Click here

advertisement

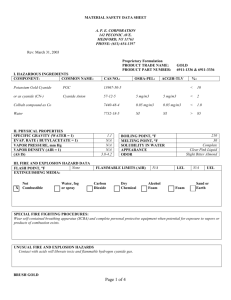

Bath Make-up 2NaCN Na2 Cu (CN)3 CuCN K2 Cu (CN)3 2KCN Double or Complex Salts Na2 Cu (CN)3 + K2 Cu (CN)3 Other Components “Free” NaNC or KCN NaOH or KOH Most commercial baths are prepared using a mixture of sodium cyanide and potassium cyanide. Presence of potassium ions increases the plating speed. The first step in preparing a bath consists of slurrying the copper cyanide in water then adding the slurry to a water solution of the sodium cyanide and potassium cyanide. Precautions must be taken in preparing the bath because considerable heat is generated in the chemical reactions forming the soluble complex salts. Too rapid addition on the slurry may cause localized over-heating and splashing out of solution. The complex salts are also available and may be used to prepare new baths and as replenishing salts for baths in operation. Excess sodium cyanide or potassium cyanide is also added to provide “free” or additional cyanide in the bath. Alkali is required for good bath conductivity and throwing power. Normally, the alkali is added as potassium hydroxide rather than as sodium hydroxide. 1 1 Swalheim, D.A. American Electroplaters and Surface Finishers Society. Cyanide Copper Plating. P.4