Cyanide Management in Gold Extraction: A Comprehensive Report

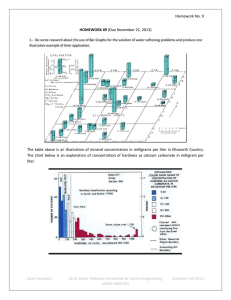

advertisement