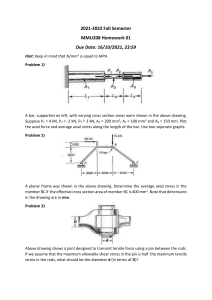

CHAPTER 8 Thin and Thick Cylinders and Spheres Problem 1. A shell 3.25 m long and 1 m diameter, is subjected to an internal pressure of 1.2 N/mm2. If the thickness of the shell is 10 mm find the circumferential and longitudinal stresses. Find also the maximum shear stress and changes in dimensions of the shell. Take E = 200 kN/mm2 and Poissons ratio = 0.3. Solution: L = 3.25 m = 3250 mm d = 1 m = 1000 mm t = 10 mm p = 1.2 N/mm2 2 E = 200 kN/mm = 200 × 103 N/mm2 pd 1.2 × 1000 = = 60 N/mm2 ∴ Hoop stress f1 = 2t 2 × 10 Longitudinal stress f2 = pd 1.2 × 1000 = = 30 N/mm2 4t 4 × 10 f1 − f 2 60 − 30 = = 15 N/mm2 2 2 δd f f Diametral strain = = e1 = 1 − µ 2 d E E 1 = ( f1 − µ f 2 ) E 1 = (60 − 0.3 × 30) 200 × 103 qmax = 2.55 × 10–4 ∴ 2.55 × 10–4 × d 2.55 × 10–4 × 1000 0.255 mm. δL f 2 f Longitudinal strain = = −µ 1 L E E 1 = ( f 2 − µ f1 ) E 1 = (30 − 0.3 × 60) 200 × 103 = δd = = = Ans. = 6 × 10–5 δL = 6 × 10–5 × L = 6 × 10–5 × 3250 = 0.195 mm. Ans. Change in volume: δV V = 2e1 + e2 = 2 × 2.55 × 10–4 + 6 × 10–5 = 5.7 × 10–4 68 δV = 5.7 × 10–4 × V = 5.7 × 10–4 × π 10002 × 3250 4 = 1454950 mm3. Ans. Problem 2. A cylindrical shell 2.4 m long 600 mm in diameter with metal thickness 12 mm is completely filled with water at atmospherical pressure. If an additional 300,000 mm3 water is then pumped in, find the stresses developed and change in dimensions. Take E = 2 × 105 N/mm2, µ = 0.3. pd p × 600 Solution: f1 = = = 25 p 2t 2 × 12 f2 = Diametrical strain e1 = = = Longitudinal strain e2 = = = Volumetric strain = = = ∴ p = = ∴ ∴ ∴ = Hoop stress = δd = d δd = δL = L pd p × 600 = = 12.5 p 4t 4 × 12 δd f f = 1 −µ 2 d E E 1 [25 p − 0.3 × 12.5 p] E 21.25 p E δL 1 = ( f 2 − µ f1 ) L E 1 [12.5 p − 0.3 × 25 p] E 5p E δV = 2e1 + e2 V 21.25 p 5 p 2× + E E p 47.5 E δV E × V 47.5 300,000 × 2 × 105 47.5 π × 6002 × 2400 4 1.861413 N/mm2 25 p = 25 × 1.861413 = 46.537 N/mm2 21.25 p e1 = E 21.25 p × 600 = 0.1186 mm E 5p e2 = E 69 5× p × L = 0.1116 mm E f2 = 12.5 p = 23.268 N/mm2 δL = δV = 300,000 mm3. Problem 3. The diameter of a riveted boiler is 1.5 m and has to withstand a pressure of 2 N/mm2. Find the thickness of plates to be used if efficiency is 85% in longitudinal joints and 40% in circumferential joints. The permissible stress is 150 N/mm2. Solution: Let ‘t’ be the thickness of plate. Equating bursting force longitudinal joint strength, we get, pdL = n1 2t L f t = pd 2 × 1500 = = 11.764 mm 2 fn1 2 × 150 × 0.85 Considering longitudinal forces ∴ πd 2 p = n2 πdtf 4 pd 2 × 1500 t = = = 12.5 mm 4 f n2 4 × 150 × 0.4 ∴ Provide a minimum thickness of 12.5 mm. Problem 4. A copper cylinder of 100 mm diameter and metal thickness 4 mm is closely wound with steel wire of 2 mm diameter with tensile stress of 60 N/mm2. Find the stresses in copper cylinder and steel wire when a fluid is filled at a pressure of 4 N/mm2. Take Es = 2 × 105 N/mm2, Ec = 1.2 × 105 N/mm2 and µc = 0.28. Solution: Consider 2 mm length of cylinder No. of wires = 1 ∴ Force exerted by steel wire at diametral section = fw0 × 2 × πd 2 ×1 4 π × 22 × 1 = 376.991 N. 4 If initial stress is fc in cylinder, then = 60 × 2 × fc × 2t × 2 = 376.991 fc = 376.991 = 23.561 N/mm2 2×4×2 (comp.) Let due to fluid pressure alone, stresses developed in steel wire be fw and in cylinder. Let it be f1 and f2. Then, f2 = longitudinal stress = pd 4 × 100 = = 25 N/mm2 (tensile) 4t 4×4 Considering the equilibrium of the cylinder (Ref. Fig. 1) of 2 mm length, we get π fw × 2 × × 22 × 1 + f1 × 2 × 4 × 2 4 = 4 × 100 × 2 70 Fig. 1 6.883 fw + 16 f1 = 800 fw + 2.546 f1 = 127.327 ... (1) Equating strain in wire to circumferential strain in cylinder, we get fw 1 = (f1 – µ × f2) Es Ec fw 5 2 × 10 = (f1 – 0.28 × 25) 1 1.2 × 105 fw = 1.667 f1 – 11.667 ... (2) Substituting it in eqn. (1), we get 1.667 f1 – 11.667 + 2.546 f1 = 127.327 ∴ f1 = 138.994 = 32.991 N/mm2 4.213 From eqn. (2), fw = 1.667 × 32.991 – 11.667 = 43.328 N/mm2 Hence, final stresses are (a) in steel wire = 60 + 43.328 = 103.328 N/mm2 (b) in cylinder = – 23.561 + 32.991 = 9.43 N/mm2 Problem 5. A thin spherical shell of diameter 1.2 m has metal thickness of 10 mm at atmospheric pressure. Find the change in diameter and the capacity of the shell if fluid pressure is raised to 2.5 N/mm2. Take E = 2 × 105 N/mm2, µ = 0.25. Solution: d = 1.2 m = 1200 mm p = 2.5 N/mm2 t = 10 mm pd 2.5 × 1200 Hoop stress = f1 = f2 = = = 75 N/mm2 4t 4 × 10 ∴ and, ∴ δd pd = = (1 – µ) d 4tE δd 2.5 × 1200 = [1 − 0.25] 1200 4 × 10 × 2 × 105 δd = 0.3375 mm. δV pd = 3 (1 − µ ) V 4 tE δV = = 3 × 2.5 × 1200 4 × 10 × 2 × 105 3 × 2.5 × 1200 4 × 10 × 2 × 105 Ans. (1 − 0.25) × × 0.75 × π 3 d 6 π × (1200)3 6 i.e. δV = 763407 mm3. Ans. Problem 6. In a chemical plant a sphere of diameter 900 mm and metal thickness 8 mm is used to store a gas. If the permissible stress in the metal is 150 N/mm2, find the maximum pressure with which the gas can be stored if (i) the sphere is seamless (ii) the efficiency of joint is 0.65. 71 Solution: (i) When the sphere is seamless : pd f = 4t p × 900 150 = 4×8 ∴ p = 5.333 N/mm2. (ii) When the efficiency of the joint is 0.85, pd f = 4t η Ans. f 4t η 150 × 4 × 8 × 0.85 = d 900 Ans. i.e. p = 3.467 N/mm2. Problem 7. A thick cylindrical pipe of outside diameter 300 mm and internal diameter of 200 mm is subjected to an internal fluid pressure of 20 N/mm2 and external fluid pressure of 5 N/mm2. Determine the maximum hoop stress developed and draw the variation of hoop stress and radial stress across the thickness. Indicate values at every 25 mm interval. 200 = 100 mm Solution: ri = 2 300 ro = = 150 mm 2 If the hoop stress and radial stress in the cylinder at a distance x from the centre of cylinder is fx and px respectively, from Lame’s equation, b b fx = + a and px = 2 − a 2 x x where a and b are constants. Now, at x = 100 mm, px = 20 N/mm2 ∴ p = ∴ 20 = At b −a 1002 x = 150 mm, px = 5 N/mm2 b −a 1502 Substituting equation (2) from equation (1), we get ∴ 5 = 15 = b 100 = b ∴ ∴ From eqn. (1), ∴ ∴ 2 − 1 1 = b − 2 150 1502 100 b 2 1502 − 1002 1002 × 1502 b = 269978.4 269978.4 20 = −a 1002 a = 6.9976 269978.4 fx = + 6.9976 x2 72 ... (1) ... (2) ∴ Maximum hoop stress occurs when x is least i.e. at x = 100 mm 269978.4 ∴ fmax = + 6.9976 1002 = 34 N/mm2 269978.4 f125 = + 6.9976 = 24.4 N/mm2 1252 269978.4 f150 = + 6.9976 = 19 N/mm2 1502 269978.4 p100 = − 6.9976 = 20 N/mm2 1002 269978.4 p125 = − 6.9976 = 10.481 N/mm2 1252 269978.4 p150 = − 6.9976 = 5 N/mm2 1502 Hence variation of fx and px are as shown in the Fig. 2: Fig. 2 Problem 8. A thick cylindrical pipe of internal radius 150 mm and external radius 200 mm is subjected to an internal fluid pressure of 17.5 N/mm2. Determine the maximum hoop stress in the cross-section. What is the percentage error if it is determined from thin cylinders theory? Solution: r1 = 150 mm r2 = 200 mm If the radial stress and hoop stress developed in the cylinder at a distance of x from the centre are px and fx respectively, from Lame’s equation, px = b x2 b −a +a x2 where a and b are arbitrary constants. At x = 150 mm px = 17.5 N/mm2 fx = ∴ 17.5 = ∴ 0 = b 1502 Again when x = 200 mm px = 0 b 2002 −a ... (1) −a ... (2) 73 From eqn. (1) and (2), we get 17.5 = b 1502 − b 2002 = b 2002 − 1502 1502 × 2002 ∴ b = 900205.76 b 900205.76 Hence a = = = 22.505 2002 2002 The value of fx is maximum when x is least i.e. at x = 150 mm 900205.76 + 22.505 1502 = 62.5 N/mm2. Ans. Internal pressure × Internal diameter 17.5 × 2 × 150 Maximum hoop stress = = = 52.5 N/mm2 2 × thickness 2(200 − 150) ∴ Maximum hoop stress = 62.5 − 52.5 × 100 62.5 = 16. Ans. Problem 9. The internal and external diameters of a thick cylinder are 300 mm and 500 mm respectively. It is subjected to an external pressure of 4 N/mm2. Find the internal pressure that can be applied if the permissible stress in cylinder is limited to 13 N/mm2. Sketch the variation of hoop stress and radial stress across the thickness of the cylinder. 300 500 = 150 mm r2 = = 250 mm Solution: r1 = 2 2 From Lame’s equations, b b px = 2 − a fx = 2 + a x x At x = 250 mm px = 4 N/mm2 ∴ Percentage error = b −a ... (1) 2502 Maximum hoop stress occurs for the least value of x i.e. at inner edge, where x = r1 = 150 mm. ∴ 4 = ∴ 13 = b 1502 +a ... (2) From eqn. (1) and (2), we get 17 = ∴ From eqn. (1), b 2502 + b 1502 =b 1502 + 2502 2502 × 1502 b = 281270.68 a = b 2 −4= 281270.68 250 2502 = 0.5 281270.68 ∴ px = − 0.5 x2 Internal pressure i.e. pressure at x = 150 mm, is 74 −4 pi = f150 = f200 = f250 = p150 = p200 = 281270.68 1502 281270.68 2 150 281270.68 2002 281270.68 2502 281270.68 1502 281270.68 2 200 281270.68 − 0.5 = 12 N/mm2 13 12 + 0.5 = 13 N/mm2 7.53 5.0 + 0.5 = 7.53 6.53 N/mm2 150 150 4.0 250 + 0.5 = 5 N/mm2 − 0.5 = 12 N/mm2 Fig. 3 − 0.5 = 6.53 N/mm2 − 0.5 = 4 N/mm2 2502 Problem 10. A compound cylinder of inner radius 100 mm, outer radius 240 mm has common radius at 180 mm. The radial pressure developed at junction is 12 N/mm2. Determine the radial and hoop stresses developed at inner, common and outer radii when the fluid is admitted at a pressure of 60 N/mm2. Solution: (a) Inner cylinder : Let Lame’s equation be, b b px = 12 − a1 and fx = 12 + a1 x x At x = r1 = 100 mm, px = 0. and p250 = 0 = b1 12 = b1 1002 At x = r2 = 180 mm, px = 12 N/mm2 ∴ 1802 − a1 ... (1) − a1 ... (2) From eqns. (1) and (2), 12 = b1 180 2 − b1 100 2 ∴ b1 = – 173565.99 ∴ a1 = ∴ f100 = b1 1002 + a1 = = f180 = b1 1802 + a1 = = (b) Outer cylinder : Let Lame’s px = At b1 = = b1 1002 − 1802 1802 × 1002 − 173565.99 = – 17.357 100 1002 − 173565.99 − 17.357 1002 – 34.717 N/mm2 − 173565.99 − 17.357 1802 – 22.71 N/mm2 equation be, b2 b − a2 and fx = 22 + a2 2 x x 2 x = 180 mm, px = 12 75 ∴ 12 = b2 1802 − a2 ... (3) − a2 ... (4) At x = 240 mm, px = 0 ∴ 0 = b2 2402 ∴ From equations (3) and (4), we get 1 2402 − 1802 1 − = b2 12 = b2 2 2 240 1802 × 2402 180 ∴ b2 = 888685.71 From equation (4), a2 = b2 = 888685.71 = 15.42 2402 888685.71 f180 = + a2 = + 15.42 = 42.84 N/mm2 1802 1802 888685.71 + 15.42 = 30.84 N/mm2 f240 = 2402 b1 − 173565.99 − a1 = − ( − 17.357) p100 = 2 100 1002 = 0 173565.99 p180 = − − ( − 17.357) = 12.0 N/mm2 1802 173565.99 − ( − 17.357) = 14.34 N/mm2 p240 = 2402 (c) When fluid is pumped in, let Lame’s equation be, b b px = 32 − a3 and fx = 32 + a3 x x At x = 100, px = 60 N/mm2 60 = 240 b2 2 b3 1002 − a3 ... (5) − a3 ... (6) and at x = 240 mm, px = 0 0 = b3 60 = b3 2402 From equations (5) and (6), we get 100 2 − b3 240 ∴ b3 = 726050.42 Hence a3 = p100 2 = b3 2402 − 1002 1002 × 2402 b3 = 12.605 2402 = 60 N/mm2 p180 = 726050.42 1802 − 12.605 = 9.804 N/mm2 76 p240 = 0 f180 726050.42 + a3 = 85.209 N/mm2 1002 = 35.014 N/mm2 f100 = f240 = 25.210 N/mm2 ∴ Final stresses are: f100 = – 34.717 + 85.209 = 50.492 N/mm2 f180, inner = – 22.71 + 35.014 = 12.304 N/mm2 f180, outer = 42.84 + 35.014 = 77.854 N/mm2 f240 = 30.84 + 25.21 = 56.05 N/mm2 Problem 11. A compound cylinder is to made with inner radius of 160 mm and outer radius of 320 mm. The radius at common junction is to be 240 mm. If the two cylinders with allowance 0.3 mm are used, find the radial pressure developed at contact surfaces. Also determine the hoop stresses induced at inner edge, common edge and outer edge of compound cylinder. Take Young’s modulus E = 2 × 105 N/mm2. Solution: r1 = 160 mm r2 = 240 mm r0 = 320 mm Let p be the radial pressure developed at junction. Let Lame’s equations for internal cylinder be b b px = 12 − a1 fx = 12 + a1 x x At x = 160 mm px = 0 0 = b1 1602 − a1 ... (1) At x = 240 mm, px = p b1 − a1 2402 From eqns. (1) and (2), we get b1 b p = − 12 2 240 160 ∴ p = or 1602 − 2402 p = b1 1602 × 2402 ∴ b1 = – 46082.94 p. Hence a1 = − 46082.94 p 1602 ... (2) = – 1.8 p. Hoop stress at junction is − 46082.94 p − 1.8 p 2402 = – 2.6 p Lame’s equation for outer cylinder be, b b px = 22 − a2 and fx = 22 + a2 x x At x = 240 mm, px = p f21 = 77 b2 − a2 ... (3) − a2 3202 From equations (3) and (4), we get ... (4) p = 2402 At x = 320 mm, px = 0 ∴ 0 = b2 p = b2 2402 − b2 3202 = b2 (3202 − 2402 ) 2402 × 3202 b2 = 131657.14 p. ∴ From eqn. (4), a2 = b2 2 = 131657.14 p 320 3202 = 1.285 p. ∴ At junction, hoop stress in outer cylinder is b2 131657.14 p = + a2 = + 1.285 p 2402 2402 = 3.57 p Considering the circumferential strain, the compatibility equation is, δr 1 = (f21 + f20) r2 E where f21 is compressive and f20 is tensile. 0.15 1 = [2.6 p + 3.57 p] 240 2 × 105 p = 20.25 N/mm2 b1 f1 = + a1 1602 − 46082.94 × 20.25 − 1.8 × 20.25 = 1602 = – 72.9 N/mm2 b1 − 46082.94 × 20.25 f2, inner = + a1 = − 1.8 × 20.25 2 240 2402 = 52.65 N/mm2 b2 f2, outer = + a2 = 3.57 p 2402 = 3.57 × 20.25 = 72.29 N/mm2 b2 131657.14 × 20.25 fouter = + a2 = + 1.285 × 20.25 3202 3202 = 52 N/mm2. Problem 12. A spherical shell with internal diameter 320 mm and 640 mm external diameter is subjected to an internal fluid pressure of 75 N/mm2. Find the hoop stresses developed at 40 mm interval across the thickness. Solution: r0 = 320 mm r1 = 160 mm p = 75 N/mm2 ∴ 78 The radial pressure and the hoop stress at any radial distance x are given by, 2b b px = 3 − a and fx = 3 + a x x Now, at x = 160 mm, px = 75 N/mm2 2b −a ... (1) −a 3203 From equations (1) and (2), we get ... (2) ∴ 75 = 1603 At x = 320 mm, px = 0 ∴ 0 = 2b 1 1 75 = 2b − 3 3203 160 ∴ From equation (2), b = 175542857 a = f = ∴ f160 = f200 = f240 = f280 = f320 = 2 × 175542857 3203 175542857 x3 175542857 1603 175542857 2003 175542857 2403 175542857 2803 175542857 3203 = 10.714 + 10.714 + 10.714 = 53.57 N/mm2 + 10.714 = 32.656 N/mm2 + 10.714 = 23.41 N/mm2 + 10.714 = 18.71 N/mm2 + 10.714 = 16.071 N/mm2 79 Ans.