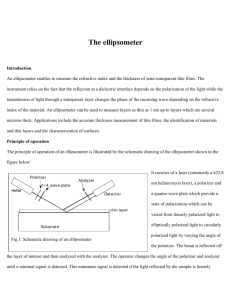

Emerging Materials and Processes (Academic Year 2021/22) WEAR PROTECTIVE GEAR!! (LAB COAT; EYE PROTECTION GLASSES AND GLOVES) Lab_3 Elipsometry. During this laboratory session, you will learn how to measure the thickness and refractive index of organic thin films using an ellipsometer. Data collected during this lab are part of the ‘Lab report’. Elipsometry is a non-destructive, a non-invasive and non-contact optical analysis method, which can be used to obtain various information such as layer thickness, refractive index and absorption coefficient of a thin film. This technique can be used to examine samples with nearly any size and shape. Both organic and inorganic thin films can be investigated by elipsometry. Exercise 1: Measure the thickness and refractive index of the PVAc thin film Objective: During this exercise, you will learn how to measure the thickness and refractive index of Polyvinyl acetate (PVAc) thin films on silicon substrate deposited during Lab_3. Session. Equipment: elipsometer and a pair of tweezers Consumables: PVAc (10mg/ml; 25mg/ml) thin films (prepared in the lab_2) Personal Protective Equipment (PPE): Lab coat, Gloves, Safety glasses ELLIPSOMETER OPERATING INSTRUCTIONS: These operating instructions are for automatic Ellipsometer Rudolf AutoEL III. This Ellipsometer uses a red class 2 laser as a light source which is harmful to eyes. There is nothing to worry about as the laser is fixed inside ellipsometer and during normal operation there is no risk involve. But don’t try to look at the laser as even reflection can be harmful. In order to operate ellipsometer. To take reliable measurements, the procedure listed below should be followed: IF EQUIPMENT NOT SWITCHED ON: If ellipsometer is not plugged in (which is unlikely), plug into wall mounted single phase socket to the rear of the ellipsometer. NOTE: IF YOU ARE UNSURE ABOUT WHAT TO DO, PLEASE DO NOT PROCEED ANY FURTHER AND ASK A MEMBER OF STAFF TO PLUG IN THE ELLIPOSMETER.. Turn on the electrical supply to the ellipsometer by turning the power key 2 position switch (on the lower left hand side of the ellipsometer) anticlockwise to the ON position. NOTE: THE POWER INDICATOR WILL LIGHT AND THE DISPLAY WILL TURN ON. Check that after approximately 30 seconds, the ellipsometer display reads UP COMP-INSERT SAMPLE-PRESS CONT. NOTE: WAIT 15 MINUTES FROM THIS POINT TO ALLOW WARM UP OF THE ELLIPSOMETER The ellipsometer is now ready for experimental usage NOTE: PLEASE BE AWARE THAT WHEN POWER IS TURNED ON TO THE ELLIPSOMETER, A CLASS 2 HeNe LASER IS ALWAYS ON AND SO CARE SHOULD BE TAKEN NOT TO REFLECT THE BEAM AWAY FROM THE SAMPLE STAGE SO AS TO ENDANGER THE EYESIGHT OF YOURSELF OR OTHERS. IF EQUIPMENT ON AND SAMPLES ARE READY FOR PLACEMENT ON SAMPLE STAGE 1. Once the laser has warmed up you can proceed with ellipsometry measurements. Ellipsometer allows measurements of thin film thickness and refractive index of the film. 2. Press ‘Reset’ button if required. ‘Reset’ button should be pressed every time sample type is changed. 3. Position sample on the measurement table. 4. Using eyepiece to align sample. 5. Look at the sensor aperture and confirm that laser beam enters sensor stage. If not realign measurement table. 6. Follow instruction on screen o Slide compensator up and press ‘Cont’. Wait for the next command o Slide compensator down. o Press ‘Prog’. o On the keypad enter program number and press ‘E’. For a single layer film on silicon programme 21 should be used. o Once measurements are finished, check the reading and record values in your lab book. 7. If additional samples of the same type needed to be measured. o Change sample o Check sample alignment o Press ‘Cont’ o Check readings and record data. IF EQUIPMENT NEEDS TO BE SWITCHED OFF: Remove the sample from the sample stage. Press the compensator slide full down, if not already down. Turn off the electrical supply to the ellipsometer by turning the power key 2 position switch (on the lower left hand side of the ellipsometer) clockwise to the OFF position. NOTE: THE DISPLAY AND POWER INDICATOR LIGHT WILL TURN OFF. Turn off the power at the wall mounted mains electricity switch. The ellipsometer has now been shut down safely Figure 1. Schematic diagram of Ellipsometer Rudolf AutoEL III. Before to test your sample(s), check that ellipsometer is operating correctly/calibrated by using a reference sample. You will find the Reference sample next to the ellipsometer. Measure the reference sample following ellipsometer operating instructions. Compare your data to calibration data for reference sample: Thickness: 95 nm Refractive index: 1.47 If measured data are within 1% of calibration data, then continue with experiment otherwise report to the lab tutor or EMTERC technician. Perform the measurements of PVAc thickness and refractive index for all deposited samples and write down their values in the lab book. Check how the thickness/refractive index of the film is influenced by deposition conditions – namely the spin speed. Plot the collected data (thickness vs. spin speed) and comment on the results. https://www.youtube.com/watch?v=2F4Gsqo-YvY https://www.youtube.com/watch?v=BycPkRIutqg