometry Modifiers (Optional)...................................................................... 393

Permeabilities (Required) .............................................................................................. 400

Netpay (Optional) ..................................................................................................... 402

Netgross (Optional)................................................................................................... 404

Transmissibility Multipliers (Optional) .................................................................... 405

Transmissibility Multipliers for Lower Indexed Block Faces (Optional)................. 408

Transmissibility Multiplier for Matrix-Fracture Flow (Optional) ............................ 410

Transmissibility Multiplier Action (Optional) .......................................................... 411

Inter Region Transmissibility Multiplier (Optional)................................................. 413

Transmissibility Multiplier Regions (Optional)........................................................ 415

Pinch Out Array (Optional) ........................................................................................... 416

Pore Volume Cut-Off Threshold (Optional) ............................................................. 418

Pinchout Tolerance (Optional).................................................................................. 419

Corner Point Tolerance (Optional) ................................................................................ 421

Faults (Optional) ....................................................................................................... 422

Aquifers (Optional) see Appendix G ........................................................................ 424

Pressure Influence Function (Conditional) see Appendix G .................................... 431

Sectors (Optional) ..................................................................................................... 433

Sector Array (Optional) ............................................................................................ 435

Sector Assignment via Names and an Array (Optional) ........................................... 436

Flux Sector (Optional) .............................................................................................. 438

Lease Planes (Optional) ............................................................................................ 440

Irregular Connection (Optional) ............................................................................... 442

Special Connections (Optional) ................................................................................ 445

Fault Array (Optional) .............................................................................................. 447

Compaction/Dilation Rock Type (Optional)............................................................. 449

Compaction/Dilation Rock Compressibility (Optional) ........................................... 451

Compaction Rock Table (Optional) .......................................................................... 452

Compaction Hysteresis Rock Table (Optional) ........................................................ 455

Treat *CCPOR/*CROCKTAB/*CROCKTABH as Depletion Parameters/

Tables (Optional) ................................................................................................. 458

Compaction Irreversibility Flag (Optional) .............................................................. 460

Dilation Rock Table in Elastic Zone (Optional) ....................................................... 461

Dilation Rock Table in the Plastic Zone (Optional) ................................................. 463

Dilation Rock Table in Unloading Zone (Optional) ................................................. 465

Dilation Rock Table in Recompacting Zone (Optional) ........................................... 468

IMEX User Guide

Contents • v

Dilation Rock Table in Reloading Zone (Optional) ................................................. 470

Compaction/Dilation Rock Region (Optional) ......................................................... 478

Dispersion Coefficients (Conditional)...................................................................... 485

Fault Transmissibilities (Optional) ........................................................................... 487

Component Properties

489

Fluid Model (Required) ............................................................................................ 489

Reservoir Temperature (Optional) ........................................................................... 493

Oil and Gas PVT Table (Optional)........................................................................... 494

Oil and Gas Differential Liberation Table (Optional) .............................................. 499

Gas PVT Table for API Model (Optional) ............................................................... 505

Oil PVT Tables for API Model (Optional) ................................................................... 508

Gas PVT Table for GASWATER Model (Optional) ............................................... 513

Condensate - Oil and Gas PVT Table (Optional) ..................................................... 516

Volatile - Oil and Gas PVT Table (Optional) .......................................................... 521

Oil Compressibility as a Function of Pressure (Optional)........................................ 527

Bo Above the Bubble Point as a Function of Pressure (Optional) ........................... 530

Oil Viscosity Above the Bubble Point as a Function of Pressure (Optional)........... 532

Bo above the Bubble Point as a Function of Pressure and STC Oil Density for

API Tracking (Optional) ..................................................................................... 534

Condensate Model - Undersaturated Eg, Bg, Zg Table............................................ 539

Condensate Model - Undersaturated Gas Viscosity Table ....................................... 543

Oil Viscosity Above the Bubble Point as a Function of Pressure and STC Oil

Density for API Tracking (Optional) .................................................................. 546

Reference Pressure for Gas-Oil Capillary Pressure (Optional) ................................ 551

Solvent PVT Table (Conditional)............................................................................. 552

Extended Oil-Solvent Mixing Parameter Table (Optional)...................................... 556

Densities (Required) ................................................................................................. 559

Under-Saturated Oil Compressibility (Optional) ..................................................... 561

Oil Phase Viscosity Pressure Dependence (Optional).............................................. 562

Water Formation Volume Factor (Required) ........................................................... 563

Water Phase Viscosity (Required) ................................................................................ 565

PVT Type (Optional)................................................................................................ 567

Maximum Rate of Increase of Solution Gas Ratio or Bubble Point Pressure

(Optional) .................................................................................................................. 568

Maximum Rate of Increase of Oil Content or Dew Point Pressure (Optional) ........ 570

Initial Gas-Oil Ratio (Conditional)........................................................................... 572

Gas and Solvent Mixing Parameter (Conditional) ................................................... 573

Minimum Solvent Saturation (Conditional) ............................................................. 574

Polymer Adsorption Table (Conditional) ................................................................. 576

Polymer Viscosity Mixing (Conditional) ................................................................. 578

Reference Polymer Viscosity (Conditional) ............................................................. 581

Reference Polymer Concentration (Conditional) ..................................................... 582

vi • Contents

IMEX User Guide

Polymer Permeability Table (Conditional) ............................................................... 583

Reference Seawater Viscosity (Conditional) ............................................................ 584

Gas Adsorption for Water Filled Blocks (Optional) ................................................. 585

Rock-Fluid Data

587

Notes on Rock-Fluid Data ........................................................................................ 587

Start of Rock-Fluid Property Input (Required) ......................................................... 590

Relative Permeability Curves by Table (Required) .................................................. 591

Water-Oil Relative Permeability Table (Conditional) .............................................. 594

Water-Oil Imbibition Relative Permeability Table................................................... 605

Liquid-Gas Relative Permeability Table (Conditional) ............................................ 607

Capillary Pressure Hysteresis Parameters (Optional) ............................................... 618

Oil-Water Relative Permeability Hysteresis Parameters (Optional)......................... 621

Gas Relative Permeability Hysteresis Parameter (Optional) .................................... 624

Reduced Vertical Extent of Pcow Cycle for Trapped Oil Hysteresis (Conditional) ....... 626

Oil-Trapping Relationship (Optional)....................................................................... 627

Method for Evaluating 3-Phase Kro (Optional)........................................................ 629

Rock Type (Optional) ............................................................................................... 632

Saturation Endpoints for each Grid Block (Optional) .............................................. 633

Endpoint Relative Permeability Value for Each Grid Block (Optional)................... 641

Endpoint Capillary Pressure Values for Each Grid Block (Optional) ...................... 644

Three Point Saturation Scaling Option (Optional).................................................... 647

Two-Point Capillary Pressure Scaling (Optional) .................................................. 650

Rock-Fluid Table-based Three-point Relative Permeability Scaling (Optional)......... 652

Extrapolation of Krw outside of the *SWT table to 1.0 (Optional) .......................... 653

Water Oil-Capillary Pressure (J Function) Shift for Each Grid Block (Optional) ........ 654

Non-Darcy Flow in Reservoir (Optional) ................................................................. 655

Non-Darcy Coefficient Correction Factor (Conditional) .......................................... 658

Fracture Velocity Width Correction for Polymer–Water Mixture Viscosity

Conditional) ......................................................................................................... 659

Pressure Gradient Threshold Arrays ......................................................................... 660

Leverett J Function Option ....................................................................................... 662

J Function Surface Tension Arrays ........................................................................... 665

Scale Deposition Table (Optional)............................................................................ 666

Scale Damage Table (Optional) ................................................................................ 667

Subdomain Reinfiltration (Optional) ........................................................................ 668

Adsorption Parameters for each Gridblock (Optional) ............................................. 670

Phase Segregation Model Modifier (Optional) ......................................................... 672

Initial Conditions

675

Notes on Initial Conditions ....................................................................................... 675

Initial Conditions Identifier (Required) .................................................................... 678

User Input or Vertical Equilibrium Selection (Required) ......................................... 679

IMEX User Guide

Contents • vii

Initial Oil Phase Reservoir Pressure (Conditional)................................................... 684

Initial Pressure vs. Depth (Conditional) ................................................................... 685

Number of Initialization Regions (Optional) ........................................................... 687

Specification of Initialization Regions (Optional) ................................................... 688

Initial Bubble Point Pressure (Conditional) ............................................................. 689

Initial Bubble Point Pressure vs. Depth (Conditional) ............................................. 690

Initial Solution Gas Ratio vs. Depth (Conditional) .................................................. 692

Initial Dew Point Pressure (Conditional) ................................................................. 694

Initial Dew Point Pressure vs. Depth (Conditional) ................................................. 695

Initial Oil Content (Rv) vs. Depth (Conditional) .......................................................... 697

Initial Solvent Bubble Point Pressure (Conditional) ................................................ 699

Initial Oil Saturation (Conditional) .......................................................................... 700

Initial Water Saturation (Conditional) ...................................................................... 701

Initial Polymer Concentration (Conditional) ............................................................ 702

Initial Seawater Volume Fraction (Conditional) ...................................................... 703

Initial Light Oil Volume Fraction (Conditional) ...................................................... 704

Initial Light Oil API Volume Fraction vs. Depth (Conditional) .............................. 705

Reference Depth and Reference Pressure (Conditional) .......................................... 707

Depth to Water-Oil Contact (Conditional) ............................................................... 709

Datum Depth Specification (Optional)..................................................................... 712

Specification of Capillary Pressure Values at Contacts (Optional) .......................... 715

Specification of Method for Computing Oil Saturations in Gas Zone ..................... 718

Specification of Water Saturation Above GOC or Below WOC (Optional) ............ 719

Specification of Minimum Initial Oil Saturation for API Tracking (Optional)........ 721

Water Saturation Input Used with Gravity-Capillary Initialization (Conditional)........ 722

Non Equilibrium Water and Oil Saturation Used with Gravity-Capillary

Equilibrium Initialization (Conditional) .............................................................. 724

Specification of Initialization Behavior when Contacts Lie Outside PBT Table

Depths.................................................................................................................. 726

Numerical Methods Control

729

Numerical Methods Control Identifier (Optional).................................................... 729

Maximum Timesteps (Optional) .............................................................................. 730

Maximum CPU Seconds (Optional)......................................................................... 731

Maximum Timestep Size (Optional) ........................................................................ 732

Minimum Timestep Size (Optional)......................................................................... 733

Normal Variation in Variables per Timestep (Optional) .......................................... 734

Relaxation Options (Optional) ................................................................................. 736

Adaptive Implicit Switching (Optional) ................................................................... 738

Convergence of Newton's Method (Optional).......................................................... 740

Maximum Newtonian Cycles (Optional) ................................................................. 743

Minimum Number of Newtonian Cycles (Optional)................................................ 744

Formulation Modification for Blocks with no Hydrocarbon.................................... 745

viii • Contents

IMEX User Guide

Force Maximum Change Checks (Optional) ............................................................ 747

Number of Cuts (Optional) ....................................................................................... 748

Convergence Tolerance for Linear Solver (Optional) .............................................. 749

Convergence Tolerance for Linear Solver (Optional) .............................................. 750

Orthogonalization (Optional) .................................................................................... 751

Solver Equation Ordering (Optional)........................................................................ 752

Solver Factorization Degree (Optional) ........................................................................ 753

Pivot Stabilization (Optional) ................................................................................... 754

Maximum Iterations (Optional) ................................................................................ 755

AIMSOL/PARASOL Switch (Optional) .................................................................. 756

Red-Black Ordering Check for Parasol (Optional) ................................................... 757

Factorization Degree within PARASOL Classes (Optional) .................................... 758

Factorization Degree between PARASOL Classes (Optional) ................................. 759

Increase PDEGAA and PDEGAB for Blocks on Class Boundaries (Optional) ....... 760

Parasol Class Partitioning Pattern (Optional) ........................................................... 761

Target number of Planes per Jacobian Domain (Optional)....................................... 766

Number of Threads to be Used (Optional) ............................................................... 767

Number of Threads for Parallel Grid-Processing (Optional) .................................... 768

Complete Storage Grid Array of Jacobian Domain Numbers (Optional) ................. 769

Target Number of Jacobian Domains (Optional)...................................................... 770

Target Number of Jacobian Domains based on Parasol Classes (Optional) ............. 772

Specify Behavior When Solver Stalls (Optional) ..................................................... 774

Sub-matrix Inversion Algorithms (Optional)............................................................ 775

Well and Recurrent Data

777

Notes on Well and Recurrent Data ........................................................................... 777

Well Management and Group Control ...................................................................... 779

Specifying the Well and Group Control Hierarchy .................................................. 781

Introducing Group Control after Start of Simulation ................................................ 783

Limitations of the Well Management and Group Control Module ........................... 784

Recurrent Data from Other Sections ......................................................................... 785

Well and Recurrent Data Identifier (Required)......................................................... 786

Well Change Date (Conditional) .............................................................................. 787

Well Change Time (Conditional).............................................................................. 788

Well Change First Time-Step Size (Optional) .......................................................... 789

Maximum and Minimum Time-Step Size (Optional) ............................................... 790

Setting Grid Blocks to Implicit or Explicit (Optional) ............................................. 791

Setting Well Blocks and Neighbours to Implicit (Optional)..................................... 792

Set Frequency of Initialization of Bottom-Hole Pressure (Optional) ....................... 794

PDRAIN Method (Optional)..................................................................................... 796

Group Identification (Optional) ................................................................................ 799

Well Identification (Required) .................................................................................. 803

Well Backflow Model (Optional) ............................................................................. 806

IMEX User Guide

Contents • ix

Well Head Method (Optional) .................................................................................. 808

Well Head Iteration (Optional)................................................................................. 810

Simultaneous BHP and Well Head Iteration (Optional) .......................................... 812

Perforations in Inactive Blocks (Optional) ............................................................... 814

Well Type Definition (Required) ............................................................................. 816

Shut in Wells above Formation (Optional) .............................................................. 818

Well Status Definition (Optional) ............................................................................ 820

Shut and Reopen a List of Wells (Optional) ............................................................ 822

Tubing Data for Injectors (Conditional) ................................................................... 824

Tubing Data for Producers (Conditional) ................................................................. 827

Wellbore Temperature (Optional) ............................................................................ 832

Composition of Injected Water, Gas, and Oil Phases (Conditional) ........................ 833

Well Operating Constraints (Required) .................................................................... 835

Maximum Number of Continue-Repeat (Optional) ................................................. 845

Monitored Well Constraints (Optional).................................................................... 846

Alter Primary Well Operating Constraint Value (Optional) .................................... 853

Reset Injection Composition (Optional)................................................................... 855

Well Current Constraint (Optional) .......................................................................... 857

Alter Well Constraint Value (Optional) ................................................................... 858

Operating Constraints in History Matching Mode (Optional).................................. 860

Alter Observed Flow Rates for History-Matching (Optional).................................. 862

Sets/Alters a Well’s Phase Productivity (Optional) ................................................. 864

User-Specified Reference Depth for Well BHP (Optional) ..................................... 868

User-Specified Pressure Gradient For Reference Depth for Well BHP

(Optional) ............................................................................................................ 870

Pressure Gradients for Calculation of Pressure Differences Between

Completions (Conditional) .................................................................................. 872

Alter Polymer Concentration (Optional) ...................................................................... 875

Alter Seawater Injection Volume Fraction (Optional) ............................................. 877

Well Scale Table Assignment (Optional) ................................................................. 879

Layer Scale Table Assignment (Optional) ............................................................... 880

Well Scale Removal (Optional) ............................................................................... 882

Layer Scale Removal (Optional) .............................................................................. 883

Data for Workover Action for Wells (Optional) ...................................................... 884

Resetting Well Operating Constraint after Value Change (Optional) ...................... 887

Gas Lift Option (Optional) ....................................................................................... 889

Gas Lift Control (Optional) ...................................................................................... 892

Gas Lift Optimization (Optional) ............................................................................. 894

Well Element Geometry (Optional) ......................................................................... 897

Location of Well Completions (Conditional) ........................................................... 900

Auto Thresholding for Well indices (Optional) ....................................................... 909

Well Geometry Parameters (Optional) ..................................................................... 911

Geometric Data for Deviated Well Completions (Conditional) ............................... 914

Simplified Geometric Data for Deviated Well Completions (Conditional) ............. 918

x • Contents

IMEX User Guide

Data for Hydraulic Fracture Proxy (HFP) Model (Conditional)............................... 920

Relative Permeability Data for Well Completions (Optional) .................................. 925

Group Production Constraints (Optional) ................................................................. 930

Group Injection Constraints (Optional) .................................................................... 936

Gas Make-up Target for Group Gas Recycling (Optional)....................................... 945

Maximum Make-up Gas Rate for Group Gas Recycling (Optional) ........................ 947

Gas Producing Group for Group Recycling/Voidage Replacement (Optional) .......... 949

Injection Group for Group Recycling/Voidage Replacement (Optional) ................. 951

Maximum Re-injection Rate for Group Gas Recycling (Optional) .......................... 953

Fuel Consumption Fraction for Group Gas Recycling (Optional) ............................ 955

Maximum Fuel Consumption Rate for Group Gas Recycling (Optional) ................ 957

Sales Rate Fraction for Group Gas Recycling (Optional)......................................... 959

Maximum Sales Rate for Group Gas Recycling (Optional) ..................................... 961

Water Make-up Target for Group Water Recycling (Optional)................................ 963

Maximum Water Make-up Rate for Group Water Recycling (Optional) ................. 965

Water Producing Group for Group Recycling (Optional) ........................................ 967

Maximum Re-injection Rate for Group Water Recycling (Optional) ...................... 969

Solvent Make-up Target for Group Solvent Recycling (Optional)........................... 971

Maximum Make-up Solvent Rate for Group Solvent Recycling (Optional) ............ 973

Solvent Producing Group for Group Recycling (Optional) ...................................... 975

Maximum Re-injection Rate for Group Solvent Recycling (Optional) .................... 977

Monitored Group Constraints (Optional).................................................................. 979

Allow a Cycling Group to be Defined (Optional)..................................................... 982

Allow Cycling Group Data to be Revised (Optional) ............................................... 992

Allow Cycling Group Data to be Revised (Optional) ............................................... 994

Select Cycling Group Cycle Part to Start and End Cycling Group Control

(Optional) ............................................................................................................. 996

Defining Group Production or Injection as Going Through a Manifold

(Optional) ............................................................................................................. 998

Pressure Constraint Translation for Manifolds (Optional) ..................................... 1000

Specification of Hydraulics Tables for Calculating Pressure Difference

Between Manifold and Surface (Optional) ........................................................ 1002

Manifold Depth for Calculating Pressure Difference Between Manifold and

Surface (Optional).............................................................................................. 1004

Group Artificial Lift Quantity Value (Optional)..................................................... 1006

Well Artificial Lift Quantity Value (Optional) ....................................................... 1008

Priority List for Automatic Drilling of Wells (Optional) ........................................ 1009

Group Apportionment Options (Optional).............................................................. 1011

Apportionment Method for Meeting Group Targets (Optional) ............................. 1013

Priority Formulae for Apportionment (Conditional) .............................................. 1017

Guide Rates for Groups or Wells ............................................................................ 1021

Flag for Specifying Groups or Wells under or not under Group

Apportionment (Optional) ................................................................................. 1024

IMEX User Guide

Contents • xi

Allows for a Set of Keywords to be Processed When a Specified Condition

(Trigger) is Satisfied (Optional) .................................................................................. 1026

Alter Well Constraint Value via a Multiplier or an Increment (Optional) ............. 1045

Group Production Constraint Multiplier or Increment (Optional) ......................... 1048

Group Injection Constraint Multiplier or Increment (Optional)............................. 1050

Define Reporting Group (Optional) ....................................................................... 1052

Well/Group On-time Fraction (Optional) ............................................................... 1054

Hydraulic Pressure Table (Conditional) ................................................................. 1058

Set Number of Points for WHP Root Search (Optional) ........................................ 1066

Control Layer Lumping Option (Optional) ............................................................ 1068

Report Layer Lumping Option (Optional) ............................................................. 1071

Control Layer Lumping Option (Optional) ............................................................ 1073

Control Layer Lumping Option (Optional) ............................................................ 1074

Control Layer Lumping Option (Optional) ............................................................ 1075

Selection of Instantaneous Versus Actual Rates (Optional)................................... 1076

Dynamic Grid Amalgamation Control (Optional) ................................................. 1077

Terminate Simulation (Required) ........................................................................... 1080

Appendix A

1081

Theoretical Outline ................................................................................................. 1081

Four Component Black-Oil Model with Dual Porosity ............................ 1081

Dual Permeability...................................................................................... 1085

Subdomain Model ..................................................................................... 1086

Matrix-Fracture Transfer Coefficient, sigma ............................................ 1086

Independent and Dependent Variables ...................................................... 1087

Appendix B

1091

Well Model ............................................................................................................. 1091

Total Mobility Weighted Injectors ............................................................ 1091

Unweighted Injectors ................................................................................ 1091

Well Injectivity.......................................................................................... 1091

Producers ................................................................................................... 1092

Wellhead Pressure Wellbore Model .......................................................... 1092

Appendix C

1095

Calculation of Well Parameters .............................................................................. 1095

Appendix D

1099

Figure D-1a: Numbering of the Grid (Non-Corner Point) .................................... 1099

Figure D-1b: Numbering of the Grid (Corner Point) ............................................ 1100

Figure D-2: Cylindrical Reservoir ......................................................................... 1101

Figure D-3: Calculation of Gravity Components for a Tilted Grid System .......... 1102

xii • Contents

IMEX User Guide

Figure D-4: Radial (Cylindrical) Coordinates ....................................................... 1103

Figure D-5a: Depth Measurement ......................................................................... 1104

Figure D-5b: 3-Dimensional Variable Thickness Grid System (8x3x2) ............... 1105

Figure D-6: Fault Throw Definition ...................................................................... 1106

Figure D-7: Typical Data Curves ........................................................................... 1107

Figure D-8: Typical Relative Permeability Curves................................................ 1108

Appendix E

1109

Polymer Option ....................................................................................................... 1109

Factors and Mechanisms Affecting Polymer Floods ................................. 1109

Polymer Types ........................................................................................... 1115

Mass Conservation Equations .................................................................... 1116

Guidelines for Polymer Application .......................................................... 1117

References for Polymer Option ................................................................. 1118

Pseudo-Miscible Option ......................................................................................... 1119

Mass Conservation Equations .................................................................... 1119

Pseudo-Miscible Considerations................................................................ 1120

References for Pseudo-Miscible Option .................................................... 1125

Appendix F

1127

The Use of IMEX in Well Testing Applications .................................................... 1127

Appendix G

1135

Analytical Aquifers ................................................................................................. 1135

Mathematical Background ...................................................................................... 1136

Van-Everdingen and Hurst Method ........................................................... 1136

Infinite Aquifer with Constant Rate Solution ............................................ 1136

Limited Aquifers with Constant Rate Solution.......................................... 1137

Carter-Tracy Method ................................................................................. 1137

Fetkovich Method ...................................................................................... 1138

Practical Aspects of Using Analytical Aquifers ..................................................... 1139

a) Selecting Type of Aquifer .................................................................... 1139

b) Selecting Method of Solution ............................................................... 1139

Aquifer Parameters .................................................................................... 1140

Model Defaults ....................................................................................................... 1141

Appendix H

1149

Running IMEX Coupled to the GAP Surface Network Model .............................. 1149

Remote Simulation Job Submission via SSH ......................................................... 1160

IMEX Results Accessible from RESOLVE Script ................................................. 1164

Operation on Well Layers via RESOLVE Script.................................................... 1170

Pseudo-Solvent Production / Injection.................................................................... 1172

IMEX User Guide

Contents • xiii

Appendix I

1173

Coupling IMEX to FORGAS ................................................................................. 1173

General Considerations and Guidelines .................................................... 1173

Preparation of the IMEX Data Set ............................................................ 1174

Recurrent Data........................................................................................... 1174

Multiple Reservoirs ................................................................................... 1177

Remote Simulation Job Submission via SSH............................................ 1177

Coupling with FORGAS ........................................................................... 1180

Getting Started Linking IMEX and FORGAS ....................................................... 1182

Keyword Index

xiv • Contents

1191

IMEX User Guide

Introduction

Important Changes between IMEX 2015.10 and IMEX 2014.10

SIMULATOR CHANGES

Solvent Run with GAP

Allow IMEX/GAP to operate in solvent models. With the command-line argument −ssolvent,

the solvent rate is added to the hydrocarbon gas rate for producers. The total gas gravity is thus

the volume-weighted gravity of the gas mixture at the bottom-hole pressure. For injectors, the

gas rate is either the rate of HC gas or solvent depending upon the injector types.

Table-based 3pt Endpoint Relative Permeability Scaling

A new keyword *TBLBAS_3PTKR is introduced to switch between the block-based and tablebased three-point endpoint relative permeability scaling. This option is required to match the

performances among CMG’s simulators.

Two-point Capillary Pressure Scaling

Use keyword *PCSCALE_2PT to activate the two end point capillary pressure scaling for

both oil-water and oil-gas capillary pressure for reservoir blocks. The default capillary

pressure scaling is the maximum factor scaling. The two point scaling requires the input of the

minimum factor, through keywords *PCWMIN, *PCWIMIN, *PCGMIN, *PCGIMIN,

*JFWMIN, *JFGMIN.

Oil-Trapping Relationship

A new keyword *OILTRAP is implemented to assign the oil-trapping relationship that is

used to determine the residual oil saturation of imbibition from the historical-maximumattained oil saturation. Different methods (the Land’s correlation, linear relationship and usersupplied table) will affect the oil recovery from the reservoir transition zone.

Mixed-Wet Hysteresis

New keywords to allow the input of water-oil imbibition relative permeability tables (*SWTI);

assign hysteresis methods of oil-water and gas relative permeabilities and signal the entry of

associated parameters (HYSKRO, *HYSKRW, *HYSKRG, *KILLOUGH_MOD_KRWCO). For

the hysteresis effect on the oil-water relative permeability, CARLSON, KILLOUGH and

KILLOUGH_MOD methods are implemented, in addition to the original Kro hysteresis which

may not be necessarily coupled with the Pc hysteresis.

IMEX User Guide

Introduction • 1

Solver Technology

New matrix inversion cofactor based algorithms introduced for 2×2 and also for 4×4 matrices.

These cofactor techniques tend to be a bit more accurate, no pivoting is required for 2×2, 3×3 and

4×4 matrices and are faster than traditional LU methods. Cofactor techniques were already used

for 3×3 block diagonal matrices in previous versions of IMEX. The corresponding keyword is

*MATINV. Sub-keyword *COFACTOR uses cofactor methods for these block diagonal

matrices. The old defaults may be obtained using *MATINV *OLD. For IMEX, *MATINV

*COFACTOR is now the default. IMEX fluid models affected by this change are OILWATER

and GASWATER (2×2) and MISCG, MISNCG, POLY, API-INT and

BLACKOIL_SEAWATER (4×4).

Template Data Set Changes

Added mxsmo069.dat to demonstrate the hydraulic fracture with planer template

Added mxsmo070.dat for mixed wet water-oil hysteresis test

Added mxsmo071.dat for Pc trapped oil hysteresis test

Added mxsmo072.dat for verification of Pc scaling

Added mxsgw021.dat to demonstrate the *PUMP2 option for iSegWell

Added mxsgw022.dat to demonstrate the *TABLE for FCD in iSegWell

Added mxsgw023.dat to demonstrate the scale removal (*SGPFSCLRMV) in iSegWell

Added mxwwm066.dat to demonstrate the general form of *PERF

Added mxwwm066.dat to demonstrate WI regulation (*WIRANGE)

Added mxwwm067.dat to demonstrate rate instability monitoring (*RATSTAB)

Added mxwwm069.dat to demonstrate hydraulic radius in head calculation (*HYRADIUS)

Added mxwwm070.dat to demonstrate WHT calculation (*TWELLBORE) from PTUBE1

Data Incompatibilities with Previous Versions of IMEX

None.

Keyword Default Changes from Previous Versions of IMEX

The target number of Jacobian domains n via command-line argument −jacdoms n was

defaulted to 2 if n is absent. It now takes from the target number of threads m if commandline argument −parasol m is specified.

WELL MANAGEMENT CHANGES

Keyword *PERF

A new tabulated list-driven format to allow layer-varying input of all the parameters (wi, dir, ff,

kh, re, rw, skin, di) involved in well index calculations. This format is very flexible and

backward compatible.

Sub-keyword *RATSTAB

Newly added wellbore rate stability monitor (*MONITOR) based on the operating BHPRATE curves as a complement to the existing *WHYSTAB monitor. A real well should

2 • Introduction

IMEX User Guide

operate only above a certain rate at which the BHP remains in the stable region of the tubingintake or tubing-outflow curve with WHP and phase ratios being held constant.

Keyword *WIRANGE

A new keyword specifies the range of the constant geometric part of the well indices (WI)

and takes proper actions if the well indices are out of the range.

Sub-keyword *HYRADIUS

Newly added well hydraulic radius input for gravitational-frictional head calculations

(*HEAD-METHOD *GRAV-FRIC). The well hydraulic radius can be different from the

default wellbore radius from *GEOMETRY.

Keyword *KRPERF

This previous secondary keyword (had to immediately follow a *PERF/*PERFV keyword)

has now become a primary keyword that an optional well list can be specified (backward

compatible). This allows for easy redefinition of the relative permeability table set numbers

and/or end points without having to redefine the entire well completions.

Enhanced Hydraulic Tables for Well-head Temperature Calculation

Keyword *PUTBE1 has been enhanced to read and process the table body of well-head

temperature (*WHT). This along with new keyword *TWELLBORE allows computation of

well-head temperature of producers using tabulated wellbore data.

GRID CHANGES

Hydraulic Fracture with Planar Template

With new grid property array qualifiers (*FZ and *NFZ) to assign data to fracture or nonfracture zone, keyword *PLNRFRAC_TEMPLATE allows you to define a template of

planar-fracture data that can be applied easily to any number of fundamental-grid cells. That

template may be used via *PLNRFRAC in both the “Reservoir Description” and “Well and

Recurrent Data” sections

IMEX User Guide

Introduction • 3

Important Changes between IMEX 2014.10 and IMEX 2013.10

SIMULATOR CHANGES

Multi-Segmented Well Module

IMEX now incorporates a multi-segmented well module. Outboard documentation is provided.

Extended Oil Solvent Mixing Parameter Tables

The *OMEGA_OST table allows the input of an extended Omega (oil-solvent mixing

parameter) table for solvent models. This table allows the user to define two separate types of

Omega, one to be used in the oil-solvent density mixing rule (omega_den) and one to be used

in the oil-solvent viscosity mixing rule (omega_vis). Sorm may also be altered in this table

using the sormadd column. Finally, it is possible to use the *OMEGA_OST table to define

tables that are functions of both pressure, P, and bubble point pressure, Pb.

‘Three Point’ Critical Saturation Relative Permeability Value Scaling Arrays Added

It is now possible to scale the relative permeability table values of Krwro, Krocrw, Krgrl and

Krogcrg at the critical saturations of oil, water, liquid and gas respectively in addition to the

values of Krwiro, Krocw, Krgcl and Krogcg, which are endpoint values at irreducible /connate

saturations. See keyword *KRWRO and the tutorial chapter ‘Two Point and Three Point

Scaling of Relative Permeability Values’ for more information.

Solver Technology

Improved Parallel Performance

Improvements to the implementation of parallelization in IMEX have allowed the Simulator

to run more efficiently on larger number of threads on Shared Memory Processors.

Other New Keywords

Loss of Miscibility Smoothing at Sorm (*MINSS *SOTHRESH soval)

‘*MINSS *SOTHRESH soval’ allows the user to control the range over which loss of miscibility

occurs at Sorm, soval is entered and loss of miscibility occurs over the range So = SORM+soval

and So = SORM-soval.

Phase Segregation Model Modifier for *TRANSFER 1 Option

The use of *PHS_SEG_MODL *MODIFIED allows the user to enter DKFRAC > DK

without having DKFRAC internally limited to DK for the capillary continuity calculation

when using the *TRANSFER 1 phase segregation model.

Explicit Specification of Initialization Behavior when Contacts Lie Outside PBT Table Depths

The CONTACT_PBT_BEHAVIOR keyword can be used to change how the simulator reacts

when initialization region phase contacts lie outside the range of the initialization region’s

PBT table. *The LEGACY option, the previous default, would issue a warning and then

change the contacts. The default is now changed to *ERROR which prevents the run from

proceeding until the table or contacts are altered. The user can choose to ignore the problem

by specifying the *WARNING option which warns but does not reset the contacts.

4 • Introduction

IMEX User Guide

Template Data Set Changes

Added mxsmo062.dat to demonstrate *PHYS_SEG_MODL

Added mxsmo063.dat to demonstrate *CONTACT_PBT_BEHAVIOR

Added mxsmo064.dat to demonstrate *AQUIFER *RESBND

Added mxsmo065.dat to demonstrate *AQUIFER *RESBND

Added mxsmo066.dat to demonstrate 3Pt Scaling of Kr Value

Added mxsmo067.dat to demonstrate 3Pt Scaling of Kr Value

Added mxsmo068.dat to demonstrate use of BLOCKGROUPS

Added mxspr010.dat to demonstrate *OMEGA_OST

Added mxspr011.dat to demonstrate *OMEGA_OST

Added mxwwm062.dat to demonstrate *WELGEO and *INCOMPWL

Added mxwwm063.dat to demonstrate *WCURRCN

Added mxwwm064.dat to demonstrate *DTWAUTO

Added mxwwm065.dat to demonstrate new trigger feature (polymer injection)

Data Incompatibilities with Previous Versions of IMEX

None.

Keyword Default Changes from Previous Versions of IMEX

CONTACT_PBT_BEHAVIOR – Default of *LEGACY changed to *ERROR

WELL MANAGEMENT CHANGES

*Triggers on Solvent/Polymer Rates and Solvent/Polymer Cumulatives

The *ON_WELL and *ON_GROUP based triggers can now be used to monitor solvent

volumetric injection/production rates and cumulative volumes as well as polymer mass rates

and cumulative mass produced/injected.

Keyword *WELGEO

*WELGEO specifies the geometric characteristics for listed wells to be used by the simulator

to calculate the well index internally.

Keyword *INCOMPWL

*INCOMPWL sets the global compositions of injected lift-gas for producers or injected

streams (gas or solvent) for injectors used in the wellbore calculations.

Keyword *WCURRCN

*WCURRCN enables wells to run on their current operating constraints without checking for

constraint violation and possible switching. This keyword allows the user to operate wells on

their current constraints without checking for constraint violation and possible constraint

switching to the most restrictive. This effectively disables all the other constraints while

*WCURRCN is active. Furthermore, wells with *WCURRCN turned on are automatically

removed from participating in the apportionment of higher-level group production or injection

IMEX User Guide

Introduction • 5

targets. However, their rates still contribute to the higher-level targets since the wells are still

members of the group structure.

Keyword *DTWAUTO

Allows the user to use DTWELL after a well management induced well change.

Subkeyword *ALL will force the simulator to use the timestep size specified on *DTWELL

if a well action is deemed significant. This could include well auto-drilling to meet group

targets, auto-well/auto-layer constraints, or changes in operating constraints. Sub-keyword

*AUTODRL will force the simulator to use the timestep size specified on *DTWELL strictly

due to the auto-drilling of a well.

Keywords Retired

*PERFVHY is no longer supported, the *PERF keyword can be used instead.

Keyword Default Changes

*APPOR-METHOD – new default is *INGUIDE, changed from *IP.

All runs using group control will be affected. To reproduce earlier results,

*APPOR_METHOD *IP must be specified for each group.

Keyword Name Changes

‘*GCONI *TARGET’ is changed to ‘*GCONI *GTARGET’ and ‘*GCONP *TARGET’ is

changed to‘*GCONP *GTARGET’ to avoid possible reading issues when a well *TARGET

is also defined.

GRID CHANGES

*AQUIFER *RESBND

The behavior of *AQUIFER *BOUNDARY is to place each aquifer connection on the grid

boundary; if a grid boundary block is null then no aquifer connection is made. *AQUIFER

*RESBND places aquifer connections on the reservoir boundary instead. The reservoir

boundary is defined as the first non-null block encountered when scanning in from the grid

boundary. *AQUIFER *BOTTOM already operates in this way through pinched out blocks.

BLOCKGROUPS

A block group is an arbitrary collection of grid blocks which can be used for addressing

frequently a particular group of blocks. A block may belong to any number of block groups,

and a block group may contain any non-zero number of blocks. A block group is useful for

assigning values to any grid array via sub-keyword *BG. See Input of Grid Property Arrays

in chapter “Keyword System”. In addition, a block group can be applied to certain blockbased data-input keywords (e.g., *REFINE).

6 • Introduction

IMEX User Guide

Important Changes between IMEX 2013.10 and IMEX 2012.10

SIMULATOR CHANGES

Initialization Regions Separate from PVT Regions

Initialization regions may be specified using the *NREGIONS and *ITYPE keywords. Previous

versions of IMEX linked PVT regions to initialization regions. Thus one PVT region was

required for each initialization region. This is no longer required. Older data sets are unaffected.

Rock Compaction Table Reassignment in Recurrent Data

The *CTYPE value (compaction table number) of gridblocks can now be reassigned in recurrent

data. This allows the user to realistically model processes where permeability modification vs.

pressure behavior is added later in a run. Hydraulically fracturing and introducing fracture

conductivity vs. pressure behavior in a new well partway through a simulation is an example of

this. Please see the manual as some restrictions apply to the use of this feature in recurrent data.

Solver Technology

Improved Parallel Performance

Improvements to the implementation of parallelization in IMEX have allowed the Simulator

to run more efficiently on larger number of threads on Shared Memory Processors.

Separate Graphics/Restart SR2 files (*RESTART_SR2 or Command Line -restart_sr2)

We have changed the default behavior when writing out SR2 graphics and restart data and

have added a keyword and a command-line option to control if graphics and restart

information in the sr2 files are combined or separated, for both input and output.