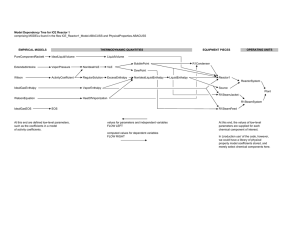

Mathematical Modelling in Civil Engineering Vol. 15‐No. 3 : 13‐27‐2019 Doi: 10.2478/mmce‐2019‐0008 WIND LOAD DESIGN OF PHOTOVOLTAIC POWER PLANTS BY COMPARISON OF DESIGN CODES AND WIND TUNNEL TESTS Ovidiu BOGDAN - Lecturer, PhD, Technical University of Civil Engineering of Bucharest, Department of Strength of Materials, Bridges and Tunnels, e-mail: obogdan@utcb.ro Dan CREŢU - Professor, PhD, Technical University of Civil Engineering of Bucharest, Department of Strength of Materials, Bridges and Tunnels Abstract:Wind load design of the ground-mounted photovoltaic (PV) power plants requires interpretation of the design code considering the particularities of these structures. The PV power plants consist on systems of several solar panels. Wind load pressure coefficient evaluation, by design code, for a single solar panel considered as a canopy roof, neglect the group effect and the air permeability of the system. On the other hand, the canopy roofs are structures with medium serviceability, but the PV power plants are structures with low serviceability. This paper discuss the difficulties of the wind load design for the PV power plants ground mounted in Romania and compares the Romanian, German, European and American wind design code specifications with the parameters provided by the wind tunnel test, for this type of structures. For Romanian wind load design an evolution of the 1990, 2004 and 2012 editions of the design codes specifications is also studied. Evaluation of the internal resultants for the structural elements of the PV panel, considering the pressure coefficients and the force coefficients, conducts to different results. Further code explanations and design specifications are required for wind design of the PV power plants. Keywords: wind pressure coefficient, wind force coefficient, photovoltaic panel, group effect 1. Introduction The green energy is assumed by the European Union strategy to cover 20% of the total energy production until 2020. Romania assumed 38% target by its national strategy, for green energy only, till 2020. The Romanian national strategy on energy policy is based on green certificates which are public paid to the investors in green energy facilities. Green energy represents around one third of the total energy power produced in Romania. About 1400 MW is the total power installed at 2016 by photovoltaic power plants, similar with the nuclear power provided by the two operational nuclear reactors located at Cernavoda. If an installation cost of about 1 million euro is considered for every MW, the total investments in photovoltaic energy reached 1.5 billion euro. The total installation cost was even bigger, since for one MW was paid around 3 million euro in 2004 and decreased to 1 million euro in 2016. From the total installation cost, an important amount represents the cost of the metallic support structure of the photovoltaic panels. The safe and structural performance guided design of this structure to wind, and eventually snow load, conducts to an eventually decrease of the structure cost. This paper describes the difficulties of the wind load design of the photovoltaic power plants in Romania and is based on a technical consultancy contract between the Strength of Materials, Bridges and Tunnels Department of the Technical University of Civil Engineering of Bucharest and a private investor and designer for PV power plants. In Romania, the wind design of the photovoltaic power plants requires the wind pressure and force evaluation based on the recently enforced Wind Load Design Code with the indicative CR 1-1-4-2012 [1]. This design code replaced the old wind load design code,2004 version, having the indicative NP-082-04 [2] and entitled „The fundamentals of design and loads on constructions. The wind load”. The new version of the Wind Load Design Code is not completely overcoming the interpretation and evaluation difficulties of the former design code. Based on the specifications of the CR 1-1-4-2012 Wind Load Design Code [1], the photovoltaic power plants needs wind load evaluation as for the canopy type structures. This assumption is completely neglecting the group effect of photovoltaic power plant panels. On the other hand, the 14 photovolatic power plants and the structural canopies have usually not the same life span. Since the photovoltaic power plants are in use for an average of about 20 years, the canopies may be used for the same duration as the main structure, if they are atached to structures. In this case, the canopies are structures of about 50 years life span. The paper is structured on subsections referring to the PV panel structural description, wind load evaluation based on the Romanian design code, wind load comparison for different wind design codes, a critical review of the Romanian wind design code regarding this type of structures, the wind tunnel experiments description and the comparison of the measured wind coefficients and forces with the design code obtained values, and the final conclusions and comments. The consulted literature review referring to PV arrays is validating the influence of the tilt angle, incidence angle of the wind, space between panels and sheltering effect of the arrays. Some of the very first experimental studies were done by Radu [3] for PV panels located on flat roofs. They used a pneumatic mediation technique to measure the pressure coefficients of the exposed surface. Shelter effects due to the marginal attics and the successive PV panel parallel rows were identified. If mounted on flat roofs, Cao et all. [4] shows on 1:50 scale models that the single PV array indicates comparable wind uplift forces for center or edge location of the array. For multiple arrays the uplift forces are decreasing with distance from the edge of the roof. The sheltering effect is indicated by larger forces for single PV array compared with multiple PV array. Mean and peak force values are increased with tilting angle and distance between PV arrays due to the increased turbulence. The building depth can be neglected, but the roof parapets decreased height are conducting to increased turbulence on PV panels if they are close to the edge of the roof. Tests and CFD simulation were compared for multiple PV arraysmounted on the roof of the parking open structures by Axinte et all. [5]. Higher turbulence for roof edge located PV arrays and the effect of the closing provided by the vehicles parked underneath were studied. For ground mounted PV stand-alone panel, tilted by 25°, the study of Jubayer [6] evaluates the wind pressure coefficients resulted from CFD analysis at full scale and compared the results with the measured parameters obtained by experiments at 1:10 scale. Good agreement of the parameters were observed, which indicates the independence of the wind pressure coefficients due to the scale model, if large scale is considered (up to 1:50). 0° and 180° wind direction are responsible for maximum drag and uplift forces, but the 45° and 135° for the maximum overturning moment. For the last, corner vortices were observed. The ASCE code indicated values for monoslope free roofs were in good agreement with mean values resulted from the numerical study. Extending the study to the PV arrays, for the same tilting angle, and performing the CFD analysis, Jubayer [7] observed that first row is always affected by the largest wind forces, independent on the wind direction, which indicates the sheltering effect on the next rows. For these rows, the wind loads are higher for oblique wind direction than for direct wind. Different tilting angles were studied by CFD analysis for PV arrays by Shademan [8] and determined that the critical panels are those located on the corners due to the increased turbulence, for all tilting angles. The tilting angle effects were also studied using CFD analysis by Irtaza [9] for ground mounted single panel and PV array and increased turbulence was determined when increasing the tilting angle. Single panel experiments were also performed by Velicu [10] and observed that force coefficients are increasing with the tilting angle. A comparison of the roof mounted to the ground mounted PV arrays was performed by Stathopoulos [11] using 1:200 scale models experiments. They observed the critical wind acting on 135° direction, with extreme values on the range 105° to 180°. For this range the panel tilting angle may be significant. The building height and panel location is not very significant, but panels located on the roof edge take the greatest net wind forces. A unified ground and roof mounted panels net pressure coefficients diagram was proposed. Spacing parameters were studied by Warsido [12] on 1:30 scale model of ground mounted and roof mounted PV arrays. Sheltering effect, increased wind forces for edge located panels, higher for diagonal wind direction, are 15 observed. No significant effect of the lateral spacing between panels for roof mounted and important variations of the wind coefficients for ground mounted were also measured. Force and overturning moments for ground mounted panels are increasing when longitudinal spacing is increased. For the roof mounted panels, the force and overturning moments are decreased if the increasing of the gap between panels and roof edge. The uncertainties of the wind measured forces as a result of the model scale were studied by Aly [13] using CFD modeling of the ground mounted PV array. The uncertainties are more significant for the ground mounted PV arrays, which are usually consider the 1:30 scale model, than for roof mounted PV arrays, since they are using the building scale, usually 1:100 to 1:500. The numerical analysis was calibrated on test available data and a hybrid experimental/computational procedure was developed and performed. Mean pressure coefficients are not dependant on the scale model, but the peak values are strongly determined by the model and turbulence scale. The commonly used BLWT are indicating smaller peak pressure coefficients values than a CFD simulated more accurate turbulence at high Reynolds numbers, like Large Eddy Simulation. Some insights of the scale factor for roof mounted PV arrays were presented also by Kray [14], who mentioned the increase of the peak pressure coefficients when reducing the model scale from 1:100 to 1:50. 2. Photovoltaic panel structural system description A photovoltaic power plant consists by several PV panels emplaced in row and by several rows (similar as in Fig. 1). A small gap, of centimeters length, is used in between panels in row. The PV panel rows are parallel, at distances of meters determined based on the panel width and inclination, so that the maximum solar exposure act on every panel. The further described PV panel is one element of a photovoltaic power plant constructed in Romania, on South of Bucharest, close to the Danube. The power plant has an installed capacity of 120 MW, one of the largest in the country. The structure of one photovoltaic panel consists of five transversal cantilever type steel frames and four longitudinal aluminum beams, supported continuously on every transversal frame. The distances in between transversal steel frames are all equal with 2.10 m. The size of the photovoltaic panel is 9740 mm by 3302 mm with an inclination of 25 degrees from horizontal plane, for the analyzed case. Fig. 1 – Photovoltaic power plant assemblage pattern (© Königsolar GmbH) The transversal steel frames are constructed by assemblage of: ⁃ a vertical S355 steel column having a total height of 2800 mm, from which 1400 mm are embedded in soil; ⁃ a 25 degrees inclined S355 steel beam having the length of 2600 mm, hinged to the top of the column; ⁃ two S235 steel braces having 988 mm and 692 mm respectively, both hinged to the beam and column. 16 The sizes of the transversal frame structural elements are indicated in Fig. 2. No foundation is required to fix the vertical steel columns. The four longitudinal aluminum beams have the same length as the photovoltaic panel, 9740 mm. The beams are located at equal distances of 825 mm in between. From top, and bottom beam respectively, to the end of the photovoltaic panel are 351 mm. On transversal direction, every panel consists of two rows of photovoltaic cells, emplaced with a gap of 22 mm in between. Fig. 2 – The sizes of transversal structural steel frame elements 3. Wind load evaluation for one panel The considered photovoltaic power plant is located in category II terrain, with low vegetation and isolated obstacles, as indicated by the Romanian Wind Load Design Code CR 1-1-4-2012 [1] and the Eurocode EN 1991-1-4:2006 [15] respectively. Based on the Romanian Wind Load Design Code [1], which basically follows the corresponding Eurocode [15], the wind load may be evaluated either as an acting pressure, by the following equation: 𝑤 𝛾 ∙𝑐 ∙𝑞 𝑧 (1) or as a resultant force, by the following equation 𝐹 𝛾 ∙𝑐 ∙𝑐 ∙𝑞 𝑧 ∙𝐴 (2) To evaluate the characteristic peak velocity wind pressure, the following equation is used, as indicated by the former mentioned wind design codes 𝑞 𝑧 𝑐 ∙𝑐 𝑧 ∙𝑐 𝑧 ∙𝑞 (3) For the considered photovoltaic power plant site location, the basic wind pressure indicated by the Romanian wind map is evaluated as 𝑞 50 𝑑𝑎𝑁/𝑚 . If changes in terrain orography are negligible 𝑐 1 and terrain roughness coefficient is determined as 𝑐 𝑧 0.496 and the peak velocity coefficient as 𝑐 𝑧 2.988 for the site and reference height considered, the peak velocity wind pressure results as 𝑞 𝑧 74.148 𝑑𝑎𝑁/𝑚 . 17 As indicated in the design code, to evaluate the wind load as a resultant force the dynamic coefficient 𝑐 it may be neglected, if the structure of the PV panel vibrates with a fundamental frequency larger than 5 Hz, which is the case of analyzed panel. Then, to compare the magnitude of the wind load obtained based on a pressure distribution (Eq. 1) with the one obtained based on a resultant force (Eq. 2), a comparison in between pressure coefficients and force coefficient values is required. The single canopy case is considered, as indicated in CR 11-4-2012 Romanian Design Code [1]. The comparison is given in Table 1 where 𝜑 represents the wind flow underneath panel blockage ratio. The pressure coefficients are mentioned for the two wind directions, first conducting to the uplifting of the canopy (wind pressure upwards – suction) and then conducting to the descent of the panel (wind pressure downwards). The second case wind load must be added to the snow load and the panel self-weight respectively, which finally conducts to the design load combination for the structural elements of the PV panel. Table 1 Pressure and force coefficients for 𝛂 zone 𝜑 0 𝑎𝑛𝑦 𝜑 𝟐𝟓°inclination A B C 𝑐 -2.6 -3.2 -3.2 -1.6 +2.0 +3.1 +2.3 +1.0 Fig. 3 – Pressure zones for a single canopy A significant increase is observed for pressure based wind design load compared with the resultant force based wind load. For the photovoltaic panel size described above, the wind resultant load for a current transversal steel frame structure is determined in the two cases:using pressure coefficients and the resultant force coefficient respectively, as indicated in Table 1. The two resultant forces acting on a current transversal steel frame are then compared. By using the resultant force coefficients, the resultant force on the transversal frame for the uplifting effect of the panel is obtained 𝐹 8.23 𝐾𝑁 and for the descending effect of the panel is obtained 𝐹 5.142 𝐾𝑁. In comparison, the same resultant force acting on a current transversal frame determined by using the pressure coefficients indicates significantly increased values: 𝐹 ∗ 14 𝐾𝑁 for the force conducting to the uplifting effect of the PV panel and 𝐹 ∗ 10.6 𝐾𝑁 for the descending effect. The star index shows the case of the resultant force obtained based on the pressure coefficients. This significant difference for the same load,acting to a current transversal steel frame and basically used for the design of the structural members of the frame, requires further and clear explanations in the wind design code. These remarks are missing from the CR 1-1-4-2012 Romanian Design Code [1]. Recommendations about what coefficients are needed to be used for the design of the PV panel structural system components (transversal frame, longitudinal beams) are required for a safe and cost efficient design. A second observation results from the additional moment obtained in the case of using the resultant force coefficients. At the steel column of every transversal frame, an additional moment will be produced by the eccentricity of the load, applied at 𝑑/4, where 𝑑represents the width of the 18 panel.This moment is not considered for the pressure coefficients case, since the obtained resultant load will act on the centroid of the PV panel. If the group effect is considered, for multiple connected canopies and several rows, a reduction factor is indicated in the design code. This factor goes to a maximum of 0.7 for all rows beyond the third, for both uplifting or descending effect of the panel. Since this reduction is applied to both cases of resultant load, the one obtained based on pressure coefficients and the one obtained based on the resultant force coefficients, no change of the above observations are to be considered. 4. Wind load comparison for different design codes The wind pressure coefficients are basically determined based on the wind tunnel tests made on real or reduced scale specimens. As a consequence, the coefficients should reveal same values, independent on the design code edition or country. Change of the pressure coefficients from code to code may be explained only if the probabilistic approach is used to determine the indicated values of the coefficients. Different safety factors conduct to different pressure coefficients even if the same structures or reduced scale models are considered. The Romanian CR 1-1-4-2012 Design Code [1] doesn’t explain clearly what assumption is used to determine the pressure coefficients. To have a complete image of the basis and evolution of the pressure coefficients for consecutive editions of the Romanian Wind Load Design Codes, a comparison with the different countries versions of the same code is done. The pressure coefficients are indicated in Fig. 4 to Fig.7 and their values are then compared for the following design codes: STAS 10101/20-90,the Romanian 1990 version [16], EN 1991-1-4, the Eurocode [15], SR EN 1991-1-4, the Romanian translation of the Eurocode [17], NP-082-04, the Romanian 2004 former version [2], CR-1-1-4-2012, the Romanian actual version in use [1], DIN 1055-4:2005-03, the German code [18] and ASCE 7-10, the American code [19]. The 10 degrees inclination of the panel is considered for the comparison, since the German design code is not indicating pressure coeficients for larger inclinations. On the other hand, it can be observed by code comparison that the Eurocodes [15,17], and the recent Romanian code versions [1,2], are both indicating pressure coeficients, to be used for the design of the roof structural members, and resultant force coefficients respectively, to be used for the eccentric applied resultant wind load and design of the steel supporting column. The German [18], the American [19] and the old 1990 version of the Romanian [16] design codes are indicating values for pressure coefficients only, for different inclination of the canopies, to be used for design of all structural members. d 0.8 0.4 1.4 0.2 h=ze or Fig. 4 – Pressure coefficients indicated by STAS 10101/20-90 [16] 19 -0.3 0.7 0.3 -0.6 0 0.3 -0.7 h=ze or Fig. 5 – Pressure coefficients indicated byDIN 1055-4:2005-03 [18] 1.6 2.1 1.2 1.5 1.6 2.1 d/10 d/10 or Fig. 6 – Pressure coefficients indicated byNP-082-04 [2], EN 1991-1-4 [15], SR EN 1991-1-4 [17] and CR 1-1-4-2012 [1] 1.53 (0.4) -0.7 (-1.57) 1.05 (1.67) 1.1 (0) case A (case B) h=ze or Fig. 7 – Pressure coefficients indicated byASCE 7-10 [19] The mechanical torsor of the external loads is then determined, at the top level of the column, for a current transversal structural steel frame, and the comparison with its values for the indicated list of the design codes is made in Table 2. The mechanical torsor components, resultant force and moment, 𝐹 and 𝑀 , normalized with the panel length and peak velocity wind pressure, are determined for the photovoltaic panel size described above, d parameter referring to the width of the panel. 10 degrees inclination of the panel cases are compared, since the German Wind Design Code [18] is not indicating pressure coefficients values for larger inclination of canopies. 20 Table 2 Comparison of the mechanical torsor components for 𝛂 Design code 𝑐 CR 1-1-4-2012 a.o. 𝑐 STAS 10101/90 DIN 1055 case A ASCE case B Descending effect 𝐹 𝑀 1.28d 0 0.5d 0.125d2 0.9d 0.083d2 0.65d 0.0875d2 1.29d 0.06d2 1.035d 0.159d2 𝟏𝟎° panel inclination Uplifting effect 𝐹 𝑀 1.62d 0 0.9d 0.225 d2 0.5d 0.05 d2 0.85d 0.0375 d2 0.2d 0.225 d2 0.785d 0.196 d2 The recent Romanian versions of the wind load design codes NP-082-04 [2], CR-1-1-4-2012 [1] and SR EN 1991-1-4 [17], as well as the Eurocode EN 1991-1-4 [15], are all presented at the same row of the table, since all are indicating same pressure coefficients for the photovoltaic panel. Moreover, they are the codes which are mentioning both pressure coefficients and resultant force coefficients for the wind load design. Comparing the mechanical torsor components, the resultant force and moment values, for the uplifting effect of the panel case, and for the descending effect respectively, it can be observed that the old Romanian version of the wind design code STAS 10101/90 [16] conducts to similar values as the German design code [18], but the Romanian recent versions of the design code [1,2,17] and the Eurocode [15] are getting closer to the American code [19]. The conclusion is that the European and the Romanian wind design codes are following the American codes in increasing the pressure coefficients values. This can be accepted only if superior level of safety is assumed, which conducts to a probabilistic approach. As a consequence, the values indicated by design codes for pressure coefficients are to be accepted as maximum expected values. They are always indicating larger values than the ones determined based on wind tunnel tests. On the other hand, the pressure coefficients values indicated by the design codes are given for the canopy type structures, which basically are individual structures with medium life, but the photovoltaic power plants are comprised on several number of individual panels and they have reduced life. Therefore, the group effect should be considered for this type of structures, which results to a reduction factor applied to the pressure coefficients values, with a maximum reduction of 30% starting with the third row of panels. By this reduction, the pressure coefficients values, as well as the resultant force and moment values, are getting closer to the old version of the Romanian code, or the German code values. This applies only for the panels located on the third row and more, which makes the first row and the second located panels to be designed for the maximum loads indicated by the code. Changing the structural solution or increasing the size of the structural members, for the supporting structure of the panels located on one row, compared with the ones located on the others, may increase the cost of the structure. The comparison of the pressure coefficients indicated by the design code with the ones measured at wind tunnel tests may reveal also important findings. 5. Wind load evaluation difficulties existent in the Romanian design code The importance of the structure designed by wind load is considered by 𝛾 importance coefficient. The Romanian wind load design code [1], as well as the Eurocode [15], is not mentioning explicitly the photovolatic power plants. If these structures are considered as constructions with class III or IV for importance, the importance coefficient shoult be taken as 1, which makes no change of the wind design load. As it was explained in the introduction of the paper, the investment cost for a photovolatic power plant construction is about 10 million euros for a 10 MW power. This is why the importance factor should be specified and take into account the investment cost and the risk involved. 21 When determining the wind load as a resultant force by Eq. (2), using the corresponding coefficient values, the Romanian and the Eurocode wind load design code [1,15] are indicating the refference area 𝐴 to be used. The Romanian code explains the reference area as the area “normal orientated to the wind direction, for buildings or for structural components”. This creates confusion since for a horizontal canopy, as example, the uplift wind effect conducts to an uplifting resultant force. Using the Romanian design code definition of the reference area, if the canopy is horizontal and wind acts laterally, the reference area “normal orientated to the wind direction” is getting zero, which results to no wind load. The mistake comes to the designer eyes if the original version of the Romanian design code, the Eurocode [15], is consulted. There is no mention of the is the reference area of direction of the refference area, relative to the wind flow direction: “𝐴 the structure or structural element, given in Section 7 or Section 8” -subchapter 5.3 point (2) and respectively “𝐴 is the area of the individual surface” - subchapter 5.3 point (3). The same is mentioned in the Romanian translation of the Eurocode, SR EN 1991-1-4 [17]. The conclusion is that the Romanian wind load design code CR-1-1-4-2012 [1], which follows the Eurocode EN 1991-1-4 [15], is using a poor translation, missing relevant terms and explanations. This is the origin of the confusion created by the Romanian code. When calculating the wind design resultant load for a structure, based on the pressure coefficient, and comparing with the one determined based on the resultant force coefficient, the first has significant larger values than the second. This was proven above in Section 4. The difference come from the much larger pressure coefficients indicated by the code, compared with the resultant force coefficients, for same type of structure. The pressure coefficients must be considered as maximum expected values, and the code assume they should be used for roof structural members design and for local connections design. Is the structural support members design, like for the transversal steel frame components of the analysed structure, not so safe like design of the roof components and connections, since the first should use in design the resultant force coefficients and the second the pressure coefficients? This requires further explanations and comments on the Romanian design code, which at this moment are missing from the code text. Anyway, is difficult to explain why the Romanian code version CR-1-1-4-2012 [1] was created and is used, since the Romanian translation of the Eurocode SR EN 1991-1-4 [17] follows the original code with no change. The Romanian National Annex, which is also done, may be used together with the Romanian translation version of Eurocode [17], for wind design of any structure located in Romania. 6. Wind tunnel tests The wind tunnel tests are done by Wacker Ingenieure GmbH from Germany [20] and a significant excerpt of their technical report is presented forward. The wind tunnel model represents a group of photovoltaic panels with 3.30 meters width and 25 degrees inclination from horizontal plane. The panels are considered to be located in category II terrain as indicated by the Romanian Wind Load Design Code CR 1-1-4-2012 [1], on rows at equal distances of 7.5 meters, as indicated in Fig. 8. The edges of the panel are located at 0.75 m (bottom) and 2.18 m respectively (top) to the ground level. Fig. 8 –The consecutive rows parameters of the PV panels 22 Fig. 9 –The reduced scale wind tunnel model of the PV panels The 1:40 reduced scale wind tunnel model is indicated in Fig. 9 and is comprised by eight consecutive panel rows. The small gaps between panels in row are completely neglected by the wind tunnel model. The access roads provided terrain roughness is also neglected by the model. The width of the property is about 50 meters and allows relevant wind observations to be done. No other panel arrangements were considered for the study. The real wind effects simulation must model a limit layer turbulent wind over the ground with similar terrain roughness. For this purpose, the reduced scale model is fixed on a plate with similar asperities as for the wind category II terrain, also indicated in Fig. 9. These boundary conditions are decisevely changing the wind average velocity profile and the turbulence parameters. The wind velocity variation 𝑣 𝑧 on heigth depends on terrain roughness and existent obstacles as buildings, trees and orography changes. On the wind tunnel is simulated the wind for a free field model, as for current locations, and the wind velocity profile on heigth is then obtained by the equation: . (4) where 𝑣 is the average wind velocity and 𝑧 is the heigth measured from the ground level. The velocity variations about the wind average velocity are required for the model. For these, the turbulence intensity 𝑇 𝑧 and the average standard deviation 𝜎 𝑧 of the wind velocity variations on 𝑧 heigth profile, as a function of average wind velocity 𝑣 𝑧 are considered. This distribution should model the real one. The wind average velocity distribution by heigth and turbulence wind variation are modeled by several rough plane elements fixed at the bottom of the wind tunnel model. The wind tunnel crosssection is 2.50 m in width and 1.85 m in heigth, and the length of the tunnel is 12 m. Fig. 10 –Wind pressure zones measured for the model 23 The wind average velocity is measured using Prandtl tubes and the turbulence wind variation velocities are measured using anemometers. The similarity of the Reynolds numbers, indicating the inertia to the viscoelastic force ratios, of the reduced scale and real model respectively, is used to corectly assume the conversion and flux over an obstacle. The intensity of the wind pressure is related with the Reynolds number. Measurements are done for every 15 degrees of the wind direction incidence angle variation. The wind pressure parameters are determined as difference in between measured positive and negative values. Five zones on panel rows, indicated in Fig. 10, are identified by wind pressure measurements: first, second, middle, second last and last row respectively. No changes for wind pressure parameters were measured starting with the third row. Six lateral zones with variable width like 1.0 m (A zone), 2.0 m (B zone), 3.0 m (C zone), 4.0 m (D zone), 6.0 m (E zone) and variable width respectively (F zone), were also measured. Measured maximum values of the resultant force 𝑐 , moment 𝑐 coefficient and eccentricity of the resultant equivalent force are indicated in Table 3 for every zone on rows and lateral direction respectively. Positive values are indicating the descending wind action on panel, and negative the ascending wind action. Fig. 11 - Definition of moment 𝑐 and resultant force 𝑐 coefficients Fig. 12 - Distribution and pressure coefficient evaluation for one panel 24 Table 3 Maximum values of the measured coefficients for the wind zones indicated in Fig. 10 1st row 2nd row Descending wind action Middle row 2nd last row Last row 1st row 2nd row Ascending wind action Middle row 2nd last row Last row 𝑐 𝑐 𝑒 𝑐 𝑐 𝑒 𝑐 𝑐 𝑒 𝑐 𝑐 𝑒 𝑐 𝑐 𝑒 𝑐 𝑐 𝑒 𝑐 𝑐 𝑒 𝑐 𝑐 𝑒 𝑐 𝑐 𝑒 𝑐 𝑐 𝑒 A 1.05 0.12 0.11 1.05 0.10 0.10 1.05 0.10 0.10 1.25 0.10 0.08 1.45 0.11 0.08 1.70 0.21 -0.12 -1.45 0.17 -0.12 -1.35 0.13 -0.10 -1.35 0.15 -0.11 -1.45 0.20 -0.14 B 0.90 0.11 0.12 0.80 0.09 0.11 0.85 0.09 0.11 0.90 0.10 0.11 1.10 0.10 0.09 -1.15 0.19 -0.17 -1.00 0.15 -0.15 -0.90 0.13 -0.14 -0.95 0.14 -0.15 -1.25 0.19 -0.15 Lateral wind zone C D 0.85 0.85 0.11 0.11 0.13 0.13 0.70 0.50 0.07 0.06 0.10 0.12 0.65 0.45 0.07 0.07 0.11 0.15 0.70 0.55 0.07 0.07 0.10 0.13 0.80 0.60 0.09 0.08 0.11 0.13 -0.85 -0.80 0.13 0.13 -0.15 -0.16 -0.75 -0.65 0.12 0.12 -0.16 -0.18 -0.70 -0.65 0.12 0.11 -0.17 -0.17 -0.85 -0.70 0.11 0.11 -0.13 -0.16 -1.10 -0.95 0.15 0.12 -0.14 -0.13 E 0.80 0.11 0.14 0.30 0.05 0.17 0.30 0.04 0.13 0.40 0.05 0.13 0.45 0.05 0.11 -0.75 0.11 -0.15 -0.65 0.10 -0.15 -0.65 0.10 -0.15 -0.65 0.11 -0.17 -0.90 0.11 -0.12 F 0.80 0.11 0.14 0.30 0.05 0.17 0.30 0.04 0.13 0.40 0.04 0.10 0.45 0.05 0.11 -0.70 0.11 -0.16 -0.65 0.10 -0.15 -0.60 0.10 -0.17 -0.65 0.10 -0.15 -0.90 0.11 -0.12 𝑐 neg -0.07 -0.06 -0.04 -0.04 -0.04 Measured maximum values of the resultant force 𝑐 , moment 𝑐 coefficient and eccentricity of the resultant equivalent force are indicated in Table 3 for every zone on rows and lateral direction respectively. Positive values are indicating the descending wind action on panel, and negative the ascending wind action. The resultant forces on the PV panel surface are then determined by the following equations 𝐹 𝑐 ∙𝑏∙𝑞 𝐻 𝑀 𝑐 ∙𝑏 ∙𝑞 𝐻 𝑘𝑁/𝑚 𝐹∙𝑒 (5) 𝑘𝑁𝑚/𝑚 (6) where 𝑞 𝐻 represents the basic wind pressure at the maximum heigth 𝐻 of the structure, measured on free field and taken from the design code wind map depending on the site location and terrain category 𝑏 represents the PV panel width 𝑒 represents the eccentricity of the resultant equivalent force 𝑒 as function of the width 𝑏. The resultant force coefficient 𝑐 is obtained by simultaneous measuring of the descending and respectively ascending effect at the top and bottom edge of the PV panel. The friction forces on 25 panel surface are determined based on the design codes. No safety coefficients were considered for the resultant coefficients indicated in Table 3. The resultant coefficients are also used to design the support structure elements of the PV panel. Table 4 Maximum and minimum measured resultant force coefficients Wind action effect Desc. Asc. +2.45 -3.00 +1.95 -1.95 +2.00 -2.10 +1.60 -1.65 1𝑚 10𝑚 1𝑚 10𝑚 Zone A-B Zone C-F Top edge of the panel Desc. Asc. +0.90 -2.70 +0.75 -1.95 +0.90 -2.00 +0.70 -1.65 Bottom edge Desc. Asc. +0.85 -2.60 +0.60 -1.80 +0.85 -1.90 +0.60 -1.50 The maximum and minimum values of the resultant force coefficients, obtained for every indicated wind zone as a function of the reference exposed area, 𝐴 1 𝑚 or 𝐴 10 𝑚 , are indicated in Table 4. The resultant forces are acting perpendicular to the panel plane and intermediate values are determined by equation 𝐹 𝐹 𝐹 𝐹 𝑙𝑔𝐴 (8) The values indicated by tables are considering the static component of the wind action and are not including the dynamic variable component. Change of the geometrical parameters may result to change of the wind load. Based on the measured values of the pressure coefficients indicated above, a comparison of the mechanical torsor components, resultant force and moment at the top of the panel supporting column, for European design code [15] and for tunnel test is presented below, in Table 5. The pannel inclination is 25 degrees from ground plane. The maximum measured values for the wind tunnel pressure coefficients are considered for a lateral A zone of 1.0 m width, and the minimum values for a central F zone. Significant differences between wind tunnel based resultant forces and moments, and the corresponding forces and moments obtained from the wind design code, are indicated by the comparison done in Table 5. Table 5 Resultant forces comparison for European design code and wind tunnel test Descending wind effect 𝐹 𝑀 EN 1991-1-4 Wind tunnel pressure coeff. force coeff. 𝑐 Max. Min. Ascending wind effect 𝐹 𝑀 2.06d 0 2.72d 0 1.00d 0.2500d2 1.60d 0.400 d2 1.45d 0.30d 0.1160d2 0.039d2 1.70d 0.60d 0.204 d2 0.102 d2 The reduced pressure coefficients measured by wind tunnel tests, compared with the design code, results to a reduction of the PV panel supporting structure elements, like columns and beams crosssection, and finnally to a reduction of the investment cost. The PV panels group effect, clearly identified by wind tunnel tests, and the significant reduction for the pressure coefficients, observed by measurements, makes the wind tunnel tests a relevant approach for the design of this category of structures. 26 7. Conclusions The photovoltaic power plants are structures with an important investment cost, which translates into the cost of the structural support also. The Romanian wind load design code, as the Eurocode which was followed, is not mentioning explicitly the importance factor value for this type of structures. If they are considered as low importance structures, based on their life duration which is about 20 years, the investment cost is not assumed at his real size. The American design codes are now using risk categories to evaluate the size of the probable loss. The Romanian wind load design code should consider an importance factor for the photovoltaic power plants or similar structures evaluating correctly the risk and the loss of the investment. The Romanian wind load design code, and the Eurocode, is recommending the use of both pressure and resultant force coefficients to evaluate the wind design load. Pressure coefficients are maximum expected parameters and their value is significantly larger than the resultant force coefficients. The German, American and older version of the Romanian wind load design code are using only pressure coefficients for the wind design. This choice might be better than using two categories of coefficients, with different safety expectation for different structural members. Finding the pressure coefficients, for photovoltaic power plants and similar structures, using the wind tunnel tests represents a valuable and safe procedure which should be recommended in this case by the Romanian wind load design code. This procedure may overcome and clarify the ambiguity of the code about what type of coefficients to be used for a safe design. The authors are acknowledging the contribution of the Romanian company Alukönigstahl srl, and German companies Königsolar GmbH and Wacker Ingenieure GmbH at the technical documents used in this paper. The study was presented on the 2nd Romanian National Conference on Wind Engineering sessions, held in Bucharest on June, 6-7. References [1] CR-1-1-4-2012, Design code. Wind actions evaluation for constructions (in Romanian) [2] NP-082-04, Design code. The fundamentals of design and actions on constructions. The wind load (in Romanian) [3] Radu A. & Axinte E. (1989). Wind forces on structures supporting solar collectors. Journal of Wind Engineering and Industrial Aerodynamics. 32, 93-100. Elsevier Science Publishers B.V. Amsterdam. DOI: 10.1016/01676105(89)90020-2 [4] Cao J., Yoshida A., SahaP. K. and Tamura Y. (2013). Wind loadingcharacteristicsofsolararraysmountedon flat roofs. Journal of Wind Engineering and Industrial Aerodynamics.123, 214-225. Elsevier Science Publishers B.V. Amsterdam. DOI: 10.1016/j.jweia.2013.08.014 [5] Axinte E.,Văsieș G., Teleman E. C., Roșca V.E. and Axinte A.O. (2015). Including solar panels on parking areas in the sustainable development concept. Wind effects. Environmental Engineering and Management Journal. 14 (2015), 9, 2255-2262, ed. by “Gheorghe Asachi” Technical University of Iasi, Romania [6] Jubayer C.M. & Hangan H. (2014). Numerical simulation of wind effects on a stand-alone ground mounted photovoltaic (PV) system. Journal of Wind Engineering and Industrial Aerodynamics.134, 56-64. Elsevier Science Publishers B.V. Amsterdam. DOI: 10.1016/j.jweia.2014.08.008 [7] Jubayer C.M. & Hangan H. (2016). A numerical approach to the investigation of wind loading on an array of ground mounted solar photovoltaic (PV) panels. Journal of Wind Engineering and Industrial Aerodynamics.153, 6070. Elsevier Science Publishers B.V. Amsterdam. DOI: 10.1016/j.jweia.2016.03.009 [8] Shademan M. & Hangan H. (2010). Wind loading on solar panels at different azimuthal and inclination angles. Proceedings of the Fifth International Symposium on Computational Wind Engineering (CWE2010).Chapel Hill, North Carolina (USA). May 23-27 [9] Irtaza H. & Agarwal A. (2018). CFD Simulation of Turbulent Wind Effect on an Array of Ground-Mounted Solar PV Panels. Journal of the Institution of Engineers (India): Series A. 99(2), 205-218. Springer Publishers. DOI:10.1007/s40030-018-0283-x 27 [10] Velicu R., Moldovean G., Scaleţchi I. and Butuc B.R. (2010). Wind loads on an azimuthal photovoltaic platform. Experimental study. Proceedings of the International Conference on Renewable Energies and Power Quality (ICREPQ’10). Granada (Spain). March 23-25 [11] Stathopoulos T., Zisis I. and Xypnitou E. (2014). Local and overall wind pressure and force coefficients for solar panels. Journal of Wind Engineering and Industrial Aerodynamics.125, 195-206. Elsevier Science Publishers B.V. Amsterdam. DOI: 10.1016/j.jweia.2013.12.007 [12] Warsido W.P., Bitsuamlak G.T., Barata J., Chowdhury A.G. (2014). Influence of spacing parameters on the wind loading of solar array. Journal of Fluids and Structures. 48, 295-315. Elsevier Science Publishers B.V. Amsterdam. DOI: 10.1016/j.jfluidstructs.2014.03.005 [13] Aly M. A. (2016).On the evaluation of wind loads on solar panels: The scale issue. Solar Energy.135, 423-434. Elsevier Science Publishers B.V. Amsterdam. DOI: 10.1016/j.solener.2016.06.018 [14] Kray T. & Paul J. (2017). Peak negative pressure coefficients on low-tilted solar arraysmounted on flat roofs: the effects of building size and model scale. Proceedings of the 7th European-African Conference on Wind Engineering (EACWE 2017).Liege (Belgium). July 4-7 [15] EN 1991-1-4:2006, Eurocode 1: Actions on structures, Part 1-4: General actions. Wind loads [16] STAS 10101/0-90, Actions on structures, Wind generated loads (in Romanian) [17] SR EN 1991-1-4:2006, Eurocode 1: Actions on structures, Part 1-4: General actions. Wind loads (in Romanian) [18] DIN 1055-4:2005-03, Effects on structures, Part 4: Wind loads (in German) [19] ASCE 7-10, Minimum Design Loads for Buildings and other Structures. Wind load Provisions [20] Wacker Ingenieure, König Solar: PV Freilandsystem 25 Grad Windkanaluntersuchungen zur Ermittlung der bemessungsrelevanten Winddruckverteilungen für geneigte,über dem Boden angebrachte Photovoltaikmodule, April 2013 (in German)