PIOT'SOPERATING

HANDBOOK

A*l9n

Skyhawk

CESSNAMODELI72N

N1 3 1 1 1

L=

*,rF 11e67l(?

PERFORUANCESPEcIFICATIONS

CESSNA

MODEL 172N

PERFORMANCE

SPECIFICATIONS

S PEED:

llarrmum at Sea Lcvel

Cnrise, ?Stc Pwer at 8000 Ft .

CRL-ISE: Recommended l-ean Mixture with fuel allowance for

engine start, taxi, takeoff, climb and 45 minutes

reserve at 45acpower.

?5]r Pover at 80O0 Ft .

Range

{O Gallms Us$le F\el

Time

?Str Pcner at 8000 Ft .

Range

5OGallons Usable l\rel

Time

llaximum Range at 10,000 Ft

Range

{O Gallms Usable F\rel

Time

Ilarimum Range at 10,000 Ft

Range

5OGallons Us$le F\el

Time

RATE OF CLIMB AT SEA LEVEL

SERVTCECEXLII,TG

TAKEOFF PERFORMANCE:

Grqrnd Roll

Totd Distance Over 50-Ft Obstacle

IA:fDb|3 PENFORMANCE:

Grourd Roll

Total Distance Over 50-Ft Obstacle

S TAL L S P E E D ( CA S ) :

PleFs Up, Power Off

fhps Dwn, Power Off .

}IATTMUM WEXGHT

STAh-DARDEMPTY WEIGHT :

Sk3rha*k.

Sk-vhawkII .

}TAXIML'M I,'SEFUL LOAD:

Skyhawk .

Skyhavk II .

BArcAGE ALLOWANCE

tffIIG LOADING: Pounds/Sq Ft

PWER I,OADING: Pounds/HP

Ft'EL CAPACITY: Total

Standard Tanks

L-org Rarge Tanks

orl- CAPACTTY

E!{GII\-E: Avco Lycoming

160 BHP at 2700 RPM

PROPELLER: Fixed Pitch. Diameter

o r6 2 -r 3

125 KNOTS

L22 KNOTS

485 NM

4. 1 HRS

630 NM

5.3 HRS

575 NM

5.7 HRS

?50 NM

?.4 HRS

??O FPM

14,200 FT

80b FT

1440 FT

520 FT

1250 FT

50 KNOTS

44 KNOTS

23OOLBS

1379 LBS

1403 LBS

921 LBS

897 LBS

120 LBS

13.2

14. 4

43 GAL.

54 GAL.

6 QTS

O-320-H2AD

?5 IN.

N13171

PILOT'S

HANDBOOK

OPERATING

\

n \.-

LESSNA.

S K Y H AWK

1977 MODEL172N

S e ri o l N o .

Regis lr olion

17e6716?

No.

M7 3?tt

T H ISH A N D BOOK IN C L UD E 5 T HE IU A TE R IA T

REOU IR E O

T O B E F U R N ISH EDTO TH E P ITOT

B Y C A RP AR T3

C ES SN A AIR C R AF T C O ' UP A N Y

W IC H IT A , K AN SA S, U S A

3.,

.c,

xi*

r*;q1'1

*&il

*

I

CONGRATUI,ATIONST

:'

lt,

*)

CESSNA

MOD E L 1?2N

. . S. .

C O N C RA T ULATI ON

and constructed

hasbeendesigned

owners! Your Cessna

Welcometo the ranksof Cessna

to giveyou the mostin performance,

economy,and comfort. lt is our desirethat you will find

a pleasant

andprofitableexperience.

or pleasure,

flyingit, eitherfor business

This Pilot'sOperatingHandbookhasbeenpreparedasa guideto helpyou get the most

equippleasure

and utility from your airplane.lt containsinformationaboutyour Cessna's

for its servicingand care. We

and performance;

and suggestions

ment, operatingprocedures,

urgeyou to readit from coverto cover,and to referto it frequently.

of a Cessna.Worldwith your purchase

hasnot ceased

Our interestin your flying pleasure

CustomerServicesDepartment

backedby the Cessna

wide,the CessnaDealerOrganization

are offeredby most CessnaDealers:

standsreadyto serveyou. The followingservices

for partsand labor,is available

THE CESSNAWARRANTY,which providescoverage

at CessnaDealersworldwide. Specificbenefitsand provisionsof warranty,plus other

importantbenefitsfor you, are containedin your CustomerCareProgrambook,supplied with your airplane.Warrantyserviceis availableto you at authorizedGessna

of your CustomerCareCardwhich

Dealersthroughoutthe world upon presentation

your eligibilityunderthe warranty.

establishes

expertservice.

to provideyou with courteous

FACTORYTRAINED PERSONNEL

t n da c c u r a t e

t o pr ov idey o u e f f i c i e n a

F A CT ORYAPPROVEDS ERVI CEEO UI PM ENT

workmanship.

A S T OCKOF GENUINECESSNASERVI CEPARTSon han dw h e ny o u n e e dt h e m .

.

T HE LATESTAUTHORI TATI VEI NFO RM ATI O NFO R SER V I C I N GC E S S N A

haveall of the ServiceManualsand Parts

Dealers

AIRPLANES,sinceCessna

kept currentby ServiceLettersand ServiceNewsLetters,publishedby

Catalogs,

Aircraft Company.

Cessna

to the fullest.

ownersto usethe CessnaDealerOrganization

We urgeall Cessna

your new airplane.The Directoryis

A currentCessnaDealerDirectoryaccompanies

revisedfrequently,and a currentcopy can be obtainedfrom your CessnaDealer. Make

your Directoryone of your cross-country

flight planningaids;a warm welcomeawaitsyou

at everyCessnaDealer.

11

CESSNA

MODEL 1?2N

TABLE OF CONTEI.ITS

TABLEOF CONTENTS

SECTION

CENERAL

. 1

LIMITATIONS

. 2

EMERCENCY

PROCEDURES

. . . . . . . . . . 3

N O R M A L P R OC E D U R E S .. ..

....

4

PE R F O RMA N C E .. ..

5

wErcHT & BALANCE/

EQUTPMENT

LIST.. . . . .

6

AIRPLANE

& SYSTEMS

D E S C R IP T ION S .

.....7

AIRPLANE

HANDLINC,

S E R V IC E & MA IN T E N A N C E. ..

SUPPLEMENTS

(OptionalSystems

Description

&OperatingProcedures)

B

. . . 9

This handbook will be kept current by Service Letters published by CessnaAircraft

Company. These are distributed to CessnaDealers and to those who subscribe

t hr o u g h t h e O w n e r Fo llo w- Up Syste m . lf yo u a r e n o t r e cei vi ngsubscri pti onservi ce,

you will want to keep in touch with your CessnaDealer for information concerning

t he c h a n g es t a t u s o f th e h a n d b o o k. Su b se q u e n tch a n g e sw i l l be made i n the form

of stickers. These should be examined and attached to the appropriate page in the

ha n d b o o k i m m e d i a t ely a fte r r e ce ip t; th e h a n d b o o k sh o u l d not be used for operational purposes until it has been updated to a current status.

iiil(iv blank)

S E C TION 1

GENERAL

C ESSN A

MODEL 172N

o N1

SECT

CENERAL

T A B TE OF CON IE N TS

Page

Three View

Introduction

Descriptive Data

Engine

Propeller

Fuel

oil

Murimum Certificated Weights

Standard A irplane Weights

Cabin and Entrv Dimensions .

Baggage Space and Entry Dimensions .

Specific Loadings.

Symbols, Abbreviations and Terminology

General Airspeed Terminology and Symbols .

Meteorological Terminology .

Engine Power Terminology

Airplane Performance and Flight Planning Terminology

Weight and Balance Terminology .

l-2

1-3

1-3

1-3

1-3

1-3

l -4

1-5

1-5

1-5

1-5

1-5

1-6

1-6

1-6

L-7

l-7

l-7

1-1

CESSNA

MODEL 172N

SECTION 1

GENERAL

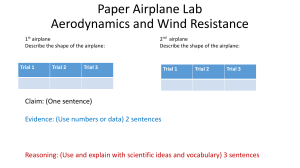

rflAX.

'1. Wing span shown wtth strobe lights

Installed.

2.

Maxrmum herght shown wrth nose

gear depressed,all trres and nose

strut properly Inflated,and flashrng

beaconInstalled.

3.

Wheelbaselength ts 65"

4.

Propellerground clearances 11 3/4"

5.

Wing areats 174 squarefeet.

6.

Minrmumturntng radius(*ptvot polnt

to outboard wtng ttp) rs 27' 5lz"

*

PIVOT POINT

l-.- ,,

F i g u re 1 -1 . Three View

1-2

C ESSN A

MODEL 172N

S E C TION 1

GENERAL

I NT R O D U C T I ON

This handbook contains 9 sections, and includes the material required

to be furnished to the pilot by CAR Part 3. It also contains supplemental

data supplied by Cessna Aircraft Company.

Section 1 provides basic data and information of general interest. It

also contains definitions or explanations of symbols, abbreviations, and

terminology commonly used.

DES CRI PTI VDEA T A

ENGINE

Number of Engines: 1.

Engine Manufacturer: Avco Lycoming.

Engine Model Number: O-320-HZAD.

Engine Type: Normally-aspirated, direct-drive, air-cooled,

horizontally- opposed, carburetor equipped, four-cylinder engine

with 320 cu. in. displacement.

Horsepower Rating and Engine Speed: 160 rated BHP at 27O0RPM.

PR OPET LE R

Propeller Manufacturer: McCauley Accessory Division.

Propeller Model Number: 1C160/DTM7557.

Number of Blades: 2.

Propeller Diameter, Maximum: 75 inches.

Minimum: 74 inches.

Propeller Type: Fixed pitch.

FUEL

Approved FueI Grades (and Colors):

100LL Grade Aviation Fuel (Blue).

100/ 130) Grade Aviation

100 (Formerly

Fuel (Green).

1-3

SEC TION 1

GENERAL

CESSNA

MODEL 172N

FueI Capacity:

Standard Tanks:

Total Capacity: 43 gallons.

Total Capacity Each Tank: 21.5 gallons.

Total Usable: 40 gallons.

Long Range Tanks:

Total Capacity: 54 gallons.

Total Capacity Each Tank: 27 gallons.

Total Usable: 50 gallons.

NOTE

To ensure maximum fuel capacity when refueling, place

the fuel selector valve in either LEFT or RIGHT position to prevent cross-feeding.

or t

Oil Grade (Specification):

MIL-L-6082 Aviation Grade Straight Mineral Oil: Use to replenish

supply furing first 25 hours and at the first 25-hour oil change.

Continue to use until a total of 50 hours has accumulated or oil

consumption has stabilized.

NOTE

The airplane was delivered from the factory with a corrosion preventive aircraft engine oil. This oil should be

drained after the first 25 hours of operation.

MIL-L-22851 Ashless Dispersant Oil: This oil must be used after

first 50 hours or oil consumption has stabifZ6.Recommended Viscosity For Temperature Range:

MIL-L-6082 Aviation Grade Straight Mineral OiI:

SAE 50 above 16oC (60oF)

SAE 40 between -1oC (30'F) and 32oC (90"F).

SAE 30 between -18oC (0"F) and 21oC (70oF).

SAE 20 below -LzoC(10"F).

MIL-L-22851 Ashless Dispersant Oil:

SAE 40 or SAE 50 above 16oC (60'F).

SAE 40 between -1oC (30'F) and 32oC (90"F).

SAE 30 or SAE 40 between -18oC (0"F) and 21oC (70"F).

SAE 30 below -12oC (10"F).

Oil Capacity:

Sump: 6 Quarts.

Total: 7 Quarts (if oil filter installed).

L- 4

SECTION 1

GENERAL

C ESSN A

MODEL 172N

fi TAXIft I U f r T CE RT I F IC AT E DWE IG H IS

Takeoff, Normal Category: 2300 lbs.

Utility Category: 2000 lbs.

Landing, Normal Category: 2300 lbs.

Utility Category: 2000 lbs.

Weight in Baggage Compartment, Normal Category:

BaggageArea 1 (or passenger on childrs seat)-station 82 to 108:

120 lbs. See note below.

BaggageArea 2 -Station 108 to 142: 50 lbs. See note below.

NOTE

capacity for baggageareas

weight

The murimum combined

1 and 2 is 120 lbs.

Weight in Baggage Compartment, Utility Category: In this category,

baggage compartment and rear seat must not be occupied.

STAN DA R, D A I RP T A N E WE IG H T S

Standard Empty Weight, Skyhawk:

Skyhawk II:

Maximum

Useful

Load:

Normal. Categor

Skyhawk:

Skyhawk

1379 lbs.

1403 lbs.

II:

@

897 lbs.

621 lbs.

597 lbs.

C ABIN A ND E NT R Y D Ifrl EN SION S

Detailed dimensions of the cabin interior and entry door openings are

illustrated in Section 6.

BAGG A G E S P A CE A N D EN IR Y D Iftl EN SION S

Dimensions of the baggagearea and baggagedoor opening are illustrated in detail in Section 6.

SPECI F I C LO A DI NG S

Wing Loading: 13.2 lbs./sq. ft.

Power Loading: 14.4lbs./hp.

1-5

CESSNA

MODEL 172N

SECTION 1

GENERAL

SYMB O L S , AB B R ,E V IA T ION S A N D TERMINOTOGY

GENER ,A LA I RS P E E D I E R frl IN O L OGY

AN D SY ft TB OI.S

KCAS

Knots Calibrated Airspeed is indicated airspeed corrected

emor and expressed in knots.

Knots calibrated airspeed is equal to KTAS in standard atmosphere at sea level.

KIAS

Knots Indicated Airspeed is the speed shown on the airspeed

in knots.

KTAS

Knots True Airspeed is the airspeed expressed in knots relwhich is KCAS corrected for altitude

ffiir

and temperature.

VA

Maleuvering Speedis the maximum speed at which you may

use abrupt control travel.

vrn

Ma:<imuLFlap E-xtendedSpeedis the highest speed permissible with wing flaps in a prescribed extended position.

vNo

Ma:<imum Struchrral Cruising Speed is the speed that should

, then only with caution.

VNE

Never Exce-gdSpeed is the speed limit that may not be exceededat any time.

vs

Stalling Speedor tlgminimum

the airplane is controllable.

uto

Stalling Speedor the nginimum steady flight speed at which

the airplane is controllable in the landing configuration at

the most forward center of gravity.

Vy.

z1

Best Angle-of-CLmb Speedis the speed which results in the

greatest gain of altitude in a given horizontal distance.

Vy

Best Rate-of-Cliqb Speedis the speed which results in the

greatest gain in altitude in a given time.

steady.lJight :peed at which

, N ETEOR Ot O G I C A L T ER ' N IN OT OGY

OAT

1-6

Outside Air Temperature is the free air static temperature.

r degrees Celsius (formerly Centigrade) or degrees Fahrenheit.

CESSNA

MODEL 172N

is 15"C at sea level pressure altitude

for each 1000 feet of altihrde.

Standard

Temperature

Pressure

Altitude

SECTION 1

GENERAL

Pressure Altitude is the altitude read from an altimeter

when the altimeter's barometric scale has been set to 29.92

inches of mercury (1013 mb).

ENGINE P O W E R TER fi IIN O tOGY

BHP

BraEe Horsepower is the power developedby the engine.

RPM

Revolutions Per Minute is engine speed.

Static

RPM

Static RPM is ergine speed attained during a full-throttle engii.e mnup when the airplane is on the ground and stationary.

AIR PtA N E P E RF O R ' VIA N C EAN D F T IG H TP T AN N IN G TE R ' U IN OLOGY

Demonstrated

Crosswind

Velocitv

Demonstrated Crosswind Velocitv is the velocitv of the crosse control of the airplane

during takeoff and landing was acfually demonstrated during

certification tests. The value shown in not considered to be

Iimiting.

Usable Fuel Usable F\rel is the fuel available for flight planning.

Unusable Fuel is the quantity of fuel that can not be safely

Unusable

Fbel

Titrfri.

GaA-in

GPH

Gallons Per Hour is the amount of fuel (in gallons) consumed

ffi

NMPG

Nautical Miles Per Gallon is the distance (in nautical miles)

gallon of fuel consumed at a specific engine power setting and/or flight configuration.

g

g is acceleration due to gravity.

WEIGHT A ND B A L A N C E T ER ' V IIN OL OGY

Reference

Datum

Reference Datum is an imaginary vertical plane from which

are measured for balance purposes.

ffitances

Station

Station is a location along the airplane fuselage given in

Tffis of the distance from the reference datum.

t-7

SECTION 1

GENERAL

CESSNA

MODEL 172N

Arm

Arm is the horizontal distance from the reference dahrm to

Tfre-centerof gravity (C. G. ) of an item.

Moment

Moment is the product of the weight of an item multiplied by

iis arrn- (Moment divided by the constant 1000 is used in

this handbookto simplify balance calculations by reducing

the number of digits. )

Center of

Gravity

(C. G. )

Center of Gravity is the point at which an airplane, or equipif suspended. Its distance from the

@ce

reference datum is found by dividing the total moment by the

total weight of the airplane.

C. G.

Arm

Center of Gravity Arm is the arm obtained by adding the

and dividing the sum by the

@oments

total weight.

C. G.

Limits

C"nt"-" of G"*ityli

are the extreme center of gravity

airplane must be operated at a

given weight.

S t a n d a rd S t @is t heweig h to fa s ta n d a rd a i rp Ia n e ,

Empty

fuII operating fluids and full engine

@

Weight

oil.

Basic Empty Basic Empty Weight is the standard empty weight plus the

Weight

weight of optional equipment.

Useful

Load

Useful Load is the difference between takeoff weight and the

Effipitweight.

Gross

(Loaded)

Weight

Gross (Loaded) Weight is the loaded weight of the airplane.

Maximum

Takeoff

Weight

Maximum Takeoff Weight is the maximum weight approved

run.

Maximum

Landing

Weight

Ma.lcimum Landing Weight is the ma:<imum weight approved

Tare

Tare is the weight of chocks, blocks, stands, etc. used

iffiin weighing an airplane, and is included in the scale readings. Tare is deductedfrom the scale reading to obtain the

achral (net) airplane weight.

1- 8

C ESSN A

MODEL 172N

SECTION 2

LIMITATIONS

2

SECTION

LIMITATIONS

T A B LE OF C ON TE N TS

Page

Introduction

Airspeed Limitations

Airspeed Indicator IMarkings

Power Plant Limitations

Power Plant Instnrment Markings

Weight Limits

Normal Cbtegory .

Utility Ch.tegory

Center of Gravity Limits

Normal Cbtegory .

Utility Category

Maneuver Limits

Normal Ca.tegory .

Utitity Category

Flight Load Factor Limits

Normal Category

Utility Category

Kinds of Operation Limits .

FueI Limitations

Placards

2-3

2-4

2-5

2-5

2-6

2-6

2-6

z- 7

2-7

2-7

2-7

2-7

2-7

2-7

2-8

2-8

2-8

2-9

2-9

2-LO

2-t/ (2-2 blank)

C ESSN A

MODEL 172N

SECTION 2

LIMITATIONS

I NT R O D U C T I ON

Section 2 includes operating limitations, instrument markings, and

basic placards necessary for the safe operation of the airplane, its engine, standard systems and standard equipment. The limitations included in this section have been approved by the Federal Aviation

Administration.

When applicable, limitations associated with optional

systems or equipment are included in Section 9.

NOTE

The airspeeds listed in the Airspeed Limitations chart

(figure 2-1) and the Airspeed Indicator Markings chart

(figure 2-2) are based on Airspeed Calibration data

shown in Section 5 with the normal static source. If the

alternate static source is being used, ample margins

should be observed to allow for the airspeed calibration

variations between the normal and alternate static sources as shown in Section 5.

Your Cessna is certificated under FAA Type Certificate No. 3,4.12as

Cessna Model No. 172N.

2-3

SECTION 2

LIMITATIONS

CESSNI

MODEL 172}

A I R , S PEED

TIM IT A TION S

Airspeed limitations and their operational significance are shown in

figure 2-1.

SPEED

KCAS

KlAS

REMARKS

Vl te

Never Exceed Speed

158

160

Do not exceed this speed in

any operation.

Vruo

MaximumStructural

CruisingSpeed

126

128

Do not exceedthis speed

exceptin smoothair, and

then only with caution.

V4

Maneuvering

Speed:

2300 Pounds

1950Pounds

1600Pounds

96

88

80

97

89

80

Do not make full or abrupt

control movements above

this speed.

MaximumFlap Extended

Speed

86

85

Do not exceed this speed

with flaps down.

MaximumWindowOpen

Speed

158

160

Do not exceed this speed

with windows open.

Vre

Figure 2-1. Airspeed Limitations

2-4

SECTION 2

LIMITATIONS

CESSN A

MODEL 172N

A I RS P E E D I N DIC A T OR MA R K IN GS

Airspeed indicator markings and their color code significance are

shown in figure 2-2.

MARKING

KI AS VALUE

O R RANG E

White Arc

41 - 85

Full Flap OperatingRange. Lower

lirnit is maximumweightVgo in

landingconfiguration.Upperlimit

is maximumspeedpermissible

with

flaps extended.

GreenArc

47 - 128

Normal OperatingRange. Lower limit

is maximumweightVg at most forward

C.G. with flaps retracted. Upper limit

is maximumstructuralcruisingspeed.

Yellow Arc

128- 160

Red Line

160

SIGNIFICANCE

Operations must be gonducted with

ca u tio n a n d onl y i n smooth ai r.

Maximumspeedfor all operations.

Figure 2-2. Airspeed Indicator Markings

P OWER PL AN T TIMITA TIO N S

Engine Manufacturer: Avco Lycoming.

Engine Model Number: O-320-HZAD.

Engine Operating Limits for Takeoff and Continuous Operations:

Maximum Power: 160 BHP.

Maximum Engine Speed: 2700 RPM.

NOTE

The static RPM range at full throttle (carburetor heat off

and full rich mixture) is 2280 to 2400 RPM.

Maximum Oil Temperature: 118oC (245"F)

Oil Pressure, Minimum: 25 psi.

Maximum: 100 psi.

Propeller Manufacturer: .McCauley Accessory Di.vision.

Propeller Model Number: 1C160/DTM7557.

Propeller Diameter, Maximum: 75 inches.

74 inches.

Minimum:

2-5

SECTION 2

LIMITATIONS

CESSNA

MODEL 172N

P OW E R PL ANT IN S TR ,U

ME N T MA R K I NG S

Power plant instrument markings and their color code significance are

shown in figure 2-3.

IN S T RUMENT

RE D LI NE

G REENARC

M I N IM UM

LIM IT

NO RM AL

O PERATI NG

Tachometer

YELLOWA R C

RED LINE

CAU T I O N

RA N G E

MAXIMUM

LIMIT

2200 27OORPM

Oil Temperature

Oil Pressure

27OORPM

10oo-2450F

25 psi

100 psi

60-90 psi

Carburetor

Air

Temperature

Figure 2-3.

2450F

- 1 5 0 to 5oC

Power Plant Instrument Markings

W EIG HT L IM ITS

N O Rfrl AI CA T E G O RY

Maximum Takeoff Weight: 2300 lbs.

Ma.:<imumLanding Weight: 2300 lbs.

Maximum Weight in Baggage Compartment:

BaggageArea 1 (or passenger on child's seat)-Station82 to 108:

120 lbs. See note below.

BaggageArea 2 -Station 108 to 142:50 lbs. See note below.

NOTE

The maximum combined weight capacity for baggage areas

1 and 2 is 120 lbs.

2- 6

CESSNA

MODEL 172N

SECTION 2

LIMITATIONS

UTIIITY CA T E G O RY

_

Maximum Takeoff Weight: 2000 lbs.

Maximum Landing Weight: 2000 lbs.

Maximum Weight in BaggageCompartment: In the utility category, the

baggagecompartment and rear seat must not be occupied.

CE N TEROF GRA V ITY TIMITS

NON ,i AA L CA I E G O N ,Y

Center of Gravity Range:

Forward: 35. 0 inches aft of dah.rmat 1950 lbs. or less, with straight

line variation to 38. 5 inches aft of datum at 2300 lbs.

Aft: 47.3 inches aft of datum at all weights.

Reference Datum: Lower portion of front face of firewall.

UTIIITY CA T E G O RY

Center of Gravity Range:

Forward: 35. 0 inches aft of datum at 1950 lbs. or less, with straight

line variation to 35. 5 inches aft of datum at 2000 lbs.

Aft: 40. 5 inches aft of datum at all weights.

Reference Datum: Lower portion of front face of firewall.

MA N EU VER L IMITS

NOR,IUA t CA T E G O R ,Y

This airplane is certificated in both the normal and utility category. The normal category is applicable to aircraft intended for nonaerobatic operations. These include any maneuvers incidental to normal flying, stalls (except whip stalls), Lazy eights, chandelles, and

turns in which the angle of bank is not more than 60o. Aerobatic maneuvers, including spins, are not approved.

U TIIIIY CA T E G O R, Y

This airplane is not designed for purely aerobatic flight. However,

in the acquisition of various certificates such as commercial pilot, instrument pilot and flight instructor, certain maneuvers are required by the

FAA. A11 of these maneuvers are permitted in this airplane when operated in the utility category.

2-7

SECTION 2

LIMITATIONS

CESSNA

MODEL 172N

In the utility category, the baggagecompartment and rear seat must

not be occupied. No aerobatic maneuvers are approved except those listed below:

IVIANEWER

RECOMMENDED ENTRY SPEED*

Chandelles.

Lazy Eights

SteepTurns

Spins

Stalls (Except Whip Stalls).

105 knots

. 105 knots

95 lmots

Slow Deceleration

SIow Deceleration

*Abrupt use of the controls is prohibited above 97 knots.

Aerobatics that may impose high loads should not be attempted. The

important thing to bear in mind in flight maneuvers is that the airplane is

clean in aerodynamic design and will build up speed quickly with the nose

down. Proper speed control is an essential requirement for execution of

any maneuver, and care should always be exercised to avoid excessive

speed which in turn can impose excessive loads. In the execution of all

maneuvers, avoid abrupt use of controls. Intentional spins with flaps extended are prohibited.

FLI G HT L O AD F A C T OR L IMIT S

N O R'Y\At CA T E G O RY

Flight Load Factors (Gross Weight - 2300 lbs. ):

* Fl a ps Up .

*Flaps Down .

+ 3.8g, -L.52g

+3.0g

*The design load factors are l50vo of the above, and in aII

cases, the struch.rre meets or exceeds design loads.

U TITITY CA T E G O RY

Flight Load Factors (Gross Weight - 2000 lbs. ):

+Fl a ps Up

*Flaps Down .

+ 4.49, -1.?69

+3.0g

*The design load factors are L50Voof the above, and in all

cases, the structure meets or exceeds design loads.

2- B

SECTION 2

LIMITATIONS

CESSNA

N.CDEL 172N

K I ND S O F O PE R ,A T ION T IMIT S

The airplane is equippedfor day VFR and may be equipped for night

VFR and,/or IFR operations. FAR Part 91 establishes the minimum required instrumentation and equipment for these operations. The reference to types of flight operations on the operating limitations placard reflects equipment installed at the time of Airworthiness Certificate issuance

Flight into known icing conditions is prohibited.

F U EL TIM ITATION S

2 Standard Tanks: 2I.5 U.S. gallons each.

Total FueI: 43 U.S. gallons.

Usable Fuel (all flight conditions): 40 U.S. gallons.

Unusable Fuel: 3 U.S. gallons.

2 Long Range Tanks: 27 U.S. gallons each.

Total Fuel: 54 U. S. gallons

Usable Fuel (a11flight conditions): 50 U.S. gallons.

U nus able F uel: 4 U . S. g a l l o n s .

NOTE

To ensure maximum fuel capacity when refueling, place

the fuel selector valve in either LEFT or RIGHT position to prevent cross-feeding.

NOTE

Takeoff and land with the fuel selector valve handle in

the BOTH position.

Approved FueI Grades (and Colors):

100LL Grade Aviation Fuel (Blue).

100 (Formerly 100/ 130) Grade Aviation Fuel (Green).

2-9

SECTION 2

LIMITATIONS

CESSNA

MODEL 172N

PT A C AR D S

The following information is displayed in the form of composite or

individual placards.

(1) In fuII view of the pilot: (The "DAY-NIGHT-VFR-IFR" entry,

shown on the example below, will vary as the airplane is equipped.)

This airplane must be operated in compliance with the operating

limitations as stated in the form of placards, markings, and

manual.s.

-IUAXIMUMS

IvIANEWERING SPEED (IAS)

GROSSWEIGHT

FLIGHT LOAD FACTOR

F lap s U p

F lap s D o w n

Normal Category

9? knots .

2300 lbs.

Utitity Category

97 knots

2000 Ibs.

+ 3 . 8 , -1 . 5 2

+ 3 .0

4,4, -1. ?6

+ 3.0

Normal Category - No acrobatic maneuvers including spins

approved.

Utility Category - Baggage compartment and rear seat must

not be occupied.

NO ACROBATIC MANEWERS APPROVED

EXCEPT THOSE LISTED BELOW

Maneuver

Recm. Entry Speed

G 6 i i d [es.r c

Lazy Eights

Steep Turns

Maneuver

Recm. Entry Speed

S pins...ffi

. 105 knots

95 knots

Stalls (except

whip stalls) Slow Deceleration

Altitude loss in stall recovery -- 180 feet.

Abrupt use of the controls prohibited above 9? knots.

Spin Recovery: opposite rudder - forward elevator - neutralize

controls. Intentional spins with flaps extended are prohibited.

Flight into known icing conditions prohibited. This airplane is

certified for the following flight operations as of date of original

airworthiness certificate :

D AY -N IGH T -VF R -IF R

2-10

C ESSN A

MODEL 172N

S E C TION 2

LIMITATIONS

(2) Forward of fuel selector valve:

BOTH TANKS ON FOR

TAKEOFF & LANDING

(3) On the fuel selector valve

(standard

tanks):

BOTH - 40 GAL. ALL FLIGHT ATTITUDES

LEFT - 20 GAL. LEVEL FLIGHT ONLY

RIGHT - 20 GAL. LEVEL FLIGHT ONLY

OFF

On the fuel selector valve

(long range tanks):

BOTH - 50 GAL. ALL FLIGHT ATTITUDES

LEFT - 25 GAL. LEVEL FLIGHT ONLY

RIGHT - 25 GAL. LEVEL FLIGHT ONLY

OFF

(4) Near fuel tank filler

cap (standard

tanks):

FUEL

1OO/130 MIN. GRADE AVIATION GASOLINE

C AP . 2 1 .5 U .S . G A L .

Near fuel tank filler

cap (long range tanks):

FUEL

1OO/130 MIN. GRADE AVIATION

CAP. 27 U.S. GAL.

GASOLINE

2-tL

SECTION 2

LIMITATIONS

(5)

CESSNA

MODEL 172N

Near flap indicator:

AVOID SLIPS WITH FLAPS EXTENDED

(6) In baggagecompartment:

120 POUNDSIVIAXIMUM

BAGGAGE AND/OR ATIXIIJARY PA SSENGER

FORWARD OF BAGC.AGEDOOR I,ATCH

50 POUNDSMAXIMUM

BAGGAGE AFT OF BAGGAGE DOOR I"ATCH

MAXIMUM 120 POUNDS COMBINED

FOR ADDITIONAL LOADING INSTRUCTIONS

SEE WEIGHT AND BAI,ANCE DATA

(7) On the instrument panel near over-voltage light:

HIGH VOLTAGE

2-t2

SECTION 3

EMEN,GENCY PR,OCEDURES

CESSNA

MODEL 172N

3

SECTION

PROCEDURES

EMERGENCY

T A BL E OF C O N TE N TS

Page

Introduction

Airspeeds For Emergency Operation

3-3

3-3

OPERATIONAL CHECKLISIS

Engine Failures

Engine Failure During Takeoff Rrn .

Engine Failure Immediately After Takeoff .

Engine Failure During Flight

Forced Landings .

Emergency Landing Without Engine Power

Precautionary Landing With Ergrne Power

Ditching .

Fi re s

During Start On Ground.

Engine Fire In Flight .

Electrical Fire In Flight

Cabin Fire

Wing Fire

Icing

Inadvertent Icing Encounter

Static Source Blockage (Erroneous Instrument Reading

Suspected).

Landing With A Flat Main Tire

Electrical Power Supply System Malfunctions

Over-Voltage Light Illuminates

Ammeter ShowsDischarge

3-3

3'3

3-3

3-4

3-4

3-4

3-4

3-5

3-5

3-5

3-6

3-6

3-6

3-?

3-?

3-7

3-8

3-8

3-8

3-8

3-8

AMPLIFIED PROCEDURES

Engine Failure .

Forced Landings .

3-9

3-10

3-1

SECTION 3

EMERGENCY PROCEDUF,ES

CESSNA

MODEL 172N

TAB L E OF C O N T EN T S (C o n ti n u e d )

Page

Landing Without Elevator Control

Fires

Emergency Operation In Clouds (Vacuum System Failure).

Executing A 180' T\rrn In Clouds .

Emergency Descent Through Clouds

Recovery From A Spira1 Dive

Flight In Icing Conditions

Static Source Bloeked

Spins

Rough Engine Operation Or Loss Of Power

Carburetor Icing

Spark Plug Fouling .

Magneto Malfunction

Low Oil Pressure

Electrical Power Supply System Malfunctions

Excessive Rate Of Charge .

Insufficient Rate Of Charge

3-2

3-10

3- 10

3-11

3- 11

3-11

3-L2

3-12

3-t2

3- 13

3 -14

3 -14

3-14

3-14

3- 14

3- 15

3-15

3-15

CESS NA

MODEL 172N

S E C TION 3

EMERGENCY PROCEDURES

I NT R O D U C T I ON

Section 3 provides checklist and amplified procedures for coping with

emergencies that may occur. Emergencies caused by airplane or engine

malfunctions are extremely rare if proper preflight inspections and maintenance are practiced. Enroute weather emergencies can be minimized

or eliminated by careful flight planning and good judgement when unexpect'

ed weather is encountered. However, should an emergency arise the basic

guidelines described in this section should be considered and applied as

necessary to correct the problem. Emergency procedures associated

with the ELT and other optional systems can be found in section g.

A IR SPEED S

FO R E ME R GE N C YOP E RA T I O N

Engine Failure After Takeoff:

Wing Flaps Up

Wing Flaps Down

Maneuvering Speed:

2300 Lbs

1950 Lbs

1600 Lbs

Maximum Glide:

2300 Lbs

Precautionary Landing With Engine Power

Landing Without Engine Power:

Wing Flaps Up

Wing Flaps Down

65 KIAS

60 KIAS

97 KIAS

89 KIAS

80 KIAS

65 KIAS

60 KIAS

65 KIAS

60 KIAS

OP E R A TIO N A LC H E C K T I S T S

E N G INE FAIL UR ,E S

EN GINE I A I LURE D U R IN G T AK EOF F R ,U N

(1)

(2)

(3)

(4)

(5)

(6)

Throttle -- IDLE.

Brakes -- Appl,y.

Wing Flaps -- RETRACT.

Mixture -- IDLE CUT-OFF.

Ignition Switch -- OFF.

Master Switch -- OFF.

EN GINE F A I T URE I ' VI' } IED IAT E T YA F T ER T AK EOFF

(1) Airspeed -- 65 KIAS (ftaps Up).

60 KLAS (flaps DOWN).

3-3

SECTION 3

EMERGENCY PROCEDURES

(2)

(3)

(4)

(5)

(6)

CESSNA

MODEL 172N

Mixture -- IDLE CUT-OFF.

Fuel Selector Valve -- OFF.

Ignition Switch -- OFF.

Wing Flaps -- AS REQUTREb.

Master Switch -- OFF.

E N GINE F A I t UR, EDUR IN G F T IG H T

(1)

(2)

(3)

(4)

(?)

(6)

Airspeed -- 65 KIAS.

Carbr.rretor Heat -- ON.

Fuel Selector Valve -- B0IH.

Mixture -- RICH.

Ignition Switch -- BOTH (or START if prope[er is stopped).

Primer -- IN and LOCKED.

F O RCEDL AN D ING S

E f tTER GE NCYT A NDI NG WIIH O U T E N GIN E POW E R ,

(1) Airspeed -- 65 KIAS (flaps UP).

60 I(IAS (flaps DOWN).

Mixture -- IDLE CUT-OFF.

F\rel Selector Valve -- OFF.

Ignition Switch -- OFF.

Wing Flaps -- AS REQUIRED (40" recommended).

Master Switch -- OFF.

Doors -. UNI,ATCH PRIOR TO TOUCHDOIWN.

Touchdorvn-- SLIGHTLY TAIL LOW.

Brakes -- APPLY HEAVILY.

PR EC AU I I O NA RY LA N D IN G WIT H E N GIN E POW E R

(1) Wing Ftaps -- 20o.

Q\ AirsPeed -- 60 KIAS.

(3) SelectedField -- FLY OVER, noting terrain and obstructions,

then retract flaps upon reaching a safe altitude and airspeed.

(4) Radio and Electrical Switches -^ OFF.

(5) Wing Flaps -- 40o (on final approach).

(6) Airspeed -- 60 I(IAS.

(7) Master Switch -- OFF.

(8) Doors -- UNLATCH PRIOR TO TOUCHDOWN.

(9) Touchdown -- SLIGHTLY TAIL LOTW.

(10) Ignition Switch -- OFF.

(11) Brakes -- APPLY HEAVILY.

3-4

S E C TION 3

EMERGENCY PROCEDURES

C ESSN A

MODEL 172N

DITCHI NG

(1) Radio -- TRANSMIT MAYDAY on LZI.5 MHz, givinglocation and

intentions.

(2) Heavy Objects (in baggage area) -- SECURE OR JETTISON.

(3) Approach -- High Winds, Heavy Seas -- INTO THE WIND.

Light Winds, Heavy Swells -- PARALLEL TO

SWELLS.

(4) Wing Flaps -- 20o - 40o.

(5) Power -- ESTABLISH 300 FT/MIN DESCENT at 55 KIAS.

NOTE

If no power is available, approach at 65 KIAS with flaps

up or at 60 KIAS with 10o flaps.

(6) Cabin Doors -- UNLATCH.

(7) Touchdown -- LEVEL ATTITUDE AT ESTABLISHED RATE OF

DE S CE NT .

(8) Face -- CUSHION at touchdown with folded coat.

(9) Airplane

EVACUATE through cabin doors. If necessary,

open window and flood cabin to equalize pressure so doors can be

opened.

(10) Life Vests and Raft -- INFLATE.

F I RE S

D URING S T A RI O N GR O U N D

(1) Cranking -- CONTINUE, to get a start which would suck the

flames and accumulated fuel through the carburetor and into the

engine.

If engine starts:

(2) Power -- 1700 RPM for a few minutes.

(3) Engine -- SHUTDOWN and inspect for damage.

If engine fails to start:

(4)

(5)

(6)

(7)

not

(8)

Throttle -- FULL OPEN.

Mixture -- IDLE CUT-OFF.

Cranking -- CONTINUE.

Fire Extinguisher -- OBTAIN (have ground attendants obtain if

installed).

Engine -- SECURE.

a. Master Switch -- OFF.

3-5

SECTION 3

EMERGENCY PROCEDURES

CESSNA

MODEL 172N

b. Ignition Switch -- OFF.

c. FueI Selector Valve -- OFF.

(9) Fire -- EXTINGUISH using fire extinguisher, wool blanket, or

dirt.

(10) Fire Damage -- INSPECT, repair damage or replace damaged

components or wiring before conducting another flight.

EN GINE FI R, EI N F T I G H T

(1) Mixture -- IDLE CUT-OFF.

(2) F\rel Selector Valve -- OFF.

(3) Master Switch -- OFF.

(4) Cabin Heat and Air -- OFF (except overhead vents).

(5) Airspeed -- 100 KIAS (If fire is not extinguished, increase glide

speed to find an airspeed which will provide an incombustible mixture).

(6) Forced Landing -- EXECUTE (as described in Emergency Landing Without Engine Power).

E TEC IRICA TF I RE I N F L IG H I

(1)

(2)

(3)

(4)

Master Switch -- OFF.

All Other Switches (except ignition switch) -- OFF.

Yents/Cabin Air,/Heat -- CLOSED.

Fire Extinguisher -- ACTWATE (if available).

W A R N IN G

After discharging an extinguisher within a closed cabin,

ventilate the cabin.

If fire appears out and electrical power is necessary for continuance

of flight:

(5) Master Switch -- ON.

(6) Circuit Breakers -- CHECK for faulty circuit, do not reset.

(7) Raaio/Electrical Switches -- ON one at a time, with delay after

each until short circuit is localized.

(8) Vents/Cabin Air/Heat -- OPEN when it is ascertained that fire

is completely extinguished.

CABIN FI RE

(1) Master Switch -- OFF.

(2) Vents/Cabin Air,/Heat -- CLOSED (to avoid drafts).

(3) Fire Extinguisher -- ACTMTE

(if available).

3-6

S E C TION 3

EMERGENCY PROCEDURES

C ESSN A

MODEL 172N

W A R N IN G

After discharging an extinguisher within a closed cabin,

ventilate the cabin.

(4) Land the airplane as soon as possible to inspect for damage.

WING F I R, E

(1 ) Navigation Light Switch -- OFF.

(2) Pitot Heat Switch (if installed) -- OFF.

(3) Strobe Light Switch (if installed) -- OFF.

NOTE

Perform a sideslip to keep the flames away from the

fuel tank and cabin, and land as soon as possible using

flaps only as required for final approach and touchdown.

IC I NG

INAD V E R, T E NTI CI N G EN C OU N T E R

(1) Turn pitot heat switch ON (if installed).

(2) Turn back or change altitude to obtain an outside air temperature

that is less condtrciveto icing.

(3) PuIl cabin heat control full out and open defroster outlet to obtain

murimum windshield defroster airflovv. Adjust cabin air control to

get ma><imumdefroster heat and airflow.

(4) Open the throttle to increase engine speed and minimize ice

build-up on propeller blades.

(5) Watch for signs of carburetor air filter ice and apply carburetor

heat as required. An unexplained loss in engine speed could be caused

by carburetor ice or air intake filter ice. Lean the mixture for ma:rimum RPM if carburetor heat is used continuously.

(6) Plan a landing at the nearest airport. With an extremely rapid

ice build-up, select a suitable "off airport" landing site.

(7) With an ice accumulation of l/4 inch or more on the wing leading

edges, be prepared for significantly higher stall speed.

(8) Leave wing flaps retracted. With a severe ice biuild-up on the

horizontal tail, the change in wing wake airflow direction caused by

wing flap extension corld result in a loss of elevator effectiveness.

3-7

SEC TION 3

EMERGENCY PROCEDURES

CESSNA

MODEL 172N

(9) Open left window and, if practical, scrape ice from a portion of

the windshield for visibility in the landing approach.

(10) Perform a landing approach using a forward slip, if necessary,

for improved visibility.

(11) Approach at 65 to ?5 KIAS, depending upon the amornt of the

accurnulation.

(12) Perform a landing in level attitude.

S TAIIC S O UR, CEB T O C K AGE

( Erro n e o us I ns t r um enl R e o d i n g S u s p e c te d )

(1) Alternate Static Source Valve -- PULL ON.

(2) Airspeed -- Consutt appropriate calibration tables in Section 5.

LA N DING WITH A FLA T MA IN TIR E

(1) Approach -- NORI\{AL.

(2) Touchdown -- GOOD TIRE FIRST, hold airplane off flat tire as

long as possible.

ELE C TR ,ICPOWE

AL

RS U P P LYS Y S TE MM A L F UNCT I O NS

OVER ,.V O t I A G E T I G H T IttU ,N IN AT E S

(1) Master Switch -- OFF (both sides).

(2) Master Switch -- ON.

(3) Over-Voltage Light -- OFF.

If over-voltage light illuminates again:

(4) Flight -- TERMINATE as soon as possible.

A,U'VIET E R,S H O W S D IS C H A R G E

(1) Alternator -- OFF.

(2) Nonessential Electrical Equipment -- OFF.

(3) Flight -- TERMINATE as soon as practical.

3-8

CESSNA

MODEL 172N

SECTION 3

EMEITGENCY PROCEDURES

A MP T IF IE D P R OC E D URES

E N G INE FAIL U R E

If an engine failure occurs during the takeoff nrr5 the most important

thing to do is stop the airplane on the remaining runway. Those extra

items on the checklist will provide added safety drring a fallure of this

type.

Prompt lowering of the nose to maintain airspeed and establish a

glide attitude is the first response to an engine failure after takeoff. In

most cases, the landing shonld be planned straight ahead with only small

changes in direction to avoid obstmctions. Altitude and airspeed are seldom sufficient to execute a 180" gliding furn necessary to return to the

runway. The checklist procedures assume that adequate time exists to

secure the fuel and ignition systems prior to touchdown.

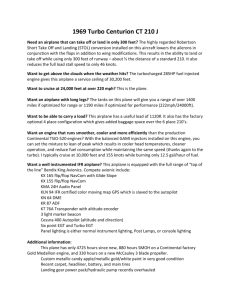

After an engine failure in flight, the best glide speed as shown in Figure 3-1 should be established as quickly as possible. While gliding toward a suitable landing area, an effort should be made to identify the cause

of the failure. If time permits, an engine restart should be attempted as

shown in the checklist. If the engine cannot be restarted, a forced landing

without power must be completed.

1 2,0 00

1-

...r.1.:I

.l,.....r.i.::'j

a! 10,000

I

z

d

8000

uJ

F

ur

o

(I)

6000

:

4ooo

F

1

t

I

..."rj:f

2ooo

,rii

l.'.'.::':'."'

I

I

* SP EE D6 5 K IA S

* P R OP EItE R W IN D ' V l II.TIN G

* F T A PSU P * ZE R O W IN D

l l tr

10

't2

14

16

18

G RO UNDDI STANCE- NAUTI C A LM I L E S

Figure 3-1.

Mzurimum Glide

3-9

SECTION 3

EMERGENCY PROCEDURES

CESSNA

MODEL 172N

F O RC EDL AND ING S

If all attempts to restart the engine fail and a forced landing is

imminent, select a suitable field and prepare for the landing as discussed in the checklist for engine-off emergency landings.

Before attempting an "off airport" landing with engine power available, one should drag the landing area at a safe but low altitude to

inspect the terrain for obstructions and surface conditions, proceeding

as discussed under the Precautionary Landing With Engine Power

checklist.

Prepare for ditching by securing or jettisoning heavy objects located in the baggage area and collect folded coats for protection of occupants' face at touchdown. Transmit Mayday message on 121.5MHz

giving location and intentions. Avoid a landing flare because of difficulty in judging height over a water surface.

L A ND IN G WITHOU T E LE V A TORC, O NT R, O L

Trim for horizontal flight(with an airspeed of approximately 60 KIAS

and flaps set to 20") by using throttle and elevator trim control. Then do

not change the elevatoi trim control settingl control the glide angle by adjusting power exclusively.

At flareout, the nose-down moment resulting from power reduction is

an adverse factor and the airplane may hit on the nose wheel. Consequently,

at flareout, the elevator trim control should be adjusted toward the full

nose-up position and the power adjusted so that the airplane will rotate to

the horizontal attitude for touchdown. Close the throttle at touchdown.

FIRE S

Although engine fires are extremely rare in flight, the steps of the

appropriate checklist should be followed if one is encountered. After

completion of this procedure, execute a forced landing. Do not attempt

to restart the engine.

The initial indication of an electrical fire is usually the odor of burning insulation. The checklist for this problem should result in elimination

of the fire,

3- 1 0

CESSN A

MODEL 172N

SECTION 3

EMERGENCY PR,OCEDUR,ES

EME R G EN C Y OP E R ,A T IONIN C T OUDS

(V o c u u m S y s t e m F q i l u re )

In the event of a vacuum system failure during flight in marginal

weather, the directional indicator and attitude indicator will be disabled,

and the pilot will have to rely on the turn coordinator or the turn and bank

indicator if he inadvertently flies into clouds. The following instnrctions

assume that only the electrically-powered turn coordinator or the turn

and bank indicator is operative, and that the pilot is not completely proficient in instnrment flying.

EXECUT I NG A I S O O T U R N IN C T O U D S

Upon inadvertently entering the clouds, an immediate plan should

be made to turn back as follows:

(1) Note the time of the minute hand and observe the position of the

sweep second hand on the clock.

(2) When the sweep second hand indicates the nearest half-minute,

initiate a standard rate left turn, holding the turn coordinator symbolic airplane wing opposite the lower left index mark for 60 seconds. Then roll back to level flight by leveling the miniature airpIane.

(3) Check accuracy of the turn by observing the compass heading

which should be the reciprocal of the original heading.

(4) If necessary, adjust heading primarily with skidding motions

rather than rolling motions so that the compass will read more

accurately.

(5) Maintain altitude and airspeed by cautious application of elevator control. Avoid overcontrolling by keeping the hands off the

control wheel as much as possible and steering only with rudder.

E'N ER G E NCY DE S C EN TIH R OU GH C tO U D S

If conditions preclude reestablishment of VFR flight by a 180" turn, a

descent through a cloud deck to VFR conditions may be appropriate, If

possible, obtain radio clearance for an emergency descent through clouds.

To guard against a spiral dive, choose an easterly or westerly heading to

minimize compass card swings due to changing bank angles. In addition,

keep hands off the control wheel and steer a straight course with nrdder

control by monitoring the turn coordinator. Occasionally check the compass heading and make minor corrections to hold an approximate course.

Before descending into the clouds, set up a stabilized let-down condition

as follows:

(1) Apply tull rich mixture.

(2) Use full carburetor heat.

3-11

CESSNA

MODEL 172N

SECTION 3

EMERGENCY PROCEDURES

(3) Reduce power to set up a 500 to 800 ftlmin rate of descent.

(4) Adjust the elevator trim and rudder trim (if installed) for a

stabilized descent at 70-80 KIAS.

(5) Keep hands off the control wheel.

(6) Monitor turn coordinator and make conections by rudder alone.

(7) Check trend of compass card movement and make cautious corrections with rudder to stop the turn.

(8) Upon breaking out of clouds, resume normal cruising ftight.

R , EC OVE RYF RO ' V I A SP IR A T D IV E

If a spiral is encountered, proceed as follows:

(1) Close the throttle.

(2) Stop the turn by using coordinated aileron and rudder control to

align the symbolic airplane in the turn coordinator with the horizon

reference line.

(3) Cautiously apply elevator back pressure to slowly reduce the

airspeed to 80 KIAS.

(4) Adjust the elevator trim control to maintain an 80 KIAS gtide.

(5) Keep hands off the control wheel, using rudder control to hold a

straight heading. Adjust rudder trim (if installed) to relieve unbalanced rudder force.

(6) Apply carburetor heat.

(7) Clear engine occasionally, but avoid using enough power to

disturb the trimmed glide.

(8) Upon breaking out of clouds, resume normal cruising flight.

FLIGH TIN IC ING C O N D ITION S

Flight into icing conditions is prohibited. An inadvertent encounter

with these conditions can best be handled using the checklist procedures.

The best procedure, of course, is to turn back or change altitude to escape icing conditions.

S TATIC SO URCE B I O C K ED

If erroneous readings of the static source instmments (airspeed,

altimeter and rate-of-climb) are suspected, the alternate static source

valve should be pulled on, thereby supplying static pressure to these

instruments from the cabin.

NOTE

In an emergency on airplanes not equipped with an alternate static source, cabin pressure can be supplied to the

3-12

S E C TION 3

EMERGENCY PROCEDURES

CESSNA

MODEL 172N

static pressure instruments by breaking the glass in the

face of the rate-of-climb indicator.

With the alternate static source on, adjust indicated airspeed slightly

during climb or approach according to the alternate static source airspeed

catibiation table in Section 5, appropriate to vent/window(s) configuration,

causing the airplane to be flown at the normal operating speeds.

Maximum airspeed and altimeter variation from normal is 4 knots and

30 feet over the normal operating range with the window(s) closed. With

window(s) open, larger variations occur near stall speed. However, maximum altimeter variation remains within 50 feet of normal.

S PI N S

Should an inadvertent spin occur, the following recovery procedure

should be used:

(1) RETARD THROTTLE TO IDLE POSITION.

(2) PLACE AILERONS IN NEUTRAL PGTTION.

(3) APPLY AND HOLD FULL RUDDER OPPOSITE TO THE DIRECTION OF ROTATI6.(4) JUST AFTER THE RUDDER REACHES THE STOP, MOVE THE

CONTROL.WEEEL BRISKLY FORWARD FAR ENOUGH TO BREAK

THE STALL. FuU Effii&ator

may be required at aft center of

gravity loadings to assure optimum recoveries,

(5) HOLD THESE CONTROL TNPUTSUlrrrl. ROTATTONSTOPS.

Prerffie

rela:<ation of the control inputs may extend the recovery.

(6) AS ROTATTON STOPS, NEUTRATTZE.RUDDER, AND TVIAKEA

SMOOTH RECOVERY FROM THE RESULTING DIVE.

NOTE

If disorientation precludes a visual determination of the

direction of rotation, the symbolic airplane in the turn

coordinator or the needle of the turn and bank indicator

may be referred to for this information.

For additional information on spins and spin recovery, see the

discussion under SPINS in Normal Procedures (Section 4).

3- 13

SECTION 3

EMERGENCY PR,OCEDURES

CESSNA

MODEL 172N

RO UG H EN G I N E OP E R A T ION OR L OSS OF POW ER

C A R BU RE T O RI CI NG

A gradual loss of RPM and evenhral engine roughness may result from

the formation of carbruretor ice. To clear the ice, apply full throttle and

pull the carburetor heat knob fulI out until the engine runs smoothly; then

remove carburetor heat and readjust the throttle. If conditions require

the continued use of carburetor heat in cnrise flight, use the minimum

amount of heat necessary to prevent ice from forming and lean the mixture for smoothest engine operation.

SPARK PtUG F O ULI NG

A slight engine roughness in flight may be caused by one or more

spark plugs becoming fouled by carbon or lead deposits. This may be

verified by turning the ignition switch momentarily from BOTH to either

L or R position. An obvious power loss in single ignition operation is

evidence of spark plug or magneto trouble. Assuming that spark plugs

are the more likely cause, lean the mixbure to the recommended lean setting for cruising flight. If the problem does not clear up in several minutes, determine if a richer mixh.rre setting will produce smoother operation. If not, proceed to the nearest airport for repairs using the BOTH

position of the ignition switch unless extreme roughness dictates the use

of a single ignition position.

T VI

A G N ET O ' V TA I F U NC T IO N

A sudden engine roughness or misfiring is usually evidence of magneto problems. Switching from BOTH to either L or R ignition switch

position will identify which magneto is maUunctioning. Select different

power settings and enrichen the mixture to determine if continued operation on BOTH magnetos is practicable. If not, switch to the good magneto

and proceed to the nearest airport for repairs.

LO W OIT P RE S S URE

If low oil pressure is accompanied by normal oil temperature, there

is a possibility the oil pressure gage or relief valve is maLfunctioning. A

leak in the line to the gage is not necessarily cause for an immediate precautionary landing because an orifice in this line will prevent a sudden

loss of oil from the engine sump. However, a landing at the nearest airport would be advisable to inspect the source of trouble.

If a total loss of oil pressure i:s accompanied by a rise in oil temperature, there is good reason to suspect an engine failure is imminent. Re3- 14

C ESSN A

MODEL 172N

S E C TION 3

EMERGENCY PROCEDURES

duce engine power immediately and select a suitable forced landing field.

Use only the minimum power required to reach the desired touchdown spot.

E LE CTR .ICPO

AT W E RS U P P LYS Y S TEMM A L F UNCT I O NS

Malfunctions in the electrical power supply system can be detected by

periodic monitoring of the ammeter and over-voltage warning light; however, the cause of these malfunctions is usually difficult to determine. A

broken alternator drive belt or wiring is most likely the cause of alternator failures, although other factors cotrld cause the problem. A damaged

or improperly adjusted voltage regulator can also cause maUunctions.

Problems of this nafure constitute an electrical emergency and should be

dealt with immediately. Electrical power malfunctions usually fall into

two categories: excessive rate of charge and insufficient rate of charge.

The following paragraphs describe the recommended remedy for each

situation.

EXCESS I V ERA T E O F C H A R ,GE

After engine starting and heavy electrical usage at low engine speeds

(such as extended tarciing) the battery condition will be low enough to accept above normal charging during the initial part of a flight. However,

after thirty minutes of cnrising flight, the ammeter should be indicating

Iess than two needle widths of charging current. If the charging rate were

to remain above this value on a long flight, the battery would overheat and

evaporate the electrolyte at an excessive rate. Electronic components in

the electrical system could be adversely affected by higher than normal

voltage if a faulty voltage regulator setting is causing the overchar$ng.

To preclude these possibilities, an over-voltage sensor will automatically

shut down the alternator and the over-voltage warning light will illuminate

if the charge voltage reaches approximately 16 volts. Assuming that the

maUunction was only momentary, an attempt should be made to reactivate

the alternator system. To do this, turn both sides of the master switch

off and then on again. If the problem no longer exists, normal alternator

charging will resume and the warning light will go off. If the light comes

on again, a malfunction is confirmed. In this event, the flight should be

terminated and/or the current drain on the battery minimized because the

battery can supply the electrical system for only a limited period of time.

If the emergency occurs at night, power must be conserved for later use

of landing lights and flaps during landing.

INSU F F I CI E NI RA I E O F C H A R GE

If the ammeter indicates a continuous discharge rate in flight, the

3-1 5

SECTION 3

EMERGENCY PROCEDURES

CESSNA

MODEL 172N

alternator is not supplying power to the system and should be shut down

since the alternator field circuit may be placing an unnecessary load on

the system. All nonessential equipment should be furned off and the

flight terminated as soon as practical.

3-16

SECTION 4

NORMAL PROCEDURES

CESSNA

MODEL 172N

SECTION

4

NORMALPROCEDURES

T A B TE OF CONTE N TS

Page

Introduction

Speeds For Normal Operation

4-3

4-3

CHECKLIST PROCEDURES

4-5

4-5

4-5

4-5

4-5

4-5

4-6

4-6

4-6

4-6

4-6

4-7

4-7

4-7

4-8

4-8

4-8

4-8

4-8

4-9

4-9

4-9

4-9

4-9

4-9

Preflight

Inspection

Cabin

Empennage

Right Wing, Trailing Edge

Right Wing

Nose

Left Wing

Left Wing, Leading Edge

Left Wing, Trailing Edge

Before Starting Engine

Starting Engine

Before Takeoff

Takeoff

Normal

Takeoff

Short Field Takeoff

Enroute Climb

Cruise

Descent

Before Landing

Landing

Normal Landing

Short Field Landing

Balked Landing

After Landing

Securing Airplane

AMPLIFIED

Starting

Engine

PROCEDURES

.4-LL

4-7

SECTION 4

NORMAL PROCEDURES

CESSNA

MODEL 172N

TA BLE O F C O N T E N IS (C o n ti n u e d )

Page

T axi i n g

Before Takeoff

Warm-Up

Magneto Check

Al te rnat or O hec k

Takeoff

Po wer Chec k

Wing Flap Settings

Short Field Takeoff

Crosswind Takeoff

Enroute Ctimb

Cruise

St a l l s

Spins

La n d i n g

Normal Landing

Short Field Landing

Crosswind Landing

Balked Landing

CoId Weather Operation

Starting

Flight Operations

Hot Weather Operation

Noise Abatement

4-2

, .

.

.4-LI

.4-13

. 4-13

.4-13

.4-LB

.4-18

.4-13

.4-L4

.4-L4

.4-15

.4-L5

.4-I5

.4-LT

.4-tz

.4-19

.4-19

.4-2O

.4-2O

.4-2O

.4-20

.4-2O

.4-22

.4-23

.4-23

CESSNA

MODEL 172N

SECTION 4

NORMAL PR,OCEDURES

I NT R , O D U C T I ON

Section 4 provides checklist and amplified procedures for the conduct

of normal operation. Normal procedures associated with Optional Systems can be found in Section 9.

SP EE D SF O R N OR MA T OP E R A T ION

Unless otherwise noted, the following speeds are based on a maximum weight of 23T0 pounds and may be used for any lesser weight.

However, to achieve the performance specified in Section 5 for takeoff

distance, the speed appropriate to the particular weight must be used.

Takeoff, Flaps Up:

Normal Climb Out

Short Fietd Takeoff, Flaps Up, Speed at 50 Feet

Enroute Climb, Flaps Up:

70-80 KIAS

59 KIAS

75.85 KIAS

Sea Level

Normal, 10,000Feet

70-80 KIAS

Best Rate of Climb, Sea Level

73 KIAS

Best R,ate of Climb, 10,000Feet

Best Angle of Climb, Sea Level

Best Angle of Climb, 10,000Feet

Landing Approach:

Normal Approach, Flaps Up

60-70 KIAS

Normal Approach, Flaps 40o

55-65 KIAS

60 KIAS

Short Field Approach, Flaps 40o

Balked Landing:

Maximum Power, Flaps 20o

55 KIAS

Maximum Recommended Turbulent Air Penetration Speed:

2300 Lbs

97 KIAS

1950 Lbs

89 KIAS

1600 Lbs

80 KIAS

Maximum Demonstrated Crosswind Velocity:

Takeoff or Landing

15 KNOTS

Normal,

:::::::: ::: :i[it:

4-3

SECTION 4

NORMAL PROCEDURES

CESSNA

MODEL 172N

NOTE

Visually check airplane for general condition during

walk-around inspection. In cold weather, remove even

small accumulations of frost, ice or snow from wing,

tail and control surfaces. Also, make sure that eontrol

surfaces contain no internal accumulations of ice or de!ris. If a night flight is planned, check operation of all

lights, and make sure a flashlight is avaiUfte.

Figure 4- 1. Preflight Inspection

4-4

SECTION 4

NORMAL PROCEDURES

CESSNA

MODEL 172N

C HE C K L IS T P R .OC E D URES

_

P RE FIIGH TIN S P E C TION

.

'

u cABtN

-

_

(1) Control Wheel Lock -- REMOVE.

(2) Ignition Switch -- OFF.

(3) Master Switch -' ON.

(4) fuet Quantity Indicators -- CHECI( QUAMITY.

(5) Master Switch -- OFF.

(6) Baggage Door -- CHECK, lock with key if childrs seat is to be

occupied.

@ Tm PEN N AG E

(1) Rudder Gust Lock -- REMOVE.

(2) Tail Tie-Down -- DISCONNECT.

(3) Control Surfaces -- CHECK freedom of movement and searrity.

@ nIGHT wtNG Troilins Edse

(1) Aileron -- CHECK freedom of movement and security.

@ nr G H Tw r N G

(1) Wing Tie-Down -- DISCONNECT.

(2) Main Wheel Tire -- CHECK for proper inflation.

(3) Before first ffight of the day and after each refueling, use

sampler cup and drain small quantity of fuel from fuel tank sump

quick-drain valve to check for water, sediment, and proper fuel

grade.

(4) FueI Quantity -- CHECK VISUALLY for desired level.

(5) Fuel Filler Cap -- SECURE.

@ nosr

(1) Engine Oil Level -- CHECK. Do not operate with less than four

quarts. F1II to six quarts for extended flight.

(2) Before first flight of the day and after each refueling, pull out

strainer drain knob for about four seconds to clear fuel strainer of

possible water and sediment. Check strainer drain closed. If water

is observed, the fuel system may contain additional water, and

further draining of the system at the strainer, fuel tank sumps, and

4-5

SECTION 4

NORMAL PROCEDURES

CESSNA

MODEL 172N

fuel selector valve drain plug will be necessary.

(3) Propeller and Spinner -- CHECK for nicks and security.

(4) Landing Light(s) -- CHECK for condition and cleanliness.

(5) Carburetor Air Filter -- CHECK for restrictions by dust or other

foreign matter.

(6) Nose Wheel Strut and Tire -- CHECK for proper inflation.

(7) Nose Tie-Down -- DISCONNECT.

(8) Static Source Opening (Ieft side of fuselage) -- CHECK for stoppage.

(!

r EFTw tN G

(1) Main Wheel Tire -- CHECK for proper inflation.

(2) Before first flight of the day and after each refueling, use

sampler cup and drain small quantity of fuel from fuel tank sump

quick-drain valve to check for water, sediment and proper fuel

grade.

(3) Fuel Quantity -- CHECK VISUALLY for desired level

(4) Fuel FiIIer Cap -- SECURE.

Q) tEFr wtNG Leodins Edge

(1) Pitot Tube Cover -- REMOVE and check opening for stoppage.

(2) Fuel Tank Vent Opening -- CHECK for stoppage.

(3) Stall Warning Opening -- CHECK for stoppage. To check the system, place a clean handkerchief over the vent opening and apply zuction; a sound from the warning horn will confirm system operation.

(4) Wing Tie-Down -- DISCONNECT.

(f

tEFT w ING Iroilins Edee

(1) Aileron -- CHECK for freedom of movement and security.

BE F ORESTAR,T IN GE N GIN E

(1)

(2)

(3)

(4)

(5)

(6)

Preflight Inspection -- COMPLETE.

Seats, Belts, Shorlder Harnesses -- ADJUST and LOCK.

FueI Selector Valve -- BOTH.

Radios, Autopilot, Electrical Equipment -- OFF.

Brakes -- TEST and SET.

Circuit Breakers -- CHECK IN.

ST AR, T I N G EN G IN E

(1) Mixture -- RICH.

4- 6

CESSNA

MODEL 172N

(2)

(3)

(4)

(5)

(6)

(7)

(8)

SECTION 4

NOR,MAL PR,OCEDURES

Carburetor Heat -- COLD.

Master Switch -- ON.

Prime -- AS REQUIRED (2 to 6 strokes; none if engine is warm).

Throttle -- OPEN 1/8 INCH.

Propeller Area -- CLEAR.

Ignition Switch -- START (release when engine starts).

OiI Pressure -- CHECK.

BE F ORETAKEO FF

-

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

Parking Brake -- SET.

Cabin Doors and Window(s) -- CLOSED and LOCKED.

Flight Controls -- FREE and CORRECT.

Flight Instruments -- SET.

Fuel Selector Valve -- BOTH.

Mixture -- RICH (below 3000 feet).

Elevator Trim and Rudder Trim (if installed) -- TAKEOFF.

Throttle -- 1700 RPM.

a. Magnetos -- CHECK (RPM drop should not exceed 125 RPM

on either magneto or 50 RPM differential between magnetos).

b. Carburetor Heat -- CHECK (for RPM drop).

c. Engine Instruments and Ammeter -- CHECK.

d. Suction Gage -- CHECK.

(9) Radios -- SET.

(10) Autopilot (if installed) -- OFF.

(11) Flashing Beacon, Navigation Lights and/or Strobe Lights -- ON

as required.

(12) Throttle Friction Lock -- ADJUST.

(13) Brakes -- RELEASE.

T A K EOFF

NORfi l A L T A K E O F F

(1)

(2)

(3)

(4)

(5)

Wing Flaps -- UP.

Carburetor Heat -- COLD.

Throttle -- FULL OPEN.

Elevator Control -- LIFT NOSE WHEEL (at b5 KIAS).

Climb Speed -- 70-80KIAS.

4-7

CESSNA

MODEL 172N

SECTION 4

NORMAL PROCEDURES

SH O RT FIE LD T A K E O T F

(1) Wing Flaps -- UP.

(2) Carburetor Heat -- COLD.

(3) Brakes -- APPLY.

(4) Throttle -- FULL OPEN.

(5) Mixture -- RICH (above 3000 feet, LEAN to obtain maximum

RPM).

(6) Brakes -- RELEASE.

(7) Elevator Control -- SLIGHTLY TAIL LOW.

(8) Climb Speed -- 59 KIAS (until aII obstailes are cleared).

E NR , OU TE

C tI M B

(1) Airspeed -- 70-85 KIAS.

NCITE

If a murimum performance climb is necess€[yr use

speeds shown in the Rate Of Climb chart in Section 5.

(2) Throttle -- FULL OPEN.

(3) Mixture -- RICH (above 3000 feet, LEAN to obtain maximum

RPM).

cRurs E

(1) Power -- }ZOO-2200RPM (no more than ?SVois recommended).

(2) Elevator and Rudder Trim (if installed) -- ADJUST.

(3) Mixture -- LEAN.

DE S C ENT

(1) Mixture -- ADJUST for smooth operation (full rich for idle power).

(2) Power -- AS DESIRED.

(3) Carburetor Heat -- AS REQUIRED (to prevent carburetor icing).

BE F O REL AND ING

(t) Seats, Belts, Harnesses -- SECURE.

(2) Fuel Selector Valve -- BOTH.

4= 8

CESSNA

MODEL 172N

SECTION 4

NORMAL PROCEDURES

(3) Mixture -- RICH.

(4) Carburetor Heat -- ON (appty full heat before closing throttle).

LA N DIN G

N OR frlA L T A N DI N G

(1)

(2)

(3)

(4)

(5)

(6)

-

Airspeed -- 60-70 KIAS (flaps UP).

Wing Flaps -- AS DESIRED (below 85 KIAS).

Airspeed -- 55-65 KIAS (flaps DOWN).

Touchdown -- MAIN WHEELS FIRST.

Landing Roll -- LOWER NOSE WHEEL GENTLY.

Braking -- MINIMUM REQUIRED.

SHORT F I E LD T A NDIN G

(1)

(2)

(3)

(4)

(5)

(6)

(7)

_

Airspeed -- 60-70 KIAS (flaps UP).

Wing Flaps -- FULL DOWN (40").

Airspeed -- 60 KIAS (until flare).

Power -- REDUCE to idle after clearing obstacle.

Touchdown -- MAIN WHEELS FIRST.

Brakes -- APPLY HEAVILY.

tittU Flaps -- RETRACT.

BATKE D T A NDI NG

(1)

(2)

(3)

(4)

(5)

Throttle -- FULL OPEN.

Carburetor Heat -- COLD.

Wing Flaps -- 20o (immediately).

Climb Speed -- 55 KIAS.

Wing Flaps -- 10o (until obstacles are cleared).

RETRACT (after reaching a safe altitude and 60

K rAS ).

A F T ERL AN D ING

(1) Wing Flaps -- UP.

(2') Carburetor Heat -- COLD.

AIRP LA N E

S E C U R ,IN G

(1) Parking Brale -- SET.

(2) Radios, Electrical Equipment, Autopilot -- OFF.

4-9

SECTION 4

NORMAL PROCEDIIRES

(3)

(4)

(5)

(6)

4- 1 0

Mixture -- IDLE CUT-OFF (prlled tuIl out).

Ignition Switch -- OFF.

Master Switch -- OFF.

Control Lock -- INSTALL.

CESSNA

MODEL 172N

SECTION 4

NORMAL PROCEDURES

CESSNA

MODEL 172N

A MP T IF IE D P R OC E D URES

S T A R,TINGENG IN E

During ergine starting, open the throttle approximately f/g inch. In

warm temperatures, one or hvo strokes of the primer should be zufficient.

In cold weather, up to six strokes of the primer may be necessary. If the

engine is warm, no primirg will be required. In extremely cold temperatures, it may be necessary to continue priming while cranking the engine.

Weak intermittent firing followed by puffs of black smoke from the

exhaust stack indicate overpriming or flooding. Excess fuel can be

cleared from the combiustion chambers by the following procedure: Set

the mixfure control full lean and the throttle full open; then crank the engine through several revolutions with the starter. Repeat the starting

procedure without any additional priming.

If the engine is underprimed (most likely in cold weather with a cold

engine) i+'will not fire at all, and additional priming will be necessary.

As soon as the cylinders begin to fire, open the throttle slightly to keep it

running.

After starting, if the oil gage does not begin to show pressure within

30 seconds in the zummertime and about twice that long in very cold

weather, stop engine and investigate, I-ack of oil pressure can cause

seriors ergine damage. After starting, avoid the use of carbretor heat

unless icing conditions prevail.

NOTE

Additional details concerning cold weather starting and

operation may be found under COLD WEATHER OPERATION paragraphs in this section.

T A XIING

When taxiing, it is important that speed and use of brakes be held to

a minimum and that all controls be utilized (see Taxiing Diagram, figure

4-2\ to maintain directional control and balance.

The carburetor heat control lcrob should be pushed full in during all

ground operations unless heat is absolutely necessary. When the lmob is

4-17

SECTION 4

NORMAL PROCEDURES

USE UP AILERON

ON LH WING AND

NEUTRAL ELEVATOR

USE UP AILERON

ON RH WING AND

NEUTRAL ELEVATOR

USE DOWN AILERON

ON LH WING AND

DOWN ELEVATOR

USE DOWN AILERON

ON RH WING AIVD

DOWN ELEVATOR

NOTE

CODE

wrNDDmECrroN )

Figure 4'2.

4-12

CESSNA

MODEL 172N

Strong quartering tail winds require caution.

Avoid sudden bursts of the throttle and sharp

braking when the airplane is in thip attitude.

Use the steerable nose wheel and rudder to

maintain direction.

Taxiing Diagrarn

CESSN A

MODEL 172N

SECTION 4

NORMAL PROCEDURES

prlled out to the heat position, air entering the engine is not filtered.

Tzu<iing over loose gravel or cinders should be done at low engine

speed to avoid abrasion and stone damage to the propeller tips.

B E F O R ETAKEO FF

WAR fr l- UP

If the engine accelerates smoothly, the airplane is ready for takeoff.

Since the engine is closely cowled for efficient in-flight engine cooling,

precautions should be taken to avoid overheating during prolonged engine

operation on the ground. Also, long periods of idling may cause fouled

spark plugs.

frl AGN E T O CHE CK

The magneto check should be made at 1700 RPM as follows. Move

ignition switch first to R position and note RPM. Next move switch back

to BOTH to clear the other set of plugs. Then move switch to the L position, note RPM and refurn the switch to the BOTH position. RPM drop

should not exceed 125 RPM on either magneto or show greater than 50

RPM differential between magnetos. If there is a doubt concerning operation of the ignition system, RPM checks at higher engine speeds will usually confirm whether a deficiency exists.

An absence of RPM drop may be an indication of faulty grounding of

one side of the ignition system or should be cause for suspicion that the

magneto timing is set in advance of the setting specified.

ATTER NA T O RCHE C K

Prior to flights where verification of proper alternator and voltage

regulator operation is essential (such as night or instrument flights), a

positive verification can be made by loading the electrical system momentarily (3 to 5 seconds) with the optional landing light (if so

equipped), or by operating the wing flaps during the engine runup

(1700 RPM). The ammeter will remain within a needle width of its initial

reading if the alternator and voltage regulator are operating properly.

T A KEOFF

POWE R CHE CK

It is important to check full-throttle engine operation early in the

4-t3

SECTION 4

NORMAL PROCEDURES

CESSNA

MODEL 172N

takeoff nrn. Any sign of rough engine operation or sluggish engine acceleration is good cause for discontinuing the takeoff. If this occurs, you are

justified in malcing a thorough full-throttle, static runup before another

takeoff is attempted. The engine should run smoothly and turn approximately 2280 to 2400 RPM with carburetor heat off and mixture tull rich.

NOTE

Carhrretor heat should not be used dunng takeoff unless

it is absolutely necessary for obtaining smooth engine

acceleration.

Full-throttle runups over loose gravel are especially harmful to propeller tips. When takeoffs must be made over a gravel surface, it is very

important that the throttle be advanced slowly. This allows the airplane

to start rolling before high RPM is developed, and the gravel will be blown