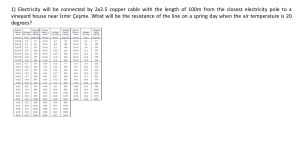

1. A six-cylinder, two-stroke marine diesel engine operates at a piston speed of 1200 rpm. The 5 in. x 5.6 in. engine has an 18:1 compression ratio. If the air intake is at 14.8 psia and 82° F, determine: (A) the displacement volume, ft3; (B) the clearance; (C) the ideal air inlet volumetric flow rate, ft3/min; and (D) the mass flow rate for a volumetric efficiency of 85%, lb/min. p1 = 14.8 psia; 5 t1 = 82° F ( A) compression ratio 2 5.6 ft ft 6 =0.3818 ft 3 4 12 12 1 1 1 (B) rV = 1+ ; c = = = 0.0588 c rV -1 17 (A) VD = • (C) V D = 14.8 lbf in2 144 in2 ft 2 P = =0.07372 lb 3 ft RT 53.34 ft-lbf lbm°R 542°R 1.4 V 13.2 (B) p2 p1 1 15 252 psia V 1.76 2 252 144 1.76 pV T2 2 2 1198 R R 53.3 q 352 T3 S T2 1198 3256 R cV 0.171 0.3188 ft 3 stroke 1200 rev min VDN = n 1 rev intake stroke = 458.16 = 458.2 ft 3 min (D) = k V1 13.2 7.5 V2 1.76 p3 RT3 53.3 3256 685 psia V3 1.76 144 k 1 V m V V D 0.85 458.2 ft 3 min 0.07372 lb ft 3 28.71 lb/min 1 (C ) T4 T3 3 3256 1454 R 7.5 V4 T 1454 p4 p1 4 15 40.8 psia 2. A diesel engine (in the above EXAMPLE) delivers 200 bhp at a piston 535 T1 speed of 1200 rpm. If the indicated power is 250 ihp find: (D) qR cV T4 T1 0.1711454 535 157 Btu lb (A) engine torque, ft-lbf; (B) brake mean effective pressure, psi; (C) indicated mean effective pressure, psi; (D) mechanical efficiency, %; and (e) friction power, fhp. wk net (E ) J (g) t 200 (h) W k 2 T 1200 PLANc 33,000 n rev power stroke 200 33,000 1 2 PLANc 33,000 n 250 ihp 33,000 ft-lbf hp-min 1 rev power stroke 2 5 12 ft 4 5.6 12 ft 1200 rev min 6 IMEP = 16,078 lbf ft 2 = 112 lbf in2 BHP 200 89 psi = = = 0.794 = 79% IHP 250 112 psi (E) FHP = IHP - BHP = 250 - 200 = 50 fhp (D) em = 3. At the beginning of the compression stroke and ideal Otto cycle has an air pressure of 15 psia, a temperature of 75° F and a specific volume of 13.2 ft3/lb. At the end of compression the specific volume is 1.76 ft3/lb. The heat supplied to the cycle is 352 Btu/lb. Calculate the following: A. the compression ratio B. the highest temperature and pressure of the cycle C. the temperature and pressure at the end of expansion of the air D. the heat rejected, Btu/lb E. the net work of the cycle, Btu/lb F. the thermal efficiency of the cycle, % G. the horsepower developed by an ideal engine operating on this cycle using 0.5 pound of air per second. p1 = 15 psia; t1 = 75° F; qS = 352 Btu/lb M wk 60 J 42.42 1 7.5 0.4 55.3% 0.5 195 60 42.42 138 hp; (A) sketch the p-v diagrams for the cycle and then calculate: (B) the temperatures and pressures at the end of compression, at the end of addition of heat and at the end of the expansion process (C) the heat rejected, Btu/lb (D) the net work, Btu/lb (E) the thermal efficiency, % (F) the horsepower developed by an ideal engine operating on the cycle and using 0.5 pound per second of air (G) the thermal efficiency of a cycle having the same initial conditions and compression ratio, but with a constant pressure heat addition of 500 Btu/lb. P = IMEP = 1 4. At the beginning of compression an ideal Diesel cycle using air has a pressure of 15 psia, a temperature of 75° F and a specific volume of 13.2 ft3/lb. For a compression ratio of 15 and a heat addition of 352 Btu/lb, 5 5.6 12 4 12 1200 6 BMEP 12,862 lbf ft 2 = 89 lbf in2 (C) IHP = k 1 1 hp = 42.42 Btu min P = BMEP 1 rV 33,000 T= 875.35 in-lb = 875 ft-lbf (B) BHP qS qR 352 157 195 Btu lb qS qR 195 55.4% qS 352 or t 1 2 TN (A) BHP = 33,000 0.4 3 v1 = 13.2 ft /lb v2 = 1.76 ft3/lb p1 = 15 psia; t1 = 75° F; qS = 352 Btu/lb v4 = v1 = 13.2 ft3/lb v1/v2 = 15.0 v1 13.2 0.88 ft 3 lb rV 15.0 (B) v2 1.4 v p2 p1 1 v2 15 15 1.4 664.7 psia 664.7 144 0.88 p2v2 1580 R R 53.3 p3 p2 664.7 psia T2 T3 T2 qS 352 1580 1580 1467 3047 R cp 0.24 RT3 53.3 3047 1.697 ft 3 lb p3 664.7 144 v3 k 1 7. Determine the volumetric analysis of a mixture which consists of 56 percent nitrogen, 12 percent carbon dioxide and 32 percent oxygen as calculated on a mass basis. M1 0.56; Mm M2 0.12; Mm M3 0.32 Mm m1 28; m2 44; m3 32 Mass Analysis N2 , 0.56 28 0.02000 0.4 v 1.697 T4 T3 3 3047 3047 0.44 1341 R v 13.2 4 T 1341 p4 p1 4 15 37.6 psia 535 T1 CO2 , 0.12 44 0.00273 V2 0.00273 8.34% CO2 Vm 0.03273 O2 , V3 0.01000 30.55% O2 Vm 0.03273 0.32 32 0.01000 (C ) qR cV T4 T1 0.171 1341 535 137.8 Btu lb wk net (D) qS qR 352 137.8 214.2 Btu lb J q qR 214.2 (E ) t S 60.9% qS 352 (F ) W k wk M J 42.42 (G) T3 ' T2 V3 ' 214.2 0.5 60 42.42 151.5 hp qS ' 1580 2083 3663 R cp RT3 ' 53.3 3663 R 2.04 ft 3 lb p3 ' 664.7 144 k 1 0.03273 8. Calculate the mass of moisture, in pounds, contained in 4000 ft3 of atmospheric air having a temperature of 90° F when the barometric pressure is 30.12 in. Hg (A) if the air is saturated and (B) if the relative humidity is 50 percent. (C) What is the dew point of the atmosphere of part (B)? (D) What is the specific humidity of the atmosphere of part (B), grains/lb dry air? PB = 30.12 in. Hg; 0.4 V ' 2.04 T4 ' T3 ' 3 3663 1736 R 13.2 V4 ' qR ' cV T4 ' T1 0.171 1736 535 205.4 Btu lb t Volumetric Analysis V1 0.02000 61.11% N2 Vm 0.03273 qS ' qR ' 500 205.4 294.6 58.9% qS ' 500 500 5. The mixture of gases shown in Figure has a pressure of one atmosphere. Using the volumetric analysis shown in the figure, calculate the partial pressures of the individual constituents. t = 90° F (A) VS Vg 467.7 ft 3 lb Steam Tables at 90 F 4000 8.55 lb 467.7 (B) pS 0.6988 psia Steam Tables at 90 F MV pV pS 0.5 0.6988 0.3494 psia 144 0.3494 4000 4.26 lb pVVm RV Tm 85.8 550 MV (C ) dew po int 68.8 F Steam Tables for 0.3494 psia (D) PB 0.49130.12 14.79 psia 4354 0.3494 105.3 grains lb dry air 4354 pV pB pV 14.79 0.3494 V 1. 9. Atmospheric air has a temperature (dry bulb) of 80° F and a wet bulb temperature of 60° F when the barometric pressure is 14.696 psia. Determine: 1 atm = 14.696 psia V3 V1 V2 =0.7; =0.1; =0.2 Vm Vm Vm p1 = pm V1 = 14.696 0.7 =10.287 psia Vm p 2 = pm V2 = 14.696 0.1 =1.470 psia Vm p 3 = pm V3 = 14.696 0.2 =2.939 psia Vm (A) the dew point, °F; (B) the relative humidity, %; and (C) the specific humidity, grains/lb dry air. PB = 14.696 psia; tD = 80° F; tW = 60° F ( A) P 'S 0.2563 psia (Steam Tables for 60 F ) 6. For the mixture shown in Figure, constituent 1 is nitrogen constituent 2 is carbon dioxide and constituent 3 is oxygen. Calculate the analysis (percentage) by mass of the mixture. PB tD tW (B)PS 0.5073 psia Steam Tables for 80 F V1 0.7; Vm m1 28; V2 0.1; Vm m2 44; Volumetric Analysis N2 , 14.696 80 60 0.2563 0.1474 psia 2700 2700 dew po int 45 F (SteamTables) PV P 'S 0.70 28 19.6 V3 0.2 Vm m3 32 Mass Analysis M1 19.6 64.47% N2 Mm 30.4 CO2 , 0.10 44 4.4 M2 4.4 14.47% CO2 Mm 30.4 O2 , M3 6.4 21.06% O2 Mm 30.4 0.20 32 6.4 30.4 PV 0.1474 100 29.1% PS 0.5073 (C ) wV 43540.1474 44.1 grains lb dry air 4354PV PB PV 14.696 0.1474 10. Calculate the enthalpy, Btu/lb dry air, for an atmosphere having a temperature (dry bulb) of 80° F and a specific humidity of 42.1 grains/lb dry air. t = 80° F; wV = 42.1 hg = 1096.4 Btu/lb (Steam Tables at 80° F) hA = 0.24t + Vhg = 0.24 80 + 42.11096.4 7000 = 25.8 Btu lb dry air 11. One hundred pounds of air per minute are to be heated from 60° F and 55° F wet bulb temperatures to a final temperature of 110°F. There is no change of total moisture during the process. Determine the heat required for the process, Btu/min: (A) by the analytical methods developed (B) by use of the psychrometric chart. Barometric pressure is 29.92 in. Hg. 13. Ten pounds of air at a dry bulb temperature of 50° F with a specific humidity of 40 grains/lb dry air are mixed with 25 lb of air having a temperature of 85° F and a specific humidity of 90 grains/lb dry air. Calculate: (A) the specific humidity of the mixture, grains/lb dry air; (B) the dry bulb temperature, °F; and (C) the enthalpy of the mixture, Btu/lb dry air. PB = 29.92 in. Hg; tD2 = 110° F; ( A) pV p 'S wV 1 tD1 = 60° F; V1 = V2; pB tD tw tw1 = 55° F M = 100 lb air/min 0.4359 29.92 60 55 0.3805 in. Hg abs 2700 2700 4354 0.3805 4354 pV 56.1 grains dryair lb pB pV 29.92 0.3805 hA 0.24tD V hg 0.24tD V 1061 0.45tD hA1 0.24tD1 V 1 1061 0.45tD1 V4 = 40 grains/lb dry air V2 = 90 grains/lb dry air tD4 = 50° F; tD2 = 85° F; M4 V 4 M2 V 2 M1 M4 V 4 M2 V 2 10 40 25 90 M4 M2 75.7 grains lb dryair 10 25 (B) Since the process is adiabatic, and no moisture is gained or lost, the hA2 hA1 0.24 0.45v1 tD2 tD1 0.45 56.1 110 60 12.2 Btu lb dry air 0.24 7000 Q12 M hA2 hA1 100 12.2 1220 Btu min energy balance for the process is as follows: H A1 H A2 H A4 M1 hA1 M2 hA2 M4 hA4 By substitution and the elimination of the quantities M1 and w V 1, the energy equation can be solved for t D1. Thus, (B)From psychrometric chart , hA1 23.3; hA2 35.6 (A) V 1 V 1 hA2 0.24tD2 V 2 1061 0.45tD2 M4 = 10 lb; M2 = 25 lb; Q12 M hA2 hA1 100 35.6 23.3 1230 Btu min 12. One hundred pounds of air per minute at a temperature of 100° F with a relative humidity of 60 percent are cooled and dehumidified to a final temperature of 50° F. Using the psychrometric chart, determine: M4 0.24 0.45V 4 tD1 tD 4 M2 0.24 0.45V 2 tD2 tD1 0.45 40 0.45 90 10 0.24 tD1 50 25 0.24 7000 85 tD1 7000 tD1 75.1 F (c) hA1 0.24tD1 V 1 1061 0.45tD1 0.24 75.1 75.7 1061 0.45 75.1 (A) the heat abstracted by the process, Btu/min, and (B) the moisture removed, lb/min 7000 29.9 Btu lb dryair 14. Using the psychrometric chart, determine (a) the enthalpy, Btu/lb of dry air, and (b) the specifc humidity, grains/lb dry air, for the mixture described in the above example. From psychrometric chart: V1 = 175.5 Va = 175.5 V2 = 53.5 hA1 = 51.7; hAa = 47.4; hA2 = 20.2; M’ = 100 lb air per min ( A) Q1a M hA1 hAa 100 51.7 47.4 430 Btu min Qa2 M hAa hA2 100 47.4 20.2 2720 Btu min Q12 Q1a Q a2 430 2720 3150 Btu min M V 1 V 2 7000 100 175.5 53.5 7000 1.743 lb tD1 tD4 = 50° F tD4 = 85° F M4tD 4 M2tD2 10 50 25 85 75 F M4 M2 10 25 Connecting points 4 and 2 with a straight line crossing the (B) dehumidification M4 = 10 lb; M2 = 25 lb; min 75 F ordinate at point 1, the state point of the mixture, then from the chart: (A) hA1 29.9 Btu lb dry air (B) V 1 75.7 grains lb dry air 15. The heat losses from a group of compartments have been determined to be 420,000 Btu/hr. Air is furnished to the compartments at a temperature of 100° F and leaves the spaces with a temperature of 70° F and a relative humidity of 50 percent. Assuming the system to use 100 percent outdoor air at a temperature of 20° F with 100 percent relative humidity, determine: (A) the mass of air which must be circulated, lb/hr; (B) the capacity of the preheating coil, Btu/hr; (C) the capacity of the reheating coil, Btu/hr; and (D) the water vapor absorbed from the washer, lb/hr. QD2 = 240,000 Btu/hr; tDC = tWC = 45° F; tDA = 83° F; tD2 = 80° F; tWA = 71° F = 40%; VD = 51 From psychrometric chart: V2 = 61 grains/lb dry air VA = 95; VC = 44 grains/lb dry air hA2 = 28.9; hAD = 20; hAA = 34.9 hAC = 17.6 Btu/lb dry air • (A) M = • QD2 240,000 = =27,000 lb hr hA2 -hAD 28.9-20 • (B) moisture absorbed= (C) F = M w V2 -w VD 7000 = 27,000 61-51 7000 =38.6 lb hr VD - VC 51 - 44 = = 0.1372 lb lb VA - VC 95 - 44 • • • (D) air through coil = MC = MD - F MD • MC = 27,000 - 27,000 0.1372 = 23,300 lb hr (E) refrigeration QDE =420,000 Btu/hr; tDE = 70° F; From psychrometric chart: hAD = 33.0; hAC = hAB = 20.5; VC = VE = VD = 55; ( A) M tDA = 20° F; E = 50%; A = 100% tDD = 100° F hAE = 25.4 hAA = 7.2 Btu/lb dry air VA = VB = 16 grains/lb dry air QDE 420,000 55,260 lb hr hAD hAE 33.0 25.4 (B) Q AB M hAB hAA 55,260 20.5 7.2 735,000 Btu hr (C ) QCD M hAD hAC 55,260 33.0 20.5 690,750 Btu hr (D) humidification M wVC wVB 55,260 55 16 7000 308 lb hr 16. For an air-conditioning system such as that described in this article and illustrated in FIGURE, the freshened air (state A) has dry and wet bulb temperatures of 83° F and 71° F, respectively, the temperature leaving the cooling coils (state C) is 45° F, the specific humidity after remixing is 51 grains/lb dry air and the temperature and relative humidity leaving the conditioned spaces (state 2) are 80° F and 40 percent, respectively. If the total sensible and latent heat gain from the spaces is 240,000 Btu/hr, calculate: (A) the mass of air that must be circulated, lb/hr; (B) the amount of moisture that can be absorbed from the conditioned spaces, lb/hr; (C) the fraction of air that bypasses the cooling coil, lb/lb; (d) the air that flows through the coil, lb/hr; and (E) the capacity of the refrigerating plant required for this system, tons. M C hAA hAC 60 200 23,300 34.9 17.6 12,000 33.6 tons 1. The specific volume of steam at atmospheric pressure and 212° F is 26.80 ft3/lb. Find (A) its density and (B) its specific weight. 1 g gC 1 3 26.80 ft 0.03731 lbf lb ft 3 g gC = 0.03731 lb 1 lbf sec 32.2 ft sec 32.2 lbft 2 ft 3 2 2. If the density of mercury is 13,600 kg/m 3, find (A) its density in lb/ft3 and (B) its specific weight in N/m3. A . Using the appropriate conversion factors g L gC 1000 kg m3 62.4278 lb ft 3 kg 3 m 16.0185 lb 3 ft 32.1740 ft 2 s p 62.4278 lb 3 ft 32.1740 lbft lbf s2 2116.21 lbf 2 ft A. B. (d) p (e) p 2116.21 lbf 2 144 in ft 2 14.6959 lbf ft 2 33, 8985 ft in2 ρ = (13,600 kg/m3)(0.4535924 kg/lb)-1(0.3048 m/ft)3 or (13,600 kg/m3)[16.01846 (kg/m3)/(lb/ft3)]-1 = 849.0 lb/ft3 9.81 m 2 g s 13,600 kg 3 m gC B. 1.0 kg m N s2 133.4 kN 3 m . 3. A pressure gauge connected to a turbine inlet reads 400 psi. A vacuum gauge connected in the exhaust trunk of the same turbine reads 28.0 in. Hg. The barometer reads 30.1 in. Hg. Find: (A) the absolute pressure at the turbine inlet, psia, and (B) the absolute pressure in the turbine exhaust trunk, in. Hg abs. 5. The difference in height of the water legs in the open manometer shown in the figure A is 20 in. (dimension in y), find the absolute pressure at point A in psia. The specific weight of water is 62.4 lbf/cu. ft. Starting from point A, and writing an equation of equilibrium through the manometer: pA p gas leg p water leg p(atm) 0 p gas leg is a negligible numerical quantity p water leg L; 62.4 lbf p 62.4 ft 3 ; L 20 in. 20 ft 12 lbf 20 x ft 104 lbf 2 ft ft 3 12 104 0.72 lbf 2 ( psi ) in 144 p(atm) 14.7 psi (assumed since atmospheric pressure (a) 1 in. Hg = 14.7/29.92 = 0.491 psi 30.1 in. Hg = 30.1 x 0.491 = 14.8 psi p = 14.8 + 400 = 414.8 psia is not specifically given) (b) p A p water leg p(atm) 0.72 14.7 15.42 psia p(gauge) = 28.0 in. Hg p(atm) = 30.1 in. Hg p(abs) =p(atm) – p(vac) p(abs) = 30.1 – 28.0 = 2.1 in. Hg abs 4. In the barometer shown in figure C, the mercury level in the vertical tube is exactly 760 mm above the mercury level in the reservoir (y = 760 mm). The following data also apply: “water” and “mercury” can be considered to be incompressible fluids having densities of 1000 kg/m3 and 13,595.1 kg/m3, respectively. The standard local acceleration of gravity is equal to 9.80665 m/s2 or 32.1740 ft/s2. Find the barometric pressure in: (a) in. Hg (b) ft H2O (c) pascals, Pa(N/m2) (d) lbf/ft2 (e) psi (lbf/in2) p 6. In the differential manometer shown in the figure B, points A and B are at the same height. The mercury used as a manometric fluid stands 9 inches higher in the B leg than in the A leg (y = 9 in.). Find the difference in pressure between points A and B in psf. Specific weight of mercury is 849 lbf per cu. ft. Writing the equilibrium equation starting from point A, pA (y in. water ) y in. Hg pB 0 pA pB (y in. Hg) y in. water p water L 62.4 9 636.8 lbf 2 ft 12 lbf pA pB 636.8 46.8 590 ft 2 1. 7. In the figure, what is the difference in potential energy per pound mass of fluid at B and at A? p Hg L 849 A. L = y = 7 60 mm = 0.76 m = 76 cm L = 76 cm/(2.54 cm/in) = 29.9213 in. Hg P.E. B. ρ1 = 1000 kg/m3 (water) ρ2 = 13,595.1 kg/m3 (mercury) g g p 1L1 2L2 gC gC 13,595.1 1 in. 1 ft L1 2 L2 76 cm 2.54 cm 12 in 1 1000 33.8985 ft H2O C. p g L gC g Z ft lbf lb gC P.E.B g ZB 30 ft lbf lb gC P.E.A g Z A 10 ft lbf lb gC P.E.B P.E.A 30 10 20 ft lbf lb 8. Steam is flowing in a pipe at a velocity of 100 ft per sec. What is the associated kinetic energy per pound of steam flowing? 9.80665 m s2 0.76 m 13,595.1 kg/m3 kg m 1.0 N s2 101,325 N 2 101.325 kPa m 9 46.8 lbf 2 ft 12 K.E V2 2gC ft lbf gC 32.2 lbft lb lbf sec2 100 K.E. 2 32.2 ; V 100 ft 2 155.3 ft lbf lb sec 14. Find the temperature, specific volume, internal energy, enthalpy and entropy of saturated saturated steam at a pressure of 1 in. Hg absolute. 9. The work delivered by a turbine is 400 Btu per lb of steam supplied when the steam flow is 20,000 lb per hour. Find: (a) the specific work in ft·lbf/lb (b) the power delivered in hp (c) the power delivered in kW (a) Saturated steam p = 1 in. Hg abs = 0.491 psia Entering Table 2, an interpolation between 0.48 and 0.50 psia wk12 400 Btu lb J wk12 is indicated. 400 778 311,200 ft lbf t = 78.32 + (11/20)(79.56 – 78.32) = 79.00° F lb 20,000 lb min 60 1 hp 2545 Btu 33,000 ft lbf hr min (b) M 20,000 lb hr Interpolation could be continued in Table 2 in the same manner for the remaining quantities. But there is a convenient shortcut thanks to the saturation temperature turning out to be a whole number. Simply enter Table 1 with 79° F. Then: υg = 652.7 ft3/lb ug = 1036.7 Btu/lb hg = 1096.0 Btu/lb sg = 2.0384 Btu/lb·°R wk12 Wk M 20,000 400 8 106 Btu hr J J 6 8 10 3143 hp 2545 or 15. Find the temperature, specific volume, internal energy, enthalpy and entropy of saturated steam at 850 psia. Wk 20,000 M wk12 311,200 103.73 106 ft lbf min J 60 6 103.73 10 3143 hp 33,000 (c) 1 kW 3413 Btu W k 8 10 Btu 6 hr Saturated steam 850 psia Using Table 2 and interpolating between 840 and 860 psia: hr 1.341hp t = 524.01 + ½ (526.76 – 524.01) = 525.39° F υg = 0.540 – ½ (0.5400 – 0.5264) = 0.5332 ft3/lb 3143 hp or 8 106 3143 Wk 2344 kW or W k 2344 kW 3413 1.341 υg = ½(0.540 + 0.5264) = 0.5332 ft3/lb ug = 1114.1 – (0.5/2) =1113.9 Btu/lb hg = 1198.0 – 0.3 = 1197.7 Btu/lb or 10. In a certain non-flow process, the internal energy decreases 20 Btu/lb, and 77,800 ft·lbf/lb of work is done on the substance. Find the heat added or abstracted. sg = 1.4106 – ½(1.4106 – 1.4080) = 1.4093 Btu/lb·°R u2 u1 20 Btu lb ;wk12 77,800 ft lbf wk12 u1 q12 u2 J wk12 q12 u2 u1 J 77,800 20 120 Btu lb 778 16. The pressure and temperature of steam in a line are determined to be 65 psia and 298° F. Since these data are inconclusive, a sample of this steam is passed through a separating calorimeter and 0.5 lb of water is collected in 5 minutes. From orifice data the rate of flow of the dry vapor is found to be 0.4 lb/min. Find (A) the quality, (B) the specific volume, (C) the entropy, (D) the enthalpy and (E) the internal energy of the steam in the line. lb abstracted U2 U1 5000 J; M 2 kg 5000 u2 u1 2500 J kg 2 wk12 q12 u2 u1 2500 J kg (on) 12. At a pressure of 100 psia and 400° F, the specific volume of steam is 4.934 ft3/lb, and the specific enthalpy is 1227.5 Btu/lb. Find the internal energy at the given state, Btu/lb. p 100psia; 4.934 ft 3 lb ; MDV mass of dry vapor MDV mass of mixture MM MDV MH2O MH2O 0.5 lb MDV 0.4 lb 5 min 2.0 lb min 2.0 x 0.8 80% 2.0 0.5 (B) m 1 x 1 0.8 0.2 mf xhg Extracting values for 298F from Table 1 or for 65 psia from Table 2 : 3 0.2 0.017 0.8 6.657 5.329 ft lb (c) s sg ms g 1.6380 0.2 1.2035 1.3973 Btu lbR (d) h hg mh g 1179.6 0.2 911.9 997.2 Btu lb (e) u ug mu g 1099.5 0.2 832.1 933.1 Btu lb ( A) x 11. In another non-flow process involving 2 kg of working substance there is no heat transferred, but the internal energy increases 5000 joules. Find the work done on or by the substance, J/kg. q12 0; hg = 1197.4 + 0.3 = 1197.7 Btu/lb h 1227.5 Btu p hu ; J p u h J 100 144 4.934 u 1227.5 1136.2 Btu lb 778 lb 17. Steam at 210 psia and 386° F has an enthalpy of 1173 Btu/lb as determined by a throttling calorimeter. Find (A) the quality and (B) the specific volume of this steam. p 210 psia; t 386F ; From Table 1 for t 386 F : p 210.06 psia; hg 1200.0 Btu 13. Find the pressure, specific volume, internal energy, enthalpy and entropy of saturated water at 300° F. From Table 2 for p 210 psia : (a) h hg mh g ; From Table 1 for 300° F: p = 66.98 psia υf =0.017448 ft3/lb uf =269.52 Btu/lb hf =269.73 Btu/lb sf =0.43720 Btu/lb·°R h 1173 Btu hg 1200.0 Btu t 385.97 F ; m hg h lb lb h g Using either table, h g 839.9 and h g 1200.0 1200.0 1173 Then, m 0.032 839.9 x 1 m 1.000 0.032 0.968 96.8% (b) g m g lb For Table 1 for 386 F : g 2.183; 0.018443 3 2.183 0.032(2.183 0.018) 2.114 ft From Table 2 for 210 psia : g 2.184; f 0.018443 lb 3 2.184 0.032(2.184 0.018) 2.115 ft lb 18. Find (a) the superheat and (b) the enthalpy of steam at 900 psia and 535° F. (a) (b) p = 900 psia; t = 535° F S.H. = t – tsat = 535 – 532.12 =2.88° F h = 1193.6 for 900 psia and 530° F h = 1204.8 for 900 psia and 540° F p1 = 600 psia; t1 =740° F; Then, for t = 535° F h = 1193.6 + ½(1204.8 – 1193.6) = 1199.2 Btu/lb From Table 3: h1 = 1373.7 s1 = s2 = 1.6067 For points that fall midway between tabulated values, as frequently occurs, calculation is simplified by adding the two appropriate entries and dividing by 2, as follows: h = (1193.6 + 1204.8)/2 = 1199.2 Btu/lb From the Mollier Chart entering with s2 and p2: h2 = 897 h1 – h2 = 1374 – 897 = 477 Btu/lb 2. 19. For steam at 600 psia and 850° F, find (a) the superheat, (b) the specific volume, (c) the internal energy, (d) the enthalpy and (e) the entropy. (a) (b) (c) (d) (e) p = 600 psia ; t = 850° F tsat = 486.33 S.H. = t – tsat =850 – 486.33 = 363.67° F At 840° F, υ = 1.2353 and at 860° F, υ = 1.2577 At 850° F, υ = (1,2353 + 1.2577)/2 = 1.2465 ft3/lb u = (1292.7 + 1301.2)/2 = 1297.0 Btu/lb h = (1429.8 + 1440.9)/2 = 1435.4 Btu/lb s = (1.6517 + 1.6601)/2 = 1.6559 Btu/lb·°R 20. In a steam propulsion plant, feed water leaves the feed heater and enters the main feed pump at 270° F and a gauge pressure of 35 psi. Find for the water: (a) the specific volume, (b) the internal energy, (c) the enthalpy and (d) the entropy. 23. Steam initially at 10 psia and a quality of 90% drops to a pressure of 2.5 psia in a non-flow reversible constant volume process. Show the process on p-v and T-s coordinates and find: (a) the final quality (b) the heat transferred, Btu/lb (a) p1 10 psia; (a) (b) (c) (d) p = 35 + 14.7 = 49.7 psia; υƒ = 0.017170 ft3/lb uƒ = 238.82 Btu/lb hƒ = 238.95 Btu/lb sƒ = 0.39597 Btu/lb·°R x1 0.9; From Table 2 : 1 0.9 38.42 0.1 0.02 34.58 2 1 34.58 p2 2.5 psia; 146.40 135.79 g 141.10 (interpolating) 2 0.016267 (by eye) x2 p = 1200 psia; t = 275° F Compressed liquid ----- Use Table 4 2 34.58 0.02 0.245 24.5% g 141.10 0.02 (b) u1 q12 u2 wk12 Equation Non-flow J 2 wk12 pd 0 since 1 2 1 J Then q12 u2 u1 h = 220.61 h = 271.46 h = (220.61 + 271.46)/2 = 246.04 p1 10 psia; At 1500 psia: t = 250° F; h = 221.65 t = 300° F; h = 272.39 t = 275° F; h = (221.65 + 272.39)/2 = 247.02 At 1200 psia: t = 275° F; h =264.04 + (2/5)(247.02 – 246.04) h = 246.04 + 0.39 = 246.43 Btu/lb 22. Steam is admitted to a turbine at 600 psia and 740° F, and exhausts to a condenser at a pressure of 1 psia. Assuming the process to be isentropic, sketch the process on T-s and h-s coordinates and find the drop in enthalpy, Btu/lb. m1 0.1 1 2 1 x1g m1 t = 270° F 21. Water from the feed pump in the earlier example enters the boiler at 1200 psia and 275° F. Find the enthalpy of the feed water. 3. At 1000 psia: t = 250° F; t = 300° F; t = 275° F; p2 = 1 psia s1 = s2 m1 0.1 u1 ug m1u g 1072.2 0.1 911.0 981.1 p2 2.5psia; x2 0.245 100.81 103.85 102.33 2 953.1 951.0 u 952.05 2 u2 u x2 u g u 4. 102.33 (0.245 952.05) 335.6 q12 u2 u1 335.6 981.1 645.5 Btu lb (abstracted) 24. Four pounds of steam initially dry and saturated expand isentropically in a non-flow process from an initial pressure of 275 psia to a final pressure of 125 psia. Show the process on p-v and T-s coordinates and find: A. the final quality B. the work done, Btu (a) p1 275 psia saturated vapor ; From Table 2 s1 1.5192 s2 ; s1 s2 u1 1117.5 p2 125psia m2 sg s2 s g 1.5853 1.5192 0.061 1.0893 x2 1 m2 1 0.061 0.939 93.9% (b) u1 q12 u2 q12 Then 2 1 wk12 J Tds 0 sin ce s1 s2 wk12 u1 u2 J u2 ug m2 u g 1108.8 0.061 793.3 1060.4 wk12 1117.5 1060.4 57.1 Btu (by ) lb J M 4lb Wk12 wk12 M 4 57.1 228.4 Btu (by) J J 1. One pound of air (consider here a perfect gas ) with an initial temperature of 200F is allowed to expand without flow between pressures of 90 and 15 psia. Which of the three processes, pv = c, pvk = c or pv1.5 = c will produce the maximum work with minimum heat supplied. P1 = 359 kPa abs T1 = 326 K R = 287 J/kg.K (A) V P1 = 90 psia P2 = 15 psia T1 = 660R Process 1-2 isentropic(reversible adiabatic, n = k ) 1 – 2’ isothermal ( T = C, n = 1.0) 1 – 2” polytropic , n = 1.5 Work Done: (A) Work Isothermal Process: w k12' RT1 P1 53.3(660) 90 Btu ln ln 81 lb J J P 778 15 2 (B) Work Isentropic Process: k 1 1.4 1 T2 P2 k 15 1.4 T2 660 396R T1 P1 90 Wk12 P2V2 P1V1 R(T2 T1 ) 53.3(396 660) Btu = 45.2 J J(1 k ) J(1 k ) 778(1 1.4) lb (C) Work Polytropic Process: n = 1.5 n 1 n 1.5 1 1.0 P 15 T2 ' T1 ' 2 660 363R P 90 1 Wk12 P2 ' V2 ' P1 ' V1 ' R(T2 ' T1 ') 53.3(363 660) Btu = 40.7 J J(1 n) J(1 n) 778(1 1.5) lb Heat Transfer: (A) Isothermal Process: wk12 ' 0 81 Btu/lb 81 Btu/lb J (B) Isentropic Process: q12 u2 ' u1 ' q 0(by definition) (C) PolytropicProcess: wk12 ' w ' C v T2 ' T1 k12 J J = 0.171 363 360 40.7 q12 ' u2 ' u1 ' = 50.8 40.7 = (-)10.1 Btu/lb 2. One kilogram of a perfect gas (air) is used as a working substance in a Carnot power cycle. At the beginning of isentropic compression, the temperature is 326K and the absolute pressure is 359 kPa. The absolute pressure at the end of the isentropic compression is 1373 kPa. For this cycle, the isothermal expansion ratio (v3/v2) is 2.0. For the cycle, calculate : (A) The pressures, temperatures and specific volumes at each process termination point. (B) The heat supplied, kJ/kg (C) The heat rejected, kJ/kg (D) The net work done by the T-s and p-v area method (E) The thermal efficiency, % P2 = 1373 Kpa V3/V2 = 2.0 RT1 (287)(326) 0.2606 m3 /kg P1 359 x 103 T2 P2 T1 P1 k 1 k 1.4 1 1373 1.4 T2 326 478.3K 359 R(T2 ) 287 (478.3) V2 0.100 m3 /kg P2 1373 (103 ) V 1 P3 P2 2 1373 686.5kPa(abs) 2 V3 T3 T2 478.3K V3 2V2 2 0.100 0.200 m3 / kg T4 = T1 = 326 K k 1.4 T k 1 326 1.4 1 P4 = P4 4 686.5 179.5 kPa T 478.3 3 287 (326) 0.5212 m3 /kg R(T4 ) V4 P4 179.5 (103 ) V (B) qs = P2 V2 ln 3 = 1373 0.100 ln 2 = 95.17 kJ/kg V2 V 0.5212 (C) qR = P4 V4 ln 4 = 179.5 0.5212 ln = 64.85 kJ/kg 0.2606 V1 (E) w k(net) qs qR 95.17 64.85 = 30.32 kJ/kg 3. Calculate the available energy in Btu/lb for a Carnot cycle with a source temperature of 3460R, a sink temperature of 520R and an energy supply as heat of 100 Btu to one pound of a working substance. Then calculate the reduction of available energy, Btu/lb, for a similar Carnot cycle in which all conditions remain the same as before except that the working substance is limited to a maximum temperature of 1960R. T1 = 3460 R T1’ = 1960 R To = 520R Qs = 100 Btu/lb (aBCb or aB’C’c) For the heat addition process B-C: q q 100 Btu ds and sC sB s 0.0289 T T1 3460 lb.R Unavailable Energy = To S BC 520 0.0289 = 15 A.E. qs To S 100 15 = 85 Btu/lb Btu lb In this non-flow system the non-flow energy equation will apply to each phase of the liquid involved. By writing the equation separately for each fluid and equating through the heat transferred terms, a heat balance is formed. From :Equation: qs qR T1 To T q and 1 - R 1 o qs T1 qs T1 T 520 qR qs o 100 15 Btu/lb 3460 T1 wk qs qR 100 15 85 Btu/lb J for 100 Btu supplied to one pound of substance at 1960R rather than 3460R: q 100 Sc ' SB ' s 0.0510 Btu/lb.R T1 ' 1960 Unavailable energy = To S B ' C ' = 520(0.0510) = 26.5 Btu/lb A. ) Ms h1 ' h2 Mw h2 h1 (1)(1150.5 - h2 ) 9(h2 28.08) h2 = 140.32 Btu/lb Reduction in A.E. = 85 - 73.5 = 11.5 Btu/lb t2 = 172.4F 4. Using the same source and receiver temperatures as in the above example (3460 R and 520R ) , assume first that 100 Btu of energy as heat supplied reversibly to a cycle such as a34b and 3460R. The entropy change for heat addition is: B.) 1 (s2 s1 ') 0.25113 1.7567 1.5056 Btu/R 6. In an ideal steam cycle, heat is added at a constant pressure of 200 psia. Water entering the boiler has an entropy of 0.0555 Btu/lb.R, and steam leaving the superheater has an entropy of 1.7395 Btu/lb.R. Superheated steam temperature is 1500F, and heat added is 1744.5 Btu/lb ( equals h2 – h1 ). Heat rejection is carried out in a condenser at a constant temperature of 60F. Average temperature of the combustion gases in the boiler furnace is 300F. Calculate: A. The available energy of combustion gases with respect to the sink temperature of 520R, Btu/lb B. The available energy of an ideal cycle receiving its energy at the constant source temperature equal to the superheated steam temperature, Btu/lb C. The available energy of the ideal steam cycle, Btu/lb D. The mean effective temperature of the working substance during heat receipt in the original steam cycle, degree F S4 S3 Q34 100 0.0289 Btu/lb.R T3 3460 C.) 9 (s2 s1 ) 9(0.25113 0.05555) 1.7602 Btu/lb D.) Net entropy change for system = (+) 1.7602 - 1.5056 = (+) 0.2546 Btu/R s1 = s4 = 0.0555 Btu/lb.R s2 = s3 = 1.7395 Btu/lb.R P2 = P1 = 2000 psia t2 = 1500F t3 = t4 = 60F t2’ = combustion temperature = 3000 F qs = 1744.5 Btu/lb From the diagram it is clear that (SB – S1 ) = (S4 – S3). Therefore, the unavailable portion of Qs is: U.A.E. = T1 (SB – S1) = 520 ( 0.0289) = 15 Btu Now assume the same quantity of heat is added reversibly, but at a constant temperature of 1960R. The resulting cycle are is represented by a26c on the figure, and the change in entropy is: S6 S2 Qs 100 0.0501 Btu/lb.R T2 1960 The unavailable portion, as determined by To(S) is: U.A.E. = T1 ( S7 – S1 ) = T1 (S6 – S2) = 520 ( 0.0510) = 26.5 5. In a perfectly insulated cylinder and piston arrangement, 1 pound of saturated steam at 212F is to be mixed with 9 pounds of water at 60F. The entire heat exchange process is to take place at standard atmospheric pressure. Calculate the following: A. B. C. D. The final temperature of the mixture: The change in entropy of steam, Btu/R. The change of entropy of the water, Btu/R The net change of entropy of the system, Btu/R 1. The first stage of a 50% reaction groups receives steam with a negligible approach velocity at a pressure of 300 psia with a temperature of 520F. The available energy to the stage is 10 Btu/lb, the fixed blade efficiency is 96%, the velocity coefficient for the moving row is 0.88, the reactive effectiveness is 90%, and the relative inlet and absolute exit velocities are 146 ft/s and 160 ft/s, respectively. Assume the stage efficiency is the same as the combined blade efficiency and calculate the following: (A) (B) (C) (D) (E) The steam velocity leaving the fixed blades, ft/s The relative exit velocity from the moving blades, ft/s The stage work, Btu/lb The combined blade efficiency, % The enthalpy of the steam entering the succeeding stage, Btu/lb for complete velocity carryover P0 = 300 psia t o = 520°F (AE)st 10 Btu/lb en = 0.96 ; Cm = 0.88 ; eR = 0.90 Vr1 146 ft/s V2 = 160 ft/s (A) AE n AE R Cm Vr2 2 2gc J = 2gc J Cm Vr1 Vr2 2 2 = eR AE R r1=1.625 in.; 2g c J eR AE R 2 492 ft/s (C) wk J = V 2 1 - V2 2 + Vr2 2 - Vr12 490 - 160 + 492 - 146 = 8.69 Btu/lb 2 2 2 32.2 778 Btu/lb h2 = 26 Btu hrg ft 2 g°F k tube = 26; k scale = 0.6 Btu hrg ftg°F (A) For clean tube: r r 1 1 3 2 r2 rt h2 h1 kt r3 r3 1 0.375 1 2.0 2.1875 26 1700 2.375 12 26 2.375 0.0007 0.0013 0.0385 0.0405 1 U 24.69 Btu hr ft 2 F external area 0.0405 (C ) For tube and scale (R' = resistance/ft 2 area): L 1 R'scale R'1 rS r1 k h1 r3 r3 0.375 1 0.0691 1.8125 1.625 12 0.6 2.375 1700 2.375 0.0691 0.0013 0.0385 0.1089 R'total U 1 1 9.18 Btu hr ft 2 F R 'total 0.1089 (D) For clean tube: h0 1269.4 Btu lb ; wk st J wk st (B) st h1= 1700; 1 U 2. To illustrate the effect of tip leakage, it is assumed that 5 percent of the steam supplied to the stage of the above example, flows past the stage without performing useful work. Assume there are no other stage losses and calculate: A. the stage work, Btu/lb B. the stage efficiency, % C. the reheat due to leakage, Btu/lb D. the actual enthalpy entering the succeeding stage for complete velocity carryover, Btu/lb J r3 = 2.375 in t water = 500° F 2 w k st 8.69 (D) ecb = = = 0.869 = 86.9% J A.E.st 10 w k st v 2 2 h 2 = ho J A.E.st 2g c J 2 160 h2 = 1269.4 - 8.7 1260.2 2 32.2 778 ( A) r2 = 2.0 in.; t gas = 2100° F; L rt = r2 + = 2.0 + 0.1875 = 2.1875 in. 2 L rS = r1 + = 1.625 + 0.1875 = 1.8175 in. 2 2gc J 2 = 1. 2. 3. 4. 5. 6. 7. 8. = 490 ft/s 0.88 146 2 32.2 778 0.90 5 the overall coefficient of heat transfer for the clean tube, Btu/hr·ft2·°F; (B) the overall heat transfer coefficient including the effect of the scale, Btu/hr·ft2·°F, and (C) the external tube surface temperature before and after the scale has formed. 10 5 Btu/lb 2 2 32.2 778 0.96 5 Vr2 2 (A) 2gc J en AE n V1 (B) AE st 3. The internal diameter of a boiler generating tube is 4 in. and the wall thickness is 0.375 in. In operation the external surface film coefficient is 26 Btu/hr·ft2·°F, the internal film coefficient is 1700 Btu/hr·ft2·°F and a 0.375 in. thickness scale having a conductivity of 0.6 Btu/hr·ft2·°F is deposited on the inner surface of the tube. The metal conductivity is 26 Btu/hr·ft2·°F, the furnace gas temperature is 2100° F and the temperature of the water is 500° F. Calculate: A.E.st 8.69 Btu lb ; 10 Btu lb h2 1260 Btu lb 0.95 8.69 8.26 Btu lb wk st J A.E.st 8.26 82.6% 10 (C ) leakage reheat 8.69 8.26 0.43 Btu lb (D) hx 1260.2 0.43 1260.6 Btu lb R '2 0.0385 t t1 t2 2100 500 1521 F 0.0405 R 'total tube surface temperature 2100 1521 579 F For tube with scale: R '2 0.0385 t t1 t2 2100 500 566 F R ' 0.1089 total t surface of tube = 2100 566 1534 F 4. A steam condenser with a net heat transfer area of 23,500 ft 2 has a design value of U of 486 Btu/hr·ft2·°F for a log mean temperature difference of 32.4 and a design operating pressure of 2.5 in. Hg abs. The water consumption at rated capacity is not to exceed 40,500 gpm with a temperature rise of 18.3°F. Measured temperatures of fresh water at this flow rate during an acceptance test were 71.5°F and 90°F at entrance and exit, respectively, and the average condenser pressure was 2.45 in. Hg abs. Assuming no subcooling of the condensate, calculate the overall heat transfer coefficient established by the acceptance test, and compare this with the manufacturer’s design value given above. 6. The following is an ultimate analysis of a typical naval fuel oil, ash and moisture free: Carbon = 0.8663 lb Hygrogen = 0.1127 lb Oxygen = 0.0019 lb Nitrogen = 0.0028 lb Sulfur = 0.0163 lb 1.0000 lb Calculate the following for “complete” or “theoretical” combustion with air, in pounds per pound of fuel: A. B. C. D. E. F. oxygen required from air nitrogen required from air air required water formed from combustion carbon dioxide formed total mass of flue gases Fuel constituents pounds per pound Twater (entering) = 71.5° F; tleaving = 90° F Psteam = 2.45 in. Hg abs water quantity = 40,500 gpm Anet = 23,500 ft2 m’ = (40,500)(8.34)(60) = 20.27 x 106 lb/hr Q 20.27 106 C = 0.8663 H = 0.1127 O = 0.0019 N = 0.0028 S = 0.0163 1 90 71.5 375 10 6 Btu hr 36.5 18 26.2 F 36.5 ln 18 m A. B. U Q 375 106 609 Btu hr ft 2 F A m 23, 500 26.2 C. t1 in = 266° C; t3 in = 593° C; Ma’ = 1.8 kg/sec Ma’ = 1.88 kg/sec t2 out = ?; t4 out = 310° C; (A) Q M g c pg t g 1.88 kg s 1090 J kg C 283 C 579.92 kJ s M a c pa t a M g c pg t g (B) Q a Q g ; M a c pa t2 t1 a M g c pg t3 t4 g t2 t1 Q M a c pa 266 579920 586.6 C 1.8 1005 2 t4 t1 t3 t2 (C) m 1 t t1 ln 1 ln 4 2 t3 t2 310 266 593 586.6 44 ln 6.4 19.5 C 0.8663(2.667) = 2.3104 0.1127(8.000) = 0.9016 reduces external O2 = -0.0019 inert = 0.0000 0.0163(1.00) = 0.0163 lb O2 required from air = 3.2264 oxygen required = 3.2264 lb/lb fuel nitrogen from air = 3.2264 (0.768/0.232) = 10.6805 lb N2/lb fuel air required = 3.2264 + 10.6805 = 13.9069 lb air/lb fuel Element + Oxygen = Combustion product C 0.8663 + 2.3104 = 3.1767 lb CO2/lb fuel H 0.1127 + 0.9016 = 1.0143 lb H2O/lb fuel O 0.0019 + --------- = -----------------------------N 0.0028 + 0.0000 = 0.0028 lb N2/lb fuel S 0.0163 + 0.0163 = 0.0326 lb SO2/lb fuel Σ = 4.2264 lb combustion products per lb fuel 5. An exhaust gas regenerator (counter-flow heat exchanger) for a marine gas turbine handles 1.8 kg kg/sec of air from its compressor and heats it by means of 1.88 kg/sec of hot exhaust gas. Exhaust gas enters the regenerator at 593° C and leaves at 310° C. Compressed air enters the regenerator at 266° C. For this temperature range a constant pressure specific heat for the exhaust gas may be estimated at 1090 J/kg·C. Assume no heat transfer other than between the regenerator fluids. Calculate: A. the energy exchanged as heat by the two fluids, kJ/sec B. the air temperature leaving the generator, C C. the log mean temperature difference for the exchanger, C Pounds of O2 required from air per pound of fuel constituent D. E. F. water from combustion = 1.0143 lb/lb fuel carbon dioxide formed = 3.1767 lb/lb fuel total mass of flue gases = 4.2264 + 10.6805 = 14.9069 lb/lb fuel 7. Calculate the following quantities in pounds per pound of fuel for combustion with 50 percent excess air using the same fuel analysis as in the example of the preceding article: A. oxygen supplied from air B. nitrogen accompanying oxygen C. air supplied D. water formed from combustion E. carbon dioxide formed F. total mass of flue gases Fuel constituents Pounds of O2 required from per pound of fuel C = 0.8663 H = 0.1127 O = 0.0019 0.8663(2.667) = 2.3104 0.1127(8.000) = 0.9016 reduces external O2 = -0.0019 N = 0.0028 S = 0.0163 1.0000 0.0163(1.00) = 0.0163 3.2264 A. oxygen supplied with 50% excess air = 1.5(3.2264) = 4.8396 lb/lb fuel B. nitrogen from air = 4.8396(0.768/0.232) = 16.0207 lb/lb fuel C. air supplied = 4.8396 + 16.0207 = 20.8603 lb/lb fuel Element + Oxygen = Combustion product C 0.8663 + 2.3104 = 3.1767 lb CO2 H 0.1127 + 0.9016 = 1.0143 lb H2O O 0.0019 + (Appears = 1.6132 lb O2 (Excess O2 = 0.5 x 3.2264) with other constituents) N 0.0028 + 0.0000 = 0.0028 lb N2/lb fuel S 0.0163 + 0.0163 = 0.0326 lb SO2/lb fuel Σ = 4.2264 lb combustion products per lb fuel D. water formed = 1.0143 lb/lb fuel E. carbon dioxide formed = 3.1767 lb/lb fuel F. total mass of flue gases = 5.8396 + 16.0207 = 21.8603 lb flue gases/lb fuel 8. An analysis of the flue gases of a combustion process, percent by volume, is as follows: CO2 = 10.0%; CO =2.0%; O2 = 8.0%; N2 = 80.0% Mols of Constituent per mol of flue gas Mol wt. Mass per mol flue gas CO2 0.11 44 = 4.84 CO 0.02 28 = 0.56 O2 0.045 32 = 1.44 N2 0.825 28 = 22.40 = 29.94 Percent mass 4.84 = 16.17% 29.94 0.56 = 1.87 % 29.94 1.44 = 4.81% 29.94 23.10 = 77.15% 29.94 =100.00% (A) mass of dry flue gas per lb of fuel: CF 0.8700 lb gas 16.69 12 12 12 12 lb fuel CO2 CO 0.1617 0.0187 44 28 44 28 (B) mass of air actually supplied: MG = N2 0.7715 0.768 CF 0.768 0.8700 lb air MA 16.77 12 12 12 12 lb fuel CO2 + CO 0.1617 0.0187 44 28 44 28 (C) air required for ideal combustion of one pound of fuel: carbon 0.8700(11.49) = 9.9963 lb of air for carbon hydrogen 0.1200(34.48) = 4.1376 lb air for hydrogen sulfur 0.0020(4.31) = 0.0086 lb air for sulfur 14.1425 total air required, lb Since the fuel contains 0.006 pound of oxygen, assume the hydrogen combines with it and reduces the external oxygen required: lb O2 lb air 4.1376 4.1376 0.006 4.31 lb fuel lb O2 4.1117 lb air for hydrogen Consti tuent Volume fraction CO2 0.10 mols CO2 lb CO2 lb 44 = 4.40 mol gas mol mol gas 4.40 = 14.71 29.92 CO 0.02 mols CO lb lb CO 28 = 0.56 mol gas mol mol gas 0.56 = 1.87 29.92 O2 0.08 mols O2 lb O2 lb 32 = 2.56 mol gas mol mol gas 2.56 = 8.56 29.92 N2 0.80 mols N2 lb N2 lb 28 = 22.40 mol gas mol mol gas 22.40 = 74.86 29.92 Mol wt. = 29.92 Percent mass of constituent lb gas mol gas Apparent molecular weight o f gas mixture = 29.92 R for the mixture = =100.00 lb gas mol gas 1545 ft lbf 51.64 29.92 lb°R A fuel oil has the following analysis on an ash-and-moisture-free basis and yields, on burning, the following Orsat analysis: Fuel analysis, lb/lb fuel C = 0.8700 H = 0.1200 N = 0.0020 S = 0.0020 O = 0.0060 Orsat Analysis CO2 = 11.0 % CO = 2.0 % O2 = 4.5 % N2 = 4.5 % Calculate: A. the mass of dry flue gas, lb/lb fuel B. the mass of air actually supplied, lb/lb fuel C. the air required for ideal combustion, lb/lb fuel D. the percent excess air supplied Then, ideal combustion of one pound of fuel requires 14.1425 0.0259 14.1166 lb air/lb fuel (D) % excess air: 16.77 14.12 18.8% 14.12 The following data were observed during an oil-fired boiler test: 1. Duration of test 1 hr 2. Steam delivered by boiler 200,000 lb 3. Average steam temperature at superheater outlet 760° F 4. Average steam pressure at superheater outlet 600 psia 5. Feed water temperature 240° F 6. Feed water pressure 700 psia 7. Fuel fired (dry basis) 15,385 lb 8. Flue gas temperature leaving last heat transfer passage 450° F 9. Dry bulb temperature of air supplied for combustion 80° F 10. Wet bulb temperature of air supplied for combustion 70° F 11. Barometric pressure at test location 29.92 in. Hg 12. Temperature of fuel supplied to burners 80° F 13. Ultimate analysis of fuel on an as-fired basis: Carbon 0.8095 lb/lb fuel Hydrogen 0.1143 lb/lb fuel Nitrogen 0.0048 lb/lb fuel Sulfur 0.0143 lb/lb fuel Oxygen 0.0095 lb/lb fuel Moisture 0.0476 lb/lb fuel Ash 0.0000 lb/lb fuel 1.0000 lb fuel 14. Volume analysis of flue gases in percent (Orsat): CO2 = 11.34% CO = 00.71% O2 = 5.06% N2 = 82.89% 100.00% 15. Higher heating value of fuel is 19,500 Btu/lb “dry” fuel. Calculate an energy balance for the tested boiler. As-fired basis Carbon 0.8095 Hydrogen 0.1143 Nitrogen 0.0048 Sulfur 0.0143 Oxygen 0.0095 Moisture 0.0476 ÷ (1 – 0.0476) = Dry basis 0.8500 lb/lb 0.1200 lb/lb 0.0050 lb/lb 0.0150 lb/lb 0.0100 lb/lb 1.000 Flue Gas Analysis: Percent volume dry Mol wt. Pounds per 100 mols gas CO2 = 11.34 44 = 498.96 CO = 0.71 28 = 19.88 O2 = 5.06 32 = 161.92 N2 = 82.89 28 = 2320.92 = 3001.68 Percent mass 498.96 = 16.62 3001.68 19.88 = 0.66 3001.68 161.92 = 5.40 3001.68 2320.92 = 77.32 3001.68 =100.00 (17.1) A boiler consumes 16,800 pounds of feul/hr when producing 210,000 lb of steam per hour at 620 psia and 800 deg F from feed water at 650 psia and 800F from feed water at 650 psia and 300F. The heating value of fuel is 18,500 Btu/lb and the furnace volume is 1250 ft3 . Calculate : (A) (B) (C) (D) The boiler Capacity (in mB/hr) Ans: 238.6 mB/hr The factor of evaporation Ans: 245,700 lb/hr The equivalent evaporation Ans: 1.17 The furnace heat-release rate, Btu/hr.ft3 Ans: 248,600 Btu/hr,ft3 (E) The boiler efficiency, % Ans: 76.8% Energy balance: (1) Energy absorbed by water and steam in boiler, Btu per pound of dry fuel: Q1 MS h2 h1 200, 000 1385.1 209.9 * 15, 385 = 13 1175.2 15, 277.6 Btu lb fuel (dry) * where h2 at 600 psia and 760 F = 1385.1 Btu lb h3 at 700 psia and 240 F = 209.9 Btu/lb (2) Energy loss to dry flue gases, Btu per pound dry fuel: Q2 MG c p t2 t1 17.65 0.24 450 80 1567.32 Btu/lb dry fuel CF 0.8500 12 12 12 12 CO2 + CO 0.1662 0.0066 44 28 44 28 = 17.65 lb dry gas/lb fuel where MG c p 0.24 (average specific heat of flue gases) t1 entering air temperature = 80 F t2 leaving flue gas temperature = 450 F (3) Energy loss due to moisture from burning hydrogen, Btu per pound (17.2) A fuel oil has the following ultimate analysis ash and moisture free: Carbon = 0.85 lb Hydrogen = 0.14 lb Oxygen = 0.00 lb Nitrogen = 0.01 lb Sulfur = 0.01 lb 1.00 lb For complete combustion with air, calculate the following in pounds per pound of fuel: (A) Oxygen required from air Ans: 3.32 (B) Nitrogen accompanying oxygen from air Ans: 10.98 (C) Air required Ans: 14.30 (D) Water formed from combustion of hydrogen Ans: 1.176 (E) Carbon dioxide formed Ans: 3.23 (F) Total mass of flue gases Ans: 15.30 of dry fuel: 9 12 9H h4 h3 100 1265.0 48.1 100 = 1314.25 Btu/lb dry fuel Q3 where H = percent hydrogen in 1 lb dry fuel h4 = 1265.0 (Table 3, Steam Tables at 1 psia and 450 F) h3 = hf at 80 F = 48.1 Btu/lb (4) Energy loss to moisture accompanying one pound dry fuel: Q4 MM 0.0476 h h3 1 0.0476 1265.0 48.1 1 MM 4 = 0.05 1216.9 60.85 Btu/lb dry fuel In spite of calculating on the dry fuel basis, account must be taken of the moisture (16.2) Air at 45F (DB) and 41F (WB) is heated and humidified to 72F (DB) and 59F (WB). To what temperature should the air be heated before humidification? Ans: 64F (16.3) Air is to be conditioned from td = 39F and = 80% to td = 74F and = 70%. (A) To what temperature should the air be heated before humidifying F? Ans:102.5F (B) How much moisture in grains is added during humidification ? Ans: 61 grains/lbda accompanying the fuel as fired: MM mass of moisture in 1 lb of fuel as received = 0.0476 lb MM 0.05 lb of moisture/lb dry fuel 1 MM (5) Energy loss to moisture in air supplied for combustion: Q5 M A MW h4 h5 17.77 0.0134 1265.0 1096.6 = 40.1 Btu/lb dry fuel 0.7732 N2 0.8500 CF 0.768 0.768 where MA 12 12 12 12 CO2 CO 0.1662 28 0.0066 44 28 44 = 17.77 lb air supplied/lb dry fuel N2 , CO2 , CO = percents by mass in flue gases MW = 0.0134 lb moisture/lb dry air (from psychrometric chart at 80 F dry bulb and 70 F wet bulb) (15.1) It is desired to produce a mixture of helium and hydrogen which will have a specific heat of 1.0 Btu/lb.F at constant volume . What must be the volumetric percentage of helium? Gas Cv Helium 0.750 Hydrogen 2.440 Ans: 74.2% (15.2) A gaseous mixture has the following mass analysis:H2 , 10%; CO2 , 5% ; N2 , 85%, Cp for common gases at room temperature : O2, 0.217; H2 3.42; N2, 0.247; CO, 0.243; CO2, 0.205. Find the: (A) specific heat at constant pressure, Ans: 0.562 Btu/lb.F h5 1096.6 Btu/lb (enthalpy of superheated steam at 80 F, read most easily from Mollier Chart; partial pressure has relatively small effect on enthalpy at this temperature evidenced by practically horizontal 80 F line on chart) (6) Energy loss to incomplete combustion, Btu per pound of dry fuel: CO Q6 CF 10,100 CO2 CO 0.71 = 0.85 10,100 505.84 Btu/lb dry fuel 11.34 0.71 CO2 , CO = volume percentages from Orsat analysis of flue gases CF 0.8500 lb carbon/lb dry fuel 10,100 = Btu loss/lb of carbon burned to CO rather than to CO2 (7) Energy loss to radiation and unaccounted-for losses: Q7 H.H.V . (Q1 Q2 Q3 Q4 Q5 Q6 ) 19, 500 15, 277.6 1567.3 1314.3 60.8 40.1 505.8 19, 500 18, 765.9 734.1 Btu/lb dry fuel (B) volumetric analysis, % H2 = 61.4%,CO2 =1.4%,N2 = 37.2% (C) Partial pressure of N2 is psia if the barometer is standard and the mixture is at barometric pressure: Ans: 5.47 psia (15.3) A tank contains air at 50 psia. Air maybe assumed to consist of 79.1 percent of N2 and 20.9% O2 by volume. Calculate: (A) the partial pressure due to the oxygen, Ans:10.45 psia (B) the partial pressure due to the nitrogen, psia. Ans: 39.55 psia (15.4) A mass analysis of gases in a compartment shows the following: O2 , 20 lb; N2 , 140 lb; CO2 , 15 lb; H2O, 4 lb. Find the volumetric analysis of the gases, %. . Ans. O2 = 10.10% ; N2 = 80.81 %; CO2 = 5.50 % ; H2O = 3.59% (15.6) Given, for atmospheric air: temperature, 82F; barometric pressure, 29.92 in. Hg; partial pressure of water vapor , 0.3632 psia. What is the dew point temperature? . Ans. 70 F (15.7) A room 14 ft x 16 ft x 10 ft contains atmospheric air at 72F. The partial pressure of the water vapor in air is 0.2140 psia. Barometer is standard. Calculate : (A) the mass of dry air in the room, lb; Ans: 164.7 lb (B) the mass of water vapor in the room Ans: 1.51 lb (C) the dew point temperature Ans: 55F . (15.13) For atmospheric air, given: dry bulb temperature, 85F ; wet bulb temperature , 70F; barometer , standard. The air cooled at constant pressure to 50F. Using psychrometric chart, calculate: (A) the water vapor condensed Ans: 32 grains (B) the heat rejected Ans: 13.7 Btu/lbda (14.1) A heat exchanger receives oil having specific heat of 0.45 Btu/lb and a temperature of 160F at the rate of 40,000 lb/hr. Fresh water at an initial temperature of 160F at the rate of 40,000 lb/hr. Fresh water at an initial temperature of 60F flows through the apparatus at the rate of 120,000 lb/hr. Assume unlimited heat transfer area and calculate : (A) the common temperature which the fluids will reach under parallel flow, F. Ans: 73F (B) the heat transferred by the heat exchanger Ans:1,560,000 Btu/hr (14.3) Calculate the heat transfer area required by a parallel flow oil cooler which removes 1,524,000 Btu/hr from the oil while cooling it from 160F at inlet to 75F at discharge, when the cooling water temperatures are 60F and 72.7F, respectively. U for the heater is 52 Btu/hr-ft2.F. Ans: 1132 ft2 (13.1) Calculate the rate of heat flow, in Btu/hr, through a 10-in wall of solid concrete which is 20 ft long by 8 ft high. The thermal conductivity of concrete is 0.10 Btu/hr.ft.F, the external surface temperature is 5F and the internal surface temperature is 45F. Ans: 7680 Btu/hr (13.2) For the wall of the previous problem , the outside film coefficient is 6.0 and the inside is 1.5 Btu/hr.ft 2.F, the outside air temperature is - 3F and the inside air temperature is 77F. Calculate (A) the overall heat transfer coefficient, Btu/hr.ft 2.F Ans: 0.60 Btu/hr.ft2 (B) the rate of heat flow through the wall Ans: 7680 Btu/hr (12.1) In a simple impulse stage, the blade speed is 150 m/s and the nozzle angle is 18 degrees. The velocity of the steam leaving the nozzle is 320 m/s. The bucket entrance and exit angles are both 33 degrees. The bucket velocity coefficient is 0.89. Find the: (A) relative velocity of entering the buckets; Ans: 184 m/s (B) relative velocity of leaving the buckets Ans: 163.8 m/s (C) total change of velocity relative to and in the direction of motion of the buckets; Ans: 291.7 m/s (D) the bucket work, kJ/kg Ans: 43.75 kJ/kg (E) the absolute exit velocity Ans: 90.1 m/s (12.2) Steam enters the buckets of a simple impulse wheel at an absolute velocity of 1200 ft/s and leaves with an absolute velocity of 245 ft/s. The relative entering velocity is 640 ft/s, and the relative exit velocity if 540 ft/s. Determine: (A) available energy to the buckets Ans: 22,360 ft-lbf/lb (B) the bucket loss , ft-lb/lb Ans: 1830 ft-lb/lb (C) the unused kinetic energy in the leaving jet Ans: 930 ft-lb/ft (D) the bucket work Ans: 19,600 ft-lb/lb and 25.2 Btu/lb (E) the diagram efficiency Ans: 87.7% (F) Power developed by the bucket s if steam is supplied at the rate of 5000 lb/hr Ans: 49.5 hp (12.3) Steam enters the nozzles of a simple stage with negligible velocity of 190 psia and 500 F. The velocity of the steam leaving the nozzles is 1175 ft/s, and the stage pressure is 140 psia. The steam leaves the bucket s with an absolute velocity of 300 ft/s and an enthalpy of 1245.5 Btu/lb. Assume the stage efficiency is equal to the nozzle-bucket efficiency and that there is negligible velocity carryover to the next stage. Find : (A) the available energy to the stage, Btu/lb Ans: 29.8 Btu/lb (B) the nozzle efficiency Ans: 92.5% (C) the nozzle reheat Ans: 2.2 Btu/lb (C) the blade reheat Ans: 3.2 Btu/lb (D) the exit reheat Ans: 1.8 Btu/lb (E) the enthalpy of steam entering the next stage Ans: 1247.3 Btu/lb (F) the stage work Ans: 1247.3 Btu/lb (G) the diagram efficiency of the buckets Ans: 82% (H) the nozzle-bucket efficiency. Ans: 75.8% (12.5) In a 50% reaction stage, the carryover velocity from the preceding stage is 55 m/s, the stage available energy is 50 kJ/kg, the fixed blade (nozzle) efficiency is 0.94 and the fixed blade velocity coefficient is 0.90. Find the velocity of the steam leaving the fixed blades, m/s. Answer: 222.4 m/s (12.6) In the turbine stage with 30% reaction, the steam enters the moving blades with relative velocity of 350 ft/s , the stage available energy is 25 Btu/lb, the reactive effectiveness is 0.90 and the moving blade velocity coefficient is 0.92. Find the relative velocity of the steam leaving the moving blades, ft/s. Answer: 665 m/s (12.7) Steam enters a 50% reaction stage in a low pressure turbine with negligible carryover velocity at 12 psia and a moisture content of 0.06. The steam leaves the fixed blades with a velocity of 670 ft/s. The relative velocities entering and leaving the moving blades are 230 ft/s and 670 ft/s respectively. The steam at exit from the moving blades has an absolute velocity of 230 ft/s and a pressure of 9.0 psia. Assume the combined blade efficiency and the stage efficiency are equal and find the (A) stage work Ans: 15.8 Btu/lb (B) the available energy to the stage Ans: 19.2 Btu/lb (C) the combined blade efficiency Ans: 82.3% (12.8) The rotative speed of a high pressure turbine at full power is 6000 rpm. The first stage is of the simple impulse configuration, and the nozzles receive steam at 900 pisa and 900F with negligible velocity. The pitch diameter of the first stage buckets is 30 inches and the nozzle angle is 17 degrees. Find these conditions (A) Blade speed Ans: 785 ft/s (B) The ideal blade speed-steam speed ratio Ans: 0.478 (C) The corresponding absolute (“sprouting”) Velocity of the steam leaving the nozzles Ans: 1642 ft/s (D) The enthalpy drop across the nozzles assuming an isentropic process. Ans: 53.8 Btu/lb (E) The entropy and enthalpy of the steam leaving the nozzles and its estimated pressure and temperature from the Mollier Chart. Ans: S = 1.6257 Btu/lb Ans: h = 1398.1 Btu/lb Ans: P = 620 psia Ans: T = 790F (8.15) A split-shaft gas turbine has its power unit receiving 140 lb/s combustion products at 45 psia and 1600 R. Exhaust temperature and pressure for the power turbine are 1245R and 0.20 in Hg gauge. Barometric pressure is 29 in. Hg absolute, while the ambient temperature is 59F. Using air tables determine: (A) isentropic turbine outlet temperature, R Ans: 1194R (B) the isentropic turbine work, Btu/lb Ans: 106 Btu/lb (C) the actual turbine work, Btu/lb Ans: 92.9 Btu/lb (D) the isentropic turbine efficiency, % Ans: 87.7% (E) the turbine internal power, hp Ans: 18,400 hp (8.16) A split-shaft gas turbine has its power turbine supplied with 150 lb/sec of gas at 50 psia and 1100 F and exhausts the gas from the power turbine at 16 psia and 800F, respectively. The power turbine exhaust is led through a counter-flow regenerator where the gas temperature is lowered another 40F. The compressor pressure ratio is 12, and the inlet conditions are 14.6 psia and 60F. Compressor discharge temperature is 740F. Using air tables calculate: (A) The power turbine efficiency % Ans: 74.5% (B) The compressed air temperature leaving the regenerator, F Ans: 780F (C) the regenerator effectiveness, Btu/lb Ans: 66.7% (8.17) A Brayton cycle aircraft gas turbine engine has an axial flow compressor which provides a pressure ratio of 10 to 1. Material design conditions limit the temperature of the working substance entering the turbine to 2200F. The engine is designed to handle 90 lb of air /sec at static conditions and 120 lb/sec at a flight speed of 400 knots when sea level ambient pressure and temperature are 15 psia and 530R, respectively. Estimate: (A) the sea level static thrust, lbf Ans: 7300 lbf (B) the thrust , lbf Ans: 7559 lbf (C) the propulsive efficiency, % for a flight speed of 400 knots at sea level . (1 knot = 1.69 ft/s) Ans: 40% (E) (8.17) A Brayton cycle aircraft gas turbine engine has an axial flow compressor which provides a pressure ratio of 12 to 1. Material design conditions limit the temperature of the working substance entering the turbine to 2000F. The engine is designed to handle 90 lb of air /sec at static conditions and 120 lb/sec at a flight speed of 500 knots when sea level ambient pressure and temperature are 15 psia and 530R, respectively. Estimate: (A) the sea level static thrust, lbf Ans: 6635 lbf (B) the thrust , lbf Ans: 6045 lbf (C) the propulsive efficiency, % Ans: 51% (D) cycle thermal efficiency , % for a flight speed of 500 knots at sea level . (1 knot = 1.69 ft/s) Ans: 55.8% Ans: 9180 lbf Ans: 44.5% hg - h2 ' m2 ' = hfg 1174.4 1085.9 9.58% 924.2 2 '= g m2 'fg 8.518 0.0958(8.501) 7.704 ft 3 /lb ' dexit 4 M2 V 4(60.1)(7.704) 144 60 2727 dexit = 0.720 in. /2 When equipped for after burning, nozzle inlet temperature is limited to 2500R. Assuming all stated performance parameters remain constant, estimate: (E)the thrust, lbf and (F) the thermal efficiency, % h2 '= h1 - KE = 1234.4 - 148.5 = 1085.9 Btu/lb rexit rthroat L r - r tan = exit t L 2 r r 0.362 - 0.25 L exit t = = 1.05 in. 0.1051 tan 2 (f) A converging-diverging nozzle receives steam at a pressure of 380 psia with temperature of 480F and expands it to a pressure of 50 psia. Assuming the velocity coefficient of 0.98 for the supersaturated throat condition and an overall nozzle efficiency of 92 percent, calculate the following: A. B. The actual throat velocity , ft/s Ans: 1582 ft/s The mass rate of flow for a throat diameter of 0.50 in Ans: 60.1 lb/min C. The actual kinetic energy available at the nozzle exit Ans: 148.5 Btu/lb D. The actual nozzle exit velocity, ft/sec Ans: 2727 ft/sec E. The required nozzle exit diameter, inches and Ans: 0.720 in. F. The length of the divergent section of the nozzle, in inches, for an included angle of 12 degrees between nozzle sides. Ans: 1.05 in. From: Steam table: At P = 380 psia and temperature of 480F. h1 = 1234.4 Btu/lb S1 = 1.5220 Btu/lb.R Pt = Pc = 0.55P1 = 0.55(380) = 209 psia st(ideal) = s1 ; m = sg - s t sfg 1.5427 - 1.5220 = = 2.08% 0.9941 ht(ideal) hg mhfg 1199.9 0.0208 840.3 = 1182.4 Btu/lb (A) Vt = Cn Videal 223.38Cn h1 htideal = 223.8 0.98 1234.4 1182.4 = 1582 ft/s (B) enozzle ' = cn 2 (0.98)2 0.96 h1 - ht actual = en' h1 - hideal 0.9604(1234.4 1182.4) = 49.9Btu/lb hactual = h1 - 49.9 = 1234.4 - 49.9 = 1184.5 Btu/lb mtactual = hg - htactual 1199.9-1184.5 = =1.83% hfg 840.3 actual = g mtfg 2.194 0.0183 2.176 = 2.154 ft 3 / lb 0.1964 2 At = ft 144 A V 0.1964(1582) 60 m' = t t = = 60.1 lb/min t (144)(2.154) (C) s2ideal s1; m2 sg s2ideal sfg 1.6589 1.5220 10.97% 1.2476 h2ideal = hg - m2hfg = 1174.4 - 0.1097(92.4) = 1073.0 Btu/lb KEactual = h1- h2' = en (h1 h2 ' ) = 0.92(1234.4-1073) = 148.5 Btu/lb (D) Vactual = V2 '= 223.8 h1 - h2' = 223.8 148.5 = 2727 ft 2 11-1 Air enters an ideal converging-diverging at a pressure of 73.5 psia with temperature of 1400F and negligible approach velocity/. For isentropic expansion to an exit pressure of 14.7 psia, calculate: (A) The temperature of the air leaving the nozzle F Ans: 714F (B) The kinetic energy of the air leaving the nozzle, Btu/lb Ans: 164.6 Btu/lb (C) The velocity of the air leaving the nozzle. Ans: 2870 ft/s 11-2 The pressure of the air entering the ideal convergent nozzle is 73.5 psia, the temperature is 1400F and the velocity of approach is negligible. The nozzle discharges against a pressure of 14.7 psia. What is the nozzle exit velocity when expansion in the nozzle exit is isentropic, ft./sec? Answer: 1930 ft/sec 11-3 Air enters a convergent-divergent nozzle having stagnation conditions of 65C and 285 kPa. The Mach number of the throat is 0.77. For isentropic expansion through the nozzle, calculate: (A) The throat pressure, kPa (B) The throat temperature, K (C) The throat velocity m/s Ans: 192.5 kPa Ans: 302.2 K Ans: 268.3 m/s 11-6 Air enters a diffuser of a jet engine with a velocity of 1800 ft/s relative to the aircraft. The intake pressure is 1.05 psia and intake temperature is - 70F. Assuming isentropic compression in the diffuser, calculate: (A) The sonic velocity at the inlet condition Ans: 968 ft/s (B) The inlet mach number Ans: 1.86 (C) Stagnation temperature Ans: 659.8R (D) The stagnation pressure Ans: 6.61 psia 5-4 Steam leaves the boiler at 600 psia and 750F at the rate of 75,000 lb/hr through the main steam line, which has a cross sectional area of 0.322 ft2. Find the velocity of the steam in the lin, ft/s Answer: 73.3 ft/s 5-5 Steams leaves the boiler at 6550 kPa absolute and 510 C at the rate of 45,400 kg/hr through the main steam line, which has cross sectional area of 0.030 m2. Determine the velocity of the steam in the line ., m/sec. The specific volume of the steam is 0.0525 m3/kg. Answer: 22.1 m/sec 5-6 An air compressor takes in 50 ft3/ min of air at 14.7 psia and 60F. The air is discharged at 100 psia and 260F. Find: (A) Mass flow rate Ans: 3.82 lb/min (B) Volume flow rate at the discharge Ans: 10.18 ft3/min 5-7 Steam enters the first stage nozzles of a large turbine with negligible velocity at a pressure of 540 psia and a temperature of 800F. The pressure at the nozzle exit is 220 psia. If the process is isentropic ; find: (A) The final enthalpy Ans: 1302 Btu/lbs (B) The kinetic energy at exit Ans: 1081 Btu/lb (C) The velocity at the exit Ans: 2327 ft/s A mass of 1.0 kg is moving at a velocity of 5 m/s. Determine the kinetic enegy on a unit mass basis: A. B. m'5 = 1000 1164.3 (104,000) 218.9 (100,000) 48.1 5000 68.1 1178.7 - 218.9 m'5 = 19,566 lb/hr In SI Unit, J/kg In Engineer’s unit, ft-lb Inserting this result into the mass balance equation gives: Solution: (A) KE = m’4 = m’1 + m’3 + m’5 – m’2 V2 2gc m’4 = 100,000 + 5000 + 19,566 – 1000 1 1 N.s2 2 m2 = 5 2 = 12.5 J/kg 2 kg.m s m’4 = 123,566 lb/hr J 1.0 kg 778 ft-lbf (B) KE = 12.5 kg 2.205 lb 1055 J ft-lb f = 4.182 lbm A Rankine regenerative steam cycle employs two stages of steam extraction for feed water heating. Boiler pressure and temperature are 1200 psia and 1050 F respectively. Saturated steam at condenser pressure has a temperature of 79 F. Steam has a value of internal energy u = 1171.9 Btu/lb at a temperature of 500F and pressure of 150 psia. Determine the values of the above in their SI equivalences. Solution: Internal Energy (SI) 2.326 kJ/kg 3 u = 1171.9 Btu/lb = 2.726 x 10 kJ/kg 1.0 Btu/lb Pressure (SI) 101.325 kPa 3 P = 150 psi = 1.034x10 kPa 14.7 psia The Universal Gas Constant: ft-lbf J R = 1545 8314 lbmol R kgmol .K Dearating feed water heater similar to the fig shown operates at 30 psia shell pressure with the following flow rates and properties: No 1 2 3 4 5 ITEM Condensate (liquid) Vent (Vapor) Drains (liquid) Feed ( liquid) Exhaust Steam Flow Rate (lb/hr) 100,000 1,000 5,000 ? ? Temp. (F) 80.00 250.34 100.00 250.34 280.00 Enthalpy 49.10 1164.3 68.1 218.9 1178.7 Determine the exhaust steam flow rate required to operate the heater under these conditions. What quantity of boiler feed will be available from the heater (lb/hr) ? m'h in m'h out Energy Balance m'1h1 + m'3h3 + m'5h5 = m'2h2 + m'4h4 m' in m' out Mass Balance m'1 + m'3 + m'5 = m'2 + m'4 Since m’4 is a function of m’5, a direct solution is achieved by solving the mass balance equation explicitly for m’4 and then substituting that the mass balance equation explicitly for m’5 as the only unknown, its magnitude may be determined: m’4 = m’1 + m’3 + m’5 – m’2 m'1h1 + m'3h3 + m'5h5 = m'2h2 + (m'1+m'3 +m'5 - m'2 )h4 m'5 h5 - h4 = m'2h2 + (m'1+m'3 - m'2 )h4 m'1h1 m'3h3 m5 m'2h2 (m'1+m'3 - m'2 )h4 m'1h1 m'3h3 h5 - h4 Calculate the following : (A) The optimum extraction pressures to the nearest pound per square inch. (B) The mass of steam removed from the turbine at each extraction point, pounds per pound of throttled steam (C) Pump work (Btu/lb) (D) The heat supplied to the cycle, Btu/lb (E) The heat rejected by the cycle, Btu/lb (F) The turbine work, Btu/lb throttled steam (G) The net cycle work, Btu/lb throttle steam (H) The thermal efficiency of the cycle, % In a PWR nuclear plant, the primary loop coolant water, pressurized to 2000 psia, enters the reactor at 500F and leaves at 600F. It then enters the steam generator (boiler) section at the same temperature where energy in the form of heat is transferred to the secondary loop. The secondary loop operates on simple Rankine cycle without regenerative feed heating or any external heat supply. Steam leaves the boiler at 420 psia with a moisture content of 1 % and enters the turbine at the same conditions. The condenser pressure is 2 psia. The pressure of the water leaving the feed pump and entering the steam generatot is 500 psia. The flow rate in the steam plant (secondary ) side is 500,000 lb/hr. Assuming no losses other than the pressure drop in the steam generator given above, find: (A) The required heat exchange rate in the steam generator, Btu/hr, (B) The primary coolant flow rate necessary to satisfy the heat transfer rate of part (A) (C) The heat supplied , Btu/lb (D) The heat rejected, Btu/lb (E) The thermal efficiency, % A large turbine receives steam at the throttle at 560 psia and 800F at the rate of 100 lb/sec. The pressure after the throttle is 500 psia. At the exhaust flange the absolute pressure is 1.5 in of mercury, the steam velocity is 1000 ft/sec and the moisture content is 10% . Find: A. B. C. D. E. F. G. H. The availability energy to the turbine, Btu/lb The throttling loss, Btu/lb The leaving loss, Btu/lb The enthalpy at the exhaust point, Btu/lb The internal turbine work, Btu/lb The internal engine efficiency Other internal losses not accounted for by (b) and (c) above, Btu/lb The internal power developed, hp A Rankine regenerative steam cycle employs two stages of steam extraction for feed water heating. Boiler pressure and temperature are 1200 psia and 1050F, respectively. Saturated steam at condenser pressure has a temperature of 79F. Sketch the cycle on T-S coordinates and calculate: A 60-kW auxiliary generator operates with dry saturated steam at 200 psi. It has three nozzles; one is always open, and the other two are fitted with manually operated nozzle control valves. With both nozzle control valves closed, the capacity of the machine is 30 kW. Speed control is obtained by use of a throttle valve actuated by the mechanical governor. At quarter load, the pressure in the steam chest is 115 psia when both hand valves are closed. At the same load with both hand valves open, the chest pressure becomes 62 psia referred to an exhaust pressure of 2.4 psia, find for this load condition: A. The throttling loss which must be accepted for control purposes B. The additional and unnecessary throttling loss if both hand nozzle valves are inadvertently opened. A. B. C. D. E. F. G. H. The optimum extraction pressure to the neared pound per square inch The mass of steam removed from the turbine at each extraction point, pounds of throttle steam Pump work, Btu/lb The heat supplied to the cycle, Btu/lb The heat rejected by the cycle , Btu/lb throttle steam The turbine work, Btu/lb throttle steam The net cycle work, Btu/lb throttle steam The thermal efficiency on the cycle, % Turbine A receives steam at the throttle at 850 psia and 940F and exhausts to the condenser at 0.70 psia; the throttle steam flow is 164,000 lb/hr. Turbine B receives steam at 620 psia and 900F, exhausting at 1.0 psia, and the throttle steam flow is 187,000 lb/hr. Under the stated conditions, both turbines deliver 30,000 shaft horsepower with mechanical efficiency of 96%. Find: A. The water rate, the heat rate , the shaft engine efficiency and the internal engine efficiency for the turbine A B. The same quantities for turbine B 1. A refrigerating plant for an air-conditioning system removes 10,000 Btu/min from the air. The plant circulates 170 lb of refrigerant/min and the internal power delivered by its compressor is 60 horsepower. The refrigerant evaporation temperature is 40F, and its condensation temperature is 100·F. Calculate : From: Freon table Attached :Appendix P1= P2 = 26.51 psia P3 = P4 = 107.9 psia t 2 = 14F A. the capacity of the plant, tons; B. the refrigerating effect, Btuflb; C. the coefficient of performance of the actual plant; and D . the coefficient of performance of the equivalent Carnot cycle. B. m' = C. Wnet heat absorbed(Btu/min) 10,000 = = 50 tons 200 Btu/min-ton 200 heat absorbed(Btu/min) 10, 000 B. RE = = = 58.8 Btu/lb mass of Refrigerant (lb/min) 170 D. COP = J x RE 58.8 COP = = = 3.93 Wnet 14.97 T (40 460) D. COPcarnot = L 8.33 TH -TL (100 460) (40 460) 2. A r e f r i g e r a t i n g plant circulates 23 lb Freon-12 per minute and is assumed to operate on a cycle similar to that of the figure . The pressure in the evaporator coil is 50 psia, the temperature of the Freon-12 entering the compressor is 50" F, the pressure in the condenser is 120 psia and the temperature of the liquid refrigerant entering the expansion valve is 86F. Calculate or determine: A. the evaporation temperature, • F; B. the condensation temperature, F; C. the refrigerating effect, Btu/lb; D. the capacity of the plant, tons; E. the power required to compress the Freon-12, hp; and F. the coefficient of performance. . heat absorbed 200xCapacity 50(200) 183.6 RE RE 54.48 = h3 - h2 = 91.13 - 80.04 = 11.09 Btu/lb h -h RE 54.48 = 2 1 = = 4.91 Wnet h3 - h 2 11.09 m'freon-12 Wnet E. Wnet/ton = x 60 2545 x capacity F. QR m'freon-12 ( h3 - h4 ) = 183.6 (91.13 - 25.56) = 12,040 Btu/min m'freon-12 2 where : G. PD = Capacity 183.6 1.516 PD = 2 1.516 ft 3 /lb = 5.57 ft 3 /min.ton 50 4. An air compression refrigeration system is to have an air pressure of 100 psia in the brine tank and an allowable air temperature increase of 60F. For standard vapor compression cycle temperatures of 77F entering the expansion cylinder and 14 F entering the compression cylinder, calculate: A. the coefficient of performance; B. the mass of air circulated per ton of refrigeration; C. the required piston displacement of the compressor cylinder, neglecting volumetric efficiency. P P=C S=C S= S=C T P=C P 183.6 x 11.09 x 60 0.96 2545 x 50 = E Wnet (Hp)(2545 Btu/Hp-min) 60 x2545 = = 14.97Btu/min J mass of Refrigerant x 60 170(60) C. A. RE = h2 - h1 = 80.04 - 25.56 = 54.48 Btu/lb PRESSUR A. Capacity = t 4 = 77F S2 S3 0.17317 Btu/lb ; h2 = 80.04 and h3 = 91.13 Btu/lb P=C C P= C P=C V h h4 = h1 = 27.72 Btu/lb h2 = 84.24 Btu/lb S2 =S3 =0.17187 h3 =91.31 Btu/lb See Attached Appendix: A. Evaporation temperature = 38.3F B. Condensation temperature = 93.4 F C. RE = h2 – h1 = 84.24 – 27.72 = 56.52 Btu/lb m'(RE) 23(56.52) = = 6.5 tons 200 200 m' h3 - h2 23 56.52 E. Wnet = = = 3.83 Hp 42.42 42.42 h -h RE 84.24 - 27.72 F. COP = = 2 1 = = 7.99 Wnet h3 - h2 91.31 - 84.24 D. Capacity ' = 3. A cooling plant using Freon-12 as the refrigerant is to have a capacity of 50 tons when operating on the refrigerant rating cycle. For this ideal plant cycle determine: D. E. F. G. . T4 = 77 + 460 = 537R T2 = 14 + 460 = 474R T2 - T1 = 60F T1 = 474 - 60 = 414R Since: Processes 3-4 and 1-2 are constant pressure: Use:Attached Figure A. B. C. S the refrigerating effect, Btu/lb; the rate of Freon-12 circulation, lb/min; the net work required per:pound of Freon-12 circulated, Btu/lb; the coefficient of performance; the power required per ton of refrigeration, hp/ton; the heat rejected by the condenser, Btu/min; and the compressor piston displacement, ft3/min·ton of refrigeration. P3 P4 and P2 P1 P4 P1 k 1 k = T T4 = 3 T1 T2 T 537 T3 = T2 4 = 474 = 615°R 414 T1 Cp T2 -T1 60 A. COP = = = 3.33 Cp T3 -T4 - Cp T2 - T1 615-537 - 60 B. RE - Cp T2 -T1 = 0.24(60) = 14.4 Btu/lb 200 Btu/min.ton =13.9 lb/min.ton 14.4 Btu/lb m'RT2 C. Piston Displacement = V2 = P2 m'air = 13.9(53.3)(474) = 24.4 ft 3 /min.ton 144 x 100 5. A simplified line diagram and TS plot for one section of a cooling system for a large aircraft are shown below. When it is used for cooling on the ground, the following Fahrenheit temperatures are experienced at the numbered points on the diagrams: T 1 3 8. A refrigerating plant for an air-conditioning system is to have a capacity of 10 tons and a coefficient of performance of 2.50 when operating With a refrigerating effect of 61.4 Btu/lb of refrigerant. Calculate : A. the refrigerant flow rate, lb/min; B. the work done on the refrigerant by the compressor, Btu/lb C. the compressor internal horsepower, hp; and D. the rate of heat rejection from the system, Btu/min. 2 5 S t (• F) 1 2 3 4 5 342 142 252 145 35 For a situation where the air flow rate through the system is 65 lb/min, specific heat of the air is assumed constant and the compressor and expander processes are assumed isentropic, calculate: (A) the heat transferred to the atmospheric air supply, Btu/min; (B) the power developed by the expander, hp; and (C) the heat transferred from auxiliary power unit compressor bleed, expressed in tons of refrigeration. A. Q1-4 =m'Cp t1 - t 2 t 3 - t 4 = 65(0.24) 342 - 142 252 - 145 = 4789.2 Btu/min m' h4 - h5 65(0.24)(145 - 35) B. Wnet = = = 40.45 hp 42.42 42.42 Q 4789.2 C. REFRIG = 1-4 = = 23.95 tons 200 200 6 . An ideal Freon-12 refrigerating system has a capacity of 50 tons. The condenser pressure is 180 psia, and the Freon12 temperature leaving the condenser is 120° F. The pressure leaving the expansion valve is 44 psia, and the temperature of the Freon-12 leaving the succeeding coil is 40° F. Circulating water enters the condenser at a temperature of 100° F and leaves it at 1 1 5 F. Determine: the mass of Freon-12 circulated, lb/hr; the compressor power for isentropic compression, Btu/hr the heat capacity of the system, Btu/hr the mass of water circulated through the condenser and heating system, lb/hr E. the useful heat furnished per Btu of compressor work (heating performance ratio) A. B. C. D. See Freon-12 table s attached Appendix/Figure: h1 = h4 = 36.16 Btu/lb h2 = 83.03 Btu/lb S2 = S3 0.17142 Btu/lb h3 = 94.31 Btu/lb 12,000 x capacity A. m = h2 -h1 ' 12,000(50) = 12,800lb/hr 83.03-36.16 B. Compressor Power = m'Wnet ' = = m' h3 - h2 = 12,800(94.31-83.03) = 144,400 Btu/hr C. Heating Effect : QR = h3 - h4 = 94.31 - 36.16 = 58.15 Btu/lb Heat Capacity = HC = m'(RE) = 12,800(58.15) = 744,300 Btu/hr HC 744,300 D. mcirculating water = = = 49,620 lb/hr C t out - tin 1(115 100) E. Heating Performance = A. 50 percent; B. 25 percent; and C. 12.5 percent. Answers: (A) 4.71 hp; (B) 1.57 hp; (C) 0.673 hp 4 point 7. Calculate the horsepower required per ton of refrigeration produced by the reversal of a Carnot cycle having a thermal efficiency of HC 744, 300 5.15 Compressor Power 144, 400 Answers: (A) 32.6lb/min; (B) 24.6 Btu/lb; (C) 18.9 hp; (D) 2800 Btu/min 9. A refrigeration system has a capacity of 25 tons and rejects heat at the rate of 6560 Btu/min. Calculate: (A) the rate of heat absorption by the refrigerant, Btu/min; (B) the power required as input to the system, Btu/min; and (C) the coefficient of performance for the system. Answers: (A) 5,000 Btu/min; (B) 1560 Btu/min; (C) 3.2 10. A modified Rankine refrigerating cycle operates with an evaporator pressure of 21.4 psia and a condenser pressure of 141 psia. Refrigerant is Freon-12 circulating through the system at 30 lb/min. Liquid refrigerant at 141 psia and 100" F enters the expansion valve, and surerheated vapor at 21.4 psia and 5" F enters the compressor. Calculate: (A) the refrigerating effect, Btu/lb; (B) the plant capacity in tons of refrigeration; (C) the power required to compress the refrigerant, hp; and (D) the plant coefficient of performance. Answers: (A) 47.86 Btu/lb; (B) 7.18 tons; (C) 10.66 hp; (D) 3.17 11. In an ideal (reversed Joule cycle) air-refrigerating system the temperature of the air entering the compression cylinder is 50F, the temperature entering the after-cooler is 160° F. and the temperature entering the brine tank is 0F. Calculate: (A) the temperature of the air leaving the after-cooler (B) the coefficient of performance; (C) the mass of air which must be circulated per ton of refrigeration, lb/min. Answers: (A) 99F (B) 4.54 (C) 16.7 lb/min CNS 04 MDSP/MESL (A) p1 14.7 psia; T1 50 460 510 R; M = 900 lb/min 1. In an ideal Brayton cycle, air enters the compressor at 15 psia and 75˚ F. The temperature of the air at turbine inlet is 1600˚ F. For maximum theoretical net work, find (A) the temperature of the air leaving the compressor, F; (B) the pressure ratio; (C) the net work, Btu/lb; and (D) the thermal efficiency. p2 162 psia; T2a 648 460 1108R p (C ) T2S T1 2 p1 If the end conditions remain unchanged but the pressure ratio is increased to 15, find: (E) the net work, Btu/lb, and (f) the thermal efficiency. C S k 1 / k 162 510 14.7 1.4 1 /1.4 1012.4 c p T2S T1 wkS 1012.4 510 0.84 or 84% wka 1108 510 c p T2a T1 (D) HPS M c p (T1 T2S ) P1 = 15 psia T1 = 75 +460 = 535 R k / k 1 (D) t max work 1 T1 / T3 1 535 / 2060 0.49 49% (E ) rp 15 k 1 / k k 1 / k T2 rp ; T2 T1 rp T1 1160 R TT 535 2060 T4 1 3 950 R T2 1160 wk c p T3 T4 c p T1 T2 J = 0.24(2060 - 950) + 0.24(535 -1160) = 266.4 - 150.0 = 116.4 Btu/lb wk 116.4 (f) t 0.539 53.9% or qs 216.0 1 rp k 1 / k 1 1 15 0.4 /1.4 p1 = 105 kPa abs ; p2 = 1260 kPa abs t1 = tA = tB = tE = 25˚ C (A) best intercooler pressure: p1 p2 105 1260 363.7 kPa abs (B) work of ideal cycle: k 1 / k p Wk t 2c pT1 1 i p1 1.4 1 /1.4 363.7 = 2 1.0048 25 273 1 105 3. An axial flow compressor discharges 900 lb/min of air. Inlet conditions are 14.7 psia and 50 F, while the actual discharge conditions are 162 psia and 648˚ F. For the process: (A) sketch the T-s diagram and then calculate (B) the capacity, ft3/min (C) the isentropic compression efficiency (D) the isentropic compression power, hp (E) the actual compression power, hp 3045 hp (on) S (A) the discharge pressure, (B) the discharge temperature (actual), and (C) the work inpt per kg f air. p (A) rp 2 ; p2 rp p1 p1 p2 3 100 kPa = 300 kPa abs (B) discharge temperature: P 2 T1 P1 T2S k 1 / k ; T2S 298 3 0.4 /1.4 407.9 K wk a c p T1 T2a c p T1 T2S / CS T2a T1 CS 1 T2S C C S wk a c p T1 T2S wkS wka c p T1 T2a c p T1 T2S C 298 0.7 1 407.9 0.7 S (C) compressor work: 455 K 1.0048 298 407.9 157.8 kJ/kg 0.70 S 2. 5. A split shaft gas turbine has a power turbine rated at 15,000 internal horsepower. Typical operating conditions for the unit are: compressor inlet 14.5 psia and 60˚ F; compressor discharge 174 psia and 716˚ F; compressor turbine inlet 171 psia and 1630˚ F; and power turbine exhaust 14.8 psia and 760˚ F. The compressor turbine at the above rating has an 85 percent isentropic turbine efficiency. For these rated conditions, (A) sketch the T-s diagram for the cycle, and then calculate: (B) the compressor isentropic efficiency, % (C) the compressor turbine discharge pressure and temperature, psia, ˚R (D) the power turbine isentropic efficiency, % (E) the compressor turbine power output, hp (F) the cycle thermal efficiency 255.2 kJ/kg 42.42 4. A 2 kW centrifugal compressor operates with suction conditions of 100 kPa abs and 25˚ C. The pressure ratio for the unit is 3 and C 0.70 Determine: 53.9% 2. Determine : (A) the best intercooler pressure and (B) the work required per kilogram of air for an ideal two-stage compressor operating between a suction pressure of 105 kPa abs and a discharge pressure of 1260 kPa abs. The suction temperature is 25˚ C. 1. 2558 hp (on) 900 0.24 510 1108 10.6 = 0.24 2060 + 535 -2 535 2060 118.9 Btu/lb t 1 (E) HPa M c p T1 T2a 1.4 / 0.4 T2 535(15) 42.42 T p 1050 (B) rp 2 2 p1 T1 535 Wk max (C ) =c p T3 T1 2 T1T3 J 0.4 /1.4 900 0.24 510 1012.4 T3 = 1600 + 460 = 2060 R (A) T2 T1T3 535 2060 1050 R = 590 F p1 MRT1 900 53.3 510 11,557 ft 3 / min p1 14.7 144 (B) V fuel 2 Combustion Chamber 3’ 3 Power Turbine compressor 1 From atmosphere Compressor Turbine Split Shaft Open Brayton Cycle (A) TS Diagram 4 to atmosphere Output 6. A split-shaft gas turbinehas a power turbine rated at 15,000 internal horsepower. Typical operating conditions for the unit are: compressor inlet, 14.5 psia and 60˚ F; compressor discharge, 174 psia and 716˚ F; compressor turbine inlet, 171 psia and 1630˚ F; and power turbine exhaust, 14.8 psia and 760˚ F. The compressor turbine has an 85% isentropic turbine efficiency at the above power rating. (A) Sketch the T-s diagram for the cycle; then, using the Air Tables, calculate: (B) the compressor isentropic efficiency, % (C) the compressor turbine discharge pressure and temperature, psia, ˚R (D) the power turbine isentropic efficiency, % (E) the compressor turbine power output, hp (F) the cycle thermal efficiency, % p1 = 14.5 psia p2 = 174 psia p3 = 171 psia p4 = 14.8 psia T1 = 60 + 460 = 520˚ R T2a = 716 + 460 = 1176˚ R T3 = 1630 + 460 = 2090˚ R T4a = 760 + 460 = 1220˚ R p1 = 14.5 psia p2 = 174 psia p3 = 171 psia p4 = 14.8 psia T1 = 60 + 460 = 520˚ R T2a = 716 + 460 = 1176˚ R T3 = 1630 + 460 = 2090˚ R T4a = 760 + 460 = 1220˚ R (A) TS - Diagram p (B) T2S T1 2 p1 k 1 k 174 520 14.5 0.4 1.4 1056.6 R isentropic compressor work T2S T1 actual copressor work T2a T1 C S 1057.6 - 520 0.8195 82.0% 1176 - 520 = (C ) W k12 W k33a ' M c p T1 T2a M c p T3 T3a ' T3a ' T1 T2a T3 520 1176 2090 1434 R t actual turbine work isentropic turbine work T3 T3 ' 0.85 T3 T3S ' S (B) From the Gas Tables: T3 T3a ' T3'S T3 0.85 2090 1434 2090 1318 R 0.85 State 1 1.4 1318 0.4 p3' = 171 34.06 psia 2090 (D) For the power turbine: State 2S k 1 0.4 P k 14.8 1.4 T4S T3a ' 4 1434 1130 R P ' 34.06 3 actual expansion work tS isentropic expansion work T3 ' T4a 1434 1220 tS a 70.4% T3a ' T4S 1434 1130 C S State 2a T 1048 12,389 lb/min Wk P = W k M c p T2a T1 P= 42.42 wk33a ' wk3 4 ' wk12a t = a a 1434 - 1220 2090 - 1176 vr 26.62 pr 22.28 u 204.59 vr 19.556 T 2090 h 529.75 pr 208.06 u 386.48 vr 3.721 M h T1 h T2a M h T3 h T3'a 45,980 hp (by) or h T3'a h T1 h T2a h T3'a = 124.27 - 285.20 + 529.75 = 368.82 12,389 0.240 1176 520 q23 u 181.11 252.95 124.27 0.7996 80.0% 285.20 124.27 45,980 hp (by) (F) Thermal efficiency: t h 285.20 42.42 pr 14.584 a State 3 12,389 0.240 2090 1434 vr 158.58 (C) W k12 W k33' For the compressor turbine: u 88.62 or 15,000 42.42 0.240 1434 1220 W k M c p T3 T3a ' h 252.95 T 1176 S W k M c p (T3a ' T4a ) M pr 1.2147 h < T2S > - h <T1 isentropic compression work actual compression work h T2a h T1 C (E ) For the power turbine: h 124.27 p 174 pr2 pr1 2 1.2147 14.576 14.5 p1 S k T3 ' k 1 p3 ' p3 S T3 T 520 wk3 4 ' a a q23 0.234 23.4% c T c p T3a ' T4a p 3 T2a State 3’a T 1499 h 368.91 pr 55.71 u 266.14 vr 9.967 T3a ' 1499 R t S h < T3 > - h <T3a ' Tamb= Ta = 530˚ R T3 = 2000˚ R pa = 15 psia actual expansion work isentropic expansion work 0.85 h T3 h T3S ' h T3S ' M = 116 lb/sec Va = 850 ft/sec h T3 h T3a ' h T3 0.85 529.75 368.91 529.75 0.85 340.53 T 1391 State 3’S h 340.55 pr 41.84 u 245.20 vr 12.315 pr 3 ' 41.84 p3 ' p3 S 171 34.39 psia 208.06 pr 3 p 14.8 (D) pr4 pr 3 ' 4 55.71 23.98 34.39 p3' S a State 4a State 4S t S T h pr u vr 1220 296.1 25.53 212.78 17.700 1200 291.30 24.01 209.05 18.514 h < T3a ' > - h <T4a actual expansion work isentropic expansion work h T3a ' h T4S 368.91 296.41 0.934 93.4% 368.91 291.30 Ram compression: V2 V2 ha a h1 1 h1 0 2gC J 2gC J (E) For the power turbine: W k M h T3a ' h T4a 15,000 42.42 M 368.91 296.41 or 8,780 lb/min W k M h T3 h T3a ' M or k or W k M h T2a h T1 p2 12p1 261.6 psia 42.42 p T2 T1 2 p1 W k 33,300 hp (by) a a q23 wk3 4 ' 0.4 590 12 1.4 1200 R Combustor: a a q23 h < T3a ' > - h <T4a h T3 h T2a 368.91 296.41 29.6% 529.75 285.2 7. A turbojet engine is equipped with a 12-stage, axial flow compressor having a mechanical compression pressure ratio of 12 to 1. The engine is designed to handle 90 lb of air per second under sea level static conditions and 116 lb of air per second at a flight velocity of 850 ft/sec at sea level. Material design considerations limit the temperature of the working substance entering the turbine to 2000˚ R at 7950 rpm. The ambient temperature and pressure are 15 psia and 530˚ R. (A) Estimate the thrust, propulsive efficiency and thermal efficiency of the engine, assuming all processes to be ideal and the engine frictionless, for a flight velocity of 850 ft/sec at sea level. (B) When the above engine is equipped for afterburning, the nozzle inlet temperature is 2500˚ R. Assuming all of the stated performance parameters remain constant, estimate the thrust with afterburning for a flight velocity of 850 ft/sec at sea level. k 1 k h2 + q23 = h3 (F) Thermal Efficiency: wk 33a ' wk3 4 ' wk12a 1.4 Compressor: 8780 285.20 124.27 t 0.24 T1 530 T k 1 590 0.4 p1 pa 1 15 21.8 psia T 530 a 850 2 32.2 778 T1 590 R 8,780 529.75 368.91 42.42 M 33,300 hp (by) Va2 c p T1 Ta 2gC J 2 For the compressor turbine: Va2 h1 ha 2gC J q23 = h3 – h2 = cp(T3 – T2) = 0.24 (2000 – 1200) = 192.0 Btu/lb p3 = p2 = 261.6 psia Turbine: h3 = h4 + wk 34 J wk 34 = h3 - h4 J wk(turbine) wk(compressor) = J J thus; h2 - h1 = h3 -h4 Cp (T2 - T1 ) = Cp ( T3 -T4 ) T4 T3 (T2 T1 ) T4 = 2000 - (1200 - 590) 1390R k 1.4 T k 1 1390 0.4 P4 = P3 4 261.6 = 73.2 psia 2000 T3 Nozzle: h4 Vj2 V42 hj 2gC J 2gC J Vj2 2gC J P Tj T4 j P4 h4 hj = Cp (T4 -Tj ) k 1 k Tj 883.7 R Vj 2gc JC p (T4 T j ) 2(32.2)(778)(0.24)(1390 883.7) Vj = 2467 ft/s Thrust; F t= M 116 2467 850 = 5825 lbf Vj Va 32.2 gc Propulsive Efficiency: p 2 2 51.3% Vj 2467 1 1 Va 850 Thermal Efficiency: qR = Cp Tj - Ta = 0.24(883.7 - 530) = 84.9 Btu/lb q -q q 84.9 th = s R = 1 - R = 1 = 55.8% qs qs 192 Part (b) k-1 0.4 P' k 15 1.4 Tj ' T4' j 2500 1589R P 73.2 4 Vj ' = 2gc JC p (T4 ' T j ') 2(32.2)(778)(0.24)(2500 1589) Vj ' = 3309 ft/s Ft = M 116 3309 850 = 8860 lbf V ' Va 32.2 gc j 0.4 15 1.4 1390 73.2 1. At the beginning of compression an ideal dual combustion cycle T1 75F 1 2 State 2S (A) The pressures and temperatures at the end of isentropic compression (B) The pressure and temperature at the end of each heat addition process (C) The temperature at the beginning of heat rejectionR (D) the heat rejected, Btu/lb (E) the net work, Btu/lb (F) The thermal efficiency, % (G) The horsepower developed by an ideal engine operating on the cycle using 0.50 lb of air per second. P1 = 15 psia T 1391 pr 41.84 u 245.20 (B) u T3 u T2 q23 245.20 176 421.2 State 3 T 2253 h 575.53 pr 283.0 u 421.09 T 2253 P3 = P2 3 467.80 757.7 psia T 1391 2 P4 = P3 = 757.7psia h T4 h T3 q34 575.53 176 751.53 State 4 T 2866 u 555.08 13.2 (C ) r 5 r 4 5 1.3700 12.92 1.4 4 k 1 State 5 T 2475 P3 = P2 3 =486 =832 psia 1446 T2 P4 = P3 832 psia T 1367 h pr 334.31 39.16 T5 1367R u 240.60 (D) qR u T5 u T1 240.60 91.19 149.41Btu / lb w k (net ) (E) qs qR 352 149.41 202.59 Btu/lb J q qR 202.59 (F) et s = 57.6% qs 352 T 13.2 3208 (C) 4 3 4 1.426 ft 3 / lb 12 2475 T3 1.426 T5 T4 4 3208 1317R 13.2 5 (D ) qR Cv T5 T1 0.1711317 535 = 134 Btu/lb 0.40 (G) w k ' 202.59(0.50)(60) 143 hp 42.42 3. A boiler produces 250,000 pounds of steam per hour at 1200 psia and 1050 F from feed water entering the boiler at 1500 psia and 300F. Fuel oil having a higher heating value of 18,000 Btu/lb is supplied to the burners at a rate of 20,500 lb/hr. Furnace volume is 1500 cubic feet. Calculate: w(net) (E) qs qR 352 134 218 Btu/lb J q qR 218 (F) e t s 61.9% qs 352 218(0.5)(60) 154.2 hp 42.42 2. At the beginning of compression an ideal dual combustion cycle using air has a pressure of 15 psia, a temperature of 75F and a specific volume of 13.2 ft3 per pound. For a compression ratio of 12 and a heat addition of 176 Btu/lb at constant volume and 176 Btu/lb at constant pressure. Calculate the following (using air table): (A) (B) (C) (D) (E) Boiler capacity, MB/hr Factor of Evaporation Equivalent Evaporation, lb/hr Furnace heat-release rate, Btu/hr.ft3 Boiler efficiency, % from: Steam Tables hsteam = 1528.9 Btu/lb h for water = hf 300 Fand 1500 psi = 272.39 Btu/lb (A) The pressure and temperature at the end of isentropic compression (B) The pressure and temperature at the end of each heat addition process (C) The temperature at the beginning of heat rejection process (D) the heat rejected, Btu/lb (E) the net work, Btu/lb (F) The thermal efficiency, % (G) The horsepower developed by an ideal engine operating on the cycle using 0.50 lb of air per second. Note: This solution is based on table attached with interpolation to the nearest degree. 1 13.2 ft 3 / lb 1 / 2 12.0 Heat Added: 176 Btu/lb at constant volume 176 Btu/lb at constant pressure T 535 h 126.78 pr 1.3416 vr 12.931 P 39.16 P5 P4 r 5 757.7 38.3 psia P 774.9 r4 q 176 T4 T2 34 2475 3208R Cp 0.24 State 1 vr 1.3700 4 3 0.40 T2 T1 1 535 12 1446R 2 q 176 (B ) T3 T2 23 1446 2475R Cv 0.171 k 1 h pr 751.54 774.9 T4 2866R T4 13.2 2866 1.40 ft 3 /lb 12 2253 T3 k (A) P2 P1 1 15(12)1.4 = 15(32.4) = 486 psia 2 T1 75F vr 29.49 T3 2253R 5 1 13.2 ft 3 / lb 1/2 = 12.0 P1 = 15 psia vr 12.315 P 41.84 P2s p1 r 2 15 467.8 psia 1.3416 Pr 1 S See Figure: ' h 340.55 T2s 1391R Heat Added: 176 Btu/lb at constant volume 176 Btu/lb at constant pressure (G ) w k 2 1 147.72 12.310 12 1 S r r using air has a pressure of 15 psia, a temperature of 75F and a specific volume of 13.2 ft3 per pound. For a compression ratio of 12 and a heat addition of 176 Btu/lb at constant volume and 176 Btu/lb at constant pressure. Calculate the following: u 91.19 vr 147.72 (A) Capacity = 250,000(1528.9 - 272.4) = 314.1mB/hr h - h 1528.9 - 272.4 (B) FE = out in = = 1.295 hfg 970.3 (D) Equivalent Evaporation =1.295(250,000) 323,750 lb/hr 250,000(18,000) (D) Furnace heat release rate = 1500 = 246,000 Btu/hr.ft 2 20,500(1528.9-272.4) (E) eboiler 85% 20,500 18,000 4. A Rankine steam power cycle operates with steam at 600 psia and (A) 850 F from the boiler and a condenser pressure of one inch of mercury absolute. Sketch the cycle on h-s and T-s coordinates and determine for the cycle: (A) Enthalpies for the steam leaving the boiler, leaving the turbine, leaving the condenser and leaving the pump, Btu/lb (B) The pump work, Btu/lb (C) Heat supplied , Btu/lb (D) Heat Rejected, Btu/lb (E) Net work, Btu/lb (F) The turbine work, Btu/lb (G) The thermal efficiency, % (H) The average temperature of heat receipt as determined by the heat added divided by the change of entropy during addition of heat, F NA = 240 rpm (SHP)A = 35,000hp em = 0.95 IHP A = SHP 35,000 = =36,840hp em 0.95 (MLHP)A =IHP-SHP=36,840-35,000=1840hp 2 N 122 (MLHP)B =(MLHP)A B =1840 =475hp 240 NA (B) SHP=4750, MLHP=475, IHP=4750+475=5225 SHP 4750 em = = = 0.909 = 90.9% IHP 5225 2 (C) Refer to figure 9-10: P1 = 1250 psia ; t1 940F ; Pa=0.70psi h1 = 1462.6 ; s1 = sa = 1.5994 ha = 876.0 (A.E.)t = h1 - ha = 1462.6 - 876 = 586.6 Btu/min wk shaft 2545 xSHP 2545 x 4750 = = 376 Btu/lb m' 32150 Wshaft 376 0.641 64.1% ees J(A.E.)t 586.6 J (D ) (wk )t 2545 xIHP 2545 x 5225 = 413.6 Btu/lb J m' 32150 wk t 413.6 eei 0.705 70.5% J ( AE )t 586.6 eei from: Steam Tables and Mollier Chart; h1 = 49.4 (from table 4) h2 = 1435.4 ; s2 =1.6559 h3 = 890 h4 = 47.1 ; s 4 = 0.09146 = s1 w k (pump) = h1 - h4 = 49.4 - 47.1 = 2.3 Btu/lb J (C) qs = h2 - h1 = 1435.4 - 49.4 = 1386.0 Btu/lb (B) (D) qR = h3 - h4 = 890 - 47.1 = 842.9 Btu/lb (E) Net Work = qs - qR 1386.0 842.9 = 543.1 Btu/lb (F) Turbine Work = h2 h1 1435.4 890.00 = 545.4 Btu/lb q qR 1386.0 842.9 (G ) e t s 39.2% qs 1386.0 et (H) t AV output Wturbine Wpump 545.4 - 2.3 = = = 39.2% input qs 1386.0 q 1386.0 s 460 460 426F s 1.5644 5. A geared turbine propulsion unit delivers 35,000 shaft horsepower at full power with a shaft speed of 240 rpm. The mechanical efficiency of the unit under this conditions is 95%. At 122 rpm the unit delivers 4750 shp, receiving steam at the throttle at 1250 psia and 940F at the rate of 32,150 lb/hr and exhausting to a condenser at 0.7 psia. Assuming the mechanical losses vary as the square of the rotative speed, find the 122-rpm condition: A. The estimated mechanical loss, hp B. The mechanical efficiency,% C. The shaft engine efficiency,% D. The internal engine efficiency, % ees 64.1 0.705 70.5% em 90.9 6. In a simple impulse stage, steam leaves the nozzles with a velocity of 1200 ft/s. The nozzle angle is 15 deg. Assume the bucket entrance and exit angles are to be the same and that the bucket velocity coefficient is 0.88. The wheel speed is 580 ft/s, and steam is supplied to the turbine at the rate of 6000 lb/hr. Find (A) (B) (C) (D) (E) The required bucket entrance angle for the given conditions The bucket work, ft-lb/lb and Btu/lb The power developed in the buckets, hp The available energy to the buckets, ft-lb/lb and Btu/lb The diagram efficiency. Refer to Fig. 12-2: V1 = 1200 ft/s = 15 Vb = 580 ft/s Cb 0.88 1 2 V1 sin 1200 sin15 (A) tan 1 V1 cos Vb 1200 cos15 580 1 = 2 28.2 V cos Vb 1200 cos15 580 Vr1 1 = 657.1 ft/s cos 1 cos 28.2 Vr2 Cb Vr1 = 0.88(657.1) = 578.2 ft/s (B) wk b 580 657.1cos 28.2 578.2cos 28.2 32.2 Btu wk b 19,610 ft-lb = 25.2 Btu/lb 778 (C) Wk ' =m'(w k ) where : m '= 6000 lb/hr = 100 lb/min Wk ' = 100(19,610) = 100(19,610) = 59.4 hp 33,000 or:Alternate Solution: Wk ' = 6000 x 25.2 Btu/hr = (D) (A.E.)b = 6000 x 25.3 59.4 hp 2545 V12 (1200)2 = 22,360 ft-lb/lb 2g c 2(32.2) 22,360 = 28.74 Btu/lb 778 (w k )b 19,610 (E) eb 0.877 87.7% A.E.b 22,360 or: ( A.E )b = 7. Steam enters a simple impulse bucket wheel with an absolute velocity of 450 m/s and a relative velocity of 270 m/s. It leaves the blades with relative velocity of 230 m/s and an absolute velocity of 105 m/s. Find: (A) (B) (C) (D) (E) The bucket velocity coefficient The available energy, kJ/kg The bucket loss, kJ/kg The unused kinetic energy at exit, kJ/kg The diagram efficiency. V22 2g c J 350 2 32.2 778 2 = 1184.7 = 1187.1 Btu/lb (E) P2 ' = 140 psia h g - h 2' m2 ' = hfg 1193.8 1187.1 0.77% 868.7 9. The first stage of a 50% reaction groups receives steam with a V1 = 450 m/s Vr2 = 230 m/s Vr1 = 270 m/s V2 = 105 m/s negligible approach velocity at a pressure of 300 psia with a temperature of 520F. The available energy to the stage is 10 Btu/lb, the fixed blade efficiency is 96%, the velocity coefficient for the moving row is 0.88, the reactive effectiveness is 90%, and the relative inlet and absolute exit velocities are 146 ft/s and 160 ft/s, respectively. Assume the stage efficiency is the same as the combined blade efficiency and calculate the following: 1 2 (A) Cb Vr2 230 0.85 Vr1 270 V12 (450)2 x10 3 = 101.25 kJ/kg 2g c 2 (B) (A.E.)b = Vr12 Vr22 270 230 x10 3 10 kJ/kg 2g c 2 2 (C) bucket loss (E) eb 2 V 2 1 V2 2 Vr 12 Vr 2 2 450 or : eb 2 3 V2 2 105 x10 = 5.51 kJ/kg 2g c 2 (D) KE 2 eb D) h2' = h2 2 1 V 2 105 2 450 230 2 The steam velocity leaving the fixed blades, ft/s The relative exit velocity from the moving blades, ft/s The stage work, Btu/lb The combined blade efficiency, % The enthalpy of the steam entering the succeeding stage, Btu/lb for complete velocity carryover 270 (A) (B) (C) (D) (E) 2 2 0.847 84.7% w k b AE b losses 101.25 10 5.51 84.7% ( AE )b 101.25 AE b P0 = 300 psia t o = 520°F (AE)st 10 Btu/lb en = 0.96 ; Cm = 0.88 ; eR = 0.90 Vr1 146 ft/s V2 = 160 ft/s (A) AE n AE R temperature of 420F when the stage pressure is 140 psia. Under these conditions the available energy to the stage is 38.5 Btu/lb, the nozzle-bucket efficiency is 85% and the absolute blade entrance and exit velocities are 1350 f/s and 350 ft/s respectively. Assume the stage efficiency is equal to the nozzle-bucket efficiency and calculate: (A) The enthalpy of the steam after isentropic expansion to the stage pressure, Btu/lb (B) The enthalpy of the steam entering the blades, Btu/lb (C) The enthalpy of the steam leaving the blades (D) The enthalpy of the steam leaving the stage if there is negligible carryover velocity, Btu/lb (E) The state of the steam leaving the stage, pressure (psia) and moisture (%) for the conditions postulated (D) above Refer to Fig. 12-2: AE st = 38.5 Btu/lb nozzle-bucket efficiency = 85% V1 = 1350 ft/s ; V2 = 350 ft/s 1350 V1 1219.8 = 1183.4 Btu/lb 2g c J (2)(32.2)(778) 2 J = emeb AE st = 0.85(38.5) = 32.7 Btu/lb h2 ho 2 = eR AE R 2g c J eR AE R 0.88 146 2 32.2 778 0.90 5 2 wk (C) J = V 2 1 - V2 2 + Vr2 2 - Vr12 490 - 160 + 492 - 146 = 8.69 Btu/lb 2 = (D) ecb = 2gc J 2 2 2 2 32.2 778 w k st J A.E.st = 8.69 = 0.869 = 86.9% 10 w k st v 2 2 J A.E.st 2g c J 2 160 = 1269.4 - 8.7 1260.2 2 32.2 778 h2 on one side of the wall is 50C, the surface temperature on the opposite side is 15C, k for the brick is 1.32 W/m.C and the wall is 20 cm thick. Calculate the heat transfer for a wall surface are of 10 m2: A = 10 m2 2gc J 350 2 32.2 778 2 = 1219.8 - 32.7 - Btu/lb t a 50C ; t b 15C w k st V2 2 J 2gc J = 490 ft/s 10. A solid brick wall separates two rooms. The surface temperature (A) ha = ho - (AE)st = 1219.8 - 38.5 = 1181.3 Btu/lb w k st 2 492 ft/s t o = 420°F P1 = P2 = P2' = 140 psia (C) Cm Vr2 = Cm Vr1 Vr2 10 5 Btu/lb 2 2 32.2 778 0.96 5 2 2gc J h2 = ho P0 = 220 psia (B) h1 ho Vr2 (B) 2 2gc J en AE n V1 8. The impulse stage of a turbine receives steam at 220 psia with a AE st = 1187.1 Btu/lb Q= ; k = 1.32 W/m.C ; L =0.20 m kA ta t b L (1.32)(10)(50 15) = 2310 W 0.20 11. A typical furnace side wall is constructed of a 1-in layer of diatomaceous earth insulating block, and 2 ½ in high temperature insulating brick faced with 4 ½ in. Firebrick with a 1/8-in steel casing. Average values of thermal conductivities are: diatomaceous earth insulating block, 0.063; insulating brick, 0.62 ; firebrick, 4.0; and steel casing 26 Btu/hr.ft.F. Average film coefficients are 3.0 and 2.2 Btu/hr.ft.2F for inner and outer surface films, respectively. The wall area is 50 ft2 , the average gas temperature is 2100F and the ambient air temperature is 100F. Calculate : (A) heat transfer coefficient, U, for this furnace wall, and (B) the heat transferred by the wall because of the conduction. (C) Calculate the temperature at the interface between the insulating brick and diatomaceous insulating block. (A) k fb = 4.0 ; k IB = 0.62; k DE = 0.063 k s = 26 Btu/hr.ft.F h1 = 3.0 ; h2 = 2.2 Btu/ft 2.hr.F 1 1 L fb LIb LDE LS 1 = + U h1 k fb kIb k DE k s h2 1 = U 1 0.30 1.45 1.60 40 12 26 4.25 4.25 1.50 1.0 1 + 2.42 3.73 1.2 12 0.08 12 0.04 4.25 4.25 U = 0.1659 Btu/lb.ft 2 F(external area) ' 2 r4 (B) Q UA t1 t 2 U x (t 1 t 2 ) 12 2 4.25 Q = 0.1659 180 (800 100) 46,516 Btu/hr 12 13. Calculate the overall heat transfer coefficient for tubular heat exchanger wherein the liquid carried in the tubes is heated by steam which surrounds them. The tubes are 5/8 in. Admiralty metal with a wall thickness of 0.049 in. The steam surface film coefficient is 1250 Btu/hr.ft2.F and the liquid surface film coefficient is 20 Btu/hr.ft2.F. 1 1 4.5 2.5 1 0.125 1 = U 3.0 12 4 12 0.62 12 0.063 12 26 2.2 U = 0.394 Btu/hr.ft 2 .F ' (B) Q UA t1 t 2 (0.394)(50)(2100 100) Q = 39,400 Btu/hr (C) for parallel Surfaces; A = A 1= A FB = A IB R1= 0.333 0.094 0.336 2.54 ; RFB = ; RFB = ; Rt = A1 A FB A IB A t1 = 2100F La LP Lm 1 1 + r r r r h h1 1 k p p k a a k m m 2 r r r 4 4 4 r4 1 = U and t 2 = 100F R + RFB + RIB t to interface = 1 t1 t 2 Rt A 0.333 + 0.094+ 0.336 = 2100 100 600F A 2.540 Temperature at interface = 2100 - 600 = 1500F 12. A high temperature steam line is covered with two successive layers of insulation. The layer in contact with the pipe is 1 ½ in thickness of asbestos for which k is 0.08 Btu/hr.ft.F. The asbestos is covered with a 1-in thickness of magnesia insulation, which has a value of 0.04. The internal pipe diameter is 2.90 in., the pipe wall thickness is 0.30 in and k for the pipe is 26 Btu/hr.ft.F. The steam temperature is 800F, and the internal surface film coefficient is 40 Btu/lb.ft2 .F, while the ambient outer temperature is 100F and the outer surface film coefficient is 1.2.Calculate : (A) the value of U based upon the external area of magnesia covering, (B) the heat loss from the steam for a length of 180 feet of pipe, Btu/hr h1=20; h2 =1250 Btu/hr.ft 2.F r2 = 0.3125 in. ; r1 = 0.2635 in; k = 70 Btu/hr.ft.F r1 + r2 0.2635 + 0.3125 = =0.288 2 2 1 1 L 1 = + U r1 rt h2 h1 k t r2 r2 rt = 1 0.0490 1 + = 0.0602 0.2635 0.288 1250 12 70 20 0.3125 0.3125 1 U = = 16.61Btu/ hr.ft 2 .F 0.0602 = 14. In the first stage of gas turbine, air enters a group of nozzles at 1200 F and leaves at 950F. The entering velocity, ft/s is negligible. A. Find the kinetic energy; Btu/lb. B. The velocity of air leaving the nozzle. (A) KE2 V22 h1 h2 ; where: h1- h2 = Cp (T1-T2 ) 2g c J KE2 = Cp (T1 - T2 ) = 0.24(1660 - 1440) = 60 Btu/lb (B) V22 h1 h2 Cp (T1-T2 ) 2g c J V2 2gc JCp T1 T2 2 32.2 778 0.24 250 = 1734 ft/s h1 = 40 ka = 0.08 t1 = 800F 15. A propulsion turbine receives steam at the throttle at 875 psia and 940F at the rate of 100,000 lb/hr. After an irreversible expansion process, the steam exhausts from the turbine at a pressure of 0.60 psia with a moisture content of 10%.Assume difference between the entrance and exit kinetic energies is negligible and find: A. Work done, Btu/lb. B. The power developed, hp 2 h2 = 1.2 Btu/hr.ft .F km = 0.04 t2 = 200 F kp = 26 Btu/hr.ft.F x = 180 ft length (A) rp = pipe mean radius = r2 - r1 1.75-1.45 = = 1.60 in. r2 1.75 ln ln 1.45 r1 ra = pipe asbestos radius = rm = mean magnesia radius = r3 - r2 3.25 -1.75 = = 2.42 in. r3 3.25 ln ln 1.75 r2 r4 - r3 4.25 -3.25 = = 3.73 in. r4 4.25 ln ln 3.25 r3 P1 = 875 psia ; t1 = 940F P2 = 0.60 psia ; m2 0.10 from:steam tables: h1 = 1475.6 and h2 = 1098.6 - 0.1(1045.4)=994.1 w (A) k12 = h2 - h1 = 1475.6 - 994.1 = 481.5 Btu/lb J m'wk12 10,000(481.5) (B) W'k12 18,920 hp 2545 2545 1. A propulsion turbine receives steam at the throttle at 875 psia and A TH 940F at the rate of 100,000 lb/hr. After an irreversible expansion process, the steam exhaust s from the turbine at a pressure of 0.60 psia with a moisture content of 10%. Assume the difference between the entrance and exit kinetic energies is negligible and find: P2 P1 1 g 32.2 where: = = = 58.82 lb f /ft 3 0.017(32.2) 1 gc 144 1200-29.8 TH = = 2864.8 ft 58.82 (A) The work done, Btu/lb (B) The power develop, hp ' B P1 = 875 psia T1 940F m2 0.10 P2 = 0.60 psia From Steam Table: h1 1475.6 Btu/lb WHP Wk12 ' M' wk12 2545J 10,000(481.5) = 18,920 hp 2545(1) 2. A boiler receives feed water at 1200 psia and 250F and delivers steam from the superheater at 900 psia and 950F. Find the heat added, Btu/lb. Refer to Fig. 5-3 P1 = 1200 psia P2 = 900 psia t1 = 250F t 2 = 950F M TH g 550g c 125,000(2864.8)(32.2) = 180.9 hp 3600(550)(32.2) WHP 180.9 = = 301.5 hp ep 0.60 (C) BHP = (D) Interpolating in Table 4 of the steam tables with: s1 = s2 0.36772 and P2 = 1200 psia h2 1098.6 (0.10)(1045.4) 994.1 wk (A) 12 = h1 - h2 = 1475.6 - 994.1 J = 481.5Btu/lb (B) M' = 100,000 lb/hr ; 1 hp = 2545 Btu/hr ; h2 = 222.30 wk12 = h1 - h2 218.59 222.30 = (-) 3.17Btu/lb J wk12(actual) wk12(isentropic) (-) 3.17 (E) = = = (-) 6.18 Btu/lb J 0.60 J epump wk12 = 218.59 + 6.18 = 224.77 Btu/lb J Entering Table 4 and interpolating between 1000 and 500 psi gives: t h 250C 221.03 300C 271.83 224.77 - 221.03 t = x 50 3.68 271.83 - 221.03 t 2 = 250 + 3.7 = 253.7F (F) h 2 = h1 - q12 = h2 - h1 2 (1.04) = 221.0 5 From Table 3: h2 = 1480.5 Btu/lb From Table 4: h1 = 220.61 + q12 = 1480.5 - 221 = 1259.5 Btu/lb 3. If, in the preceding example, the feed water entering has a velocity of 3 m/s and the steam leaving the super heater has a velocity of 50 m/s. Find: (A) The additional heat required to accommodate the change in kinetic energy across the boiler, J/kg 5. A water cooled reciprocating air compressor takes in air at 15 psia and 60F and discharges it at 60 psia and 200F. Heat is removed in the amount of 21.4 Btu/lb. Assume steady flow conditions and the work done, Btu/lb. P1 = 15 psia T1 = 40+ 460 = 520R P2 = 60 psia T2 = 200 + 460 = 660R q12 = - 21.4 Btu/lb (B) The percentage error introduced by neglecting the kinetic energy change. wk12 = q12 + h1 - h2 J where : h1 - h2 Cp T 0.24(520 660) 33.6 wk12 = -21.4 - 33.6 = - 55 Btu/lb (on) J (A) q12 = h2 - h1 - V22 -V12 (50)2 (3)3 1245 J / kg 2gc 2(1) Btu J / kg (B)q12 = 1259.2 2326 = 2930 x 10 3 J/kg lb Btu / lb 1245.5 x 100 Error = 0.043% 2930 x 103 4. Saturated water at 250F enters a centrifugal main feed pump and is discharges at 1200 psia. The pump efficiency is 60% and the delivery rate is 125,000 lb/hr. Find: (A) (B) (C) (D) (E) (F) The total head developed by the pump, ft The water horsepower, WHP The brakepower, BHP The ideal (isentropic) pump work, Btu/lb The actual pump work, Btu/lb The estimated temperature of the water at discharge. ; P1 = 29.8 psia 1 0.017001 ft 3 / lb ; P2 1200 psia M'=125,000 lb/hr V1 V2 ; Z1 Z2 pressure is 215 psia and passed through an Ellison throttling calorimeter. The calorimeter thermometer reads 250 F and the barometer is standard. Find for the line steam: A. B. C. D. The enthalpy The quality The entropy The temperature to the nearest whole degree P1 = 215 psia P2 = 14.696 psia T2 = 250F (A) from table 3: h2 = 1168.8 h1 = h2 = 1168.8 Btu/min throttling(h=constant) (B) from table 2 for 215 psia: h g 1200.3; hfg 838.1 t1 = 250F (sat.water) h1 218.59 Btu/lb 6. A sample of steam is removed from a steam line where the h1 hg - m1hfg ; epump 60% m1 hg - h1 hfg 1200.3 1168.8 31.5 0.0376 838.1 838.1 x1 = 1 - m1 = 1 - 0.0376 = 0.9624 = 96.24% (C) s1 sg m1sfg 1.5403 0.0376(0.9887) 1.5031 Btu/lb.R (D) t1 387.97 388F 7. In a lube oil cooler, oil enters at 140F and leaves at 100F, at the rate of 400 lb/min. The cooling medium is sea water , which enters at 60F. The average specific heat of the oil is 0.50 Btu/lb.F and the salt water is 0.94 Btu/lb.F. If the flow of the sea water is at the rate of 500 lb/min, find the overload discharge temperature. t 2 100F t1 = 40°F t 3 60F M'A = 400 lb/min; C A = 0.50 Btu/lb.F M'B = 500 lb/min; CB 0.94 Btu/lb.F M'A h1 - h2 M'B h4 - h3 Btu / min M'ACA t1 - t 2 M'BCB t 4 - t 3 Btu / min 400 0.50 140-100 t4 - t3 = t4 - 60 = 17 t 4 = 77°F 500 0.94 M'o = 60,000 lb/hr Co 0.50 Btu/lb.F = 17 A = 258 ft 2 A. Q' = M'oCo t1 t 2 (60,000)(0.50)(145 120) = 750,000 Btu/hr 55 45 m 1 2 49.8F 1 55 ln ln 45 2 8. Steam enters the condenser of propulsion plant at 0.50 psia and a quality of 89 percent at the rate of 100,000 lb/hr and with a velocity of 1000 ft/s. It leaves the condenser hotwell as saturated liquid without any change in pressure but a velocity of 10 ft/s. The salt water inlet ( injection ) temperature is 70F and the discharge (overboard ) temperature is 85F. Sea water has a specific heat of 0.94 Btu/lb.F and a density of 64 lb/ft3 . The injection and overboard velocities are substantially equal. Calculate the following: (A) The rate at which energy is extracted from the condensing steam as heat, (B) The flow of sea water required, gallons per minute (gpm) B. For parallel flow: Q' 750,000 Btu/hr U = 58.4Btu/hr-ft 2 F 70 30 m 1 2 47.2F 1 70 ln ln 30 2 P1 = P2 0.50 psia t 3 70F m1 1 0.89 0.11 t 4 85F V1 1000 ft/s A= CB 0.94 Btu/lb.F 10. A steam superheater has a net heat transfer area of 1620 ft 2 B = 64 lb/ft 3 V2 10 ft/s M' A = 100,000 lb/hr ; 1 ft 3 = 7.481 gal (A) q12 = h2 - h1 V22 V12 2g c J h1 1096.2 0.11 (1048.6) 980.9 Btu/lb h2 47.7 10 1000 2 32.2 778 2 q12 = 47.7 980.9 + M'A q12 = 2 = 953.2 Btu lb M'B 1,588,700 Btu/min 60 M 'B xCB t 4 t 3 Q '34 1,588,700 = 112,670 lb/min CB t 4 t3 0.94(85 70) flow, (gpm) = 7.481 gal M ' ft 3 B 7.481112,670 64 = 13,170 gpm 9. A counter-flow lubricating oil cooler with a net heat transfer area of 258 ft2 cools 60,000 lb of oil per hour from a temperature of 145F at inlet to 120F at discharge. The temperatures of the cooling water are 75F and 90F respectively, and the specific heat of the oil is 0.50 Btu/lb.F. Calculate: B. and a design capacity of 221,000 lb of steam/hr when receiving saturated steam at 650 psia and discharging at 850F with a pressure drop if not of not more than 25 psi and through heater. The design heat transfer coefficient is 30 Btu/hr.ft2.F. In operation of superheater receives 220,000 lb of saturated steam per hour at a pressure of 650 psia and discharges against a pressure of 630 psia with a temperature s at entrance and exit are 2100F and 1430F, respectively. Calculate the operating heat transfer coefficient using counter flow log mean temperature difference. 100,000 953.2 (b) (-)Q'12 Q '34 A. Q' 750,000 = 272 ft 2 Um 58.4 47.2 The value of the overall heat transfer coefficient under these operating conditions, Btu/hr.ft2F, and the required area for a parallel flow device having the same capacity under identical operating conditions. Q ' Ms hs 220,000 1434.2 1203.1 51x10 6 Btu / hr m U 1250 935 1085F 1250 ln 935 Q' 51x106 29 Btu / hr ft 2F A 1620 1085