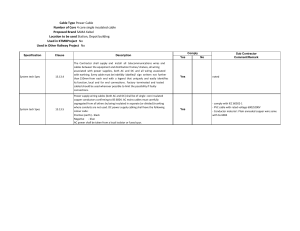

OptiX RTN 980 Radio Transmission System V100 IDU Quick Installation Guide (Indoor) Issue: 01 Date: 2018-10-30 HUAWEI TECHNOLOGIES CO., LTD. Copyright © Huawei Technologies Co., Ltd. 2018. All rights reserved. No part of this document may be reproduced or transmitted in any form or by any means without prior written consent of Huawei Technologies Co., Ltd. Trademarks and Permissions and other Huawei trademarks are trademarks of Huawei Technologies Co., Ltd. All other trademarks and trade names mentioned in this document are the property of their respective holders. Notice The purchased products, services and features are stipulated by the contract made bet ween Huawei and the customer. All or part of the products, services and features described in this document may not be within the purchase scope or the usage scope. Unless otherwise specified in the contract, all statements, information, and recommendations in this document are provided "AS IS" without warranties, guarantees or representations of any kind, either express or implied. The information in this document is subject to change without notice. E very effort has been made in the preparation of this document to ensure accuracy of the contents, but all statements, information, and recommendations in this document do not constitute a warranty of any kind, express or implied. Huawei Technologies Co., Ltd. Address: Huawei Industrial Base Bantian, Longgang Shenzhen 518129 People's Republic of China Website: http://www.huawei.com Email: support@huawei.com Installation Process Start Before You Start Page 2 Page17 Installing PGND Cables Pages 18 to 19 Installing Power Cables Precautions for Handling the Toggle Lever Switch Page 19 Installing E1 Cables Pages 5 to 6 Precautions for Handling IF Cables Page 20 Installing Ethernet Service Cables Page 7 Precautions for Handling IF Boards Page 20 Installing XPIC Cables Page 8 Tools for Installation Page 21 Installing IF Jumpers Pages 9 to 11 Introduction to the RTN 980 Equipment Pages 22 to 23 Installing Fibers Pages 12 to 14 Installing the RTN 980 Page 23 Installing STM-1e Cables Pages 14 to 15 Optional: Installing the E1 Panel Pages 23 to 24 Installing NM Cables Page 24 Installing Orderwire Phone Cables Page 25 Installing External Clock Cables Page 26 Installing Asynchronous and Synchronous Data Cables Page 27 Installing External Alarm Cables Page 28 Cable Layout Effectiveness Page 3 Page 4 Pages 11 to12 Installing the Chassis in the 19Inch Cabinet Pages 12 to 13 Installing the Chassis in the ETSI Cabinet Page 16 Pages 35 to37 Installing Power Cables for the C3 PDU Pages 38 to 40 Assembling Cable Connectors Precautions Instructions and Precautions for Handling Boards Installing Boards Pages 17 to 28 Installing IDU Cables Page 34 Checking the Installation Pages 35 to40 Appendixes End Commissioning Process Start Page 29 Powering On the Equipment Page 30 Configuring the NE Data (by Using the Web LCT) Pages 31 to 33 Aligning the Antennas Page 33 Checking the Radio Link Status End 1 Pages 31 to 32 Aligning the SinglePolarized Antennas Pages 32 to 33 Aligning the DualPolarized Antennas Precautions NOTE This document provides quick guidelines for hardware installation. This document does not describe pre-delivery assembly. This document describes only procedures for onsite installation. CAUTION Power Supply The equipment uses a -48 V/-60 V DC power supply. An AC power supply or a high-voltage power supply may cause equipment damage or even human injuries and therefore is forbidden. CAUTION Electrostatic Discharge Wear ESD gloves or an ESD wrist strap prior to contact with the equipment or before handling the plug-boards, boards, and IC chips to prevent damage to sensitive components caused by electrostatic discharge from the human body. Ensure that the other end of the ESD wrist strap is properly grounded. CAUTION Binding Cables Binding intervals between cable ties or optical fiber binding straps inside the cabinet cannot exceed 250 mm. (The distance cannot exceed 200 mm for user cables). Binding intervals between cable ties for all cables and corrugated pipes outside the cabinet are determined according to the distance between the two horizontal beams. If the cable trough does not contain any beams, the binding intervals between cable ties cannot exceed 250 mm. CAUTION Pre-installation Check Check the telecommunications room, cabinet, power supply, ground wires, optical cables, and associated facilities prior to installation. Start the installation according to the engineering design documents after verifying that conditions are met. 2 Instructions and Precautions for Handling Boards CAUTION Do not hold a board without hand protection. Wear an ESD wrist strip or ESD gloves before handling a board. Wearing ESD gloves Wearing an ESD strip Holding a board without hand protection CAUTION Hold the front panel of a board with hands. CAUTION Insert filler panels into vacant slots on an NE to prevent foreign matters from getting into the NE, which may result in faults on the NE. Boards are fragile and valuable. When handling or placing a board, exercise caution and put it into a dedicated packing box. 3 Precautions for Handling the Toggle Lever Switch • Position and description of the toggle lever switch O: OFF CAUTION Turn the toggle lever switch only after gently pulling it out. I : ON NOTE A dual-channel IF board does not have a toggle lever switch. •Turning on the switch 1 1 Pull the switch out gently. 3 2 2 Turn the switch. 3 Release the switch. •Turning off the switch 1 1 Pull the switch out gently. 3 2 2 Turn the switch. 4 3 Release the switch. Precautions for Handling IDU-side IF Cables (SingleChannel IF Board) CAUTION CAUTION Connect or disconnect an IF cable only after powering off the ODU. Do not connect or disconnect an IF cable when the ODU is powered on. 1 Power off the ODU. 2 Connect or disconnect the IF cable . Precautions for Handling ODU-side IF Cables (SingleChannel IF Board) CAUTION CAUTION Connect or disconnect an IF cable only after powering off the ODU. Do not connect or disconnect an IF cable when the ODU is powered on. Power off the ODU. Connect or disconnect the IF cable. 5 Precautions for Installing IF Cables (Dual-Channel IF Board) CAUTION When installing an IF cable, connect one end of the cable to the ODU and then connect the other end of the cable to the IDU. Connect the IF cable to the ODU. Connect the IF cable to the IDU. Precautions for Removing IF Cables (Dual-Channel IF Board) CAUTION When removing or replacing an IF cable, disconnect one end of the cable from the IDU and then disconnect the other end of the cable from the ODU. Disconnect the IF cable from the IDU. Disconnect the IF cable from the ODU. 6 Precautions for Handling IF Boards CAUTION Remove or insert an IF board only after powering off the ODU. 1 2 3 Remove the IF board. 3 Insert the IF board. Power off the ODU. Skip this step if a dual-channel IF board is concerned. Disconnect the IF jumper. CAUTION Do not remove or insert an IF board when the ODU is powered on. 7 Remove or insert the IF board. Tools for Installation Long measuring tape Level Socket w rench Torque w rench Wire stripper RJ45 crimping tool Bayonet w rench Combination pliers Hammer drill Marker ESD gloves ESD w rist strap Vacuum cleaner Binding strap Phillips screwdriver Flat-head screwdriver Adjustable w rench Hex key COAX crimping tool Wire clippers Diagonal pliers Cold press pliers Needle-nose pliers File Multimeter Heat gun Utility knife Ladder Insulation tape 8 Claw hammer Antistatic gloves Electric iron Impact tool Coax stripper Netw ork cable tester Introduction to the RTN 980 Equipment 1 Exterior of the RTN 980 a Front View b Oblique View c 9 Side View 2 Installation Requirements of the Cabinet and Mounting Ears NOTE Before installing the equipment, ensure that the cabinet has already been installed. The cabinet can be installed on the ESD floor or concrete floor. For details about how to install the cabinet, see the Cab inet Installation Guide delivered with the cabinet. The equipment can be installed in an ETSI cabinet, a 21-inch open rack, or a 19-inch standard cabinet. NOTE The equipment can be installed when no guide rail is provided. You can install the mounting ears and equipment based on the following procedure: 1. Separately mount M6 screws into the bottom -lower floating nuts of the mounting bar on both sides of the cabinet, and reserve sufficient space for installing mounting ears between the screws and the mounting bar. Then, confirm that an appropriate length of M6 screws is inserted into the floating nuts to avoid fall -off of the chassis. 2. Place the chassis into the cabinet. Note: Place the cucurbit-shape holes in the lower part of the mounting ears onto the M6 screws and use the M6 screws to secure the chassis onto the cabinet. 10 NOTE The default mounting ears are applicable to the situation where the equipment is installed in a 19 -inch standard cabinet. When installing the equipment in another type of cabinet, use other mounting ears as required. When installing the equipment in a 21-inch cabinet, install two sets of mounting ears. That is, retain the default mounting ears, and install another set of mounting ears for the equipment installed in the 21 -inch cabinet. Generally, install mounting ears in an ETSI cabinet. Install mounting ears in a19-inch standard cabinet. 19-inch ear ETSI ear Install mounting ears in an N63B cabinet. ETSI ear NOTE Cabinet-sharing Installation The RTN 980 can be placed in a stacked manner. When the RTN 980 and other type of equipment are installed in the same cabinet, it is recommended that you reserve a 2U or greater space for heat dissipation. When the RTN 980 and other type of equipment are installed in the same cabinet, the temperature in the air outlet needs to be lower than 50°C if the lower equipment emits the air on its top. Otherwise, use an air guide plate for separation between the upper equipment and the lower equipment. 11 Installing the RTN 980 1 Installing the Chassis in the 19-Inch Cabinet a Fixing Floating Nuts Floating nut Installation hole NOTE When tightening floating nuts, ensure a minimum of 25 mm space on the left and right sides of the RTN 980 for ventilation. b Removing Screws NOTE Store the removed screws properly for installing PGND cables. 12 c Installing the Chassis in the Cabinetd Installing PGND Cables To the ground point on the column of the cabinet or the indoor ground bar Cable tray M6 30±3 Kgf.cm Connect PGND cables by using the removed screws. 2 Installing the Chassis in the ETSI Cabinet a b Fixing Floating Nuts Replacing Mounting Ears NOTE Before installing the chassis in an ETSI cabinet, replace mounting ears based on the type of the cabinet. Installation hole Floating nut M4 When tightening floating nuts, ensure a minimum of 25 mm space on the left and right sides of the RTN 980 for ventilation. M4 screw 13 12±1.2 Kgf.cm c d Installing PGND Cables Installing the Chassis in the Cabinet To the ground point on the column of the cabinet or the indoor ground bar M6 M6 30±3 Kgf.cm NOTE 30±3 Kgf.cm Install the cable tray if provided. Connect PGND cables by using the removed screws. Optional: Installing the E1 Panel 1 Fixing Floating Nuts Floating nut Installation hole 14 2 Fixing the E1 Panel M6 30±3 Kgf.cm 3 Installing PGND Cables on the E1 Panel To the ground point on the column of the cabinet or the indoor ground bar 15 Installing Boards 2 1 3 4 Guide rail Loosen the screws on the filler panel and remove the filler panel. Hold the ejector levers on the panel with hands and raise them to form an angle of approximately 45 degrees between the ejector levers and the panel. Push the board gently along the guide rail until the board is secure. Lower the two ejector levers of the board. Tighten the screws on the panel. NOTE Before installing and removing/inserting a board, wear an ESD wrist strap or ESD gloves. Before you insert a board, ensure that the slot is correct. If it is difficult to insert the board, stop the operation. 16 Installing Cables for the RTN 980 1 Installing PGND Cables When installing a PGND cable in the ETSI cabinet, connect the PGND cable to the ground point on the left side of the chassis. When installing a PGND cable in the 19-inch cabinet, connect the PGND cable to the ground point of the left mounting ear of the chassis. 17 2 Installing Power Cables M6 -48 V 0V 50±5 Kgf.cm 1 2 3 CAUTION If the AC power box (ETP 4890) is used, the IDU needs to use the BGND power cable and -48 V power cable that are delivered with the AC power box. For details on the AC power box and its cables, see the IDU hardware description. Open the cover and remove the bolt. Install the power cable by using the removed bolt. Check the voltage and polarity of the external power supply. Check the fuse current of the external power supply. Recommended Current Value of the External Fuse Reseat the cover. Standard Voltage of the Input Power Allowable Voltage Range –48 V ( DC ) –38.4 V to –57.6 V ( DC ) –60 V ( DC ) –48 V to –72 V ( DC ) 40 A WARNING The IDU does not support AC power. Do not connect the IDU to an AC power supply. Otherwise, equipment may be damaged and you may be injured. 18 6 Ensure that the circuit breaker of the PDU is set to the OFF state. Insert the DC connector into the power port of the PDU. Ensure that the two groups of power cables are connected to different wiring terminals, PIU boards in 1+1 hot backup mode Power box 0V -48V 0V -48V CAUTION If the C3 PDU is available, see “Installing Power Cables for the C3 PDU” in Appendixes. If an external power box is used, cut off the input of the power box before you connect power cables. 3 Installing E1 Cables a Optional:Connecting E1 Cables to the External Equipment b Optional: Connecting E1 Cables to the E1 Panel The SP3D, MD1, ML1, and SP3S boards provide the E1 port. SP3D board NOTE SP3D board For information about the wiring sequence of the E1 cables, see the wiring table delivered with the E1 cables or the cable part in the Hardware Description. For a 1.6 mm diameter E1 cable, use a type 75-1-1 connector and a 2.5 mm or 1.7 mm COAX crimping tool when assembling the DDF-side connector of the E1 cable. 19 4 Installing Ethernet Service Cables The EFP8, EM6T, EM6TA, EM6F, EM6FA, and EMS6 boards provide the FE ports. The CSHN, CSHNA, EM6T, EM6TA, EG4, and EG4P boards provide the GE electrical ports. EM6T board NOTE The Ethernet service port supports the MDI/MDI-X adaptive function. Therefore, you can assemble either a crossover cable or a straight-through cable. It is recommended that you assemble a straight-through cable. 5 Installing XPIC Cables The ISX2, ISM6, and ISV3 (XPIC function enabled) boards support the XPIC function. X-OUT X-IN X-OUT X-IN XPIC IF board NOTE The IN port on one XPIC IF board must be connected to the OUT port on the other XPIC IF board. CAUTION •If the XPIC function is disenabled on an ISX2 board, use a short XPIC cable to connect the IN and OUT ports on the board. Otherwise, board performance will be affected. •If the XPIC function is disenabled on an ISV3 board, do not use a short XPIC cable to connect the IN and OUT ports on the board. Otherwise, the board performance will be affected. •ISM6 boards support intra-board XPIC. Therefore, you do not need to install XPIC cables. 20 6 Installing IF Jumpers a Installing an IF Jumper The ISM6, ISV3, IF1, IFU2, ISU2, ISX2, and IFX2 boards provide the IF port. ISU2 board ODU switch CAUTION Before installing an IF jumper on a single-channel IF board, turn off the ODU switch on the IF board. If an RG-8U IF cable or a 1/2-inch IF cable is used, an IF jumper is required to connect the IF cable and IDU; if a 5D IF cable is used, the 5D IF cable is directly connected to the IDU. b Connecting the IF Jumper Directly to the IF Cable IF jumper IF cable NOTE When connecting an IF jumper to an IF cable, you must test the connectivity of the IF cable. On the equipment configured with IF 1+1 protection, the IF cable of the active ODU must be connected to the IF jumper of the active IF board, and the IF cable of the standby ODU must be connected to the IF jumper of the standby IF board. If the XPIC IF board is used, the IF cable connected to the vertically polarized ODU must be connected to the IF jumper on the IF board that processes vertically polarized waves, and the IF cable connected to the horizontally polarized ODU must be connected to the IF jumper of the IF board that processes horizontally polarized waves. 21 7 Installing Fibers a Precautions CAUTION When installing or maintaining fibers, do not look into the optical port without eye protection. See Figure 1. Coil up the inter-office fibers on the ODF and then route them into the cabinet. Do not coil up external fibers in the cabinet. NOTE When routing fibers, take proper measures to avoid any damage to fiber connectors After installation of the fibers, place protective caps on to the idle optical ports, and place fiber caps on to the idle fibers. See Figure 2. Figure 1 Figure 2 Fiber w ith a short protective tube Fiber cap Dustproof cap Pluggable optical module NOTE For a closed corrugated pipe, take protective measures and then route fibers into the corrugated pipe. For an open corrugated pipe, route fibers into the corrugated pipe and then take protective measures. After routing fibers into a corrugated pipe, wrap PVC insulation tapes around the cuts of the corrugated pipe. Do not feed a large number of fibers in a corrugated pipe. It is recommended that you feed not more than sixty 2 mm diameter fibers in an open corrugated pipe and not more than twenty 2 mm diameter fibers in a closed corrugated pipe (See Figure 3). The corrugated pipe needs to be routed into the cabinet for approximately 10 cm (See Figure 4). Figure 3 Figure 4 10 cm 22 b Installing Fibers The CQ1, SL1D, SL1DA, CSHN, CSHNA, EM6F , EM6FA, EMS6, EG4, and EG4P boards provide the optical port. SL1D board 8 Installing STM-1e Cables The CQ1, SL1D, SL1DA board provides the STM-1e electrical port. SL1D board 9 Installing NM Cables a Installing the NM Cables (for a Gateway NE) The CSHN, CSHNA board provides the NMS/COM port. NMS/COM CSHN board NMS 23 b Installing the NM Cables (for Multiple Interconnected NEs at a Site) EXT EXT MD1 MD1 NMS/COM MD1 NMS/COM NOTE Assemble a crossover cable or a straight-through cable on site. Ensure that the interconnected network cables do not form a loop and the standby CSH/CSTA board is not connected to another network cable. 10 Installing Orderwire Phone Cables The AUX board provides the PHONE port. PHONE AUX board 24 11 Installing External Clock Cables a Assembling External Clock Cables Based on the Pin Assignment Pin 1 Color Relationship White/Orange CLK/TOD1 Negative receive end of the external clock Twisted pair 2 3 6 4 Orange Positive receive end of the external clock White/Green External time 1_N Twisted pair Green External time 1_P Negative transmit end of the external clock Blue Twisted pair 5 White/Blue 7 White/Brown Positive transmit end of the external clock External time 2_N Twisted pair 8 Brown External time 2_P b Installing External Clock/Time Cables for the RTN 980 The CSHN, CSHNA board provides the CLK/TOD1 port. CLK/TOD1 CSHN board 25 12 Installing Asynchronous and Synchronous Data Cables a Assembling Asynchronous and Synchronous Data Cables Based on the Pin Assignment Pin Assignment Pin 1 2 3 6 4 5 7 8 b Color Relationship Function White/Orange Transmits asynchronous data signals. Twisted pair Orange Grounding Receives asynchronous data signals. White/Green Twisted pair Green Grounding Blue Transmits synchronous data signals (TIP). Twisted pair White/Blue Transmits synchronous data signals (RING). White/Brown Receives synchronous data signals (TIP). Twisted pair Brown Receives synchronous data signals (RING). Installing Synchronous and Asynchronous Data Cables for the RTN 980 The AUX board provides the F1/S1 port. F1/S1 AUX board 26 13 Installing External Alarm Cables a Assembling External Alarm Cables Based on the Pin Assignment Pin 1 2 3 Color Relationship White/Orange ALMO ALMI External alarm signal input 1 Positive alarm signal output 1 Twisted pair Orange Grounding White/Green Negative alarm signal output 1 Positive alarm signal output 2 External alarm signal input 2 Twisted pair 6 4 5 b Green Grounding Blue Negative alarm signal output 2 External alarm signal input 3 Positive alarm signal output 1 Twisted pair White/Blue 7 White/Brown 8 Brown Grounding Negative alarm signal output 1 External alarm signal input 4 Positive alarm signal output 2 Twisted pair Grounding Negative alarm signal output 2 Installing External Alarm Cables for the RTN 980 The AUX board provides the ALMO port and ALMI port. ALMI ALMO AUX board 27 14 Cable Layout Effectiveness a Cable Connections 5 9 7 2 12 1 MD1 6 3 11 8 10 4 b PGND Cables Ethernet Service Cables NM Cables 10 Asynchronous and Synchronous Data Cables Pow er Cables IF Jumpers Orderw ire Phone Cables 11 External Alarm Cables E1 Cables Fibers/STM-1 Cables External Clock Cables 12 XPIC Cables Cable Layout Effectiveness 28 Powering On the Equipment CAUTION Before powering on the equipment, ensure that the installation of the ODU is completed and the ODU switch on the IF board is set to the OFF state. ALM PWR ALM PWR ALM ALM MD1 PWR PWR FAN Status Description of Indicators Indicator Status Description PWR Constantly on and green The power is functioning properly. Off ALM The power supply fails. Constantly on and green Constantly on and red Off FAN The board is being initialized. The power board reports an alarm. No alarm is reported. Normally on in green color Constantly on and red Off The fan is functioning properly. The fan is malfunctioning. The fan is powered off. Check and ensure that the STAT indicators on the system control, switching, and timing board are on in green color. 29 MD1 Configuring NE Data (by Using the Web LCT) CSHN board NMS/COM You can use the Web LCT to configure NE data, including basic data of the NE, IF/ODU information of the radio link, parameters for the IF ports, and parameters for the ODU ports. 30 Aligning Antennas 1 Aligning Single-Polarized Antennas Determine the azimuth of the antenna according to the installation position and height of the antenna. Adjust the elevation of the antenna to the horizontal position. Connect a multimeter to the RSSI port on the ODU at the local end and measure the voltage value VBNC. NOTE The red line of the multimeter is connected to the pin, and the black line of the multimeter is connected to the inner wall (ground pin). Elevation adjustment screw Level adjustment screw Retain the remote antenna secure. Adjust the level adjustment screw. At the local end, rotate the antenna widely in the horizontal direction. a If three signal peaks are tracked, adjust the azimuth of the antenna so that the received signal level (RSL) reaches the peak value at position 2. b If two signal peaks are tracked, adjust the azimuth of the antenna to the middle of positions 4 and 5. Then, adjust the elevation of the antenna so that the three signal peaks such as the signals on the line AA' can appear. Adjust the antenna so that the RSL reaches the peak value at position 2. c If one signal peak is tracked, adjust the azimuth of the antenna to the middle of positions 6 and 7. Then, adjust the elevation of the antenna so that the three signal peaks such as the signals on the line AA' can appear. Adjust the antenna so that the RSL reaches the peak value at position 2. 31 Front view of the lines tracked at different elevations of the antenna RSL value of each line 天线不同仰角下扫描路径的正面图 各路径信号值 6 7 6 C B A 7 C' 5 4 1 2 5 4 B' 3 C' C B' B A' 2 1 A 3 A' Adjust the elevation adjustment screw. At the local end, gently adjust the elevation and azimuth until the RSL reaches the peak within the tracked range. Repeat Steps 3 to 4 to ensure that three signal peaks are tracked in both horizontal and vertical directions. When the local RSL reaches the maximum peak value, tighten the local antenna. Adjust the remote antenna to ensure that the RSL at the local end and the RSL at the remote end reach the peak value. Check the status of the ODU indicator on the IF board. The ODU indicator on the IF board is off. If the ODU indicator on the IF board is yellow and blinks every 300 ms, continue aligning the antenna. Tighten all the screws of the antennas after the alignment is completed. 2 Aligning Dual-Polarized Antennas NOTE If an OMT is used to connect the ODUs to the antenna in direct-mounting mode, align the antenna in the same method as that for aligning single-polarized antennas. If soft waveguides are used to connect the ODUs to the antenna in separate-mounting mode, follow the procedure to align the antenna: Power off the vertically polarized ODUs at both ends of a radio link, power on the horizontally polarized ODUs at both ends of the radio link. This ensures that the antennas at both ends transmit horizontally polarized signals. Adjust the azimuth and elevation of the antennas at both ends by referring to the description in “Aligning Single-Polarized Antennas”, and ensure that the main lobes of the horizontally polarized signals are aligned with the antennas. 32 Use a multimeter to measure the RSL (P1) on the RSSI port of the horizontally polarized ODU at the local end. Power on the vertically polarized ODU at the local end. Use a multimeter to measure the RSL on the RSSI port of the vertically polarized ODU. Release the holder of the feed boom gently, and turn the feed boom gently until the RSL reaches the minimum value (P2). The calculated XPD1 (XPD1 = P1 - P2) cannot be less than 24 dB. Record the current angle (D1) of the feed boom. Power off the horizontally polarized ODUs at both ends of the radio link, and power on the vertically polarized ODUs at both ends of the radio link. Adjust the azimuth and elevation of the antennas at both ends by referring to the description in “Aligning Single-Polarized Antennas”, and ensure that the main lobes of the vertically polarized signals are aligned with the antennas. Refer to Steps 3 and 4 to ensure that the calculated XPD2 (XPD2 = P3 - P4) is equal to or more than 24 dB. Record the current angle (D2) of the feed boom. Repeat Steps 1 to 6 to adjust the feed boom gently (ranging from D1 to D2), and ensure that XPD1 and XPD2 are equal to or more than 24 dB. Tighten all the screws of the antennas after the alignment is completed. Checking the Radio Link Status LINK indicator Check the status of the LINK indicator on the IF board. a b c d If the LINK indicator is on (green), the radio link is functioning properly. If the LINK indicator is on (red), check whether the configuration data is correct. If the configuration data is incorrect, configure correct data. If the LINK indicator blinks yellow at intervals of 300 ms, check whether the antennas are aligned properly. If the antennas are not aligned properly, realign the antennas. If the LINK indicator is off, check whether the logical units of the IF unit and the ODU have been added on the NMS. If yes, check for a fault in the IF jumper, IF cable, or the ODU. 33 Checking the Installation No. What to Check For 1 The chassis must be installed securely in the position as specified in the engineering design documents. 2 Each chassis component does not have any paint drop, damage, or stain. Otherwise, re -paint or clean the component. 3 For a board inserted into the chassis, the screws on the front panel are tightened. 4 Filler panels are installed for vacant slots in the chassis. 5 Cable routes comply with the engineering design documents and facilitate maintenance and expansion. 6 Cables are not damaged, broken, or jointed in between. 7 Each core of the cables is tested for connectivity. 8 Cables are properly bound. Cable ties are installed at equal spacing and in the same direction. The excess of cable ties is trimmed off without remaining rough edges. 9 Signal cables are routed correctly in the cabinet. 10 Cables outside the cabinet are routed as follows: • The cables are placed tidily and are not cross -connected. • If a cabling ladder is used, the cables are bound onto the ladder beam tidily. If the cabling frame is 0.8 m or more higher than the cabinet top, a cabling ladder is available on the cabinet top to support the cables and to ease stress. 11 Cable turns are smooth and have a great bending radius. 12 Cable labels are filled in correctly and attached securely. They are aligned and face to the same direction. Preferably, the labels are attached 2 cm away from the connectors. 13 The power cable and ground cable are routed separately from the signal cables. 14 Idle cable connectors are protected. For example, protective caps are installed on the idle connectors. 15 Protective tube for fiber jumpers are routed into the cabinet for 10 cm and bound securely. 16 The cuts of protective tubes for fiber jumpers are smooth. Otherwise, they need to be wrapped by an insulation tape. 17 Fiber jumpers are bound gently to ensure free move in the cable tie. 18 Connecting points of fiber jumpers are clean. Protective caps (plugs) are installed for idle fiber connectors and optical ports. 34 Appendixes 1 Installing Power Cables for the C3 PDU a Installing and Routing the Power Cables – DC Power Distribution Box Power output area Power switch area Power input area A A 48 48 V V G N D G - G N 48 48 N D V V D SW1 G N 48 48 D V V SW2 Item Input power Output power G N D G N 48 48 D V V SW3 G N D G N D SW4 S S S S WWWW 1 2 3 4 Power switch area Specifications Rated input voltage -48 V DC to -60 V DC Input voltage range -38.4 V DC to -72 V DC Input mode 2 DC power inputs from different power facilities Maximum input current A maximum of 80 A current for each power input Input terminal type M8 OT terminal Rated output voltage -48 V DC to -60 V DC Output voltage range -38.4 V DC to -72 V DC Number of power outputs Eight power outputs under control of four circuit breakers. For the OptiX RTN 980 equipment, one circuit breaker is required to control one power output. Maximum current of each circuit breaker 40 A Output protection The overcurrent protection function is available, but manual recovery is required. Output terminal type Cord end terminal (12-10AWG) 35 b Installing Mounting Ears for the C3 PDU Installing the C3 PDU in a 19-inch cabinet Installing the C3 PDU in an ETSI cabinet NOTE By default, the C3 PDU is installed in a 19-inch cabinet. When the C3 PDU is installed in an ETSI cabinet, the mounting ear needs to be removed and then installed in another direction. When the C3 PDU is installed in an ETSI cabinet, the mounting ear needs to be installed based on the requirement. 36 Connections Between Power Cables NOTE Pow er cable for the subrack PGND cable C3 PDU can be used only in the central telecommunications room. A maximum of two RTN 980 NEs can be installed in a cabinet. A B Cover A B PGND cable RTN (+) NEG (-) PIU boards in 1+1 hot backup mode MD1 c Ensure that the circuit breaker of the PDU is set to the OFF state. Insert the DC connector into the power port of the PDU. Ensure that the two groups of power cables are connected to different wiring terminals, 37 2 Assembling Cable Connectors a Assembling OT Terminals and Power Cables • Components of an OT terminal and a power cable Wire stripper A B Heat gun C D A Heat shrink tube B Bare crimp terminal C Insulation layer of a power cable D Conductor of a power cable • Installation procedure 1 2 L A C B L2 B C L1 D Strip a part of the insulation layer C of the power cable according to the cross -sectional area of the conductor, and ensure that the conductor D of the power cable is exposed for the length L1. Route the power cable into the heat shrink tube A. Route the exposed conductor of the power cable into the OT terminal B, and then remain the OT terminal close to the insulation layer C of the power cable. CAUTION When stripping the insulation layer of a power cable, do not damage the metallic conductor of the power cable. If the bare crimp terminal is not provided by Huawei, change the value of L1 according to the actual value L of the bare crimp terminal. L1 = L + (1-2) mm. After the conductor is routed into the OT terminal, the exposed part L2 of the conductor of the power cable cannot be more than 2 mm. 38 3 4 Crimp the joint parts of the bare crimp terminal and the conductor of the power cable by using a crimping tool. Push the heat shrink tube A towards the connector until the heat shrink tube covers the crimped parts of the bare crimp terminal and the conductor of the power cable. Then, heat the heat shrink tube by using a heat gun. NOTE The shapes of the crimped parts may vary according to the types of crimping dies. CAUTION Do not heat the heat shrink tube for a very long time to avoid damage to the insulation layer. b Assembling Cord End Terminals and Power Cables Wire stripper • Components of a cord end terminal and a power cable B C A 39 Crimp pliers for the cord end terminal • Installation procedure 1 2 L1 B B A C A Strip a part of the insulation layer B of the power cable according to the cross -sectional area of the conductor, and ensure that the conductor C of the power cable is exposed for the length L1. Route the conductor of the power cable into the cord end terminal A, and then align the conductor with the edge of the cord end terminal. CAUTION When stripping the insulation layer of a power cable, do not damage the metallic conductor of the power cable. After the conductor is fed into the cord end terminal, the exposed part of the conductor of the power cable cannot be more than 1 mm long. 3 4 H W2 W1 A 3 Crimp the joint parts of the cord end terminal and the conductor of the power cable based on a proper cross-sectional area by using a crimping tool. 管状端子截面积 (mm2) 0.25 0.5 1.0 1.5 2.5 4 6 10 16 Cross-Sectional Area (mm2) 端子的最大压接宽度 Maximum Width (mm) (mm) 1 1 1.5 1.5 2.4 3.1 4 5.3 6 4 After crimping the terminal, check the maximum width of the terminal, which needs to be less than the maximum width specified in the table. 40 HUAWEI TECHNOLOGIES CO., LTD. Huawei Industrial Base Bantian Longgang Shenzhen 518129 People’s Republic of China www.huawei.com