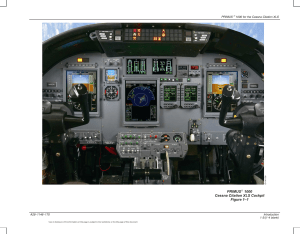

Cessna Single Engine Maintenance Manual: 172, 182, 206

advertisement