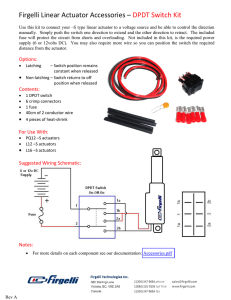

Actuators & Power Transmission Elements . Actuators Introduction • Actuators are the muscles of robots. • links and the joints are the skeleton of the robot, the actuators act as muscles, which move or rotate the links of the robots. • The actuator must have enough power to accelerate and decelerate the links and to carry the loads, be light, economical, accurate, responsive, reliable, and easy to maintain. Types of Actuators 1) Hydraulic Actuators (Uses pressurized oil) 1) Rotary type (Produce rotational motion) 2) Reciprocating type(Produce translational motion) 2) Pneumatic Actuators (Uses pressurized air) 1) Rotary type (Produce rotational motion) 2) Reciprocating type (Produce translational motion) 3) Electrical Actuators (Uses electric current).- Rotational motion alone (Use mechanical transmission elements to get translational motion) Types Hydraulic & Pneumatic Actuators LINEAR ACTUATOR PUMP LOAD PISTON & ROD TO RESERVOIR ROTARY ACTUATOR PUMP HYDRO MOTOR Comparison HYDRAULIC ELECTRICAL Speed Speed - High Robot Size - Large PNEUMATIC - Less Robot Size - Small &Medium Speed - High Robot Size - Smaller Floor occupancy - Large Floor occupancy - Less Floor occupancy - Very less Accuracy - High Accuracy - High Accuracy - Less Maintenance - Not Easy Maintenance - Easy Maintenance - Easy Cost - More Cost - Little less Cost - Cheaper Preferred Envn. - Explosive Preferred Envn. - Cleaner Preferred Envn. - Designed for less DoF 6 Power Transmission Elements Gear drive • • • • Spur Gears - Parallel Helical Gears - Parallel Bevel Gears - Perpendicular Worm gears – Non parallel Non Intersecting Gear drive • • • • • Less floor space No possibility of slip Easy to maintain Difficult to construct High cost Belt drive • Belt drive: Method of transferring rotary motion between two shafts. • Construction: A belt drive includes one pulley on each shaft and one or more continuous belts over the two pulleys. • Principle: The motion of the driving pulley is, generally, transferred to the driven pulley via the friction between the belt and the pulley. • Belt: Looped strip of flexible material, used to mechanically link two or more rotating shafts. • Pulley: Wheel with a groove between two flanges around its circumference. Pulleys are keyed to the shafts. Belt Drives • Inexpensive and Easy to design • Maintenance is easy • Elasticity present in the belts can provide damping and shock absorption which results in less vibration • Slip • Huge in size • Torque capacity is limited Chain drives • Chains are used for power transmission. The chain drives have some features of both belt (flexibility of location of driver and driven) and gear drives (ruggedness). • A chain drive consists of an endless chain wrapped around sprocket • The chain has a number of links connected by pins. • The sprockets have teeth of special profile. CHAIN AND SPROCKET • • • • • • • High Torque, Low Speed Long as well as short center distance More compact than belt or gear drives Positive drive Chain doesn’t require initial tension Transmit more power than belt drives Operate in any atmospheric conditions • • • • • • Precise alignment of shaft required than belt drives Not Suitable for non parallel shafts High maintenance Noisy Operation Weight & Vibration Complicated design Thank You………