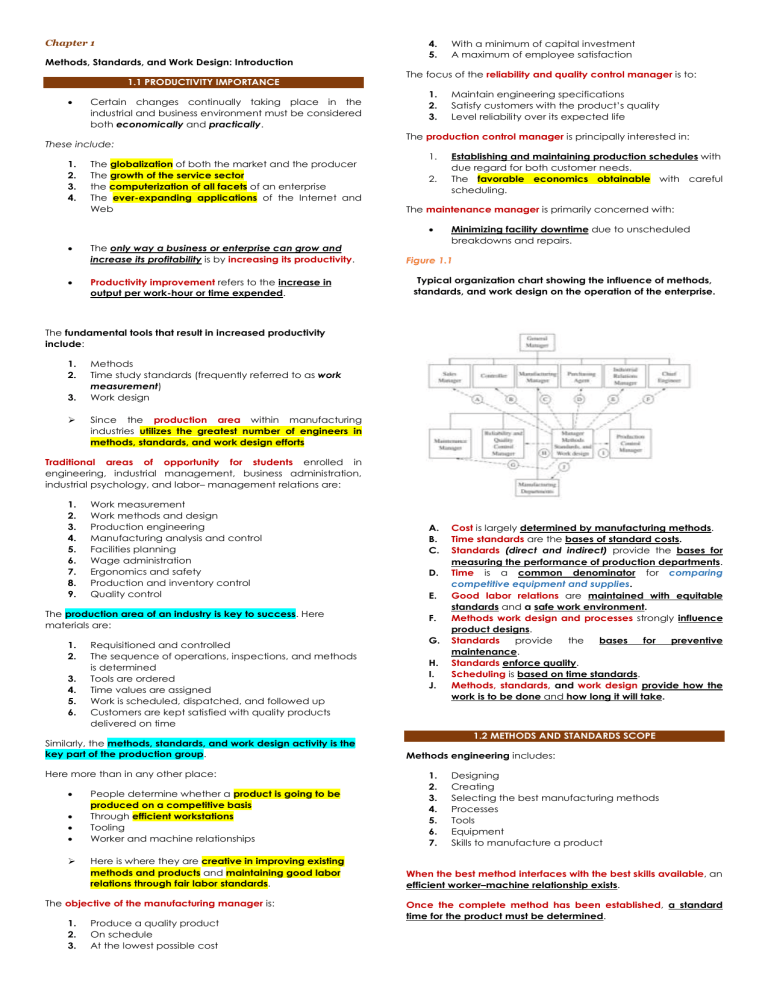

Chapter 1 Methods, Standards, and Work Design: Introduction 1.1 PRODUCTIVITY IMPORTANCE Certain changes continually taking place in the industrial and business environment must be considered both economically and practically. These include: 1. 2. 3. 4. The globalization of both the market and the producer The growth of the service sector the computerization of all facets of an enterprise The ever-expanding applications of the Internet and Web 4. 5. The focus of the reliability and quality control manager is to: 1. 2. 3. The only way a business or enterprise can grow and increase its profitability is by increasing its productivity. Productivity improvement refers to the increase in output per work-hour or time expended. Maintain engineering specifications Satisfy customers with the product’s quality Level reliability over its expected life The production control manager is principally interested in: 1. 2. Establishing and maintaining production schedules with due regard for both customer needs. The favorable economics obtainable with careful scheduling. The maintenance manager is primarily concerned with: With a minimum of capital investment A maximum of employee satisfaction Minimizing facility downtime due to unscheduled breakdowns and repairs. Figure 1.1 Typical organization chart showing the influence of methods, standards, and work design on the operation of the enterprise. The fundamental tools that result in increased productivity include: 1. 2. 3. Methods Time study standards (frequently referred to as work measurement) Work design Since the production area within manufacturing industries utilizes the greatest number of engineers in methods, standards, and work design efforts Traditional areas of opportunity for students enrolled in engineering, industrial management, business administration, industrial psychology, and labor– management relations are: 1. 2. 3. 4. 5. 6. 7. 8. 9. Work measurement Work methods and design Production engineering Manufacturing analysis and control Facilities planning Wage administration Ergonomics and safety Production and inventory control Quality control The production area of an industry is key to success. Here materials are: 1. 2. 3. 4. 5. 6. Requisitioned and controlled The sequence of operations, inspections, and methods is determined Tools are ordered Time values are assigned Work is scheduled, dispatched, and followed up Customers are kept satisfied with quality products delivered on time Similarly, the methods, standards, and work design activity is the key part of the production group. Here more than in any other place: People determine whether a product is going to be produced on a competitive basis Through efficient workstations Tooling Worker and machine relationships Here is where they are creative in improving existing methods and products and maintaining good labor relations through fair labor standards. The objective of the manufacturing manager is: 1. 2. 3. Produce a quality product On schedule At the lowest possible cost A. B. C. D. E. F. G. H. I. J. Cost is largely determined by manufacturing methods. Time standards are the bases of standard costs. Standards (direct and indirect) provide the bases for measuring the performance of production departments. Time is a common denominator for comparing competitive equipment and supplies. Good labor relations are maintained with equitable standards and a safe work environment. Methods work design and processes strongly influence product designs. Standards provide the bases for preventive maintenance. Standards enforce quality. Scheduling is based on time standards. Methods, standards, and work design provide how the work is to be done and how long it will take. 1.2 METHODS AND STANDARDS SCOPE Methods engineering includes: 1. 2. 3. 4. 5. 6. 7. Designing Creating Selecting the best manufacturing methods Processes Tools Equipment Skills to manufacture a product When the best method interfaces with the best skills available, an efficient worker–machine relationship exists. Once the complete method has been established, a standard time for the product must be determined. Opportunities for savings through the applications of methods engineering and time study. As long as they continue to emphasize research and development, methods engineering through technological innovation will be instrumental in their ability to provide high-level goods and services. Figure 1.3 The principal steps in a methods engineering program METHODS ENGINEERING The terms operation analysis, work design, work simplification, and methods engineering and corporate reengineering are frequently used synonymously. Productivity improvement the person is referring to a technique for increasing the production per unit of time or decreasing the cost per unit output Methods Engineers Use A Systematic Procedure to Develop A Work Center, Produce A Product, Or Provide A Service: However, methods engineering, as defined in this text, entails analyses at two different times during the history of a product. 1. 2. responsible for designing and developing the various work centers where the product will be produced. must continually restudy the work centers to find a better way to produce the product and/or improve its quality. 1. Select the Project represent either new products or existing products that have a high cost of manufacture and a low profit. Also, products that are currently experiencing difficulties in maintaining quality and are having problems meeting competition are logical projects for methods engineering. In recent years, this second analysis has been called corporate reengineering. business must introduce changes if it is to continue profitable operation. desirable to introduce changes outside the manufacturing area. 2. Get and Present the Data The more thorough the methods study during the planning stages, the less the necessity for additional methods studies during the life of the product. Methods engineering implies technological capability. the utilization of Research and development (R&D) leading to new technology is therefore essential to methods engineering. 3. Analyze the Data United States Switzerland Sweden Netherlands Germany Norway France Israel Belgium Japan Utilize the primary approaches to operations analysis to decide which alternative will result in the best product or service. 4. Develop the Ideal Method The 10 countries with the highest R&D expenditures per worker, as reported by the United Nations Industrial Development Organization (1985), are: 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. Assemble all the important facts relating to the product or service. Select the best procedure for each operation, inspection, and transportation by considering the various constraints associated with each alternative, including: Productivity Ergonomics Health and safety implications 5. Present and Install the Method Explain the proposed method in detail to those responsible for its operation and maintenance. Consider all details of the work center, to ensure that the proposed method will provide the results anticipated. 6. Develop a Job Analysis Conduct a job analysis of the installed method to ensure that the operators are adequately selected, trained, and rewarded. 7. Establish Time Standards The ability to produce more for less will result in more jobs for more people for a greater number of hours per year. Only through the intelligent application of the principles of methods, standards, and work design can producers of goods and services increase, while, at the same time, the purchasing potential of all consumers grows. Through these principles, unemployment and relief rolls can be minimized. Thus, reducing the spiraling cost of economic support to nonproducers. Establish a fair and equitable standard for the installed method. 8. Follow up the Method At regular intervals, audit the installed method to determine if the anticipated productivity and quality are being realized, whether costs were correctly projected. IN SUMMARY Methods engineering is the systematic close scrutiny of all direct and indirect operations to: Find improvements that make work easier to perform, in terms of worker health and safety Also, allow work to be done in less time with less investment per unit (i.e., greater profitability). WORK DESIGN Principles of work design Frederick W. Taylor must be used to fit the task and workstation ergonomically to the human operator. typically forgotten in the quest for increased productivity. Overly simplified procedures 1.3 HISTORICAL DEVELOPMENTS result in machinelike repetitive jobs for the operators, leading to increased rates of work-related musculoskeletal disorders. Thus, it is necessary for the methods engineer to incorporate the principles of work design into any new method Shop Management Standards are the end result of time study or work measurement. This technique establishes a time standard allowed to perform a given task, based on measurements of the work content of the prescribed method Time study analysts use several techniques to establish a standard: 1. 2. 3. 4. 5. 6. A stopwatch time study Computerized data collection Standard data Predetermined time systems Work sampling Estimates based on historical data Wage payment activity performed by the same group responsible for the methods and standards work. Famous paper which included the elements of Scientific Management 113 plants that had installed scientific management Pig-iron experiment most celebrated demonstrations of his principles. Taylor–White process of heat treatment for tool steel STANDARDS founder of modern time study in this country. However, time studies were conducted in Europe many years before Taylor’s time. Taylor died of pneumonia in 1915, at the age of 59. Taylor began his time study work in 1881 serving as an apprentice. he evolved a system based on the “task.” the work of each employee be planned out by the management at least one day in advance. breaking up the work assignment into small divisions of effort known as “elements” Taylor’s well-known contributions hardening a chrome–tungsten steel alloy without rendering it brittle In 1760, Jean Rodolphe Perronet, French engineer made extensive time studies on the manufacture of No. 6 common pins. Charles W. Babbage English economist conducted time studies on the manufacture of No. 11 common pins. MOTION STUDY AND THE WORK OF THE GILBRETHS Frank and Lilian Gilbreth were the founders of the modern motion-study technique, which may be defined as the study of the body motions introduced his ideas and philosophies into the bricklayer’s trade in which he was employed. Frank died death at the age of 55 Lilian passed away in 1972 at age of 93. Adjustable scaffold and operator training OBJECTIVES OF METHODS, STANDARDS, AND WORK DESIGN The principal objectives of methods, standards, and work design are: 1) 2) To increase productivity and product reliability safely. To lower unit cost, thus allowing more quality goods and services to be produced for more people. he was able to increase the average number of bricks laid to 350 per worker per hour. Micromotion study technique of filming motions to study them known as. The study of movements through the aid of the slowmotion moving picture is by no means confined to industrial applications. Cyclegraphic involves attaching a small electric lightbulb to the finger or hand or part of the body Humane approach Chronocyclegraph its electric circuit is interrupted regularly, causing the light to flash. HENRY LAURENCE GANTT Workers tend to fear methods and time study Henry Laurence Gantt must be well versed in the study of human behavior and accomplished in the art of communication. be good listeners, respecting the ideas and thinking of others. to use the questioning attitude emphasized by the Gilbreths, Taylor, and the other pioneers in the field. The idea that there is “always a better way” invented the task and bonus system or earned-hour plan. Gantt advocated a livable wage with a sizable bonus for performance over 100%. interested in operator selection, training, and motivation. RALPH M. BARNES for they see that the results are an increase in productivity. To them, this means less work and consequently less pay. unpleasant experiences with efficiency experts. To many workers, motion and time study is synonymous with the speedup of work and the use of incentives to spur employees to higher levels of output. Ralph M. Barnes first and best-known professors of engineering in the field of work measurement. His achievements included writing the longest published text on work measurement. numerous methods studies of activities with motion picture cameras and developed rating films for training time study technologists. SUMMARY Industry, business, and government are in agreement that the untapped potential for increasing productivity is the best hope for dealing with inflation and competition. The principal key to increased productivity is a continuing application of the principles of methods, standards, and work design. EMERGENCE OF WORK DESIGN Work design Chapter 2 is a relatively new science that deals with designing the task, work station, and working environment to fit the human operator better. In the United States, it is more typically known as human factors, while internationally it is better known as ergonomics, which is derived from the Greek words for work (erg) and laws (nomos). Technical organizations Most crucial step: identification of the problem in a clear and logical form. have contributed much toward bringing the science of time study, work design, and methods engineering up to present-day standards. Maintaining the practice of industrial engineering on a professional level; Fostering a high degree of integrity among the members of the industrial engineering profession; Encouraging and assisting education and research in areas of interest to industrial engineers; Promoting the interchange of ideas and in formation among members of the industrial engineering profession In the area of work design, the first professional organization, the Ergonomics Research Society, was founded in the United Kingdom in It started the first professional journal, Ergonomics, in 1957. Problems could be large amounts of scrap or rework, excessive material handling, in terms of either cost or distance Technical considerations may include: 1. Processing techniques that need to be improved. 2. Quality control problems due to the method. 3. Product performance problems compared to the competition. Human considerations may involve: 1. Highly repetitive jobs. 2. Leading to work-related musculoskeletal injuries. 3. High-accident-rate jobs. 4. Excessively fatiguing jobs. 5. Jobs about which workers constantly complain. a direct bearing on emerged during the 1940s need for better project planning and control of complex military projects. useful in identifying problems in an industrial setting. Bottleneck Practitioners of methods, standards, and work design have come to realize that such factors as: Age Health and well-being, Physical size and strength, Training attitudes, Job satisfaction Motivation response have productivity. evolved from Japanese quality circles of the early 1960s improving quality and reducing costs in their manufacturing processes. Gantt and PERT charts Currently, there are well over 5,000 members organized in 20 different technical groups. PRESENT TRENDS So the methods engineer uses appropriate tools to do a better job in a shorter time. Pareto analysis and fish diagrams The Institute of Industrial Engineers (IIE) was founded in 1948 with the purposes of: Good methods engineering program: will follow an orderly process ORGANIZATIONS PROBLEM-SOLVING TOOLS The first four exploratory tools are most typically used in the analyst’s office. Job/worksite analysis guide helps identify problems within a particular area, department, or worksite provides a subjective identification of key worker, task, environmental, or administrative factors necessary first step before extensive quantitative data are collected on the present method. Get and present the data The next five tools are used to record the present method, and they comprise the second step of methods analysis, in response to the need to manage complex defense projects and systems better. shows the anticipated completion times for various project activities as bars plotted against time on the horizontal axis. Actual completion times are shown by shading the bars appropriately. provides a quick snapshot of the progress of the project at any given time. be utilized for sequencing machine activity on the plant floor. Develop the ideal method. The final three tools are more useful as a quantitative approach in the fourth step of methods analysis, Once the facts are presented clearly and accurately, they are examined critically 2.1 EXPLORATORY TOOLS PERT CHARTING Program Evaluation and Review Technique(PERT) PARETO ANALYSIS technique developed by the economist Vilfredo Pareto to explain the concentration of wealth. items of interest are identified and measured on a common scale and then are ordered in descending order, as a cumulative distribution. transformed to a straight line using a lognormal transformation 80-20 rule 20 percent of the ranked items account for 80 percent or more of the total activity Events (represented by nodes) concentrates the greatest effort on the few jobs that produce most of the problems. FISH DIAGRAMS also known as cause-and-effect diagrams, were developed by Ishikawa in the early 1950s while he was working on a quality control project for Kawasaki Steel Company. The process is continued until all possible causes are listed. worked quite successfully in Japanese quality circles The effect, as the “fish head” The causes, as the “fish bones” The principal causes are typically subdivided into five or six major categories: are positions in time that show the start and completion of a particular operation or group of operations. Arc: each operation or group of operations in a department is defined as an activity. Methods analyst network diagram or critical path method, It is a planning and control tool graphically portrays the optimum way to attain some predetermined objective, generally in terms of time. was employed by the U.S. military in the design of such processes as the Polaris missile Methods analysts usually use PERT charting to improve scheduling through cost reduction or customer satisfaction. Each arc has an attached number representing the time needed to complete the activity. Dummy activities activities that utilize no time or cost necessary to maintain a correct sequence, and are shown as dotted lines. Typically used to indicate precedence or dependencies, each activity has a unique set of nodes. Minimum time The minimum time needed to complete the project is the longest path from node 1 to node 12. Time flexibility (freedom) is referred to as float the amount of time that a noncritical activity can be lengthened without delaying the project’s completion date. Critical path can be found through trial and error 1. The human 2. Machines 3. Methods 4. Materials 5. Environmental Latest start time latest time an activity can start without delaying the project. 6. Administrative—each of which is further subdivided into sub-causes. Latest finish time: minimum of the latest start times of the emanating activities Two predecessor activities the earliest start is computed as the maximum of the previous earliest furnishes Good diagram will have several levels of bones and will provide a very good overview of a problem and its contributing factors. 2.2 RECORDING AND ANALYSIS TOOLS OPERATION PROCESS CHART GANTT CHART first project planning and control technique to emerge during the 1940s shows the chronological sequence of all operations, inspections, time allowances, and materials used in a manufacturing subassemblies to the main assembly. details at a glance an ideal plant layout methods analysts: developing improving existing ones. new layouts and Two symbols are used 1. 2. Right-hand column: provides space for the analyst to enter comments or make recommendations for potential changes. Longer a part stays in storage or is delayed, the more cost it accumulates and the longer the customer must wait for delivery. A small circle denotes an operation. A small square denotes an inspection. Operation: intentionally transformed Inspection: examined to determine its conformity Vertical lines: indicate the general flow of the process Horizontal lines: indicate material Figure 2.6 Flowcharting Conventions FLOW DIAGRAM Time values: based on either estimates or actual measurements FLOW PROCESS CHART greater detail than the operation process chart. it is not usually applied to entire assemblies but rather for each component of an assembly. valuable in recording nonproduction hidden costs the information it provides can lead to a reduction of both the quantity and duration of these elements. exceptionally valuable in showing how the layout of a plant can be improved. show all the moves and storage delays encountered by an item as it goes through the plant. A pictorial representation of the layout showing the locations of all activities analysts identify each activity by symbols and numbers corresponding to those appearing on the flow process chart. helpful supplement to the flow process chart because it indicates backtracking and possible traffic congestion areas, and it facilitates developing an ideal plant layout. Five symbols are used: 1. 2. 3. 4. 5. A small circle denotes an operation. A small square denotes an inspection A small arrow signifies transportation, which can be defined as moving an object from one place to another, A large capital D indicates a delay, which occurs when a part is not immediately permitted to be processed at the next workstation. An equilateral triangle standing on its vertex signifies a storage, which occurs when a part is held and protected against unauthorized removal. Two types of flowcharts are currently in general use: 1. Product or material provides the details of the events. 2. Operative or person how a person performs an operational sequence. WORKER AND MACHINE PROCESS CHARTS used to study, analyze, and improve one workstation at a time. shows the exact time relationship between the working cycle of the person and the operating cycle of the machine. clearly shows the areas in which both idle machine time and idle worker time occur. These areas are generally a good place to start in effecting improvements. The analyst should never use overall stopwatch readings in the construction of the chart. Many machine tools are either: 1. Completely machine) automatic (the automatic screw 2. Semiautomatic (the turret lathe) Machine coupling having one employee operate more than one machine. increases the percentage of “effort time” greater incentive earnings are possible if a company is on an incentive wage payment plan. The longer the cycle time of the operation being charted, the shorter the distance per decimal minute of time. The productive time plus the idle time of the worker must equal the productive time plus the idle time of each machine that the worker operates. Accurate elemental time values are necessary before the worker and machine chart can be constructed. RANDOM SERVICING Completely random servicing situations are those cases in which it is not known when a facility needs to be serviced or how long servicing takes. Mean values are usually known or can be determined; with these averages, Laws of probability can provide a useful tool in determining the number of machines to assign a single operator. COMPLEX RELATIONSHIPS the servicing time is relatively constant, but the machines are serviced randomly. the time between breakdowns is assumed to have a particular distribution. As the number of machines increases and the relationship between the operator and machines becomes more complex, machine interference and consequent delay times increase. LINE BALANCING GANG PROCESS CHARTS an adaptation of the worker and machine chart. several workers are needed to operate one machine effectively. shows the exact relationship between the idle and operating cycles of the machine and the idle and operating times per cycle of the workers who service that machine. reveals the possibilities for improvement by reducing both idle operator time and idle machine time. company is employing two more operators than are needed. The problem of determining the ideal number of workers to be assigned to a production line is analogous to that of determining the number of workers to be assigned to a workstation one that is very often encountered, is one in which several operators, each performing consecutive operations, work as a unit. the rate of production is dependent on the slowest operator. the operator will probably better the standard in view of the performance of the operators on the line with less work content in their assignments. Line be perfectly balanced standard minutes to perform an operation would be identical for each member of the team. “standard minutes to perform an operation” is not really a standard. It is only a standard to the individual who established it. Also, involves dividing a work element Sequence of individual work elements 2.2 QUANTITATIVE TOOLS, WORKER AND MACHINE RELATIONSHIPS SYNCHRONOUS SERVICING Assigning more than one machine to an operator seldom results in the ideal case where both the worker and the machine are occupied during the whole cycle. The fewer the restrictions on the order, the greater the probability that a favorable balance in the work assignments will be achieved. Zoning restraints A zone represents a subdivision that may or may not be physically separated or identified from other zones in the system. may help to identify physically specific stages of a component n = No. of machines the operator is assigned l = total operator loading and unloading time per machine SUMMARY m = total machine running time Pareto and fish diagrams Assume a total cycle time of 4 min to produce a product, as measured from the start of the unloading of the previously completed product to the end of the machine cycle time. Operator servicing, which includes both the unloading of the completed product and the loading of the raw materials, is 1 min, while the cycle time of the automatic machine cycle is 3 min. used to select a critical operation to identify the root causes and contributing factors leading to the problem. Gantt and PERT charts: project scheduling tools. Gantt chart: only a good overview PERT chart: quantifies the interactions between different activities. Job/worksite analysis guide primarily used on a physical walkthrough Operation process chart provides a good overview of the relationships between different operations and inspections on assemblies involving several components. Flow process chart its ability to satisfy given needs. considered when reviewing the design, Methods analysts should be well versed in the details of cost and should be fully aware of what unnecessarily close tolerances the company can reduce the costs of inspection, minimize scrap, diminish repair costs, and keep quality high. Inspection: verification of quantity, quality, dimensions, and performance. provides more details for the analysis of manufacturing operations, to find hidden or indirect costs, such as delay time, storage costs, and material handling costs. Flow diagram Spot inspection: is a periodic check to ensure that established standards are being realized. Lot-by-lot inspection: is a sampling procedure in which a sample is examined to determine the quality of the production run or lot. useful supplement to the flow process chart in developing plant layouts. 3.4 MATERIAL FINDING A LESS EXPENSIVE AND LIGHTER MATERIAL can be used as anchor points from which to judge the application of new materials. Chapter 3 Operation Analysis Methods analysts use operation analysis to study all productive and nonproductive elements of an operation, while maintaining or improving quality. simplifying operational procedures and material handling and by utilizing equipment more effectively. analysis takes place and the various components of the proposed method crystallize Lean manufacturing repackaged format originated with the Toyota Motor Corporation means of eliminating waste in the aftermath of the 1973 oil embargo. A material that was not competitive in price yesterday may be very competitive today. One company used Micarta spacer bars between the windings of transformer coils. Separating the windings permitted the circulation of air between the windings. An investigation revealed that glass tubing could be substituted for the Micarta bars at a considerable savings. The glass tubing was less expensive, and it met service requirements better because the glass could withstand higher temperatures. Furthermore, the hollow tubing permitted greater air circulation than did the solid Micarta bars. Another company also used a less expensive material that still met service requirements in the production of distribution transformers. Originally, a porcelain plate separated and held the wire leads coming out of the transformers. The company found that a fullerboard plate stood up just as well in service, yet was considerably less expensive. Today, one of the many types of plastic available would provide an even cheaper solution. FINDING A MATERIAL THAT IS EASIER TO PROCESS 3.1 OPERATION PURPOSE the most important of the nine points of operation analysis devise some way to get the same or better results at no additional cost. Analyst’s cardinal rule is to try to eliminate or combine an operation before trying to improve it. Eliminating an activity the task/process should not be simplified or improved, but eliminated entirely. saves money on the installation of an improved method there is no interruption or delay because no improved method is being developed, tested, and installed. Unnecessary operations frequently result from improper planning when the job is first set up. often develop because of the improper performance of a previous operation. Second operation must be done to “touch up” or make acceptable the work done by the first operation. the analyst was able to eliminate the touch-up operation by considering that an unnecessary operation may have developed of the improper performance 3.3 TOLERANCES AND SPECIFICATIONS Some materials are usually more readily processed than others. Referring to handbook data on the physical properties usually helps analysts discern which material will react most favorably to the processes to which it must be subjected in its conversion from raw material to finished product. machinability varies inversely with hardness, and hardness usually varies directly with strength. Today the most versatile material is reinforced composites. Resin transfer molding can produce more complex parts advantageously from the standpoint of quality and production rate than most other metal and plastic forming procedures. Thus, by specifying a plastic made of reinforcing carbon fibers and epoxy, the analyst can substitute a composite for a metal part, at both a quality and a cost advantage. This step is also addressing the muda of inappropriate processing. USING MATERIAL MORE ECONOMICALLY The possibility of using material more economically is a fertile field for analysis. If the ratio of scrap material to that actually going into the product is high, then greater utilization should be examined. For example, if the material put into a plastic compression mold is preweighed, it may be possible to use only the exact amount required to fill the cavity; excessive flash can also be eliminated. In another example, the production of stampings from sheet metal should utilize multiple dies carefully arranged to assure maximum use of material. Given consistent raw material and standard-sized dies, this typically is done through the use of CAD-assisted layout, yielding efficiencies exceeding 95% (i.e., less than 5% scrap). Similar approaches are utilized in the garment industry in the layout of patterns on cloth and the glass industry for the cutting of different sized windows. However, if the material is not consistent, then problems arise and the layout may still need to be performed by a human operator. The production of leather seats for automobiles requires layout of cutting dies on a tanned hide before entering a rolling press, which applies pressure on the dies to cut the leather in appropriate patterns. The operator needs to be highly skilled in handling variably sized cow hides full of imperfections from brands and barbed wire, especially to maximize the usage of quite expensive leather (see Figure 3.6). Many world-class manufacturers are finding it not only desirable, but absolutely necessary, to take weight out of existing designs. For example, Ford engineers all looking a 40 percent weight reduction to achieve an 80 mi/gal fuel efficiency for the Taurus. This will require the cladding of stainless steel to highstrength aluminum to replace chrome-plated steel bumpers, as well as a much greater use of plastics and structural composites to replace ferrous components. Similar weight reduction is taking place on many other well-known products, such as washing machines, video cameras, VCRs, suitcases, and TV sets. Today, powder coating is a proven technology that is replacing many other methods of metal finishing. Coating powders are finely divided particles of organic polymers (acrylic, epoxy, polyester, or blends) that usually contain pigments, fillers, and additives. Powder coating is the application of a suitable formulation to a substrate, which are then fused into a continuous film by the application of heat, forming a protective and decorative finish. In view of current environmental regulations affecting traditional metal finishing operations, such