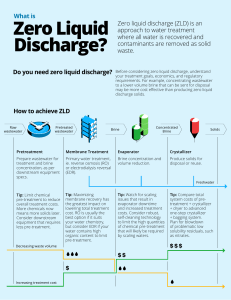

First ESCO Solvent ZLD Process Hyper brine Concentration and Zero Liquid Discharge What is ZLD ➢ ZLD –Zero Liquid Discharge is a treatment Process designed to remove all waste liquid from the system ➢ Objective of ZLD is to economically extract all water from waste stream so that water can be recycled ➢ ZLD is expected to recover the entire water from the waste stream and remove solids as a cake Need for ZLD ➢ As per Environmental regulations, Reject water from Industrial effluent treatment plants can not be discharged in to river / water bodies. ZLD will be deployed to process the reject water to remove the waste solids and recycle the water. ➢ RO (Reverse Osmosis) plants have reject water with high concentration which can not be processed further ( TDS>90000 mg/Lit). Instead of discharging the hyper brine to either ocean or ground, same can be processed further with ZLD to reuse the water ➢ Where there is fresh water scarcity, Industrial effluent water may be treated with ZLD for recycling and reuse Applications of FE-Solvent ZLD Process ➢ ETP / WTP / Desalination plant Reject water Recycling to meet environmental regulations ➢ Recycling of Industrial effluent Water for reuse ➢ Black Liquor Concentration for Kraft Recovery Boiler process ➢ Brine saturation in Caustic Soda Manufacturing Plants ➢ Process Liquid Concentration ZLD- Conventional Technologies ➢ Multi effect Distillation by vacuum evaporation ➢ Falling film vacuum evaporation ➢ MVR ➢ Crystallization For all these technologies , specific energy consumption Is very high ZLD- Conventional Technology RO-ZLD Conventional Technology MVR Evaporator - Conventional Technology First ESCO Solvent ZLD Process ➢ This process makes use of property of some solvents to absorb water at elevated temperatures ➢ In this process, solvent and Hyper Brine are heated to 80 Deg C and mixed together ➢ Solvent absorbs Pure water Leaving salts/ concentrated brine. ➢ Solvent and pure water emulsion is separated from the brine by settling in a tower ➢ Next stage Solvent plus pure water emulsion is cooled to 36 deg C. Pure water is separated from emulsion by settlement in a settling tower. ➢ Concentrated brine is reheated to 80 deg C and circulated to continue the process. First ESCO Solvent ZLD- Process - Concept FE RO-Solvent ZLD Process - Paper Mill ETP First ESCO Solvent ZLD Process – Applications ➢ Brine saturation for Caustic soda manufacturing ➢ Black liquor Concentration in Kraft process ( paper&Pulp) ➢ Sugar cane Juice Concentration for Sugar Plants ➢ Desalination Plant reject Brine Treatment for Zero Liquid Discharge ➢ Effluent treatment Plant Zero Liquid Discharge ➢ Retrofit of existing ZLD plants to replace Multi effect Evaporator Next steps Please send us following details ➢ Waste water / Hyper Brine Flow rate (M3/Hr) ➢ Waste Water/ Hyper brine analysis ➢ Details of Present waste Water Treatment facilities ➢ Details of Present ZLD process if any ➢ Present Specific Energy for ZLD (kwh/M3 and KWth/M3) ➢ Present Water treatment cost Rs./M3 We will submit our assessment and potential solutions for Zero Liquid discharge and economical water recycling Thank you First ESCO India Pvt.Ltd. 3rd Floor, KR Towers Road No.12, Banjara Hills HYDERABAD – 500034, INDIA Mobile : +91-9985502589 Email : info@firstesco.in Web : www.firstesco.in